Preshift education for calcium carbonate processing plant

ReviewProgress in reducing calcination reaction temperature of

2022年12月15日 Reducing CaCO 3 calcination temperature is effective in preventing sintering of CaO sorbents A systematic understanding of fundamental aspects of the CaCO 3 calcination is reviewed The CO 2 capture performance under mild and severe calcination conditions was The calcium looping (CaL) process is a promising CO 2 capture technology based on a reveA Critical Review2013年2月19日 This paper evaluates various calciumbased chemical looping concepts to be applied in Integrated Gasification Combined Cycle (IGCC) plants for decarbonised energy Assessment of calciumbased chemical looping options for 2023年6月4日 Unlike the traditional precombustion carbon capture based on Selexol physical absorption, this method avoids the adoption of complex twostage water gas shift (WGS) Energy and exergy analyses of biomass IGCC power plant using

CaCO3 decomposition for calciumlooping applications: Kinetic

2020年11月1日 Calcium looping (CaL) has attracted interest as a process with various potential environmental applications (Anthony, 2011, Hanak et al, 2018) The abundance of nontoxic In the production of ultrafine calcium carbonate additives, various aspects must be considered when selecting and deciding among available types of processing systems: Fineness range, Calcium Carbonate (GCC) Hosokawa Alpine2020年4月30日 The calcium looping (CaL) process is a promising CO 2 capture technology, which uses CaObased sorbents by employing a reversible reaction between CaO and CO 2, Review on the Development of Sorbents for Calcium LoopingCOMPLETE SOLUTIONS FROM ONE SINGLE SOURCE – FOR EVERY REQUIREMENT CONSISTENTLY HIGH QUALITY THANKS TO THE LATEST AUTOMATION AND PROCESS CALCIUM CARBONATE (GCC) Hosokawa Alpine

.jpg)

How Calcium Carbonate is Produced?|Manufacturing|CORE

Calcium carbonate is divided into two industrial categories: Ground Calcium Carbonate (GCC) and precipitated calcium carbonate (PCC) The two categories use different manufacturing 2023年3月28日 Several methods for reducing specific CO 2 emissions have been reported in the cement industry, including calcium looping, which uses the reversible reaction between Experimental analysis on calcination and carbonation process in 2010年7月24日 Calcium (Ca) is an essential macronutrient for plants and animals where it plays indispensable structural and signalling roles Soluble calcium ions (Ca 2+) are extracted from the soil solution by plants to form the primary source of Ca in the food chainIn recent years, our understanding of the signalling role of Ca 2+ in organisms has developed significantly (eg Calcium storage in plants and the implications for calcium 2022年9月28日 In this work, hydration acceleration efficiency of calcium carbonate (CaCO3, CC) was tuned via surface deposition with calcium silicate hydrate (C–S–H) nanogel through seeding Multiple calcium Tuning the Hydration Acceleration Efficiency of

.jpg)

Calcium Carbonate Ball Mill Plant DASWELL

The calcium carbonate ball mill plant has the lowest energy consumption and the best particle size distribution, which is most suitable for market demand A closedloop processing system can be formed The coarse powder under PLANT CAPACITY AND PRODUCTION PROGRAM 1 Plant Capacity In determining the plant capacity of the calcium carbonate The lease period ranges from 99 years for education 1,500 18,000 9 Purchaser 2 6,000 72,000 10 Store Keeper 2 2,400 28,800 11 Chemist 3 9,000 108,000 12 Shift Leader 3 9,000 108,000 13 Operator 12 PROFILE ON THE PRODUCTION OF CALCIUM CARBONATE AND KEY WORDS : calcium carbonate, calcium hydroxide, calcium oxide, lime, unslaked, slaked, limestone, acid mine drainage, AMD, acid mine water, neutralisation, coal processing plant, model, iron oxidation, sulphate, treatment BACKGROUND Mining has been the single most important sector of the South African economy for many yearsNeutralisation of acid leachate in a coal processing plant with calcium 2012年2月1日 Hybrid calcium carbonate (HCC) is prepared by preflocculating calcium oxide and ground calcium carbonate (GCC) with ionic polymers, and by injecting carbon dioxide to the preflocculated flocs (PDF) Preflocculation of precipitated calcium carbonate filler

.jpg)

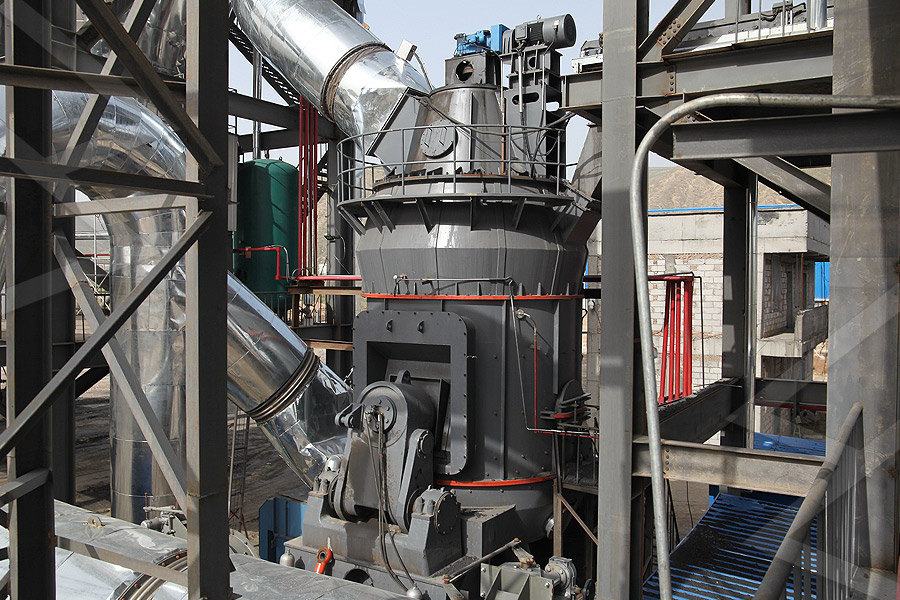

Exploring Different Grinding Mills for Calcium Carbonate Processing

2023年9月28日 A calcium carbonate processing plant is a facility where calcium carbonate is processed and produced for various industrial applications The specific processes and equipment used in a calcium carbonate processing plant may vary depending on the source of calcium carbonate (such as limestone or marble) and the desired end product specificationsAbout Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright Processing Plant for Calcium Carbonate YouTube2022年4月26日 Effect of processing temperatures on decarbonisation of calcium carbonate in sodium hydroxide solutions at ambient conditions April 2022 DOI: 1021203/rs3rs/v1Effect of processing temperatures on decarbonisation of calcium 2022年9月29日 In calcium carbonate processing plant, grinding mill is the core equipment to process raw calcium carbonate into powder The commonly used calcium carbonate fineness is 03mm, 80425mesh and 253000mesh 80425mesh heavy calcium powder grinding mill4 Steps To Build A Calcium Carbonate Processing Plant Zenith

Calcium Carbonate Grinding Production Line TAYMACHINERY

The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERY2021年11月18日 Eight atmospheric carbon dioxide samples (as calcium carbonate—CaCO 3 —precipitates) from Lindesnes site (58ºN, 7ºE), belonging to 1963 and 1980 (four samples from each year) and stored at Decarbonisation of calcium carbonate at atmospheric temperatures 2021年5月6日 Every year a million tonnes of calcium rich agro and industrial waste are generated around the whole globe These calcium rich waste like finger citron, shells of cockle, mussel, oysters etc, and egg shell are biological sources which have various organic compounds The inorganic calcium rich waste includes gypsum, dolomite, sludge etc, which are produced The Processing of Calcium Rich Agricultural and Industrial Waste

Production of precipitated calcium carbonate from calcium

2005年11月1日 Calcium carbonate (CaCO 3) is used in large amounts in the pulp and paper industry as a paper filler and in coatings to provide opacity, high brightness and improved printability due to its good ink receptivityIn Finland, 700 kt/a 1 of calcium carbonate is used for coating and 300 kt/a as a filler The calcium carbonate is mined and extracted simultaneously 2016年12月31日 PDF Calcium carbonate is a chemical compound with the formula CaCO3 formed by three main elements: carbon, It has been found that supersaturation is critical in determining the pre(PDF) Calcium Carbonate ResearchGate2015年8月5日 CaCO3 Calcium Carbonate Processing Plant Posted: CaCO3 (Calcium Carbonate) and its usage: Calcium carbonate is a chemical compound with the formula CaCO3 It is a common substance found in rocks in all parts of the world, and is the main component of shells of marine organisms, snails, coal balls, pearls, and eggshellsCaCO3 Calcium Carbonate Processing Plant2021年3月19日 Three series of soft polyvinyl chloride (soft PVC) compounds were prepared at different processing conditions during PVC powder mixing The processing conditions varied in two different adding procedures of calcium carbonate (CaCO3) powder, two discharge temperatures and two mixing frequencies The influences of the processing conditions on the Influences of processing conditions on the glass transition of soft

.jpg)

Calcium Carbonate Plant Manufacturers Suppliers in India

Find here Calcium Carbonate Plant manufacturers OEM manufacturers in India CALCIUM CARBONATE PROCESSING PLANT ₹9,00,00,000/ Piece Size/Dimension Customized Capacity 200 TPD to 500 TPD Automation Grade Fully Automatic Weight 2500 Ton to 5000 Ton Power Consumption 3 MW to 7 MW2020年11月26日 Utilization of Gaseous Carbon Dioxide and Industrial CaRich Waste for Calcium Carbonate Precipitation: A Review(PDF) Utilization of Gaseous Carbon Dioxide and Industrial CaRich 2016年2月22日 As calcium carbonate is precipitated in a solution containing ammonium chloride, calcium chloride, and ammonia, the product needs to be washed and hence filteredPerformance of Separation Processes for 2017年7月20日 Recent experimental evidence and computer modeling have shown that the crystallization of a range of minerals does not necessarily follow classical models and theories In several systems, liquid precursors, stable Hydration Effects on the Stability of Calcium

.jpg)

Polypropylene/calcium carbonate

2010年9月4日 The evaluation of filler dispersion in compounding machines is an important part of their design Calcium carbonate–filled polypropylene (PP) was used as a model compound to study filler dispersion2024年9月18日 Calcium carbonate, renowned for its affordability and potent dephosphorization capabilities, finds widespread use as a dephosphorization agent in the direct reduction roasting of highphosphorus oolitic hematite (HPOIO) However, its precise impact on iron recovery and the dephosphorization of iron minerals with phosphorus within HPOIO, particularly the mineral Calcium Carbonate as Dephosphorization Agent in Direct 2019年5月9日 Carbonation is one of the methods for the production of precipitated calcium carbonate (PCC) on the industrial scale A gaseous CO2 is used as a reagent in this processThe overview of reactors used for the production of precipitated The report examines onetime costs associated with the construction of a plant and the continuing costs associated with the daily operation of such a plant The analysis assumes a United Statesbased plant capable of producing 50 kt of Calcium Carbonate per year and includes: * Capital Investment, broken down by:Calcium Carbonate Production from Lime and Carbon Dioxide

(PDF) InSitu Precipitated Calcium Carbonate Paper

2021年12月28日 In the 1970s a shift from acid to neutral papermaking started which made it possible to use precipitated calcium carbonate in the paper manufacturing process New printing technologies required Calcium is an immobile nutrient, meaning that the plant cannot transport calcium from one area to another inside the plant What this means for you, the grower, is that you need to provide a constant supply of Calcium to prevent deficiency in your plant So, let's talk about some of the best sources of calcium for plantsCalcium For Plants: Deficiency, Toxicity, Sources, Moreto an existing cement plant in New South Wales for deeply reducing CO 2 emissions The reference cement plant is based on a dry process with 4 stages of preheaters, a precalciner and a rotary kiln with a clinker production of 184 t/h Specific objectives of this project are: • Technology survey of CO 2Retrofitting calcium carbonate looping to an existing cement plant 2013年1月1日 In the FTIR spectrum of Anadara granosa seashell powder as shown in the figure 1, a peak observed at 1080cm 1 was due to symmetric stretching CO (ν1) of calcium carbonate which correlated with Processing and Characterization of Cockle Shell Calcium Carbonate

.jpg)

Calcium storage in plants and the implications for calcium

2010年7月24日 Calcium (Ca) is an essential macronutrient for plants and animals where it plays indispensable structural and signalling roles Soluble calcium ions (Ca 2+) are extracted from the soil solution by plants to form the primary source of Ca in the food chainIn recent years, our understanding of the signalling role of Ca 2+ in organisms has developed significantly (eg 2022年9月28日 In this work, hydration acceleration efficiency of calcium carbonate (CaCO3, CC) was tuned via surface deposition with calcium silicate hydrate (C–S–H) nanogel through seeding Multiple calcium Tuning the Hydration Acceleration Efficiency of The calcium carbonate ball mill plant has the lowest energy consumption and the best particle size distribution, which is most suitable for market demand A closedloop processing system can be formed The coarse powder under Calcium Carbonate Ball Mill Plant DASWELLPLANT CAPACITY AND PRODUCTION PROGRAM 1 Plant Capacity In determining the plant capacity of the calcium carbonate The lease period ranges from 99 years for education 1,500 18,000 9 Purchaser 2 6,000 72,000 10 Store Keeper 2 2,400 28,800 11 Chemist 3 9,000 108,000 12 Shift Leader 3 9,000 108,000 13 Operator 12 PROFILE ON THE PRODUCTION OF CALCIUM CARBONATE AND

.jpg)

Neutralisation of acid leachate in a coal processing plant with calcium

KEY WORDS : calcium carbonate, calcium hydroxide, calcium oxide, lime, unslaked, slaked, limestone, acid mine drainage, AMD, acid mine water, neutralisation, coal processing plant, model, iron oxidation, sulphate, treatment BACKGROUND Mining has been the single most important sector of the South African economy for many years2012年2月1日 Hybrid calcium carbonate (HCC) is prepared by preflocculating calcium oxide and ground calcium carbonate (GCC) with ionic polymers, and by injecting carbon dioxide to the preflocculated flocs (PDF) Preflocculation of precipitated calcium carbonate filler 2023年9月28日 A calcium carbonate processing plant is a facility where calcium carbonate is processed and produced for various industrial applications The specific processes and equipment used in a calcium carbonate processing plant may vary depending on the source of calcium carbonate (such as limestone or marble) and the desired end product specificationsExploring Different Grinding Mills for Calcium Carbonate ProcessingAbout Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright Processing Plant for Calcium Carbonate YouTube

.jpg)

Effect of processing temperatures on decarbonisation of calcium

2022年4月26日 Effect of processing temperatures on decarbonisation of calcium carbonate in sodium hydroxide solutions at ambient conditions April 2022 DOI: 1021203/rs3rs/v12022年9月29日 In calcium carbonate processing plant, grinding mill is the core equipment to process raw calcium carbonate into powder The commonly used calcium carbonate fineness is 03mm, 80425mesh and 253000mesh 80425mesh heavy calcium powder grinding mill4 Steps To Build A Calcium Carbonate Processing Plant Zenith