HOME→Gypsum powder making process and uses Gypsum powder making process and uses Gypsum powder making process and uses

Gypsum powder making process and uses Gypsum powder making process and uses Gypsum powder making process and uses

Gypsum Powder Manufacturing Gypsum Powder

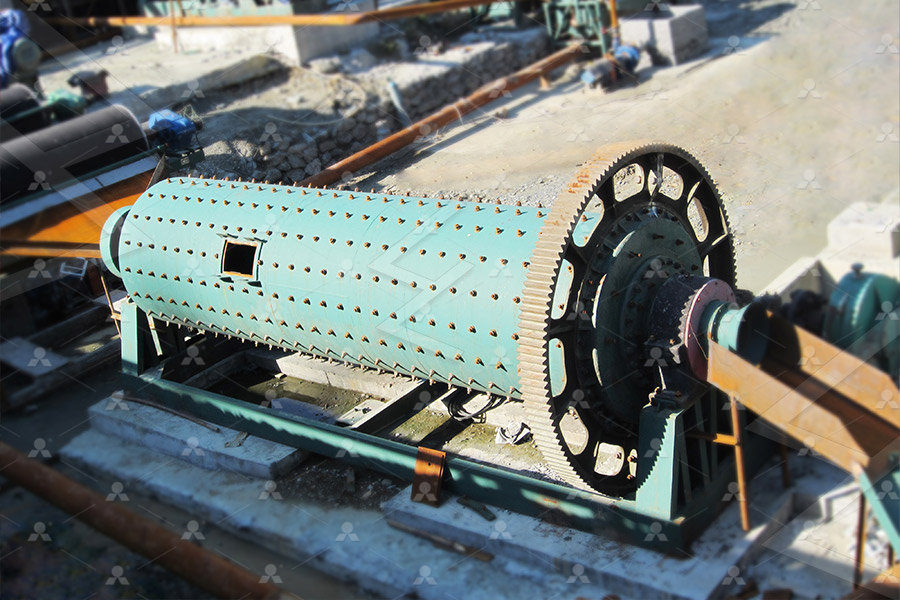

Gypsum powdermaking process According to the process requirements, the construction gypsum production line is usually divided into five parts, including crushing system, storage conveying system, grinding system, calcining Gypsum can be processed relatively simply with basic equipment and techniques as well as on a large and industrialized scale as is done in some countries such as the United Kingdom It is Gypsum processing and use Humanitarian Library2024年4月12日 This paper explores the mechanism of efficiently modified phosphogypsum and constructs a model and evaluation system for heavy metal leaching and migration Highly efficient modified phosphogypsum building gypsum 2024年5月16日 Gypsum Manufacturing Process The gypsum manufacturing process involves several steps, from sourcing raw materials to ensuring the quality of the final product This section will provide an overview of the key The Gypsum Board Manufacturing Process Unveiled

.jpg)

Gypsum Products SpringerLink

2021年3月3日 Explain briefly the production process of calcined gypsum What are the main properties of gypsum? List the components of gypsum plasters Define Glass fiber reinforced ASTM standards govern the manufacture of gypsum board and set strict criteria for strength, water resistance, and other characteristics To produce gypsum board, crushed natural Making Gypsum Board Gypsum Association"Tiger Board" is produced in the factory automated production line Let's see the manufacturing process "Gypsum" is baked in a furnace and made into "calcined plaster" which will solidify Gypsum Board production flow2024年6月21日 Industrial byproduct gypsum was used in recycling and resuing for various building products like gypsum powder, blocks, bricks, and boards It served as a cement Recycling, reusing and environmental safety of industrial by

Gypsum Chemical Formula, Properties, Types, Uses and FAQ

Gypsum rock is first mined or quarried, then crushed and ground to a fine powder It then goes through a process called calcining where heat at 350 degrees is supplied to the gypsum powder which removes 3/4 th of the water molecules Hemihydrate is the name of calcined gypsum which is then used in gypsum board, gypsum plaster, and other productshomes, gypsum plaster is used to make walls; in industry, it is used to make molds Three types of gypsum products are plaster, stone, and highstrength or improved stone The Gypsum and the Gypsum products are used for construction purposes It is also used in industry for making pottery, moulds etc It is used by orthopedics to make plaster Handbook on Gypsum and Gypsum Based Products NIIR USE Gypsum is a particularly useful processed material Its main application is as a building material, mostly produced as socalled plaster of Paris for plastering walls and making decorative features in buildings However gypsum also has a diversity of other uses including making writing chalk, soil conditioning for agriculture, makingGypsum processing and use Humanitarian Library2023年10月9日 Gypsum usage can be traced back to 7000 BCE where it is found in the remnants of Mesopotamian cities found along the Euphrates and Tigris rivers in the Middle East Mesopotamian peoples seem to have used gypsum in their homes, lining walls with gypsum powder to act as a fire retardant, as well as using gypsum stone in the construction of city What is Gypsum? Definition, History, Uses Benefits

.jpg)

Making Gypsum Board Gypsum Association

ASTM standards govern the manufacture of gypsum board and set strict criteria for strength, water resistance, and other characteristics To produce gypsum board, crushed natural gypsum or synthetic gypsum is heated or calcined to dehydrate the feedstock Next the calcined gypsum is mixed with water and additives to form a slurry which is fedGypsum works, Valencian Museum of Ethnology Old Alfarb kiln for making plaster as a construction material British Gypsum, Kirkby Thore Map of gypsum deposits in northern Ohio, black squares indicate the location of deposits, from "Geography of Ohio", 1923 Gypsum is used in a wide variety of applications:Gypsum Wikipedia2021年1月28日 The main significance out of this is to prevent health related problem that faced on workers, and in addition to this making low cost and it can purchase each individual person 111 Gypsum powder and board There are two types of gypsum powder is produced; a) Gypsum Mold (Ceiling); It used to decorate building construction, It used as a Design and Fabrication of Gypsum Board Making MachineGypsum powder is also used in making drywalls 5 Also, different types of tofu are prepared with gypsum powder 2 Uses of Gypsum in Agriculture Gypsum gives nutrients to plants by providing sulphur and calcium where calcium helps in the absorption of nutrients in the roots and sulphur improves crop yield 2Uses of gypsum Uses of gypsum in agriculture and various other gypsum

Infrastructure and Construction Materials Guide — Gypsum

The earliest use of gypsum plaster dates to about 8000 BCE with the discovery of its use in Anatolia (Turkey) Gypsum plaster was used as early as 7000 BCE as a construction material in Egypt Gypsum was first discovered and utilized in North America in Nova Scotia, Canada in 1770 Surface exposures of gypsum were dug and used on agricultural 2023年4月27日 Gypsum plaster, also known as Plaster of Paris (PoP), is a white powder made by heating gypsum, a soft mineral composed of calcium sulfate dihydrate, to a temperature of about 150°C (302°F) The resulting powder can be mixed with water to form a paste that can be applied to walls, ceilings, and other surfacesA Comprehensive Guide to Gypsum Plaster And Its Uses2024年11月4日 Gypsum occurs in extensive beds associated with other evaporite minerals (eg, anhydrite and halite), particularly in Permian and Triassic sedimentary formations; it is deposited from ocean brine, followed by Gypsum Definition, Uses, Facts BritannicaGypsum powder, scientifically known as calcium sulfate dihydrate, is primarily composed of calcium, sulfur, and oxygen, with two molecules of water This powder form originates from the dehydration of gypsum rock into a fine powder During this process, the gypsum is heated, which leads to the loss of crystalline water resulting in a free Demystifying Gypsum Powder: Properties and Applications

The Gypsum Board Manufacturing Process Unveiled Osum

2024年5月16日 Use this information to develop a comprehensive gypsum business plan and identify gypsum business opportunities that align with the needs of your target market Setting Up Your Gypsum Business Before diving into the gypsum manufacturing process, it is essential to set up your gypsum business properlyMultiple processes are taken in production of the plant First, gypsum ores are being crushed, conveyed and stored into raw material bin, and then the crushed gypsum ores get grinded into powder with fineness required by the raymond mill, and the gypsum powder is then conveyed into calcining section via metering feeding device to get calcined, and the calcined gypsum gets Gypsum Powder Plant Iron Powder Making MachineGypsum is normally only screened to remove ‘fines’ (mainly mudstones), then crushed and finely ground Gypsum/Anhydrite for cement manufacture is supplied in crushed form for further fine grinding with cement clinker C Processing Natural Gypsum When Gypsum ( CaSO 4,2H 2O) is ground to a powder and heated at 150° to 165° C, threeFactsheet on: What is Gypsum?Gypsum Products Contents 81 Introduction – 196 82 Denitions – 198 83 Raw Materials – 199 831 Natural Gypsum – 199 832 Synthetic Gypsum – 201 84 Calcined Gypsum Manufacturing Process – 203 85 Properties of Gypsum – 205 851 Fire Properties – 206 852 Acoustic Properties – 207 853 Thermal Properties – 208Gypsum Products Springer

.jpg)

Gypsum Powder Making Machine Gypsum Powder Production

The technology of FD chamber boiling furnace technology can effectively prevent the mixing of raw materials with gypsum powder in the process of calcining Traditional calcining technologies such as vertical boiling furnace , rotary kiln ,general boiling furnace, etcDue to the effect of mixing function of the machinery and air flow, dihydrate gypsum ,semihydratedgypsum and anhydrite 2024年6月21日 Gypsum and its derivatives have garnered significant attention as inorganic, ecofriendly building materials Gypsum building products encompass gypsum powder, gypsum blocks and gypsum boards However, due to the low fire resistance and water resistance of the products produced, as well as the large consumption of natural gypsumRecycling, reusing and environmental safety of industrial by ★ Another important use of gypsum is the production of plaster of Paris Gypsum is heated to about 300 degree Fahrenheit to produce plaster of Paris, which is also known as gypsum plaster It is mainly used as a sculpting material ★ Gypsum is used in making surgical and orthopedic casts, such as surgical splints and casting moldsProperties and Uses of Gypsum Science StruckGypsum Powder: 80200mesh Composition: Content of βCaSO41/2H2O (mass fraction) in calcined gypsum should be not less than 75% The Initial Setting Time: Shall Not Be Less Than 3 Minutes, The Final Setting Time: Shall Not Be More Than 20 Minutes 2 Main Technology Gypsum Powder Plant(Nature Gypsum Rock)Gypsum Powder Making Machine Phospho Gypsum Powder

.jpg)

Gypsum Powder Grinding And Processing Plant

2024年1月23日 Step 4: Calcination of stone powder Gypsum powder meets the fineness requirement and enters a fluidized bed furnace for calcination treatment After calcination, the gypsum powder goes to a storage bin to complete the A nontoxic mineral, gypsum can be helpful to humans, animals, plant life, and the environment While the majority of gypsum produced in North America is used to manufacture gypsum panel products or building plasters, gypsum can also be used: As a soil additive (sometimes called land plaster) to improve the soil’s workability and receptivity toOther Uses of GypsumThis document provides information on various gypsum products used in dentistry, including their classification, manufacturing process, properties, and uses There are five main types of gypsum products impression plaster, model plaster, dental stone, high strength dental stone, and high strength high expansion dental stone Gypsum is calcined through dry calcination or Gypsum Products Compositions, Properties and Uses2020年2月11日 For additional ancillary materials related to this chapter, please visit thePoint Objectives After studying this chapter, the student will be able to do the following: 1 Define the following terms: study model, cast, and die 2 Discuss the major differences between dental plaster, stone, and improved stone 3 Explain the meaning of initial and finalGypsum Materials Pocket Dentistry

Gypsum Powder Making MadeinChina

Sourcing Guide for Gypsum Powder Making: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: methyl cellulose, cmc hec mhec hemc, detergent additive2020年11月20日 Particle size distribution of (a) cementitious materials; (b) aggregates Note: Coarse aggregate data retrieved from Bandarage and Sadeghian (Bandarage and Sadeghian, 2019)Recycled gypsum powder from waste drywalls combined with 2024年10月6日 4 Gypsum Powder Gypsum powder is a naturally occurring material Which is used especially in the United States It is found as soft, white mineral rock Dry powder is made by processing it Gypsum powder is mainly used in building materials like drywall Also useful for the growth of plants in agriculture 4 Types of Gypsum BoardWhat Gypsum Is Used For: A Comprehensive Guide 9To5CivilFind here online price details of companies selling Gypsum Powder Get info of suppliers, manufacturers, exporters, White Gypsum Powder For Making Cornice, Grade: A Grade, Size: 25 Kg ₹ 200/Bag GREEN DUST BIO PROCESS ENGINEER Central Bus Stand, Coimbatore No 198, Nehru Street, Ram Nagar 1st Floor, Gypsum Powder at Best Price in India India Business Directory

Characterization of Natural Gypsum Materials and Their

2019年6月14日 Due to the high impact of the building sector on the environment, a growing interest focuses on insulating materials able to ensure good thermoacoustic performance for the building envelope from Gypsum rock is first mined or quarried, then crushed and ground to a fine powder It then goes through a process called calcining where heat at 350 degrees is supplied to the gypsum powder which removes 3/4 th of the water molecules Hemihydrate is the name of calcined gypsum which is then used in gypsum board, gypsum plaster, and other productsGypsum Chemical Formula, Properties, Types, Uses and FAQhomes, gypsum plaster is used to make walls; in industry, it is used to make molds Three types of gypsum products are plaster, stone, and highstrength or improved stone The Gypsum and the Gypsum products are used for construction purposes It is also used in industry for making pottery, moulds etc It is used by orthopedics to make plaster Handbook on Gypsum and Gypsum Based Products NIIR USE Gypsum is a particularly useful processed material Its main application is as a building material, mostly produced as socalled plaster of Paris for plastering walls and making decorative features in buildings However gypsum also has a diversity of other uses including making writing chalk, soil conditioning for agriculture, makingGypsum processing and use Humanitarian Library

.jpg)

What is Gypsum? Definition, History, Uses Benefits

2023年10月9日 Gypsum usage can be traced back to 7000 BCE where it is found in the remnants of Mesopotamian cities found along the Euphrates and Tigris rivers in the Middle East Mesopotamian peoples seem to have used gypsum in their homes, lining walls with gypsum powder to act as a fire retardant, as well as using gypsum stone in the construction of city ASTM standards govern the manufacture of gypsum board and set strict criteria for strength, water resistance, and other characteristics To produce gypsum board, crushed natural gypsum or synthetic gypsum is heated or calcined to dehydrate the feedstock Next the calcined gypsum is mixed with water and additives to form a slurry which is fedMaking Gypsum Board Gypsum AssociationGypsum works, Valencian Museum of Ethnology Old Alfarb kiln for making plaster as a construction material British Gypsum, Kirkby Thore Map of gypsum deposits in northern Ohio, black squares indicate the location of deposits, from "Geography of Ohio", 1923 Gypsum is used in a wide variety of applications:Gypsum Wikipedia2021年1月28日 The main significance out of this is to prevent health related problem that faced on workers, and in addition to this making low cost and it can purchase each individual person 111 Gypsum powder and board There are two types of gypsum powder is produced; a) Gypsum Mold (Ceiling); It used to decorate building construction, It used as a Design and Fabrication of Gypsum Board Making Machine

Uses of gypsum Uses of gypsum in agriculture and various other gypsum

Gypsum powder is also used in making drywalls 5 Also, different types of tofu are prepared with gypsum powder 2 Uses of Gypsum in Agriculture Gypsum gives nutrients to plants by providing sulphur and calcium where calcium helps in the absorption of nutrients in the roots and sulphur improves crop yield 2The earliest use of gypsum plaster dates to about 8000 BCE with the discovery of its use in Anatolia (Turkey) Gypsum plaster was used as early as 7000 BCE as a construction material in Egypt Gypsum was first discovered and utilized in North America in Nova Scotia, Canada in 1770 Surface exposures of gypsum were dug and used on agricultural Infrastructure and Construction Materials Guide — Gypsum