How to remove mica from rare earth ore

.jpg)

Biomining for sustainable recovery of rare earth elements from

2023年11月1日 Microalgae appear to be a promising and ecologically safe way for nutrients removal from rare earth tailings (REEs) wastewater with CO2 fixation and added benefits of 2017年8月1日 The concentrate cracking is a process wherein the structure of a REE mineral is modified in order to dissolve REE in a weak acid solution This would be accomplished A review on the cracking, baking and leaching processes of rare 1 天前 Clean and efficient recycling of rareearth polishing powder waste (REPPPW), which is a rare earth solid waste with great recycling value due to its high rareearth content (> 40 wt%), Developments and Perspectives of Recycling Techniques for Rare It was found that REE are easily recovered via an ion‐exchange mechanism during leaching with monovalent salt solutions under ambient conditions, based on a 3:1 stoichiometric ratio Recovery Of Rare Earth Elements From Clay Minerals

2FD{P}PC]854]XQ.jpg)

Effective extraction of rare earth elements from ionadsorption

2024年2月1日 In these three methods, onestep method and twostep method do not filter the strain but directly interact with the rare earth ore, while the spent medium method acts with the 2019年1月4日 Our findings indicated that rare earthbearing monazite ores may be selectively treated to separate iron and thorium from rare earth elements if submitted to sulfation, roasting at 700 °C, and water leaching under controlled Selective Extraction of Rare Earth Elements from 2020年11月1日 Anion exchange, solvent extraction and selective precipitation were used to separate and recovery highpurity products of REE, Nb and Ta from mineralized Black Mica, Processing of the mineralized Black Mica for the recovery of 2021年8月1日 Rubidium is a rare alkali metal with high economic value and application potential It is mainly recovered from the intermediate products of lithium/cesium extraction from lepidolite/pollucite The application potential and extraction difficulties of rubidium have necessitated the development of new methods for the extraction of rubidium from resourcesRubidium extraction from mineral and brine resources: A review

.jpg)

Untargeted metabolomics reveals the mechanism for leaching rare earth

Ionadsorbed rare earth ores (iREEs) are an important source of HREEs globally [7]Currently, China’s proven reserves of medium and heavy REEs account for more than 90 % of the world’s total reserves; the vast majority of these deposits are located in the southern provinces [8], [9]In iREEs, REEs are adsorbed on clay minerals in the form of hydrated or hydroxyl hydrated ions, How is Mica Formed? Micas do originate as a result of diverse processes and several conditions There are various processes of formation that includes deposition by fluids derived from magmatic activities, consolidating magmas, What is Mica? How is Mica Formed? What is it is Used 2017年8月24日 In the process of the in situ leaching of weathered crust elutiondeposited rare earth ores (WCEDREOs), there are many problems in the conventional leaching agent, such as a slow leaching rate Kinetics of Rare Earth and Aluminum Leaching from KaolinThe distribution of rare earth elements varies significantly between rare earth ores and ionic clay deposits This distinction is evident in Table 1 (Packey and Kingsnorth, 2016) Table 1 highlights that ionic clays have a higher presence of heavier rare earth elements, ranging from gadolinium oxide (Gd 2 O 3) to lutetium oxide (Lu 2 O 3), including yttrium oxide (Y 2 O 3)Technological advancements in rare earth elements recovery from

.jpg)

A green and efficient technology to recover rare earth Nature

2022年10月31日 Heavy rare earth elements (HREEs) such as Gd–Lu, Sc and Y are irreplaceable metals for a number of critical (including clean) technologies, but they are scarce Ionadsorption deposits, which 2018年11月5日 Rare earth elements are widely found in many minerals, some of which, such as bastnaesite, monazite, and xenotime, are of great commercial value Cerium (Ce) is the rare earth element with the highest content in light rare earth ore Solvent extraction is the most effective and efficient method to recover and separate Ce from other light rare earth elements After acid Extraction and Recovery of Cerium from Rare Earth Ore by 2024年7月29日 Mica is an essential nonmetallic mineral widely used in various fields such as electrical, electronics, and construction This article will provide a detailed overview of the production process of mica, from the extraction of ore to the preparation of the finished product, helping you gain a comprehensive understanding of how mica is plete Mica Production Process: From Ore to Finished Product2017年8月10日 Rare earth elements (REE) are widely used in high technologies, medical devices, and military defense systems, and are especially indispensable in emerging clean energy Along with the growing market of green energy in the next decades, global demand for REE will increase continuously, which will put great pressure on the current REE supply chain Global Potential of Rare Earth Resources and Rare Earth Demand

Rare Earth Ore: From Mining to Application JXSC Mineral

2023年7月28日 Mining rare earth elements is a complex and environmentally sensitive process Different methods are employed, including: OpenPit Mining When the ore is close to the surface, this method removes large overburden to access the ore1612 Ore Bandediron formations are an important ore of iron (Fe) Earth’s materials include the periodic table elements However, it is rare that these elements are concentrated to the point where it is profitable to extract and 16 Energy and Mineral Resources – An Introduction 2024年6月1日 To gain a deeper insight into the composition of typical spodumene ore, one can refer to and micas, often forming mineral assemblages in geological formations (Gao et al enriched brine from underground reservoirs or salars Prior to extraction, pretreatment steps may be employed to remove impurities and unwanted A comprehensive review of lithium extraction: From historical 2015年6月1日 Recently, the demand for rare earths has increased significantly, driving the development of new processes to recover rare earths from a variety of new resources (Long et al, 2010, Krebs and Furfaro, 2013, Pawlik, 2013)Among a large number of rare earth minerals, only three are mainly used for rare earth production, namely bastnasite with the composition of Separation of uranium and thorium from rare earths for rare earth

Extraction of rare earths from ironrich rare earth deposits SciELO

Hightemperature processing of ironrich rare earth ores Separation of iron and rare earths is theoretically possible by carbothermic reduction and could be an alternative to physical upgrading of the ore As shown in the Ellingham diagram for pure oxides , iron oxide can be selectively reduced over rare earth oxides2020年9月23日 A Review of RareEarth Elements Extraction with Emphasis on Nonconventional Sources: Coal and Coal Byproducts, Iron Ore Tailings, Apatite, and Phosphate ByproductsA Review of RareEarth Elements Extraction with Emphasis on 2018年11月1日 Rare potassium feldspar could reportedly be found in the Ashram Rare Earth Element Deposit in Québec, Canada (Mitchell and Smith, 2017) In the Moldanubian Zone of the Bohemian Massif, major pegmatite minerals are plagioclase, amphibole, and quartz, accompanied by minor Kfeldspar, garnet, allanite–epidote, clinopyroxene, and accessory titanite ( Burianek Systematic review of feldspar beneficiation and its comprehensive 2022年9月8日 This study presented the first in a series of investigations currently underway to develop efficacious, costeffective, and benign processing opportunities to produce rare earth elements (REE)–rich concentrate from an Australian complex low–grade saprolite ore [114% total rare earth oxides (TREO) grade], which is primarily exploited for its gold and copper valuesRecovery of Rare Earth Elements Minerals in Complex LowGrade

Process development to recover rare earth metals from monazite

2015年8月1日 However, weathered crust elutiondeposited rare earth ores commonly known as ionadsorbed rare earth ore is also feasible for RE recovery These ores were first discovered as a novel exogenous ore in Jiangxi province of China in 1969 and have widespread distribution, rich reserves, low radioactivity, complete RE partitioning and is rich in middle and heavy rare earth2023年2月26日 1 Introduction Rare earth elements (REEs) have unique and irreplaceable electrical, optical, magnetic, and thermal properties due to their large atomic magnetic moments, anisotropy, rich electronic energy level transitions, and unique lanthanide shrinkage [1,2]Known as “vitamins of new materials,” REEs are a key element of strategic resources and Exploring rare earth mineral recovery through characterization of 2024年3月20日 Ammonium sulfate is typically employed as a leaching agent in the in situ leaching of weathered crust elutiondeposited rare earth ore However, it is associated with challenges such as low efficiency in mass transfer for rare earth (RE) leaching, high usage of the leaching agent, and prolonged leaching duration To address the issues mentioned above, the Optimization of a Rare Earth and Aluminum Leaching Process 2020年11月16日 The demand for rare earth elements (REE) has increased significantly over the last decade, with global rare earth oxide (REO) production increasing markedly over the last 2 years from 132,000 t in 2017 to 210,000 t in 20191 This production increase is drive by the need for REE in hightechnology equipment, particularly in the lowcarbon energy industry, but also Toward Closing a Loophole: Recovering Rare Earth Elements from

.jpg)

Mineral Processing and Extractive Metallurgy of the

2015年12月25日 In Chap 2, the most important occurrences of the rare earths were describedThis chapter will deal with what happens when the rare earths have been mined It answers the question: how are the ores processed? 2018年8月1日 The rare earth elements (REEs) have very similar chemical properties They have generally categorized into two groups based on their doublesalt solubility: light rare earth elements (LREEs) are called the cerium subgroup elements (lanthanum to europium) and heavy rare earth elements (HREEs) are known as yttrium subgroup elements (gadolinium to lutetium Recovery of light and heavy rare earth elements from apatite ore 2016年6月17日 Then the team pumped solutions of various pH balances through the filter With each successive pH wash, different rare earths detached The researchers found that lighter lanthanides, such as Europium and Praseodymium, desorbed with higherpH washes while heavier lanthanides, such as Thulium, Lutetium, and Ytterbium, desorbed with lower pHA clean way to extract rare earth metals Harvard John A2024年1月26日 Rare earth elements (REEs) are a group of 17 chemically similar elements that are essential for a wide range of modern technologies One of the main sources of REEs is monazite, which contains (PDF) EXPLORING THE POTENTIAL OF RARE EARTH ELEMENT

.jpg)

A novel process for the separation and recovery of phosphorus and rare

2024年7月15日 Rare earth elements (REEs) exhibit exceptional physical and chemical properties, earning the moniker of “industrial vitamins”, and have become strategic mineral resources essential for the development of high precision industries in various countries [17], [5], [45]REEs are fairly abundant on Earth, albeit not in concentrated forms, making their efficient 2016年2月11日 Each rare earth deposit is unique and is always composed of a variety of minerals For example, the Baiyun Obo deposit, the largest rare earth mine in production in China, contains bastnaesite, monazite, fluorite, magnetite, barite, calcite, quartz, feldspar, etc (Cheng et al 2007a, b)In order to make a rare earth project economically feasible, a series of ore Rare Earth Beneficiation and Hydrometallurgical Processing11 Rare earths ores The term rare earths was originally used to designate the lanthanoids in row 3 of the periodic table which includes oxides of scandium (Sc, 21), yttrium (Y, 39), lanthanum (La, 57) and the 14 elements following lanthanum in the periodic table of elements, ie from cerium (Ce, 58) to lutetium (Lu, 71) inclusiveA critical review on solvent extraction of rare earths from 2018年10月31日 The rareearth elements (REEs) remain very important due to the growing increase in their demand and for their critical and indispensable use in many hightech industries today(PDF) Rare earth elements removal techniques from water

Wet gravity separation and froth floatation techniques for rare earth

2023年9月1日 Jiao et al [30] utilized the Froth Floatation technique to beneficiate the Dalucao rare earth ore located in Dechang, Sichuan Province, China Kim et al [33] also used a Wilfley shaking table to remove the light gangue minerals, which mainly consisted of SiO 2 and Al 2 O 3 from the sample2021年8月1日 Rubidium is a rare alkali metal with high economic value and application potential It is mainly recovered from the intermediate products of lithium/cesium extraction from lepidolite/pollucite The application potential and extraction difficulties of rubidium have necessitated the development of new methods for the extraction of rubidium from resourcesRubidium extraction from mineral and brine resources: A reviewIonadsorbed rare earth ores (iREEs) are an important source of HREEs globally [7]Currently, China’s proven reserves of medium and heavy REEs account for more than 90 % of the world’s total reserves; the vast majority of these deposits are located in the southern provinces [8], [9]In iREEs, REEs are adsorbed on clay minerals in the form of hydrated or hydroxyl hydrated ions, Untargeted metabolomics reveals the mechanism for leaching rare earth How is Mica Formed? Micas do originate as a result of diverse processes and several conditions There are various processes of formation that includes deposition by fluids derived from magmatic activities, consolidating magmas, What is Mica? How is Mica Formed? What is it is Used

.jpg)

Kinetics of Rare Earth and Aluminum Leaching from Kaolin

2017年8月24日 In the process of the in situ leaching of weathered crust elutiondeposited rare earth ores (WCEDREOs), there are many problems in the conventional leaching agent, such as a slow leaching rate The distribution of rare earth elements varies significantly between rare earth ores and ionic clay deposits This distinction is evident in Table 1 (Packey and Kingsnorth, 2016) Table 1 highlights that ionic clays have a higher presence of heavier rare earth elements, ranging from gadolinium oxide (Gd 2 O 3) to lutetium oxide (Lu 2 O 3), including yttrium oxide (Y 2 O 3)Technological advancements in rare earth elements recovery from 2022年10月31日 Heavy rare earth elements (HREEs) such as Gd–Lu, Sc and Y are irreplaceable metals for a number of critical (including clean) technologies, but they are scarce Ionadsorption deposits, which A green and efficient technology to recover rare earth Nature2018年11月5日 Rare earth elements are widely found in many minerals, some of which, such as bastnaesite, monazite, and xenotime, are of great commercial value Cerium (Ce) is the rare earth element with the highest content in light rare earth ore Solvent extraction is the most effective and efficient method to recover and separate Ce from other light rare earth elements After acid Extraction and Recovery of Cerium from Rare Earth Ore by

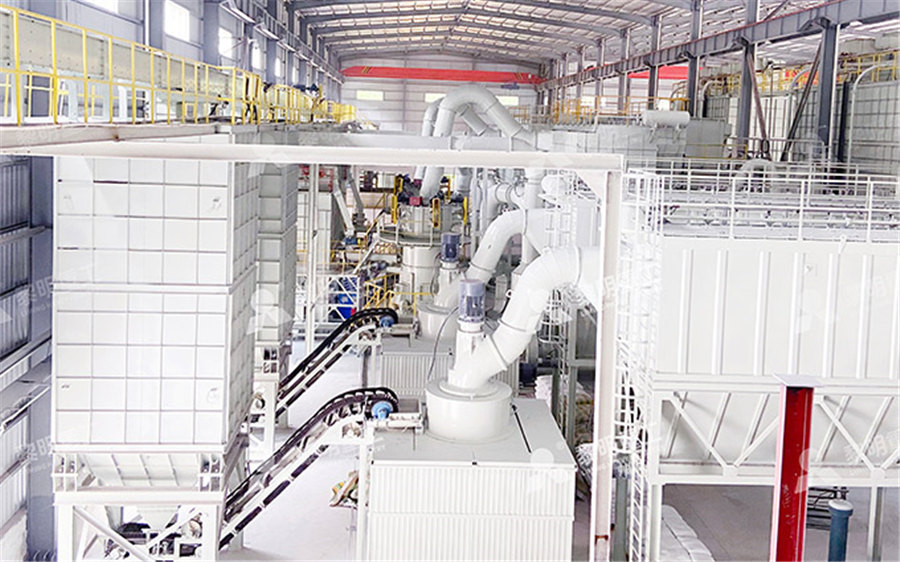

Complete Mica Production Process: From Ore to Finished Product

2024年7月29日 Mica is an essential nonmetallic mineral widely used in various fields such as electrical, electronics, and construction This article will provide a detailed overview of the production process of mica, from the extraction of ore to the preparation of the finished product, helping you gain a comprehensive understanding of how mica is produced2017年8月10日 Rare earth elements (REE) are widely used in high technologies, medical devices, and military defense systems, and are especially indispensable in emerging clean energy Along with the growing market of green energy in the next decades, global demand for REE will increase continuously, which will put great pressure on the current REE supply chain Global Potential of Rare Earth Resources and Rare Earth Demand 2023年7月28日 Mining rare earth elements is a complex and environmentally sensitive process Different methods are employed, including: OpenPit Mining When the ore is close to the surface, this method removes large overburden to access the oreRare Earth Ore: From Mining to Application JXSC Mineral