2200 coal mill vertical mill system transformation implementation

.jpg)

Vertical Coal Mill Magotteaux

As a leading innovator with power station technologies – and other industries that need to process coal, Magotteaux is the ideal firm to turn to when seeking cuttingedge vertical coal mill Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90 % Reprint from ZKG 3 Gebr Pfeiffer2015年3月1日 The model explicitly incorporates mill design data (mill diameter, grinding table diameter, air classifier geometry) and operational conditions (coal feed rate, air flow rate, air Modelling of vertical spindle mills Part 2: Integrated models for E this dissertation was to investigate the effect of coal feedstock property variation on the vertical spindle coal pulverising mill’s performance to facilitate optimal plant performance Plant design Performance optimisation of vertical spindle coal pulverisers

.jpg)

An investigation of performance characteristics and energetic

2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical a vertical roller mill (VRM) • Surpasses the classic methods if the controlled process demonstrates significant disturbances • A high degree of attention to the process states is required in order PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS2020年8月12日 To understand the performance of a vertical roller coal mill, the real operational tests have been performed considering three different coal sources Obtained results indicate An investigation of performance characteristics and energetic 2016年2月1日 A new model of VSMs has been developed which enabled interlinked simulation of comminution and classification operations that occur in the mill The multicomponent A multicomponent model for the vertical spindle mill

.jpg)

A unified thermomechanical model for coal mill operation

2015年11月1日 Coal mills are bottleneck in coal–fired power generation process due to difficulty in developing efficient controls and faults occurring inside the mills In this paper, a dynamic A mathematical model of a vertical spindle mill used in coalfired power plant is presented The model is developed based on a mill size mass balance (SMB) and mill global mass and energy Modelling of Vertical Spindle Mills in Coal Fired Power Plants2006年1月1日 Zhang et al developed a nonlinear mathematical model for the normal grinding process of Vertical Spindle coal mills using onsite measurement data and an evolutionary computation technique in Multisegment pulverised coal mill model and online implementation Our ATOX® Coal Mill can also be equipped with a water injection system to compensate for low water content in the raw coal The ATOX® Coal Mill’s large rollers can handle up to 200mm feed lumps, reducing the need for a separate ATOX® Coal Mill FLSmidth Cement

(PDF) MPS mills for coal grinding ResearchGate

2014年1月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on The Raymond® Bowl Mill is considered the finest vertical rollermill available for pulverizing coal Each bowl mill system is designed to achieve thebest solution forthe processing application The mill, feeder, classifier, fan, cyclone,dust collector and other system components are selected to meet the requirementsand characteristics of the material processedRaymond® Bowl Mill Coperion2) A lowoxygen extracorporeal circulation system is provided on the pulverized coal vertical mill: the gas external circulation system includes a circulating fan, a heat source system, an inert gas supplementary pipe and an explosionproof bag dust collector: the explosionproof bag dust collector is connected to the pulverized coal vertical millWhat is the process flow of vertical mill to produce pulverized coal?Coal Mill; Preheat Calcination Menu Toggle Cyclone Preheater; Rotary Cement Kiln; Indirect Rotary Kiln; LFP Rotary Kiln; Vertical Shaft Kiln; Milling System: Vertical Roller Mill: Ball Mill: Feed size(mm) ≤50: ≤25: Feed coal water content (%) ≤15: ≤10: Coal powder fineness (008mm hole sieve residue, %) 8: 8: Grinding capacity(t Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball Mill

.jpg)

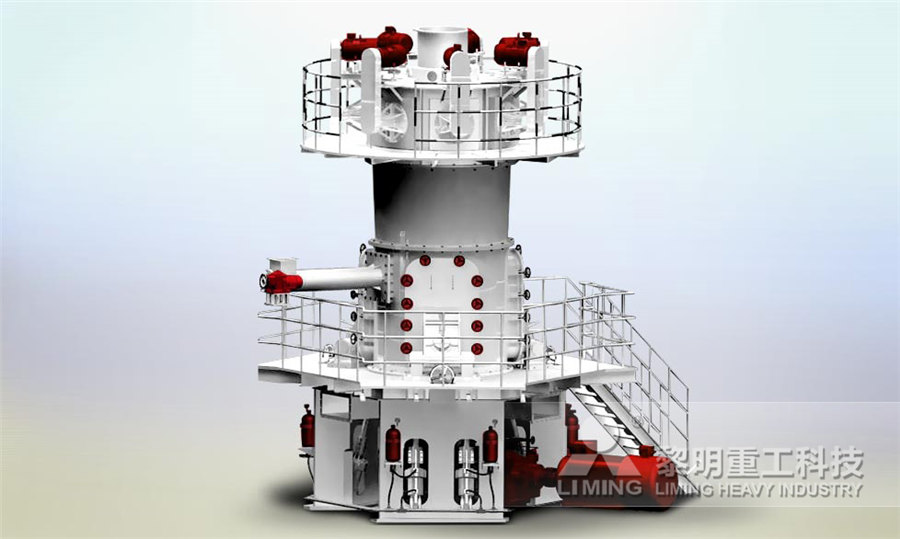

Vertical Grinding Mill (Coal Pulverizer) Explained saVRee

Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring mill2003年1月1日 In addition to the size reduction and classification operations in the mill, some of the researchers have considered the pressure drop (Lee, 1986;Shoji et al, 1998;Zhou et al, 2000; Zhang et al Coal mill modeling by machine learning based on onsite measurements 2014年4月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on (PDF) The latest innovative technology for vertical roller mills 2021年1月22日 In the whole process of cement production, the electricity consumption of a raw material mill accounts for about 24% of the total Based on the statistics of the electricity consumption of the raw A Survey and Analysis on Electricity Consumption of Raw Material Mill

An investigation of performance characteristics and

2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose LM Series Vertical Roller Mill is used to pulverize materials, material can be pulverized into 80400Mesh with this mill Feed particle size : 070mm Production capacity : 4300 tons / hourLM Vertical Roller Mill, Vertical Mill Manufacturer7 // Almost any plant for the grinding of cement raw material is a combination of machines specially adapted to the particular physical properties of the material to be ground As a result, our plants work efficiently without any trouble » Highly efficient grinding, drying, and separating in one unit » Outstanding production capacities exceeding 1,400 t/h in one single millPFEIFFER MILLS FOR THE CEMENT INDUSTRYPRODUCT OVERVIEW LM series vertical mill is a new type of milling equipment with advanced technology, excellent performance and drying functionIt integrates the functions of drying, grinding and powder classifying,used in construction,coal,power plant,steel plant,construction,cement,ceramic and easy maintenance, power saving, fast investment LM series vertical mill

.jpg)

vertical roller mill, vertical coal mill, vertical slag mill, superfine

Vertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, and ultrafine vertical millcoal mill Pulverizing System Wenlan Wang 1* , Xionghuai Bai 2 and Wanku Liang 3 1 College of Electricity, Inner Mongolia University of Technology, Hohhot, InnerOptimization and transformation of 300MV units steel ball coal mill 7 // Almost any plant for the grinding of cement raw material is a combination of machines specially adapted to the particular physical properties of the material to be ground As a result, our plants work efficiently without any trouble » Highly efficient grinding, drying, and separating in one unit » Outstanding production capacities exceeding 1,400 t/h in one single millPFEIFFER MILLS FOR THE CEMENT INDUSTRYDownload scientific diagram Technical specifications of vertical roller coal mill from publication: An investigation of performance characteristics and energetic efficiency of vertical roller Technical specifications of vertical roller coal mill

.jpg)

MPS ZGM Coal MillGrinding Equipment YingYong Machinery

The MPS ZGM coal mill is a type of coal mill that operates at a speed of 50300r/min This equipment is used to prepare and process auxiliary materials for blast furnace ironmaking It provides suitable coal powder for the blast furnace ironmaking systemThis vertical coal mill is typically designed to process materials in medium hardness, like soft coal or bituminous coal, and it is mainly used in positive pressure pulverizing system of soft coal Tel:+86513 Email: tical Coal Mill—China Grinding Equipment ManufacturersOptimisation of coal mill systems, with fire and explosion protection This talk pertains to indirect firing systems in form of airswept mill systems, both horizontal ball mill and vertical roller mill systems Click on the button below to download this publication Download (pptx) #PRESENTATIONS VideoOptimisation of coal mill systems, with fire and explosion Energetic Efficiency An investigation of performance characteristics and energetic

Coal Mill in Cement Plant Vertical Roller Mill Air

Vertical Roller Coal Mill Vertical roller mill is a popular pulverized coal mill in recent years Milling System: Vertical Roller Mill: Ball Mill: Feed size(mm) ≤50: ≤25: Feed coal water content (%) ≤15: ≤10: Coal powder fineness (008mm 2010年6月22日 The failure analysis results of coal mill vertical shaft used in thermal power plant as carried out in a case study, will be available to the designer and manufacturer, besides the users and the Root cause failure analysis of coal mill vertical shaft ResearchGateCoal, lignite or petcoke are ground in the Pfeiffer vertical mill by using available hot process gases The grinding plant can be inerted The raw coal is dried while being ground in the mill even if feed moisture exceeds 25% The feed size that can be handled is up to 100 mm, making twostep precrushing unnecessaryCoal mills for all requirements Gebr PfeifferBased on the analysis of the process of cement raw meal vertical milling system, this paper points out the key control output in the process, the mill vibration, and designs a controller to control it by iterative learning and modelfree adaptive control methods Firstly, the PPD state observer is designed for dynamic linearization, and the controller design is based on the MFAC method of ModelFree Adaptive Controller Design Based on Data IEEE

.jpg)

Vertical roller mills FLSmidth Cement

Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs What’s more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and ATOX® mills that eliminates unexpected downtime and ensures continuous high performanceMaterial circulation inside the mill FSmidth Cement flsmidthcement 3 ATOX coal mill Proven technology Today the airswept vertical roller mill is the standard solution for coal grinding installations And thanks to our continuous refinement of the ATOX coal mill over the years, today’s leading airswept vertical roller mill is the ATOX COAL MILLProcess introduction GRMC coal vertical mill produced by CHAENG adopts a special structure design and production technology, and the quality is up to the leading level in China It is the first choice equipment for grinding raw coal and bituminous coal 1 The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the grid screenCOAL VERTICAL MILL Xinxiang Great Wall Machinery Co, LtdMill Fig1 Flow of Conventional Vertical Mill Grinding System Mill Kiln IDF (Kiln gas exhaust fan) Fig2 Flow of direct dust collection system Results Power consumption of fan(s) reduces about 3 to4 kWh/t Cost estimation When a mill with a production capacity of 420 t/h was newly constructed, the total cost was about 25 million US$ [1US$=¥ Vertical roller mill for raw Application p rocess materials

.jpg)

Multisegment pulverised coal mill model and online implementation

2006年1月1日 Zhang et al developed a nonlinear mathematical model for the normal grinding process of Vertical Spindle coal mills using onsite measurement data and an evolutionary computation technique in Our ATOX® Coal Mill can also be equipped with a water injection system to compensate for low water content in the raw coal The ATOX® Coal Mill’s large rollers can handle up to 200mm feed lumps, reducing the need for a separate ATOX® Coal Mill FLSmidth Cement2014年1月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on (PDF) MPS mills for coal grinding ResearchGateThe Raymond® Bowl Mill is considered the finest vertical rollermill available for pulverizing coal Each bowl mill system is designed to achieve thebest solution forthe processing application The mill, feeder, classifier, fan, cyclone,dust collector and other system components are selected to meet the requirementsand characteristics of the material processedRaymond® Bowl Mill Coperion

What is the process flow of vertical mill to produce pulverized coal?

2) A lowoxygen extracorporeal circulation system is provided on the pulverized coal vertical mill: the gas external circulation system includes a circulating fan, a heat source system, an inert gas supplementary pipe and an explosionproof bag dust collector: the explosionproof bag dust collector is connected to the pulverized coal vertical millCoal Mill; Preheat Calcination Menu Toggle Cyclone Preheater; Rotary Cement Kiln; Indirect Rotary Kiln; LFP Rotary Kiln; Vertical Shaft Kiln; Milling System: Vertical Roller Mill: Ball Mill: Feed size(mm) ≤50: ≤25: Feed coal water content (%) ≤15: ≤10: Coal powder fineness (008mm hole sieve residue, %) 8: 8: Grinding capacity(t Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball MillIntroduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a vertical grinding bowl millOther grinding mill types include the ball tube mill, hammer mill, ball and race mill, and , roll and ring millVertical Grinding Mill (Coal Pulverizer) Explained saVRee2003年1月1日 In addition to the size reduction and classification operations in the mill, some of the researchers have considered the pressure drop (Lee, 1986;Shoji et al, 1998;Zhou et al, 2000; Zhang et al Coal mill modeling by machine learning based on onsite measurements

(PDF) The latest innovative technology for vertical roller mills

2014年4月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on 2021年1月22日 In the whole process of cement production, the electricity consumption of a raw material mill accounts for about 24% of the total Based on the statistics of the electricity consumption of the raw A Survey and Analysis on Electricity Consumption of Raw Material Mill