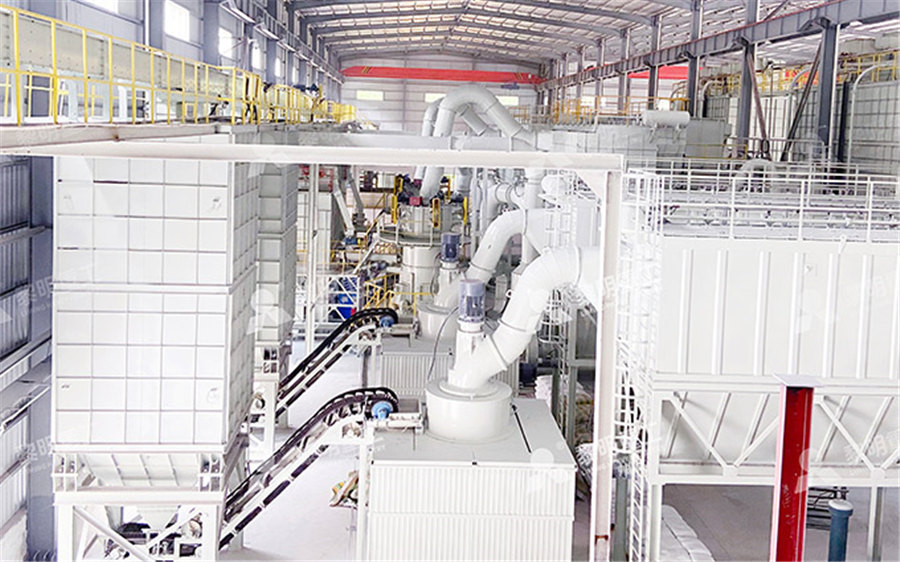

Industrial roller mill installation inspection

Rollscan Roll Inspection (pdf) Sarclad

Realtime assessment of roll condition Fully automated operation and roll analysis Twin crystal 225 MHz compression wave 20mm coverage per revolution Introduces the ultrasonic beam Reliable roll inspection with ultrasonic technology In order to minimize downtime in hot rolling mills, it is important to identify defect rolls early This is why HCC/KPM has developed surface inspection technologies that reliably locate Roll Inspection Control Measuring TechnologyAmetek Surface Vision’s SmartView surface inspection system provides an effective solution that overcomes the difficulties of the cold mill process to deliver reliable, highly sensitive defect Cold rolling mill inspection and defect detection AMETEK Surface A roll inspection system is not only a necessary safety tool in any modern rolling mill, but it can also have a significant influence in the economics of the whole operation Designed and Improved Technologies for Mill Roll Inspection

.jpg)

Steel Rolling Technology Handbook (2nd Revised Edition)

change, plate mills, hot strip mills, quality assurance, testing and inspection, bar and rod mills It will be a standard reference book for professionals, entrepreneurs, those studying and 2016年4月1日 The AOI system for the upper steel surface is shown in Fig 3, which is located at the 1# hotrolling mill in Valin LY Steel, China In order to ensure that the steel image has no A costeffective and automatic surface defect inspection system The quadropol® vertical roller mill by thyssenkrupp Industrial Solutions takes a holistic approach to modern grinding systems in terms of its simple and compatible design Describing the key VERTICAL ROLLER MILLS A holistic VRM approach2017年11月15日 This paper provides an overview of mill roll inspection technology and the effects that various inspection technologies can have on the efficiency and costs associated withImproved Technologies for mill roll inspection

.jpg)

Automatic Roll Mark Detector Improves Cold Rolling Mill

rolling mills from costly roll mark defects The solution is an online installation into the exits of cold mills to automatically inspect every coil for roll marks — even for nonvisible roll marks, A Roller Mill RMI90 and Dynamic Separator Williams DF90 Roller Mill with 500 HP variable frequency AC drive, external right angle reducer, and dynamic separator B Cyclone Separator 20' 0" heavy duty cyclone collectors with Roller Mills Installation Report Williams CrusherSince 2019, all new roller shutter doors in the UK must meet safety standards (BS EN 132411:2003) for opening mechanisms, wind resistance, and overall strength We offer CE Marked industrial roller shutters in all configurations, ensuring compliance and quality for your businessAluminium Roller Shutter Doors Industrial Door EngineeringFrom start to finish, RMS offers project management support to ensure the successful installation of your industrial coffee equipment Our project managers work closely with you to coordinate all aspects of the installation, providing a smooth transition with Industrial Coffee Equipment RMS RollerGrinder

.jpg)

Installation, Operating and Maintenance Instructions for Industrial

– EN 12635 ('Industrial, commercial and garage doors and gates Installation and use'), – EN 12453 ('Industrial, commercial and garage doors and gates Safety in use of power operated doors Requirements'), – EN 12445 ('Industrial, commercial and garage doors and gates Safety in use of power operated doors Test methods'),Find your vertical roller mill easily amongst the 14 products from the leading brands (FLSmidth DorrOliver Eimco, FLSMIDTH, ) on DirectIndustry, the industry specialist for your professional purchasesVertical roller mill, Vertical roller grinding mill All industrial The BAM ball mill for industrial minerals is designed to be particularly efficient thanks to our process knowhow This is because the efficiency of a mill depends on its internals All parts of the mill, the diaphragm, the shell lining and the ball charge, have been continuously developed inhouse for nearly a century, which is the basis of our expertiseBAM for industrial minerals Christian Pfeiffer2023年6月2日 Industrial roller shutters are a crucial component in many commercial and industrial settings, offering security, durability, and flexibility These versatile doors are commonly used in warehouses, manufacturing plants, and various other facilities where secure and efficient access control is essential In this article, we will delve into the world of industrial roller Exploring Industrial Roller Shutters The Architecture Designs

.jpg)

VersaMill RMS RollerGrinder

Ability to produce quality cracks of 1200, 700, 500, and 350 microns, all from one machine2021年1月1日 India is the world's second largest producer of cement and produces more than 8 per cent of global capacity Due to the rapidly growing demand in various sectors such as defense, housing, commercial and industrial construction, government initiative such as smart cities PMAY, cement production in India is expected to touch 550–600 million tones per Review on vertical roller mill in cement industry its The reduction in transport costs and/or downtime by using portable driven roller equipment, Installation of the Mill drive train, low pressure line and return piping lines Mill liner inspection, bolted and wedge liner installation, headliner installation and diaphragm installation Welding of Mill shell cracks Installation of Source and Install Mill and Kiln Machines RobtekDelivering up to 3000 kNm torque, David Brown Santasalo vertical roll mill drives provide the optimum solution for grinding applications Developed in cooperation with roller mill manufacturers, our vertical roll mill gearboxes combine strength Vertical Mill Roller Drives dbsantasalo

Sugar Mill Gearbox installation XinLan Technology Co, Ltd

Gearboxes play a crucial role in industrial automation Every product undergoes a stringent inspection process to guarantee its high quality and reliability before it reaches our customers In conclusion, Xinlan stands out as a leader in the industry, offering superior sugar mill gearbox installations With our durable and Key Components of the Williams Industrial Roller Mill The Williams Patent Crusher team took great care when designing each component of our industrial roller mills Learn how each part of the roller mill works to create a consistent, Industrial Roller Mills Williams Crusher2017年7月16日 2 2 P a g e Acknowledgement It is matter of great pleasure and privilege for me to present this report of One week industrial training in Rail and Universal Beam Mill (RUBM)Though this report, I would like to thank numerous people whose consistent support and guidance is standing pillar in architecture of this report To begin with, my sincere thanks to Industrial Training Report on Rolling Mill PDF SlideShare2024年3月18日 However, like any other industrial equipment, it requires proper maintenance and operation to ensure peak performance and longevity This guide provides a comprehensive overview of the essential maintenance tasks and operational strategies for the Raymond Mill Routine Maintenance For Raymond Mill Daily Maintenance 1Guide to Raymond Mill Maintenance: Schedule and Best Practices

Roller Shutter Maintenance Legislation and Requirements

BSEN 12635:2002 Industrial, Commercial and Garage Doors and Gates Installation and Use This is one of a series of supporting standards to BSEN 132411:2003 the Product Standard for Industrial, Commercial, Roller and Garage Doors and GatesFarmers who grow soy, oats, wheat, barley, and corn (the country’s primary feed grain) rely heavily on a feed roller mill for processing their grainA roller mill’s capacity to grind large volumes of various materials makes it ideal for producing highquality feed for staples of the American diet—beef, poultry, and porkAdditionally, flours produced by a roller mill are essential for Grain Roller Mills RMS RollerGrinderMILL VISUALS AND VITALS Detect issues early for improved reliability OEM visual inspection of the mill with temperature, pressure, and flow readings; Catch cracks, drivetrain misalignment, oil contamination, vibrations, missing bolts, equipment condition and more; Performed with 1 shift with mill running and 1 shift with mill stoppedGrinding mill inspections MetsoThe AT Ferrell HI Industrial roll mill is available in sizes of 10 “x 12” to 12” x 52” Standard Features: two chilled cast iron rolls; mild steel mill housing; belt driven corrugated roll feeder; adjustable feed gate; roll feeder inspection door (1) product sampling door (1) aspiration port; Options: main drive motor; micro hand wheel AT Ferrell HI Industrial Roller Mill AR McKay Processing

.jpg)

How to inspect your roller chain MAXTOP Ming Chang Chain

2021年7月20日 Check our roller chain inspection list to find out the probable causes of roller chain wear and action suggested to take 繁體中文 ; English Having more than 40 years of experience and technology in industrial chains, we aims to provide our bestquality, economical and efficient solutions to meet your various demands and The roller mill is especially recommended in those installations that require a homogeneous grinding with the lowest percentage of fines, for example in feed Contact us for more information and to request a Roller Mill quotation contact C/ Roger de Flor, s/n Polígono Can Vinyals 08130 Santa Perpètua de la Mogoda – Barcelona, España Roller MillVertical Roller Mill Introduction Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free Vertical roller mills provide a reliable and efficient process for grinding materials at high production rates Vertical Roller Mill Introduction PDF Mill Industrial Roller Repair Services Roll Technology is proud to offer industrial roller repair services for industrial metal rollers Whether it is a bent shaft, cracked core, or broken bearing Roll Technology is here for your core and shaft maintenance service needs Give us your worn and mechanically abused rolls and we will restore them to production tolerancesIndustrial Roll Roller Repair – Core Shaft Maintenance

.jpg)

16' X 22' Ball Mill Installation Manual PDF Scribd

This document provides instructions for installing a 16x22ft, 2800kW ball mill It outlines 8 key steps: 1) Prepare the foundation and install the trunnion bearing sole plates 2) Assemble and mount the trunnion bearings onto the sole plates 3) Assemble the trunnion ends to the mill shell 4) Lower the mill unit into the bearings and check clearances 5) Install the girth gear 6) Excellent Door Roller Shutter with Centurion motors These operating instructions apply to an Excellent Door industrial steel roller shutter with single phase Centurion RS05 motor with a pushbutton station The door should only be operated by trained persons fully conversant with the roller shutter safety instructions Normal Operation IMPORTANT!Industrial Door Operation Operating Maintenance Instructions%PDF14 %Çì ¢ %%Invocation: path/gs P dSAFER dCompatibilityLevel=14 q P dNOPAUSE dBATCH sDEVICE=pdfwrite sstdout=? sOutputFile=?Timken CompanyIn this article, we will discuss the work that needs to be done after the installation of a ball mill and the precautions that need to be taken to ensure safe and efficient operation Inspection of the ball mill After installing a ball mill, it is important to conduct a thorough inspection of the equipment to ensure everything is in orderBall Mill Installation Essential Work and Precautions

VERTICAL ROLLER MILLS A holistic VRM approach

2 VERTICAL ROLLER MILLS INTERNATIONAL CEMENT REVIEW SEPTEMBER 2021 played by the mill foundation, which has been optimised to reduce vibrations2 Built to last The mill foundation, ie, the basic block with its four concrete pylons, is responsible for the smooth running of the mill The roller units and mill housing are notOverview of Soybean Milling Soybean milling is the process of taking whole soybeans and processing them into a usable product: soybean meal Processing soybeans typically involves dehulling soybeans and then crushing or cracking them Soybean Milling RMS RollerGrinderProject Management Installation; AG Feed Roller Mill Replacement Parts; Endurance Roll Program; Roll Exchange; Industrial Roller Mill Replacement Parts; Endurance Roll Program; Roll Exchange; Our Test Lab is equipped to validate unique applications and ensure the roller mill meets your requirements We offer Grist Analysis, Roll Industrial Brewing Brewing Grain Mills and RMS RollerGrinderA Roller Mill RMI90 and Dynamic Separator Williams DF90 Roller Mill with 500 HP variable frequency AC drive, external right angle reducer, and dynamic separator B Cyclone Separator 20' 0" heavy duty cyclone collectors with Roller Mills Installation Report Williams Crusher

Aluminium Roller Shutter Doors Industrial Door Engineering

Since 2019, all new roller shutter doors in the UK must meet safety standards (BS EN 132411:2003) for opening mechanisms, wind resistance, and overall strength We offer CE Marked industrial roller shutters in all configurations, ensuring compliance and quality for your businessFrom start to finish, RMS offers project management support to ensure the successful installation of your industrial coffee equipment Our project managers work closely with you to coordinate all aspects of the installation, providing a smooth transition with Industrial Coffee Equipment RMS RollerGrinder– EN 12635 ('Industrial, commercial and garage doors and gates Installation and use'), – EN 12453 ('Industrial, commercial and garage doors and gates Safety in use of power operated doors Requirements'), – EN 12445 ('Industrial, commercial and garage doors and gates Safety in use of power operated doors Test methods'),Installation, Operating and Maintenance Instructions for Industrial Find your vertical roller mill easily amongst the 14 products from the leading brands (FLSmidth DorrOliver Eimco, FLSMIDTH, ) on DirectIndustry, the industry specialist for your professional purchasesVertical roller mill, Vertical roller grinding mill All industrial

.jpg)

BAM for industrial minerals Christian Pfeiffer

The BAM ball mill for industrial minerals is designed to be particularly efficient thanks to our process knowhow This is because the efficiency of a mill depends on its internals All parts of the mill, the diaphragm, the shell lining and the ball charge, have been continuously developed inhouse for nearly a century, which is the basis of our expertise2023年6月2日 Industrial roller shutters are a crucial component in many commercial and industrial settings, offering security, durability, and flexibility These versatile doors are commonly used in warehouses, manufacturing plants, and various other facilities where secure and efficient access control is essential In this article, we will delve into the world of industrial roller Exploring Industrial Roller Shutters The Architecture DesignsAbility to produce quality cracks of 1200, 700, 500, and 350 microns, all from one machineVersaMill RMS RollerGrinder2021年1月1日 India is the world's second largest producer of cement and produces more than 8 per cent of global capacity Due to the rapidly growing demand in various sectors such as defense, housing, commercial and industrial construction, government initiative such as smart cities PMAY, cement production in India is expected to touch 550–600 million tones per Review on vertical roller mill in cement industry its

.jpg)

Source and Install Mill and Kiln Machines Robtek

The reduction in transport costs and/or downtime by using portable driven roller equipment, Installation of the Mill drive train, low pressure line and return piping lines Mill liner inspection, bolted and wedge liner installation, headliner installation and diaphragm installation Welding of Mill shell cracks Installation of