Lead and tin gravity powder processing process flow chart

.jpg)

Gravity Separation SGS

SGS has significant expertise with gravity separation to treat a wide range of commodities including gold, tin, tantalum, lead/zinc, platinum and mineral sands We can readily provide A general framework for optimal material selection, parameter selection, and processing procedure is proposed to develop the FGM linerFlowchart of the powder metallurgy process ResearchGateLead mining process, how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design read moreLead Mining Processing Equipment Flow Chart Cases JXSC2023年6月1日 In the modern innovative powder flow method techniques, different instruments can measure powder characteristics, such as powder flow tester, FT4 powder rheometer, ring A concise summary of powder processing methodologies for flow

What is Powder Flow Analysis?

A typical industrial powder processing line will include several storage vessels (eg bins, bunkers, silos, hoppers, Intermediate Bulk Containers or IBCs, sacks etc), feeding or handling steps Satin tin or tin/lead plating process for standard chip capacitor/chip resistor plating applications Suitable for barrel plating or SBE equipment See TDS for 90/10 and 60/40 tin/lead PROCESS APPLICATION GUIDE TechnicBelow are some tin ores which may be described as “Complex” or “Simple” based on grain size of the cassiterite and dissemination through the mineral suite, ease of liberation through the TIN ORES SOME ASPECTS OF PROCESS METALLURGY AusIMMThese include the primary and secondary production routes of five nonferrous metals (tin, copper, lead, nickel, zinc), ironmaking and two wasteprocessing applications (spent pot lining Process flow sheet for TSL lead smelting ResearchGate

.jpg)

THE QUICK POCKET REFERENCE FOR TIN/LEAD AND LEADFREE

For ease of use, this guide is broken down into sections that follow the normal progression of an assembly line All leadfree sections are highlighted in green to speed leadfree review If a 2019年9月25日 The raw ore treatment of the tin dressing plant can be roughly divided into the following items: ore washing, desliming, crushing, screening, batching, pulping, heavy medium preseparation, etcFor different tin Tin Processing Equipment, Process Flow, Cases50TPH Diamond Extraction Process Flow Chart 150TPH Coltan Ore Processing Plant in GhanaLead, zinc, iron, manganese, etc 200TPH Rock Manganese Mining Plant in Zambia 150TPH Iron Ore Processing Plant in Tantalum Mining Processing Equipment Flow Sharretts Plating Can Handle All of Your Tinning Needs Sharretts Plating Company has been in business since 1925 Over the course of nine decades, we have developed and perfected an effective and affordable tin plating process The Tin Plating Process: A StepByStep Guide

.jpg)

PVC Compounding INDIAN VINYL COUNCIL

Lead based Stabilizers: TBLS, DBLS, DBLP, DBLP,LS Tin Based Stabilizer: DiButyl Tin Dilaurate, DiOctyl Tin Maleate, Dibutyl Tin Bis isooctyl Mercapto acetate, Monomethyl TinTris 2Mercapto ethyl oleate Etc Ca/Zn stabilizers are very popular for rigid films for food packaging in pipes/ cables as also bottles for mineral water2024年11月21日 For this reason, our JXSC Mining Machinery have researched and designed a high efficiency tungstentin ore beneficiation production line and process flow Process flow of tungstentin ore beneficiation production line In the tungstentin ore beneficiation process, the reelection method is most widely usedTungstentin ore beneficiation process design and it’s equipmentLead Zinc Mining Process, how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design read more Skip to content Menu Home; Target concentrate: lead >45%, zinc >45% 2 Gravity separator to process 0 Lead Zinc Mining Process Equipment Flow Cases JXSCLeadzinc ore beneficiation process is gravitymagneticflotation separation Contact us to get the process and equipment price The bottom flow of the thickener passes through the slurry pump and enters the third disc vacuum filter for Tin Ore Processing Plant; Lead Zinc Ore Processing; Chrome Washing Process; Contact Us +86Lead Zinc Processing Solution JXSC Machinery

.jpg)

Quartz mining and processing flow chart at selected deposits

Download scientific diagram Quartz mining and processing flow chart at selected deposits and model processing plant from publication: Production of industryspecific quartz raw material using 2015年8月26日 Copper Mining Extraction Process Flow Chart This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore)Copper Mining Extraction Process Flow Chart2019年8月23日 The content of lead in the earth’s crust is 00016%, and its reserves are relatively abundant Australia, China, Russia, the United States, Peru and Mexico, the countries with the most lead reserves in the world, account for 87% of the world ’s reserves, with Australia accounting for the largest 40%, China accounting for 16%, and the US accounting for 6% Peru Lead Processing Equipment, Process Flow, Cases JXSC MachineIn the present paper, nickel powder was recycled from ferrous scrap, a lowcost and largely available material, by an effective hydrometallurgical recovery process Then, this recycled powder was General flow sheet for producing electrolytic zinc

Flow chart of powder metallurgy process

Download scientific diagram Flow chart of powder metallurgy process from publication: Effect of Powder Metallurgy Process and its Parameters on the Mechanical and Electrical Properties of Copper Download scientific diagram Schematic flow chart of mining and processing activity from publication: Towards Sustainable Mining: Exploiting Raw Materials from Extractive Waste Facilities The Schematic flow chart of mining and processing activityTypical Tin Beneficiation Flow Sheet Multotec specialises in tin beneficiation equipment with over 50 years of global experience and leading technology Our team of metallurgists and engineers will partner with you to customise your equipment, helping your process run more efficiently while lowering your overall cost per tonTypical Tin Processing Flowsheet MultotecDownload scientific diagram Simple Process Flow Chart of Powder Metallurgy from publication: A Review: The Potential of Powder Metallurgy in Recycling Aluminum Chips (Al 6061 Al 7075 Simple Process Flow Chart of Powder Metallurgy

.jpg)

Mineral Processing and Metallurgical Treatment of Lead Vanadate

2020年2月22日 As main gangue minerals, calcite, dolomite, and some silicates are present in both ore types Before 1960, the leadvanadatecontaining ore from different ore bodies was processed using gravity concentration The processing plant for flotation of lead, zinc, and vanadate minerals was introduced by the end of 1961 and closed in 19782024年1月13日 Continuous manufacturing minimizes batchtobatch variations and enhances control over powder flow, ensuring a more reliable production process Additionally, breakthroughs in particle engineering technologies have allowed for the creation of tailormade powder particles with improved flow characteristicsPowder Processing Challenges: Mastering force and flow Tin, Gravity Separation, Physical Separation, leadbearing minerals The other one is the separation process in an upward flow of water which will separate the particles by their densityTHE EFFECTIVENESS OF PHYSICAL SEPARATION PROCESS FOR THE ALLUVIAL TIN Download scientific diagram Flow chart for the processing of turmeric rhizome into powder from publication: Functional and Physicochemical Properties of Turmeric Powder as Affected by Processing Flow chart for the processing of turmeric rhizome into powder

Tin ore processing plant beneficiation machine separate Se

Tin ore processing plant beneficiation machine separate Se mining , Condition: New Origin: Henan, China Capacity: 02500 Ton/h Method: Gravity plant , gravityflotation plant Used for: widely used in all kinds of tin ore, gold ,copper ore etc2024年4月1日 This technique has a high utilization rate of RE resources and has been applied to industrialscale production of ores from Bayan Obo, Mountain Pass and Weishan Lake with the process flow charts in Fig 4 55, 61 It is worth mentioning that the flotation feed of Mountain Pass and Weishan Lake is the raw ore, while the flotation feed of Bayan Obo is derived from iron Recent process developments in beneficiation and metallurgy of 2024年7月11日 Gravity separation is a separation method that uses the density difference between tin and associated minerals During the gravity separation process, the tin ore is layered and separated according to the density Tin Ore Dressing: Gravity, Flotation And Magnetic Learn about types of flow charts and flowchart symbols Learn how to make a flowchart Close bigger deals with reproducible processes that lead to successful onboarding and training License Everyone For as Low as $5 per Flowchart Process Flow Charts, Templates, How To,

.jpg)

(DOC) TIN PROCESSING efa wakerkwa Academia

1 Introduction 11 Background Tin processed from tin ore which is obtained from the rock or mineral of tin (cassiterite SnO2) Tin metal production processes from the seeds are involves a series of fairly complicated process which is mineral processing (elevated lead levels / physical processes and is also called upgrading), preparation of the material to be melted, the process 2024年11月21日 It is an ideal choice for the beneficiation of Sands The equipment for gravity separation of sand tin ore is mainly jig Sometimes, the rocking bed is also used to improve the recovery rate of finely grained tin ore The technological process of gravity separation for sand tin ore is screening, jigging and dewateringHow to extraction tin from tin ores JXSC MachineryLead processing, preparation of the ore for use in various products Lead (Pb) is one of the oldest metals known, being one of seven metals used in the ancient world (the others are gold, silver, copper, iron, tin, and mercury) Its low melting point of 327 °C (621 °F), coupled with its easyLead processing Smelting, Refining Uses BritannicaFlow Charts Related Articles How to Spot Fake News Information Gathering Business Reports Good Charts and Good Charts Workbook How to Use Gantt Charts Article • 9 min read Flow Charts Identify and Communicate Your Optimal Process Flow Charts Identify and Communicate Your Optimal Process

.jpg)

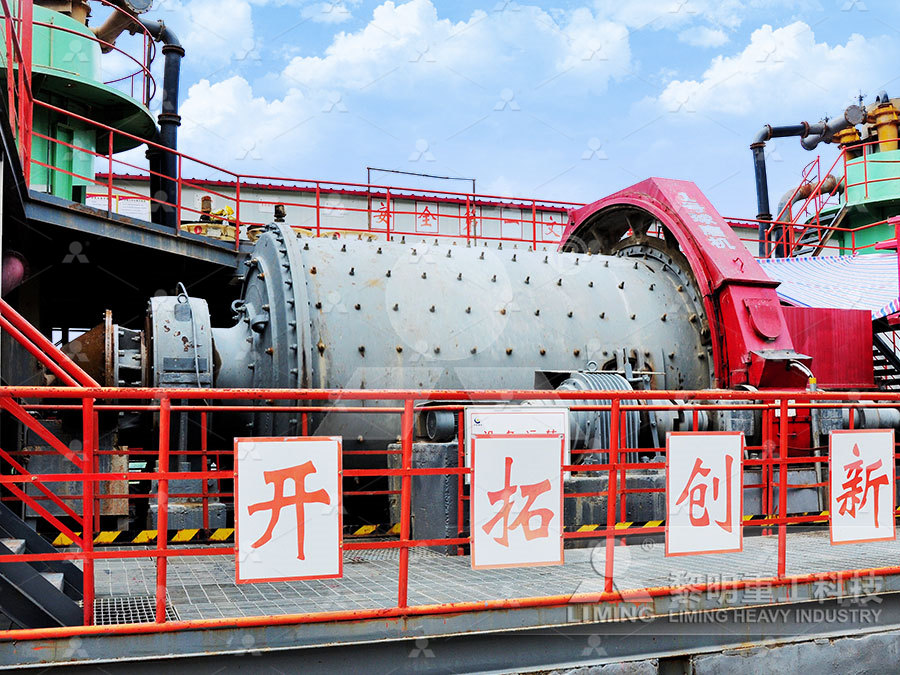

Tin Ore Processing Plant JXSC Machinery

Tin(Cassiterite) ore processing refers to the process of extracting tin from ore Gravity separation, magnetic separation and flotation are mainly used to grade tin concentrate and remove other impurities In order to achieve high efficient, lowcost beneficiation flow, JXSC will custom process and equipment according to ore characteristicsDownload scientific diagram Process flow sheet for TSL lead smelting from publication: SmallScale Secondary Lead Processing using Ausmelt TSL Technology Over the past 15 years, Ausmelt TSL Process flow sheet for TSL lead smelting ResearchGate2023年7月25日 Common Questions about Gravity Separation: Primary Equipment: Rotary scrubbers or trommel screens tackle impurities, followed by jigs or spiral chutes for rough concentration, and finally shaking tables for further concentration Process Breakdown: Gravity separation utilizes the different densities of minerals Heavier tin ore settles faster than lighter Gravity Separation for Alluvial Tin Ore: Equipment and Process 2019年9月25日 The raw ore treatment of the tin dressing plant can be roughly divided into the following items: ore washing, desliming, crushing, screening, batching, pulping, heavy medium preseparation, etcFor different tin Tin Processing Equipment, Process Flow, Cases

Tantalum Mining Processing Equipment Flow

50TPH Diamond Extraction Process Flow Chart 150TPH Coltan Ore Processing Plant in GhanaLead, zinc, iron, manganese, etc 200TPH Rock Manganese Mining Plant in Zambia 150TPH Iron Ore Processing Plant in Sharretts Plating Can Handle All of Your Tinning Needs Sharretts Plating Company has been in business since 1925 Over the course of nine decades, we have developed and perfected an effective and affordable tin plating process The Tin Plating Process: A StepByStep GuideLead based Stabilizers: TBLS, DBLS, DBLP, DBLP,LS Tin Based Stabilizer: DiButyl Tin Dilaurate, DiOctyl Tin Maleate, Dibutyl Tin Bis isooctyl Mercapto acetate, Monomethyl TinTris 2Mercapto ethyl oleate Etc Ca/Zn stabilizers are very popular for rigid films for food packaging in pipes/ cables as also bottles for mineral waterPVC Compounding INDIAN VINYL COUNCIL2024年11月21日 For this reason, our JXSC Mining Machinery have researched and designed a high efficiency tungstentin ore beneficiation production line and process flow Process flow of tungstentin ore beneficiation production line In the tungstentin ore beneficiation process, the reelection method is most widely usedTungstentin ore beneficiation process design and it’s equipment

Lead Zinc Mining Process Equipment Flow Cases JXSC

Lead Zinc Mining Process, how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design read more Skip to content Menu Home; Target concentrate: lead >45%, zinc >45% 2 Gravity separator to process 0 Leadzinc ore beneficiation process is gravitymagneticflotation separation Contact us to get the process and equipment price The bottom flow of the thickener passes through the slurry pump and enters the third disc vacuum filter for Tin Ore Processing Plant; Lead Zinc Ore Processing; Chrome Washing Process; Contact Us +86Lead Zinc Processing Solution JXSC MachineryDownload scientific diagram Quartz mining and processing flow chart at selected deposits and model processing plant from publication: Production of industryspecific quartz raw material using Quartz mining and processing flow chart at selected deposits 2015年8月26日 Copper Mining Extraction Process Flow Chart This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore)Copper Mining Extraction Process Flow Chart

Lead Processing Equipment, Process Flow, Cases JXSC Machine

2019年8月23日 The content of lead in the earth’s crust is 00016%, and its reserves are relatively abundant Australia, China, Russia, the United States, Peru and Mexico, the countries with the most lead reserves in the world, account for 87% of the world ’s reserves, with Australia accounting for the largest 40%, China accounting for 16%, and the US accounting for 6% Peru