Selection of coal crusher for power plant

Spring Support of Coal Crusher Foundations in Power Plants

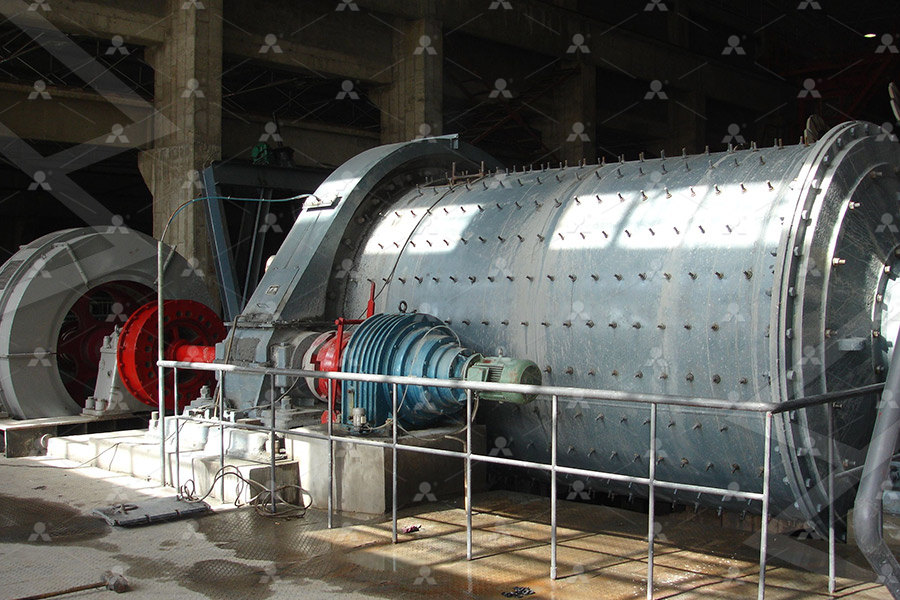

Coal crushers in power plants are normally elevated in the structure A proper conventional foundation design demands a thorough dynamic analysis of the foundation, including the When selecting a crusher for coal handling, several factors must be considered, including the type of coal, desired particle size, capacity requirements, and energy efficiency Each type of The Ultimate Guide to Coal Crushing: Understanding the Different The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator Secondary coal crusher: Used when the coal coming from the supplier is Primary Crusher an overview ScienceDirect TopicsCoal characteristics are integral to pulverizer system selection, sizing and performance The production capaci ty for each mill depends upon the following feed properties: In general,the A Comparison of Three Types of Coal Pulverizers Babcock Power

.jpg)

Coal Crushers Coal Pulverizers Mills Williams Crusher

Pulverized coal is typically used in power plants heated in fired furnaces Williams’ Vertical Roller Mill Pulverizers are perfect for coal and pet coke applications These normally require fine to ultrafine particle sizes for direct 2020年3月19日 Tracked mobile crushers are ideally suited for applications that require movement within a job site, as they can move under their own power They are also easily transported from one site to another by loading them on a Selecting the right crusher for your operations Quarrymal power plant as the starting point, firstly, this paper analyzes the process layout and structure selection, and then the structural design and vibration design requirements of coalResearch on Structural Design of Coal Crusher House in Thermal 2020年7月24日 This paper takes the specific characteristics of pulverized coal room in thermal power plant as the starting point,firstly, this paper analyzes the process layout and structure selection,Research on Structural Design of Coal Crusher House

OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL

Coal crushing equipment of coal handling plant system in the thermal power plant is very important for Plant efficiency improvement Keywords: India coal grades, Crusher, Construction, Crushing stages, Defect identification INTRODUCTION The coal handling plant (CHP) in a thermal power station covers unloading of coal, its2036 Lihua ZHAO and YLihua ZHAO / Procedia Engineering 00 (in LIN / Procedia Engineering 26 (2011) 2032 – ) 000–000 5 222 b Application and maintenance of Ring hammer coal crusher hammerOperation and Maintenance of Coal Handling System in Thermal Power Plant2011年12月31日 In order to ensure the safety of power generation in Poland and to maintain energy production from coalfired units with the long inservice time, it is required to develop a strategy for the Operation and Maintenance of Coal Handling 2020年7月24日 Article history Received: 3 July 2020 Accepted: 3 July 2020 Published Online: 30 July 2020 This paper takes the specific characteristics of pulverized coal room in thermal power plant as the starting point, firstly, this paper analyzes the process layout and structure selection, and then the structural design and vibration design requirements of coal crusher Research on Structural Design of Coal Crusher House in Thermal Power Plant

Crusher; Crushing; and Classification Equipment PPT SlideShare

2020年11月8日 VPEmobilejawcrusherplant700x394 Jaw Mobile Crushing Station • Application: Sand quarry, mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc 64This paper takes the specific characteristics of pulverized coal room in thermal power plant as the starting point,firstly, this paper analyzes the process layout and structure selection, and then the structural design and vibration design requirements of coal crusher house are introduced in this paper Finally, based on the engineering example, a new structure form of vibration isolation Research on Structural Design of Coal Crusher House in Thermal Power Plant2014年6月16日 14 • Once the coal is in plant it has to undergo some preparatory processes before being fed into the boiler • First the coal goes to the crusher house where the coal is crushed manually into a size of about 20mm This coal is then passed further some part of it is fed into the plant while the other is stored • Generally most of the power plants store a coal for the Coal based power plant PPT Free Download SlideShare2013年7月17日 In a coal based thermal power plant, the initial process in the power generation is "Coal Handling' Boiler used in the power plant is suspended type for: Home; Membership; Coal rises from crusher house and reaches the dead storage by passing through transfer point 8Coal handling plant in a thermal power generating station EEP

.jpg)

Thermal Power Plant Coal Fuel Conveyor System SKE SKE

Coal feeding system of power plant: Coal feeding equipment is installed in the middle link, which is mainly used to complete the transportation, crushing, iron removal, screening, pulverization and loadbearing measurement of coal fuel Power plant coal storage system: It is the buffer link of2023年8月2日 The site selection of a thermal power plant is a complex task that requires careful planning and consideration of various factors A thermal power plant is an industrial facility used to generate electricity from thermal energy, which is obtained by converting the heat released by the combustion of fossil fuels, such as coal, oil, or natural gasSite Selection for Thermal Power Plant – Explained in Detail2020年10月13日 Abstract Due to the increased penetration of renewable power sources into the electric grid, the current number of existing coalfired power plants shifting from baseload to loadfollowing operations has also increased This shift creates challenges especially for the power industry as coalfired power plants were not designed for ramping situations, leading to Modeling and Control of Subcritical CoalFired Power Plant 2020年3月19日 Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but there are application drawbacks that may make another crushing solution more appealing First, cone crushers cannot accept Selecting the right crusher for your operations

CONTROL AND INSTRUMENTATION OF POWER PLANT

2016年8月14日 4 4 P a g e ABSTRACT My project includes the study of basic layout of power plant various cycles and instruments used in power plant (National Thermal Power Cooperation, Dadri) for producing electricity and sea or river The transportation of coal by trucks is used if the railway facilities are not available UNLOADING The type of equipment to be used for unloading the coal received at the power station depends on how coal is received atthe power station If coal is delivered by trucks, there is no need of unloadingUNIT – I – STEAM POWER PLANT – SMEA1403Inorder to calculate the coal handling and coal storage bunkercapacity, first we need to know the coal requireent per day for a plant, coal handling maintenance stratergy We shall calculate the coal handling bunker capacity by taking an example of 25 MW thermal power plant consuming coal of GCV 4900 kcal/kg having heat rate 3200 kcal/kwh running at 100% PLFCalculation of coal handling plant and bunker capacitydesign, so that they can identify ways of reducing overall electrical power consumption • Electronic control of crusher discharge opening and feed rate With adjustment of a crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001)Crushing Plant Design and Layout Considerations 911 Metallurgist

A Comparison of Three Types of Coal Pulverizers Babcock Power

As shown in Figure 2, coal and preheated primary air first enter the crusher section Here the coal is im pacted on a grid section by swing hammers, reducing the coal to a nominal 1/4" size Drying of the coal also occurs in this section After the coal passes through the grid section, it enters the twostage pulverizing sec tionH Power consumed by the crushers will directly affect productivity; and, The amount of energy applied per unit of feed (the crusher power rate) will affect product fineness The only variables in the process which the engineer can routinely control are feed rate and setting change to the crusher These affect the power consumed at the driveScientific Methods to Design Crushing and Screening Plants2015年12月24日 How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 lbs per yard3 and Primary Crusher Selection Design 911Metallurgist2015年2月25日 Crushing efficiency • Generally the efficiency of crusher has been calculated from the Power point of view • As per a data in US, 1 % of the energy generated is used up for Size reduction Processes • The literature in the area have mostly talked about size energy relationships but we will look into the performance of crusher from customer point of view Crushing of coal and calculation of size reduction efficiency

UNITI: Thermal Power Stations Site selection of Thermal Power plant

11) The application of thermal power plant is most economical if sited near coal mines and by the side of river or canal 162 Disadvantages of Thermal Power plant 1) Thermal power plant requires large quantity of water for boiler and condenser 2) The fuel transportation cost is high especially when the power plants are away from coal lines2019年6月15日 The results were applied in optimizing an industrialscale crushing system and twotoothed roll crusher of a coal ganguefired power plant Investigations demonstrated that the PSD can improve the combustion efficiencies of the CFB significantly by 3%, as well as a 3× extension of the original service life of the twotoothed roll crusherOptimization of particle size distribution in circulating fluidized Keywords Coal handling system ring, etc thick roller screen Hammer coal crusher, thermal power plant 751 Introduction Coal screen and coal crusher are the key equipment of coal conveying system in thermal power plant (Lang 1998;Zhaoetal2001a, b) Coal conveying system usually set a screening crushing machine room; broken coal and screeningOperation and Maintenance of Coal Conveying System Screening 6 Construction and Maintenance of Belt Conveyors for Coal and Bulk Material Handling Plants practicalmaintenance also oscillating horizontally This phenomenon results in internal agitation to the material on belt and therefore the material’s external faces assume inclination at surcharge angleConstruction and Maintenance of Belt Conveyors for Coal and

Power Generation from Coal

Coal is the biggest single source of energy for electricity production and its share is growing The efficiency of converting coal into electricity matters: more efficient power plants use less fuel and emit less climatedamaging carbon dioxide This book explores how efficiency is measured and reported at coalfired power plants2016年3月11日 Short Head (Tertiary) Cone Crusher (Refer to Fig 2): The Short Head Cone crusher is normally applied as a third stage crusher in plants designed for three or four stages of crushers Feed opening and product size ranges for the various models of Short Head Cone crushers are as follows: a) Maximum Feed Opening — 250MM (10 In)Crushing Plant Flowsheet DesignLayout 911Metallurgist%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 AusIMM – Leading the way for people in resources2021年2月11日 Methods that have been used to select sites for coalfired power plants are reviewed A specific site selection procedure is presented that has been successfully applied in a number of cases This procedure addresses the challenging features of site Selecting Sites for CoalFired Power Plants Journal of the Energy

Operation and Maintenance of Coal Conveying System

2013年1月1日 Now, coal crusher used in the coal handling system of domestic large and mediumsized power plant, according to their structural features can be divided into hammer type, strike back type and ring hammer type etc, which ring hammer coal crusher is more advanced models, high quality and efficiently fragmentation of anthracite coal, common coal, inferior coal 2016年9月1日 Download Citation Fault diagnosis of Coal Ring Crusher in Thermal Power plant: A case study In order to increase the efficiency of machine, it is required to measure the faults generated Fault diagnosis of Coal Ring Crusher in Thermal Power plant: A Coal crushing equipment of coal handling plant system in the thermal power plant is very important for Plant efficiency improvement Keywords: India coal grades, Crusher, Construction, Crushing stages, Defect identification INTRODUCTION The coal handling plant (CHP) in a thermal power station covers unloading of coal, itsOPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL 2036 Lihua ZHAO and YLihua ZHAO / Procedia Engineering 00 (in LIN / Procedia Engineering 26 (2011) 2032 – ) 000–000 5 222 b Application and maintenance of Ring hammer coal crusher hammerOperation and Maintenance of Coal Handling System in Thermal Power Plant

Operation and Maintenance of Coal Handling

2011年12月31日 In order to ensure the safety of power generation in Poland and to maintain energy production from coalfired units with the long inservice time, it is required to develop a strategy for the 2020年7月24日 Article history Received: 3 July 2020 Accepted: 3 July 2020 Published Online: 30 July 2020 This paper takes the specific characteristics of pulverized coal room in thermal power plant as the starting point, firstly, this paper analyzes the process layout and structure selection, and then the structural design and vibration design requirements of coal crusher Research on Structural Design of Coal Crusher House in Thermal Power Plant2020年11月8日 VPEmobilejawcrusherplant700x394 Jaw Mobile Crushing Station • Application: Sand quarry, mining, coal mining, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc 64Crusher; Crushing; and Classification Equipment PPT SlideShareThis paper takes the specific characteristics of pulverized coal room in thermal power plant as the starting point,firstly, this paper analyzes the process layout and structure selection, and then the structural design and vibration design requirements of coal crusher house are introduced in this paper Finally, based on the engineering example, a new structure form of vibration isolation Research on Structural Design of Coal Crusher House in Thermal Power Plant

Coal based power plant PPT Free Download SlideShare

2014年6月16日 14 • Once the coal is in plant it has to undergo some preparatory processes before being fed into the boiler • First the coal goes to the crusher house where the coal is crushed manually into a size of about 20mm This coal is then passed further some part of it is fed into the plant while the other is stored • Generally most of the power plants store a coal for the 2013年7月17日 In a coal based thermal power plant, the initial process in the power generation is "Coal Handling' Boiler used in the power plant is suspended type for: Home; Membership; Coal rises from crusher house and reaches the dead storage by passing through transfer point 8Coal handling plant in a thermal power generating station EEPCoal feeding system of power plant: Coal feeding equipment is installed in the middle link, which is mainly used to complete the transportation, crushing, iron removal, screening, pulverization and loadbearing measurement of coal fuel Power plant coal storage system: It is the buffer link ofThermal Power Plant Coal Fuel Conveyor System SKE SKE 2023年8月2日 The site selection of a thermal power plant is a complex task that requires careful planning and consideration of various factors A thermal power plant is an industrial facility used to generate electricity from thermal energy, which is obtained by converting the heat released by the combustion of fossil fuels, such as coal, oil, or natural gasSite Selection for Thermal Power Plant – Explained in Detail