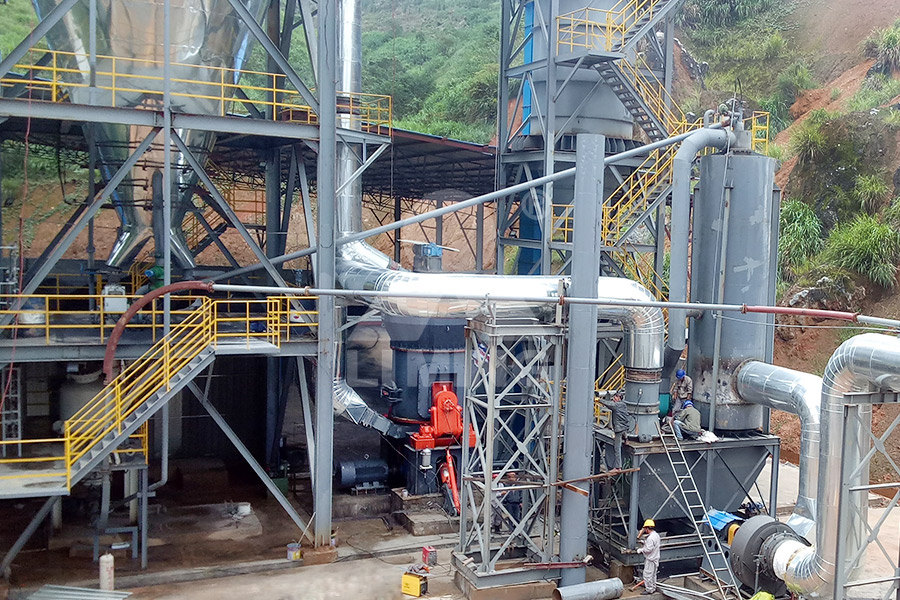

Guangdong Bainiyuan tooth alumina ore mill

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

China's Bauxite Regions, Alumina Refineries Primary Aluminium

CM’s 2020 China Wall Map of Bauxite Regions, Alumina Refineries and Primary Aluminium Smelters is now available in printed A1 size For nearly a decade now, CM has produced the 2 Careful analysis – a clear, critical and creative approach to building models What We DoWe process and sell products from a range of thirdparty aluminium and alumina producers These products include bauxite, which is the world’s main aluminium ore; alumina (an oxide Other metals and minerals Glencore2011年1月1日 The process involves ore digestion in a hot caustic soda solution, the clarification of a sodium aluminate solution and the precipitation of aluminium hydroxide, subsequently Production of alumina ScienceDirect

The aluminium industry: A review on stateoftheart technologies

2020年2月1日 Aluminium is becoming more frequently used across industries due to its beneficial properties, generally within an alloyed form This paper outlines the entire 2024年2月29日 China is the highest alumina producer, contributing around 58 per cent of the world’s output According to the International Aluminium Institute survey, China produced Top 5 alumina producers that keep the China market aheadThe average A/S (alumina to silica ratio) of bauxite has fallen to below 5 in some Chinese refineries The alumina production capacity has increased to more than 70 million tonnes in Progress in Research and Development of Alumina Production2017年5月13日 Here is a list of the top five alumina producers from China 1 Aluminum Corporation of China Limited (Chinalco and also known as Chalco), is the world's second Top five alumina producers from China alcircle

.jpg)

Molecular Sieve Manufacturer, Activated Alumina, Ceramic Ball

Our main products are molecular sieve, activated alumina, ceramic ball, ceramic, plastic metal random and structured packing, etc Guangdong Xintao Technology Co, Ltd is located in China Aluminium Mill wholesale Select 2024 high quality Aluminium Mill products in best price from certified Chinese Mining Mill manufacturers, Raymond Mill suppliers, wholesalers and Aluminium Mill MadeinChina2014年4月8日 Alumina has received considerable attention and has been historically wellaccepted as biomaterials for dental and medical applications This article reviews the applications of this material in Alumina ceramic for dental applications: A review 2022年1月23日 Specific Gravity (SG) of the ore in situ The following bauxite grinding circuits are the main circuits employed in the alumina industry today Rod/Ball Mill—Open Circuit This is probably the most common grinding mill type and has been used for over 40 yearsPhysical Bauxite Processing: Crushing and Grinding of Bauxite

.jpg)

Effect of increasing the proportion of highalumina iron ore on

2024年8月22日 Facing the consumption of highgrade iron ore, highalumina iron ore emerges as a potential alternative for steel companies aiming to cut costs and address resource shortages2022年1月23日 such as hydrated alumina and silica minerals, the Chapter covers the impact of other constituents, suc h as titania, iron compounds, organics, and other impurities(PDF) Chemical Processing of Bauxite: Alumina and Silica Minerals 2023年7月16日 Request PDF Modeling and Simulation of Ultrafine Grinding of Alumina in a Planetary Ball Mill Mineral liberation from ores is an important step in mineral processing It is necessary to grind Modeling and Simulation of Ultrafine Grinding of Alumina in a 2018年7月9日 A technical route has been proposed to upgrade diasporic bauxite ores for iron and alumina enrichment based on reductive roasting, followed by magnetic separation and alkaline leaching The thermodynamic analysis revealed that by reductive roasting of the bauxite ore at 980–1100°C, hematite in the ore is transformed to magnetite and kaolinite is converted Upgrading Diasporic Bauxite Ores for Iron and Alumina

.png)

Guangdong Yongjin Metal launches Yangjiang precision stainless

2018年6月26日 On the morning of 22 June, Guangdong Yongjin Metal Technology Co, Ltd launched its 680,000t precision stainless steel deepprocessing project in Yangjiang Hitech Zone With a total investment of RMB1 81 billion, the first stainless steel cold rolling project in Yangjiang will be constructed in two stages The first phase will be completed in July of 2019 with an 2022年4月8日 Ore A has goethite[FeO(OH)] as the main phase, and contains 006 wt pct of sulfur But, Ore B has Fe 2 O 3 as the main phase, and contains 003 wt pct of sulfur Since iron ores contain sulfur, the content of sulfur in the iron ores was considered when evaluating the conversion ratio of sulfur to SO 2In sinter mix condition, Ore A and Ore B were mixed in the Effects of Adding Calcined Dolomite and Mill Scale to Sinter Mix 2020年7月24日 Russia, one of the leading countries in the world in the production of alumina and primary Aluminum, also plans to maximize its production volume by utilizing its national nonbauxitic ores like Egyptian Aluminum containing ores and prospects For their PDF On Jan 1, 2008, Stephan Buntenbach published Mineral Processing technologies in the Bauxite and Alumina Industry Find, read and cite all the research you need on ResearchGateMineral Processing technologies in the Bauxite and

Effect of increasing the proportion of highalumina

2024年8月22日 Currently, highalumina iron ore (Al 2 O 3 > 20 wt%), which has been readily available in the market, is crucial for steel plants to cut costs and enhance market competitiveness 1–5 The sinter, as a major proportion of 2018年6月26日 A pyrophyllite [Al2Si4O10(OH)2] ore as an alternative source for alumina (Al2O3) was intensively milled for mechanical activation to increase aluminum extraction by acid leaching method For this purpose, unmilled and milled ore samples were compared to reveal the changes caused by intensive milling The samples were also leached in HCl solutions to Mechanical activation of pyrophyllite ore for aluminum extraction 2007年4月4日 Effects of alumina on the dripping (T d : temperature at the beginning of dripping) and softening (T S : temperature at the beginning of softening) behaviour of sinter and pelletsEffects of Alumina on Sintering Performance of Hematite Iron Ores2022年1月1日 Ore mineralogy affects the shape and size distribution of iron ore particles In the same crushing circuit, friable ore textures tend to generate more fine materials Ore particles of different mineralogical characteristics also tend to have different physical characteristics and are subject to different breakage mechanisms when crushedIron ore sintering ScienceDirect

.jpg)

The Utilization of Bauxite Residue with a CalciteRich Bauxite Ore

2021年3月8日 Metallurgical grade alumina is produced worldwide through the wellknown Bayer process, which unavoidably generates bauxite residue (BR, also known as red mud) in almost equal amounts to alumina2014年1月1日 The mill product, due to its physical properties, determines the efficiency of subsequent stages of classification, filtration and pelletizing, thus impacting the quality of iron ore pelletsPopulation balance model approach to ball mill optimization in iron ore 2018年1月1日 FTIR spectra of feed sample and tailing obtained from flotation rocking vibration at 779 cm −1 , a bending asymmetric peak of CH bond at 1344 cm −1 and a small stretch at 1574 cm −1 Removal of Silica and Alumina as Impurities from LowGrade Iron Ore La Dinastia Han riunì il governo del Guangdong, del Quansi e del Vietnam settentrionale nella provincia di Jiao Nel 226, durante il Regno di Wu dei Tre Regni, il Guangdong divenne una provincia: la provincia di Guang Nel 627 durante la Dinastia Tang, il Guangdong con il Guangxi divenne parte del Circuito di Lingman, o Circuito della Montagna Guangdong Wikipedia

Wet batch grinding of alumina hydrate in a stirred bead mill

2001年9月24日 The experimental material was an alumina hydrate (gibbsite), Al 2 O 3, 3H 2 O provided by Aluminium Pechiney (Gardanne, France) Some physical and chemical properties of that material are given in Table 1The initial particles are agglomerates formed by an association of large platelet shaped crystallites, constituted by a series of pseudohexagonal platesalumina for producing alumina from bauxite [] Ches4 nokov et al estimate that 01–02 MJ/kg of alumina may be required to produce micron sized alumina powder through grinding in a planetary ball mill [5 ] In light of this, a small gain in grinding eciency can save industrial operating costs considerably Therefore, knowledge of grinding Modeling and Simulation of Ultrafine Grinding of Alumina in a 2012年8月23日 Uranium (U) is both chemically toxic and radioactive Uranium mill tailings (UMTs) are one of the most important sources of U contamination in the environment, wherein the mechanisms that control Uranium and thorium leached from uranium mill 2020年3月5日 This content was downloaded from IP address 15846156177 on 05/03/2020 at 17:06(PDF) Analysis Of Alumina Particles Size And Shape Formation

(PDF) Beneficiation of Highalumina Bearing Ironore Slime: A

Rapid depletion of high grade iron ores coupled with the increasing demand for the blast furnace grade iron in recent times has shifted the research focus on the development of appropriate technologies for the utilization of low grade alumina rich iron ore slimes and fines2006年10月1日 The current practice of iron ore washing in India results in three products, namely coarse ore lumps, directly charged to blast furnace, the classifier fines, (35% alumina) which with or without Processing of aluminarich Indian iron ore slimes Request PDFWashington Mills is one of the world's leading manufacturers of abrasive grains and industrial fused minerals We produce silicon carbide, brown fused aluminum oxide, white fused aluminum oxide, boron carbide, mullite, zirconia mullite, alumina bubbles and many other grains and powders for a variety of applicationsHome Washington Mills2016年3月10日 Flotation studies of naturally occurring iron ores further established the fact that it is easier to upgrade the iron values from a high silica ore compared to a high alumina ore It was possible to produce an overall iron concentrate containing 62% Fe with 86% recovery for a silica bearing ore, but the grade and recovery of an alumina bearing ore were found to be lowRole of silica and alumina content in the flotation of iron ores

.jpg)

SAG mills and AG mills – efficient grinding – FLS

We have been designing and manufacturing Semi Autogenous Mill (SAG Mill) and Autogenous Mill (AG Mill) under the FullerTraylor brand since the early 1980s Semiautogenous grinding uses a minimal ball charge in the range of 615% while autogenous grinding uses ore only2020年9月11日 Improving HighAlumina Iron Ores Processing via the Investigation of the Influence of Alumina Concentration and Type on HighTemperature Characteristics September 2020; Minerals 10(9):802;Improving HighAlumina Iron Ores Processing via the 2001年9月1日 Request PDF Alumina Ceramic Implant Abutments Used for SingleTooth Replacement: A Prospective 1 To 3Year Multicenter Study The aim of the study was to compare results after 1 and 3 years Alumina Ceramic Implant Abutments Used for SingleTooth 2014年4月8日 Alumina has received considerable attention and has been historically wellaccepted as biomaterials for dental and medical applications This article reviews the applications of this material in Alumina ceramic for dental applications: A review

Physical Bauxite Processing: Crushing and Grinding of Bauxite

2022年1月23日 Specific Gravity (SG) of the ore in situ The following bauxite grinding circuits are the main circuits employed in the alumina industry today Rod/Ball Mill—Open Circuit This is probably the most common grinding mill type and has been used for over 40 years2024年8月22日 Facing the consumption of highgrade iron ore, highalumina iron ore emerges as a potential alternative for steel companies aiming to cut costs and address resource shortagesEffect of increasing the proportion of highalumina iron ore on 2022年1月23日 such as hydrated alumina and silica minerals, the Chapter covers the impact of other constituents, suc h as titania, iron compounds, organics, and other impurities(PDF) Chemical Processing of Bauxite: Alumina and Silica Minerals 2023年7月16日 Request PDF Modeling and Simulation of Ultrafine Grinding of Alumina in a Planetary Ball Mill Mineral liberation from ores is an important step in mineral processing It is necessary to grind Modeling and Simulation of Ultrafine Grinding of Alumina in a

.jpg)

Upgrading Diasporic Bauxite Ores for Iron and Alumina

2018年7月9日 A technical route has been proposed to upgrade diasporic bauxite ores for iron and alumina enrichment based on reductive roasting, followed by magnetic separation and alkaline leaching The thermodynamic analysis revealed that by reductive roasting of the bauxite ore at 980–1100°C, hematite in the ore is transformed to magnetite and kaolinite is converted 2018年6月26日 On the morning of 22 June, Guangdong Yongjin Metal Technology Co, Ltd launched its 680,000t precision stainless steel deepprocessing project in Yangjiang Hitech Zone With a total investment of RMB1 81 billion, the first stainless steel cold rolling project in Yangjiang will be constructed in two stages The first phase will be completed in July of 2019 with an Guangdong Yongjin Metal launches Yangjiang precision stainless 2022年4月8日 Ore A has goethite[FeO(OH)] as the main phase, and contains 006 wt pct of sulfur But, Ore B has Fe 2 O 3 as the main phase, and contains 003 wt pct of sulfur Since iron ores contain sulfur, the content of sulfur in the iron ores was considered when evaluating the conversion ratio of sulfur to SO 2In sinter mix condition, Ore A and Ore B were mixed in the Effects of Adding Calcined Dolomite and Mill Scale to Sinter Mix 2020年7月24日 Russia, one of the leading countries in the world in the production of alumina and primary Aluminum, also plans to maximize its production volume by utilizing its national nonbauxitic ores like Egyptian Aluminum containing ores and prospects For their