Highefficiency coal powder vertical mill intelligent automation Energy saving

.jpg)

HighEfficiency Vertical Coal Mill Enhancing Coal

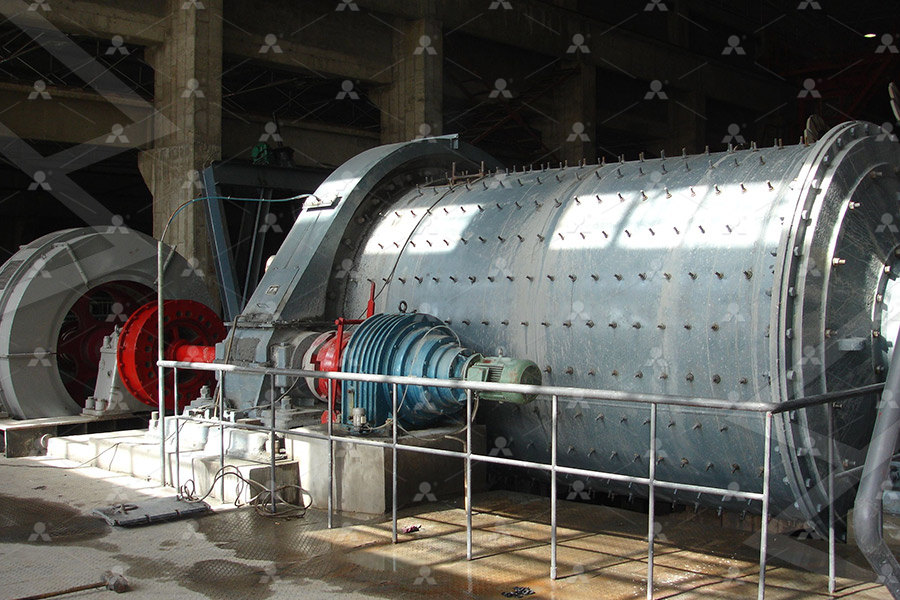

Our coal vertical mill utilizes advanced dynamic and static separators for efficient particle separation during coal grinding The advanced control system and grinding structure precisely control key parameters, ensuring the desired Vertical Roller Mill: These mills are known for their high efficiency and energy savings The vertical roller mill is capable of producing highquality 200 mesh coal powder, with precise control over the particle size distribution Ball Mill: The ball mill is a traditional grinding machine that uses steel balls as the grinding mediumChoosing the right vertical mill for 200 mesh coal powder Vertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, and ultrafine vertical millvertical roller mill, vertical coal mill, vertical slag mill, superfine 4 HMM series bowl coal mill The HMM series bowl mill is a highefficiency, low consumption, adaptable, energysaving and environmentally friendly coal grinding equipment developed by Guilin Hongcheng based on the market demand and coal powder characteristics of power coalGuilin Hongcheng HMM Series Bowl Coal Mill Promoting Efficient,

Fluorite Fine Powder Grinding Mill SBM Ultrafine Powder

2021年10月13日 The fluorite fine powder grinding mill is an industrial ore milling equipment independently developed and produced by SBM The equipment includes two series of HGM ultra fine grinding mill and CLUM vertical roller mill, both of which can grind nonmetallic ore powder of 1503000 meshVertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fields Its special design structure and production process creates the higher production efficiency with lower energy consumption, less dust, lower noise than ball mill, which meets national standard of energy saving industryVertical Coal Mill Great WallHighefficiency HP bowl coal mill is a new type of energysaving product launched by our company, The qualified fine powder exits the mill along with the airflow and is collected by the dust collection device as the final product resulting in low energy consumption, saving up to 30% to 40% compared to ball mill systems HP Vertical Mill Revolutionizing Efficiency and PerformanceHCM's HLM series mineral powder vertical mill equipment, which has always focused on high efficiency, energy saving, intelligent environmental protection, Powder Paint Grinding Mill From China Supplier, Ultra Fine Grinding Mill, Coal Grind, Phone Tel 86 Email Email hcmkt@hcmilling Top Hit enter to search or ESC to News [Conference News] HCM’s Vertical Mill Injects Green And

COAL VERTICAL MILL Xinxiang Great Wall Machinery Co, Ltd

Process introduction GRMC coal vertical mill produced by CHAENG adopts a special structure design and production technology, and the quality is up to the leading level in China It is the first choice equipment for grinding raw coal and bituminous coal 1 The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the grid screen2024年1月31日 Significant energy savings were achieved annually through optimised control The system enhances safety by automating adjustments while minimising costs and environmental impacts Datadriven strategies overcome the limitations of traditional methods, representing an advance for intelligent management of industrial processesIntelligent process control system for predicting operating I: Product Profile Vertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fieldsThe coal vertical mill has less dust, low noise, high efficiency granular composition, Its special design structure and production process creates the higher production efficiency with lower energy consumption, less dust Coal Vertical Roller Mill即时翻译文本完整的文档文件。为个人和团队提供准确的翻译。每天有数百万人使用DeepL进行翻译。DeepL翻译:全世界最准确的翻译 DeepL Translate

.jpg)

Intelligent Optimization and Impact Analysis of Energy Efficiency

2024年11月5日 The coordinated optimization of energy conservation, efficiency improvement, and pollution reduction in the sintering production process is vital for the efficient and sustainable development of the sintering department However, previous studies have shown shortcomings in the multiobjective collaborative optimization of sintering systems and the quantification of High grinding efficiency:High grinding efficiency and low energy consumption, saving 40% 50% power consumption compared to ball millSpecial structure design of grinding roller and grinding table, large diameter of grinding roller, LUM series superfine vertical roller grinding millThe GRMC coal vertical mill produced by CHAENG adopts special structural design and production process, which is energysaving and environmentally friendly +79; High efficiency and large outputcoal grinding machine CHAENGDownload scientific diagram The layout of the coal mill with a rotary classifier from publication: An investigation of performance characteristics and energetic efficiency of vertical roller The layout of the coal mill with a rotary classifier

.jpg)

MPS ZGM Coal MillGrinding Equipment YingYong Machinery

The MPS ZGM coal mill is a type of coal mill that operates at a speed of 50300r/min This equipment is used to prepare and process auxiliary materials for blast furnace ironmaking It provides suitable coal powder for the blast furnace ironmaking systemType: Vertical Roller Mill Motor Type: AC Motor Motor Power: 135kw Rotationl Speed: 1315r/min Application: Mine Materials: Coal, Slag, Flyash, Cement, Calcium CarbonateEnergySaving Coal Pulverizer Cement Clinker Mill Plant Flyash For over 60 years of experience in the mineral processing industry, CITIC Heavy Industries (CITIC HIC) has been always committed to increase the grinding efficiency of minerals by constantly searching for ways to improve and develop energysaving highefficiency ore grinding equipmentVertical Stirred Mill Mineral Processing Equipment CITIC HICHigh Efficiency Ultrafine Calcium Carbonate Coal Slag Cement Vertical Roller Mill Fine Powder Production Plant, Find Details and Price about Vertical Roller Mill Coal Mill from High Efficiency Ultrafine Calcium Carbonate Coal Slag Cement Vertical Roller Mill Fine Powder Production Plant Baichy Heavy Industrial Machinery Co, LtdHigh Efficiency Ultrafine Calcium Carbonate Coal Slag Cement Vertical

LM VERTICAL MIVipeak Heavy Industry Machinery Group

LM vertical roller mill is a kind of high efficiency and energy saving product perfectly combined with 30 years of mature vertical grinding technology, LM type pulverized coal vertical mill (medium speed coal mill) parameters Coal powder moisture: ≤1% 5%: Inlet air temperature (℃) 55:CHAENG GRMR Vertical Raw Mill is a type of highefficiency, energysaving, and environmentally friendly grinding equipment for cement raw mill grinding system +79Vertical Raw Mill CHAENG2017年4月5日 An intelligent integrated distributed control, automation system enables power plants to have real time online control of energy efficiency, system security, safety systems at an improved ENERGY efficiency which Intelligent Coal Fired Thermal Power Plants – Next 2022年9月20日 CLUM vertical roller mill integrates powder grinding, screening and powder collection, with high production efficiency, stable work, energy saving and environmental protection The ultrafine powder produced by this mill has Coal Gangue Vertical Roller Mill SBM Ultrafine

.jpg)

Energy Saving Factory Automation Equipment and the Environment

2007年5月15日 The application of energy efficient motor systems can greatly reduce the overall environmental impact and cost to operate this equipment Advancements in electric motor design and the associated drive system in modern automation equipment can be extremely energy efficient Much of the time the most energy efficient machine will also have the highest Date of publication xxxx 00, 0000, date of current version xxxx 00, 0000 Digital Object Identifier 101109/ACCESS2022 Research on coal volume detection andResearch on coal volume detection and energysaving 2022年7月11日 HLM Series Vertical Grinding Mill The classifier adopts a structure combining dynamic and static elements, resulting in higher classification efficiency With variable frequency speed control, the product fineness is easily adjustable, allowing the finished product size to range from 50 to 800 mesh, and ensuring a narrow particle size distributionHLM SERIES VERTICAL GRINDING MILL Fote Machinery1 The vertical roller mill is a highefficiency and energysaving grinding equipment widely used in preparing raw materials and clinker, grinding slag, ore, industrial silicon, calcium carbide slag and coal gangue in the cement industry and in coal chemical industry, power plant desulfurization industry and coal powder preparation industry 2 The LRM type vertical roller mill integrates Supply Vertical Roller Mill Customized Factory SINOMALY

.jpg)

China LM Series Vertical Mill Factory, Manufacturer JINGHUA

It adopts material layer roll crushing, friction and impact as the crushing mechanism, which has high efficiency and large energy saving (2030% energy saving compared to ball mill) 2 The crushing process takes a short time, the repeated grinding rate is small, the particle size distribution is uniform, and the particle size adjustment is continuously adjustable2022年5月9日 Modeling of energy consumption factors for an industrial cement vertical roller mill by SHAPXGBoost: a "conscious lab" approachModeling of energy consumption factors for an industrial cement WTM intelligent vertical mill is dedicated to the highefficiency dissociation of minerals, providing users with energysaving, consumptionreducing, qualityenhancing and efficiencyenhancing solutions, realizing maximum monomer dissociation of minerals, and laying a solid foundation for quality improvement and efficiency enhancement,The WTM Intelligent Vertical Stirring Mill (Tower Mill) Vertical Roller Mill: These mills are known for their high efficiency and energy savings The vertical roller mill is capable of producing highquality 200 mesh coal powder, with precise control over the particle size distribution Ball Mill: The ball mill is a traditional grinding machine that uses steel balls as the grinding mediumChoosing the right vertical mill for 200 mesh coal powder

vertical roller mill, vertical coal mill, vertical slag mill, superfine

Vertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, and ultrafine vertical mill4 HMM series bowl coal mill The HMM series bowl mill is a highefficiency, low consumption, adaptable, energysaving and environmentally friendly coal grinding equipment developed by Guilin Hongcheng based on the market demand and coal powder characteristics of power coalGuilin Hongcheng HMM Series Bowl Coal Mill Promoting Efficient, 2021年10月13日 The fluorite fine powder grinding mill is an industrial ore milling equipment independently developed and produced by SBM The equipment includes two series of HGM ultra fine grinding mill and CLUM vertical roller mill, both of which can grind nonmetallic ore powder of 1503000 meshFluorite Fine Powder Grinding Mill SBM Ultrafine Powder Vertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fields Its special design structure and production process creates the higher production efficiency with lower energy consumption, less dust, lower noise than ball mill, which meets national standard of energy saving industryVertical Coal Mill Great Wall

HP Vertical Mill Revolutionizing Efficiency and Performance

Highefficiency HP bowl coal mill is a new type of energysaving product launched by our company, The qualified fine powder exits the mill along with the airflow and is collected by the dust collection device as the final product resulting in low energy consumption, saving up to 30% to 40% compared to ball mill systems HCM's HLM series mineral powder vertical mill equipment, which has always focused on high efficiency, energy saving, intelligent environmental protection, Powder Paint Grinding Mill From China Supplier, Ultra Fine Grinding Mill, Coal Grind, Phone Tel 86 Email Email hcmkt@hcmilling Top Hit enter to search or ESC to News [Conference News] HCM’s Vertical Mill Injects Green And Process introduction GRMC coal vertical mill produced by CHAENG adopts a special structure design and production technology, and the quality is up to the leading level in China It is the first choice equipment for grinding raw coal and bituminous coal 1 The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the grid screenCOAL VERTICAL MILL Xinxiang Great Wall Machinery Co, Ltd2024年1月31日 Significant energy savings were achieved annually through optimised control The system enhances safety by automating adjustments while minimising costs and environmental impacts Datadriven strategies overcome the limitations of traditional methods, representing an advance for intelligent management of industrial processesIntelligent process control system for predicting operating

.jpg)

Coal Vertical Roller Mill

I: Product Profile Vertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fieldsThe coal vertical mill has less dust, low noise, high efficiency granular composition, Its special design structure and production process creates the higher production efficiency with lower energy consumption, less dust