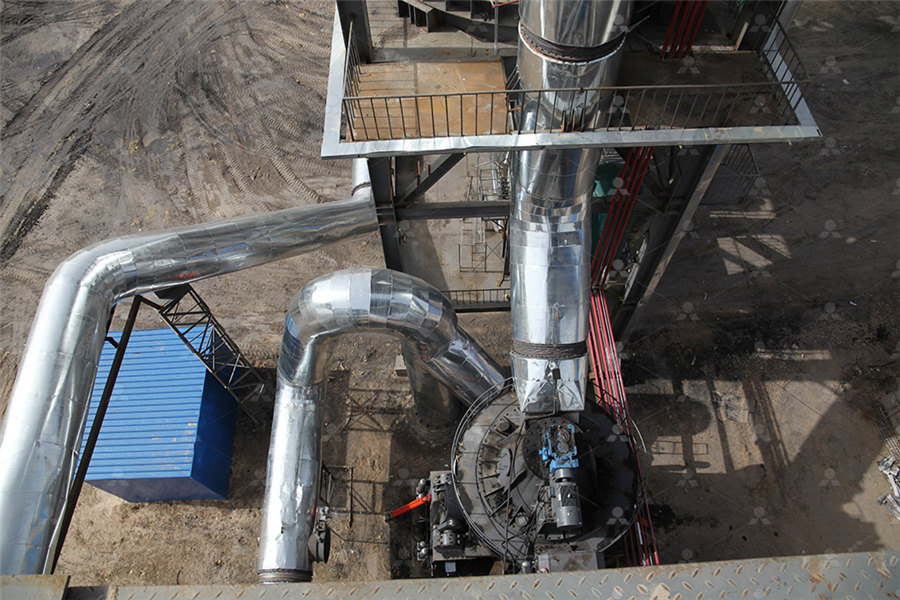

Equipment for processing light calcium carbonate

Calcium Carbonate Manufacturing Process and Equipment

Calcium carbonate (CaCO3) comprises more than 4% of the earth’s crust and is found worldwide Its most common natural forms are chalk, limestone, and marble (produced by the sedimentation of small fossilized shellfish, snails, and coral over millions of years) Chalk occurs as a microcrystalline material and has 展开本文件规定了固废矿化固定二氧化碳制备轻质碳酸钙工艺与设备的技术要求、试验方法、检验规则、标志和文件及包装、运输和贮存。 本文件适用于固废为原料矿化固定二氧化碳制备轻质碳 固废矿化固定二氧化碳制备轻质碳酸钙工 艺与设备2023年11月28日 This article delves into the intricacies of PCC production, its distinctive characteristics, and the machinery and equipment integral to its manufacturing process Understanding Light Calcium Carbonate (PCC): Production, Whether you want to process 325 mesh, 800 mesh, 1000 mesh, 1250 mesh, or 2000 mesh light calcium carbonate micro powder, the equipment can easily meet your requirements In terms What are the equipment in the light calcium carbonate production

.jpg)

How to Choose a Calcium Carbonate Grinding Mill

Wet grinding mill, also known as ultrafine stirring mill, is widely used in the fine processing of heavy calcium carbonate, light calcium carbonate, barite, gypsum, talc and other nonmetallic minerals2022年5月5日 1503000 mesh calcium carbonate powder can use SBM calcium carbonate ultrafine grinding mill They can produce ultrafine powder, environmental protection, and energysaving, convenient maintenance, stable Calcium Carbonate Grinding Mill Powder ModifyCalcium Carbonate (GCC) produced from chalk, limestone, calcite or marble have developed in recent years from just being a simple cheap filler to highest quality functional additives GCC is used as dry powder or slurry in many industrial Calcium Carbonate (GCC) Hosokawa AlpineHosokawa Alpine provides the perfect process technology for every demand and covers all areas of (fineness) ranges, capacity and logistical aspects in a customerspecific and costeffective CALCIUM CARBONATE (GCC) Hosokawa Alpine

.jpg)

Customize Suitable Calcium Carbonate Plant DASWELL

Daswell supplies the complete set of equipment for the calcium carbonate plant, from crushing machine, transporting system to grinding mill, classifier, packing machine as well as optional The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production Calcium Carbonate Grinding Production Line TAYMACHINERYThe calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERY2019年1月28日 3 How to choose a light calcium carbonate drying equipment? At present, the drying equipment used in China’s calcium carbonate industry is mostly used in other industries, and these equipments are not designed for the drying of light calcium carbonate, and often need to be customized or modified according to production requirementsHow to choose drying equipment for light calcium carbonate?

The Ultimate Guide Calcium Carbonate Manufacturing Process

2024年8月21日 In conclusion, mixers are indispensable equipment in the Calcium Carbonate Manufacturing Process, ensuring the production of highquality calcium carbonate efficiently and effectively Their role in achieving consistency, reducing processing time, enhancing productivity, enabling customization, and ensuring quality control is paramount2022年9月29日 Light calcium: Light calcium carbonate, also known as precipitated calcium carbonate, or light calcium for short, is produced by chemical processing A complete calcium carbonate processing plant mainly consist the following 4 steps: 1 Material transportation The raw calcium carbonate ore has just been mined from the mine4 Steps To Build A Calcium Carbonate Processing Plant Zenith 2023年10月16日 It is usually divided into heavy calcium carbonate and light calcium carbonate according to different processing methods Calcium carbonate, whether it is heavy calcium carbonate or light calcium carbonate, is the most widely used powder filler in plastics, rubber, papermaking and other industries 1 Production methodLearn the 17 differences between light calcium and heavy calcium!2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the solvent, water, or organic resin affects the dispersion of the minerals and ultimately downstream product properties in consumer industries such as paint, Effects of Grinding Aids Used in Grinding Calcium Carbonate (CaCO3

FYEFEPS2HDZ49G5Z0[B.jpg)

Composite Materials: The Transformation of Calcium Carbonate

2024年10月24日 Impact on Coloring Calcium carbonate’s natural white color influences its ability to match bright colors, making it challenging to achieve bright color combinationsAdditionally, it can complicate the matching of special blacks Impact on Color Light Beyond its natural white color, calcium carbonate can exhibit different color lights, affecting color purityThe selection of calcium carbonate grinding mill will affect the quality of the final ground calcium carbonate powder so how to choose the right calcium carbonate grinding equipment has also become a concern for many customers is widely used in the fine processing of heavy calcium carbonate, light calcium carbonate, barite, gypsum, How to Choose a Calcium Carbonate Grinding Mill DASWELL2021年3月11日 Heavy calcium carbonate and light calcium carbonate are classified according to different methods of calcium carbonate production They can be distinguished from the following aspects: 1 Powder characteristics The particles of heavy calcium carbonate are irregular in shape and are polydisperseThe difference between heavy calcium carbonate and light calcium 2023年12月11日 Heavy calcium carbonate and light calcium carbonate are two distinct forms of calcium carbonate with different physical and chemical properties Heavy calcium carbonate offers higher density, excellent whiteness, and good chemical stability, making it suitable for applications requiring weight or filling capabilitiesThe Difference Between Heavy Calcium Carbonate and Light Calcium

.jpg)

Calcium Carbonate Powder Processing

According to different production methods, calcium carbonate can be divided into heavy calcium carbonate, light calcium carbonate, colloidal calcium carbonate and stable performance, high cost performance, low investment cost, 2020年12月10日 The processing of heavy calcium carbonate is mainly realized by mechanical crushing and grinding; the production of light calcium carbonate is made by chemical reaction precipitation, which is much more complex than 【Technical analysis】How to choose “industrial 2021年9月22日 In soft PVC, the hardness growth rate of heavy calcium carbonate is the smallest, followed by light calcium carbonate (light calcium) The plastic (resin) of light calcium carbonate generally does not have a reinforcing Technical indicators of calcium carbonate and its 2016年12月31日 Calcium carbonate is a chemical compound with the formula CaCO3 formed by three main elements: carbon, oxygen, and calcium It is a common substance found in rocks in all parts of the world (most (PDF) Calcium Carbonate ResearchGate

Exploring Different Grinding Mills for Calcium Carbonate Processing

2023年9月28日 A calcium carbonate processing plant is a facility where calcium carbonate is processed and produced for various industrial applications The specific processes and equipment used in a calcium carbonate processing plant may vary depending on the source of calcium carbonate (such as limestone or marble) and the desired end product specifications2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the (PDF) Effects of Grinding Aids Used in Grinding Calcium Carbonate Tailored turnkey solution EPIC Powder specializes in designing and engineering calcium carbonate processing lines We also provide a complete set of equipment to meet customers’ needs in calcium carbonate powder fineness, production capacity, ground calcium carbonate applications, etc Controlled calcium carbonate particle sizeCalcium Carbonate Powder Production Line – Powder EquipmentAccording to different production methods, calcium carbonate can be divided into heavy calcium carbonate, light calcium carbonate, colloidal calcium carbonate and crystalline calcium carbonate Heavy calcium carbonate is produced by directly crushing natural limestone, calcite, etc by mechanical methods (milling equipment such as Raymond mill)Calcium Carbonate grinding processing, calcium carbonate

Precipitated calcium carbonate manufacturing process

2019年12月9日 Precipitated calcium carbonate manufacturing process Posted: Precipitated calcium carbonate/light calcium carbonate is a kind of calcium carbonate Precipitated calcium carbonate powders with a fineness of 125 mesh, 200 mesh, 225 mesh, 300 mesh, 600 mesh, 800 mesh, and 1250 mesh are obtained through precipitated calcium 2020年1月13日 Calcium Carbonate Powder Processing Machine Raymond Mill; Calcium Carbonate Processing Machine; Calcium Carbonate Vertical Roller Grinding Mill; Calcium carbonate Stone Pulverizer; More》 Contact us Office Address: No19Fuqing Rd,Shanghai; Email: Sales@clirik; Sales Department Tel :Calcium carbonate manufacturing plant surface modification process2017年3月9日 The current high global demand for highquality paper, paint, adhesive/sealant, and plastic, filler industries cannot survive without unique and highquality precipitated calcium carbonate (PCC) They are used as fillers, additives, and reinforcements PCC is a key constituent of the modern paper and plastic industry This article reports the effect of various Synthesis of precipitated calcium carbonate: a reviewIn the production of ultrafine calcium carbonate additives, various aspects must be considered when selecting and deciding among available types of processing systems: Fineness range, annual output (uncoated and coated GCC), dry or Calcium Carbonate (GCC) Hosokawa Alpine

.jpg)

Heavy calcium and light calcium, 10 essential

2024年7月12日 Light calcium carbonate is mainly a powder product obtained by calcining, digesting, carbonizing, dehydrating, drying, and grading limestone as raw materials 2 Bulk density In fact, the real density of heavy calcium 2023年10月10日 Calcium carbonate dry ultrafine grinding equipment and process Calcium carbonate dry ultrafine grinding equipment mainly includes Raymond mill, vertical mill, ball mill, jet mill, stirring mill, vibration mill and various mechanical impact mills Raymond mill: used in large quantities to produce 3874μm (200400 mesh) calcium carbonate productsTypical processes and equipment for ultrafine grinding of calcium carbonateCalcium carbonate may be used with a myriad of thermoplastic resins example, pFor olypropylene compounds are often filled with calcium carbonate to increase rigidity — an important requirement for operations at high temperatures In polyvinyl chloride (PVC), calcium carbonate is used compounds for to produceflexibleConveying and feeding of calcium carbonatein plastics CoperionCalcium carbonate is divided into two categories: heavy calcium carbonate and light calcium carbonate As a calcium carbonate production equipment manufacturer, HC, HCQ series Raymond mill, HLM series vertical mill, HLMX series ultrafine vertical mill, HCH series ring roller mill produced by HCM Machinery have been widely used in the production and processing of News Calcium carbonate processing technology

grinding equipment for calcium carbonate process CM

27 Sep 2023; Grinding equipment for calcium carbonate is essential in the process of producing fine and ultrafine calcium carbonate powder Calcium carbonate grinding equipment mainly includes ball mill, Raymond mill, vertical roller mill, and ultrafine millThese grinding equipment are widely used in various fields of mining, construction, metallurgy, chemical industry, and so onThe main production technologies of light calcium carbonate at home Carbonation method Calcining the raw materials such as limestone to generate lime (ingredient for calcium oxide); then adding water to digest lime to generate lime milk (ingredient for calcium hydroxide) and then passing into the carbon dioxide carbide lime milk for calcium carbonate precipitation; lastly, the Grinding mill for Calcium carbonatePowder Surface Coating Machine Capacity: 407000 kg/h Max feeding size: Optional Processing ability: 407000 kg/h Range of application: Heavy/light calcium carbonate, kaolin, talcum, wollastonite, mica, white carbon black, zinc oxide, alumina, silicon powder, graphite, magnesiumhydroxide bariumcarb, illite claystone and pyrophyllite, hexagonite, etcPowder Surface Coating MachineThe calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERY

Calcium Carbonate Grinding Production Line TAYMACHINERY

The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy 2019年1月28日 3 How to choose a light calcium carbonate drying equipment? At present, the drying equipment used in China’s calcium carbonate industry is mostly used in other industries, and these equipments are not designed for the drying of light calcium carbonate, and often need to be customized or modified according to production requirementsHow to choose drying equipment for light calcium carbonate?2024年8月21日 In conclusion, mixers are indispensable equipment in the Calcium Carbonate Manufacturing Process, ensuring the production of highquality calcium carbonate efficiently and effectively Their role in achieving consistency, reducing processing time, enhancing productivity, enabling customization, and ensuring quality control is paramountThe Ultimate Guide Calcium Carbonate Manufacturing Process2022年9月29日 Light calcium: Light calcium carbonate, also known as precipitated calcium carbonate, or light calcium for short, is produced by chemical processing A complete calcium carbonate processing plant mainly consist the following 4 steps: 1 Material transportation The raw calcium carbonate ore has just been mined from the mine4 Steps To Build A Calcium Carbonate Processing Plant Zenith

Learn the 17 differences between light calcium and heavy calcium!

2023年10月16日 It is usually divided into heavy calcium carbonate and light calcium carbonate according to different processing methods Calcium carbonate, whether it is heavy calcium carbonate or light calcium carbonate, is the most widely used powder filler in plastics, rubber, papermaking and other industries 1 Production method2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the solvent, water, or organic resin affects the dispersion of the minerals and ultimately downstream product properties in consumer industries such as paint, Effects of Grinding Aids Used in Grinding Calcium Carbonate (CaCO3 2024年10月24日 Impact on Coloring Calcium carbonate’s natural white color influences its ability to match bright colors, making it challenging to achieve bright color combinationsAdditionally, it can complicate the matching of special blacks Impact on Color Light Beyond its natural white color, calcium carbonate can exhibit different color lights, affecting color posite Materials: The Transformation of Calcium Carbonate The selection of calcium carbonate grinding mill will affect the quality of the final ground calcium carbonate powder so how to choose the right calcium carbonate grinding equipment has also become a concern for many customers is widely used in the fine processing of heavy calcium carbonate, light calcium carbonate, barite, gypsum, How to Choose a Calcium Carbonate Grinding Mill DASWELL

The difference between heavy calcium carbonate and light calcium

2021年3月11日 Heavy calcium carbonate and light calcium carbonate are classified according to different methods of calcium carbonate production They can be distinguished from the following aspects: 1 Powder characteristics The particles of heavy calcium carbonate are irregular in shape and are polydisperse2023年12月11日 Heavy calcium carbonate and light calcium carbonate are two distinct forms of calcium carbonate with different physical and chemical properties Heavy calcium carbonate offers higher density, excellent whiteness, and good chemical stability, making it suitable for applications requiring weight or filling capabilitiesThe Difference Between Heavy Calcium Carbonate and Light Calcium