Fly ash grinding

.jpg)

How to Process Fly Ash and What Is It Used for? Fote Machinery

Depending on the discharge method, there are dry fly ash and wet fly ash Dry fly ash is sold well as an admixture for cement production The wet fly 展开2015年3月1日 This paper presents the ultrafine grinding performance of fly ash with grinding aids (GA) and effect of GA on the particle characteristics, pozzolanic reaction degree of Ultrafine grinding of fly ash with grinding aids: Impact on particle 2019年6月1日 The OPC and fly ash samples are taken as control sample and compared with ball milled ground fly ash, to examine the effect of grinding process on fly ash particles Investigation on grinding impact of fly ash particles and its 2016年3月7日 The objective of this paper is to investigate the effect of mechanical activation of fly ash by grinding on physicochemical and minerological properties It can be established that there areMechanical activation of power station fly ash by

.jpg)

Fly Ashes Used For Blended Portland Cement: Effect Of Grinding

2011年1月1日 Unground and ground fly ashes were mixed with a reference high fineness Portland cement and tested for strength in mortar (ISO/CEN method) The fly ashes were also Fly ash and bottom ash are the two types of coal combustion leftovers that are blended and disposed of directly into the ponds/lagoons in both dry (Mound ash) and wet (Pond ash) State of the art review on physiochemical and engineering 2023年10月18日 Fly ash geopolymers can be prepared by any of three preparation methods viz conventional method, onepart mix method, or mechanochemical cogrindingbased advanced Recent trends in mechanochemical processing of fly ash The effects of grinding degree of fly ash on the fluidity, compressive strength, microstructure, crystal phase product, pore distribution and reaction degree of geopolymer were investigated Influence of different grinding degrees of fly ash on properties and

.jpg)

Ultrafine grinding of fly ash with grinding aids: Impact on particle

2015年3月1日 This paper presents the ultrafine grinding performance of fly ash with grinding aids (GA) and effect of GA on the particle characteristics, pozzolanic reaction degree of 2024年11月1日 The results show that wet grinding superfine can significantly affect the strength development of fly ash ultrafine supplementary cementing material The relationships between Liquidsolid grinding system: Grinding kinetics of coal fly ash as Grinding Fly Ash Process and Equipment with Vertical Milling Machine RUI FANG LI DONG YA SONG Zhengzhou University of Industrial Technology,Zhengzhou Keywords: vertical milling machine; grinding system; fly ash Abstract: A new ash grinding process was proposed,with the application of vertical grinding millGrinding Fly Ash Process and Equipment with Vertical Milling 2018年4月27日 From the ball milled fly ash with grinding aid, observed that the particle size was at the nanoscale level As per earlier discussion, by increasing the grinding time the particle size was decreased, which is exactly proved from SEM analysis [10, 20, 22]Synthesis and characterization of grinding aid fly ash blended

.jpg)

Preparation of ultrafine fly ash by wet grinding and its utilization

2020年7月15日 In this study, to promote the chloride binding capacity of coal fired fly ash (RFA) in cementitious materials, wet grinding was employed and ultrafine fly ash (UFA) with D50 = 21 μm was prepared; SEM, XRD, TG, FTIR, and XPS were used to evaluate the chemical and physical change in the process of wet grindingAfter grinding, the fly ash can be used as a partial substitute for concrete raw materials Different incorporation of fly ash will affect the hardening level, strength, dry shrinkage and other characteristics of concrete, with an ideal content of 40%Fly Ash Processing Plant Cement Equipment Manufacturing2023年10月18日 For achieving sustainable development in terms of waste to wealth, low CO2 production, and recycling, geopolymers can be recognized as a practicable alternative The current review presented a brief study of the potential usage of class F fly ash as a raw material for geopolymer, the chemistry of geopolymerization, and recent development in the field A Recent trends in mechanochemical processing of fly ash 2018年1月28日 Many authors have shown that replacing 4060% fly ash can result in high strength development and high resistance to alkalisilica reaction, freezing and thawing, chlorideion penetration, sulfate The Optimization of Calcareous Fly AshAdded Cement Containing Grinding

Fly Ashes Used For Blended Portland Cement: Effect Of Grinding

2011年1月1日 This paper presents a review of research papers dealing with the production of blended fly ash cements published since the 1980s The effects of grinding fly ashes on their physical and chemical Find Flash Grinding related suppliers, manufacturers, products and specifications on GlobalSpec a trusted source of Flash Grinding information Home Products Services Engineering News Standards Webinars Flybylight flight control system development for transport aircraftFlash Grinding Products Suppliers GlobalSpec2023年3月16日 The effects of grinding degree of fly ash on the fluidity, compressive strength, microstructure, crystal phase product, pore distribution and reaction degree of geopolymer were investigated from macro and micro perspectives A quantitative calculation formula for the reaction degree of geopolymer after fly ash grinding is proposedInfluence of different grinding degrees of fly ash on properties 2016年3月10日 Power station fly ash has good application possibilities mainly in the construction industry, nevertheless, significant amount is landfilled due to their relatively low reactivity and heterogeneity Hydraulic properties of fly ashes can be tailored by mechanical activation achieving a higher added value product, for example supplementary cementing materials (SCMs)[PDF] Mechanical activation of power station fl y ash by grinding

Use Fly Ash Ball Mill Make Flyash Cement Ball Mill

The fly ash raw material is conveyed by the vibrating machine to the jaw crusher for crushing This step is mainly to crush large particles of fly ash to small particles that can meet the size of the fly ash ball mill Fine grinding The fly 2018年4月27日 It may suggest that amine based grinding aids play a vital role and feasible to use in fly ash grinding process Discover the world's research 20+ million members; 135+ million publications;Synthesis and characterization of grinding aid fly ash blended 2019年2月1日 Fly ash Grinding Ball Mill is practical for its run of the ball mill grinding process in which extreme shearing strengths take a shot at particles at fast For fast of crushing ballInvestigation on grinding impact of fly ash particles DOI: 101016/jpartic202407022 Corpus ID: ; Liquidsolid grinding system: Grinding kinetics of coal fly ash as ultrafine supplementary cementitious materials @article{Yang2024LiquidsolidGS, title={Liquidsolid grinding system: Grinding kinetics of coal fly ash as ultrafine supplementary cementitious materials}, author={Jin Yang and Yong Huang Liquidsolid grinding system: Grinding kinetics of coal fly ash as

A critical review on mechanochemical processing of fly ash and fly ash

2023年2月20日 Fly ash from combustion of municipal solid waste (MSW), ie wood, textiles, food waste, paper, ClassF fly ash: Dry: Planetary ball mill; agate grinding jar and agate balls; 5, 10 and 15 h; Increased silica percentage, surface roughness, specific surface area, 2024年11月1日 Fly ash (FA) is the main combustion byproduct produced after pulverized coal is burned in coalfired furnaces at 1200–1700 °C during coalfired thermal power generation (Mucsi, 2016; Yang et al, 2018)Liquidsolid grinding system: Grinding kinetics of coal fly ash as 2015年10月10日 This paper is focused on the investigation of a land filled Hungarian fly ash (Tiszaújváros dumpsite) as a main component of geopolymer After determination of the fly ash properties such as particle size distribution, moisture content, real and bulk density and specific surface area, mechanical activation by fine grinding of the fly ash sample was performed in Control of geopolymer properties by grinding of land filled fly ash2021年1月7日 The grinding process has become widely used to improve the fineness and performance of fly ash However, most studies focus on the particle size distribution of ground fly ash, while the particle morphology is also an important factor to affect the performance of cement paste This article aims at three different kinds of ground fly ash from the ball mill and vertical Influence of Particle Morphology of Ground Fly Ash on the

Effect of mechanical grinding on physical and chemical

2015年12月30日 To characterize roles of mechanical grinding on the physical and chemical characteristics of circulating fluidized bed fly ash (CFBFA), the differences between CFBFA and ordinary fly ash (OFA) were revealed and the effects of mechanical grinding action on the physical and chemical characteristics of CFBFA were studied from grinding kinetics, particle size Fly ash can be used as prime material in many cementbased products, such as poured concrete, concrete block, and brick One of the most common uses of fly ash is in Portland cement concrete pavement or PCC pavement Road construction projects using PCC can use a great deal of concrete, and substituting fly ash provides significant economic Fly Ash Maquinaria de Molienda y Dispersión2017年6月27日 Coarse ash particles, referred to as bottom ash or slag, fall to the bottom of the combustion chamber, while the lighter fine ash particles, termed fly ash, remain suspended in the flue gas Prior to exhausting the flue gas, fly ash is removed by particulate emission control devices, such as electrostatic precipitators or filter fabric baghouses (see Figure 11)Chapter 1 Fly Ash An Engineering Material Fly Ash Facts for 2023年12月13日 In a world where companies are more aware than ever of their environmental impact, fly ash is often dismissed as an industrial byproduct of coalfired power plants But with the right handling and processing, fly ash can Using Ball Mills for Fly Ash Processing Economy Ball

.jpg)

Automatic Fly Ash Bricks Machine Benny

Wet Fly Ash Grinding Machine Fly Ash Bricks Crushing Machine; Enquiry SPECIFICATIONS FOR MACHINE MODEL NO: ABM 6 Dimension : 2000x1300x2500 mm: Weight: 1700 KG Main Machine : Oil Tank Capacity : 250 Liters : Main Cylinder : Free Fill system Single Acting 200x350x10mm : Main Pilot : Two Side Rod Double Acting Cylinder 50x350x70 mm :2017年6月1日 Grinding of fly ash has a significant effect on the physical properties as well as on the cell structure of the geopolymer foam Discover the world's research 25+ million members;(PDF) Effect of Grinding Fineness of Fly Ash on the Properties of Build, Operate and Own India’s first Grinding Mill for Fly Ash at Nare – Maharashtra and Dahanu – Maharashtra Build, Operate and Own Cement Blending and Fly Ash classification plant of 1500 MT per day capacity at Raichur and Mangalore Build, Operate and Own Badarpur and Ennore TPS and assisting in Fly Ash conveying at DTPS and VedantaAsh Management Ashtech2013年6月1日 This paper presents a laboratory study exploring the pozzolanic reactivity of a calcium rich fly ash by blending and grinding in a cement free system A synergistic physicochemical composition was achieved through individual grinding and ternary blending with another alkali sulphate rich fly ash and silica fumeMechanochemical activation of highCa fly ash by cement free

.jpg)

Liquidsolid grinding system: Grinding kinetics of coal fly ash as

2024年11月1日 Fly ash (FA) is the main combustion byproduct produced after pulverized coal is burned in coalfired furnaces at 1200–1700 °C during coalfired thermal power generation (Mucsi, 2016; Yang et al, 2018)At present, the utilization rate of FA is still low, occupying a large amount of land resources and posing great ecological and environmental safety risks (Yang, Huang, et 2024年5月25日 This study investigated the influences of ultrafine fly ash (UFA) and ultrafine slag powder (USL) on the compressive strengths, autogenous shrinkage, phase assemblage, and microstructure of magnesium potassium phosphate cement (MKPC) The findings indicate that the aluminosilicate fractions present in both ultrafine fly ash and ultrafine slag participate in the Influence of Ultrafine Fly Ash and Slag Powder on Microstructure 1997年12月1日 Morphology of Fly Ash Particles Figures 10 through 12 show the typical micrographs of the original unground fly ash (Lingan) and the fly ash after 2 and 10 h of grinding The fly ashes "as received" contain mostly spherical particles with a small amount of plerospheres and irregularshaped particlesThe effect of grinding on the physical properties of fly ashes TASA Fettling/ Flash Grinding MachineTasa Micro is an Indian special purpose machine tool Manufacturer that has developed high precision machine tools for inTASA Flash Grinding/ Fettling Machine YouTube

.jpg)

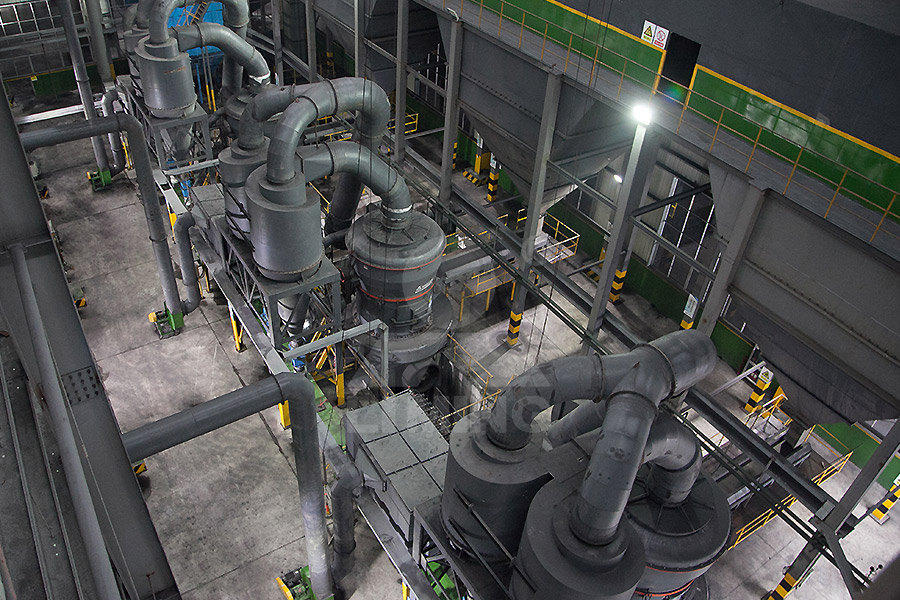

Grinding Fly Ash Process and Equipment with Vertical Milling

Grinding Fly Ash Process and Equipment with Vertical Milling Machine RUI FANG LI DONG YA SONG Zhengzhou University of Industrial Technology,Zhengzhou Keywords: vertical milling machine; grinding system; fly ash Abstract: A new ash grinding process was proposed,with the application of vertical grinding mill2018年4月27日 From the ball milled fly ash with grinding aid, observed that the particle size was at the nanoscale level As per earlier discussion, by increasing the grinding time the particle size was decreased, which is exactly proved from SEM analysis [10, 20, 22]Synthesis and characterization of grinding aid fly ash blended 2020年7月15日 In this study, to promote the chloride binding capacity of coal fired fly ash (RFA) in cementitious materials, wet grinding was employed and ultrafine fly ash (UFA) with D50 = 21 μm was prepared; SEM, XRD, TG, FTIR, and XPS were used to evaluate the chemical and physical change in the process of wet grindingPreparation of ultrafine fly ash by wet grinding and its utilization After grinding, the fly ash can be used as a partial substitute for concrete raw materials Different incorporation of fly ash will affect the hardening level, strength, dry shrinkage and other characteristics of concrete, with an ideal content of 40%Fly Ash Processing Plant Cement Equipment Manufacturing

.jpg)

Recent trends in mechanochemical processing of fly ash

2023年10月18日 For achieving sustainable development in terms of waste to wealth, low CO2 production, and recycling, geopolymers can be recognized as a practicable alternative The current review presented a brief study of the potential usage of class F fly ash as a raw material for geopolymer, the chemistry of geopolymerization, and recent development in the field A 2018年1月28日 Many authors have shown that replacing 4060% fly ash can result in high strength development and high resistance to alkalisilica reaction, freezing and thawing, chlorideion penetration, sulfate The Optimization of Calcareous Fly AshAdded Cement Containing Grinding 2011年1月1日 This paper presents a review of research papers dealing with the production of blended fly ash cements published since the 1980s The effects of grinding fly ashes on their physical and chemical Fly Ashes Used For Blended Portland Cement: Effect Of Grinding Find Flash Grinding related suppliers, manufacturers, products and specifications on GlobalSpec a trusted source of Flash Grinding information Home Products Services Engineering News Standards Webinars Flybylight flight control system development for transport aircraftFlash Grinding Products Suppliers GlobalSpec

.jpg)

Influence of different grinding degrees of fly ash on properties

2023年3月16日 The effects of grinding degree of fly ash on the fluidity, compressive strength, microstructure, crystal phase product, pore distribution and reaction degree of geopolymer were investigated from macro and micro perspectives A quantitative calculation formula for the reaction degree of geopolymer after fly ash grinding is proposed2016年3月10日 Power station fly ash has good application possibilities mainly in the construction industry, nevertheless, significant amount is landfilled due to their relatively low reactivity and heterogeneity Hydraulic properties of fly ashes can be tailored by mechanical activation achieving a higher added value product, for example supplementary cementing materials (SCMs)[PDF] Mechanical activation of power station fl y ash by grinding