Limestone crusher smelting waste slag treatment stone material

Characterization of Stone Waste Sludge and Preliminary

2024年10月22日 The paper presents the preliminary results of a research activity aimed at developing TLPbased green materials, such as mortars and plasters, by partial substitution of natural aggregates with stone processing waste, called SWS, from the Apricena limestone Major rock types processed by the crushed stone industry include limestone, granite, dolomite, traprock, sandstone, quartz, and quartzite Minor types include calcareous marl, marble, shell, 11192 Crushed Stone Processing and Pulverized Mineral Processing2023年12月7日 This study investigates the alterations in the ratios of components such as class C fly ash (FA), blast furnace slag (BFS), and waste stone powder (WSP) types of limestone The Effects of Fly Ash, Blast Furnace Slag, and Limestone Powder2013年3月1日 This research study was conducted to evaluate the effect of quantity of steel slag on the mechanical properties of blended mixes with crushed limestone aggregates, which Evaluation of steel slag and crushed limestone mixtures as

.jpg)

Limestone impact on properties, microstructure and CO

2024年10月10日 This study highlights the significant potential of utilizing blended blast furnace slag and limestone powder (BFSLSP) as precursors in onepart cements activated with solid 2003年3月1日 This research study was conducted to evaluate the mechanical properties and durability characteristics of steel slag aggregate concrete in comparison with the crushed Comparison of properties of steel slag and crushed limestone 2024年5月30日 In this study, to develop a new recycling method for waste crushed stone powder (CSP) based on alkaliactivation technology, the authors produced AAMs using Recycling of waste crushed stone powder for alkaliactivated This research study was conducted to evaluate the effect of quantity of steel slag on the mechanical properties of blended mixes with crushed limestone aggregates, which used as Evaluation of steel slag and crushed limestone mixtures as

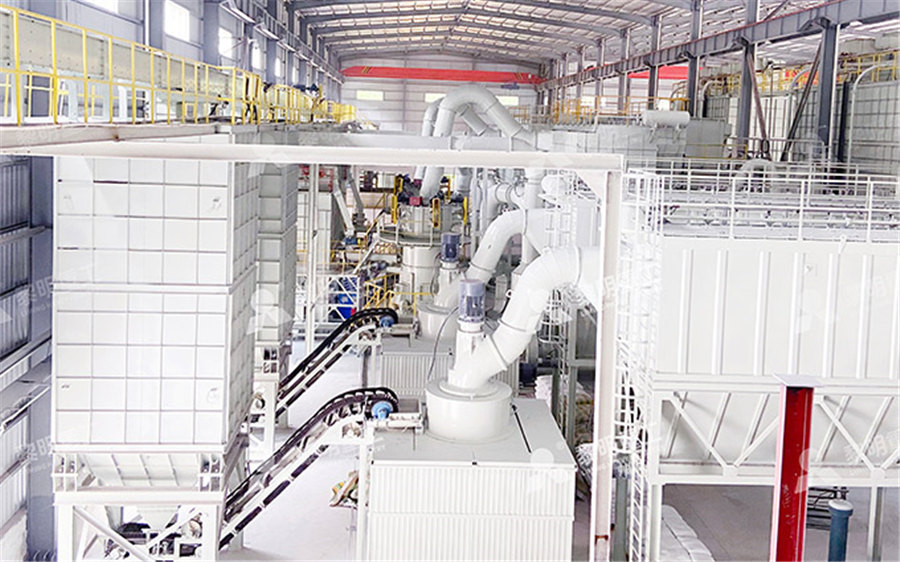

Limestone Crushing Process JXSC Mineral

400TPH Limestone Crushing Plant – Sand Making The process begins with limestone extraction from a quarry or mine This may involve drilling, blasting, and other methods to break the Blasting, drilling and scaling out limestone from the Earth requires the right equipment—and when it comes to reducing the size of that limestone material, it’s no different Williams Patent Crusher is committed to designing and Limestone Mills Limestone Crushers Pulverizers2020年6月3日 Smelting slag is a typical hazardous waste generated in the smelting and metallurgy industry 1,2 Slag contains high concentrations of heavy metals, such as Cu, Zn, Cr and Ni, which are harmful if Highpurity recycling of hematite and Zn/Cu mixture from waste smelting 2022年11月1日 Until now, relevant scholars have done a lot of works on the environmental assessment of various recycling technologies of steel slag For instance, Qian et al (Qian et al, 2021) adopt Bacillus Mucilaginosus (BM) to absorb carbon dioxide to promote the carbonization of dead burned lime and pared with traditional cement, Carbonized steel slag as a Life cycle assessment of melting reduction treatment for iron and

.jpg)

Applicability of gold tailings, waste limestone, red mud, and

2018年12月1日 Environmental issues have increased the importance of recycling and management of the byproducts of smelting and mining wastes The Center for Sustainable Resource Processing (CSRP) supported by the Australian government evaluated various waste streams produced by the mineral industry from technical, economic, and environmental aspects2024年7月17日 Jaw Crusher Jaw crushers use the compressive and bending action of a fixed jaw plate and a movable jaw plate to crush materials of various hardnesses When the two jaw plates come together, the material is crushed; when the plates move apart, material smaller than the discharge opening is released from the bottom The crushing action is Types of Crushers: Choosing the Right One for Each Stage2017年1月1日 Hughes 2000) Reductive sulfurizing smelting of slag with added CaO has been found conducive to Co recovery (Li et al 2018b) Treatment in slag cleaning furnaces does give rise to dust formation (PDF) Reductivesulfurizing smelting treatment of smelter slag 2016年5月16日 Reduce, reuse, and recycle are important techniques for waste management These become significant for improving environmental and economic condition of industries Integrated steel industries are generating huge amounts of steel slag as waste through the blast furnace and Linz–Donawitz (LD) process Presently, these wastes are disposed by dumping in Sustainable Approaches for LD Slag Waste Management in Steel

Applicability of gold tailings, waste limestone, red mud, and

2018年12月1日 The meltinghomogenization temperature (T mh ) is very near the melting point; the hold time is 1560 min [19,20] In contrast, the fiberforming viscosity (V ff ) of continuous fibers is higher 2018年12月1日 Increasing concerns about environmental issues have led to more attention being paid to the recycling of mining wastes and smelting byproducts In the present study, the utilization of gold tailings, waste limestone, red mud, and ferronickel slag was investigated for producing continuous glass fibersTo verify the applicability of the downdrawing process, the Applicability of gold tailings, waste limestone, red mud, and Download scientific diagram Particle size distribution of raw materials including limestone powder, tailing A, tailings B, and cement from publication: Effect of Incorporating Waste Limestone Particle size distribution of raw materials including limestone 2019年9月3日 Industrially, the pyrometallurgical treatment of laterites is mostly accomplished with a wellestablished method, namely, the rotary kiln–electric arc furnace (RKEF) process, which includes (PDF) Nickel Laterite Smelting Processes and Some

.jpg)

Comparison of properties of steel slag and crushed limestone aggregate

2003年3月1日 Up to now, the main methods of using steel slag were used as sinter material, hot metal dephosphorizing agent, waste water treatment materials, reclamation of waste steel, concrete admixtures, CO2 2021年3月16日 Alcoa treats the SPL produced from its US smelters at the Gum Springs, AR, hazardous waste treatment facility (Figure 3), which uses a thermal treatment process to detoxify SPL in a rotary kiln 35 The plant The SPL Waste Management Challenge in Primary References 1 T Annunziata Branca, V Colla: Possible Uses of Steelmaking Slag in Agriculture: An Overview, Material Recycling Trends and Perspectives, Dr Dimitris Achilias (Ed), 2012, ISBN: 9789535103271, InTech, Accessed April 2020; 2 Xmi You, Nchuan Yang, W Ling, D Jiang: The Second International Conference on Mining Engineering and Metallurgical More Metal, Less Waste: the Zero Slag Process Total Materia2014年7月29日 Recycling slag minimizes waste and disposal costs, reduces energy use, extends furnace life, and lowers the amount of additives needed to make slag The concerns with slag recycling are that first, because slag can contain environmentally hazardous materials, it must be analyzed for elemental composition before reuseSlag: From Byproduct to Valuable Construction Material

(PDF) Evaluation of steel slag and crushed limestone mixtures as

2013年3月1日 The objective is to use as few costeffective materials as possible to achieve the appropriate curb thickness The mixture of steel slag and limestone has a higher resistance to deflection and application of slag as well as slag treatment are reviewed and discussed In Germany, Japan, USA and some other countries, slag is not classified as hazardous wasteIRON AND STEELMAKING SLAGS: ARE THEY HAZARDOUS WASTEA RM 90GO! mobile impact crusher was used to produce a 1¼“ base material and a 1¼“3" clear stone product for building new roads Producing asphalt stone products A RM 100GO! and a RM MSC8500M 3deck incline screen produce 4 different asphalt stone products including limestone dustCrushing Limestone Impact Jaw Crushers RUBBLE MASTER2013年3月1日 1 Introduction Chang in modern traffic characteristics has led to higher vehicle loads, tire pressures and traffic volumes Current research illustrates that truck weights over 1134 ton (250,000 lb) and tire pressures of 150 psi have been frequently reportedThese changes represent a serious challenge to the pavement layers as they have caused predatory Evaluation of steel slag and crushed limestone mixtures as subbase

Resource utilization strategy of Febearing smelting slag in China:

Taking copper slag as an example, copper slag is a solid waste containing iron, lead, and zinc produced in the process of copper smelting, which is a typical nonferrous smelting slag Besides oxides of Ca, Mg, Si, and Al, copper slag also contains 20 %–40 % total iron (TFe) and a certain amount of lead and zinc, which has a high comprehensive utilization value ( Zhang et al, 2020 Steel Slag crusher and Steel Slag grinding mill are used to processing Steel Slag to small size or slag powder, then the material can be use in deep processing industry Slag properties vary greatly, it is subject to charge, smelting of steel Steel Slag Crusher and Grinding Mill2023年3月3日 Copper slag, a waste solid produced in the copper smelting process, is a highquality secondary resource with huge output The recycling and utilization of copper slag is of great interest because it avoids the loss of valuable metals and the threat of harmful metals, and saves a lot of natural resources and energy This paper firstly reviews the main methods for Review on Comprehensive Recovery Valuable Metals and 2022年1月19日 Increasing global cement and steel consumption means that a significant amount of greenhouse gases and metallurgical wastes are discharged every year Using metallurgical waste as supplementary cementitious Research Progress on Controlled LowStrength

.jpg)

General Situation of Iron and Steel Smelting and Solid Waste Treatment

2023年8月26日 With the change of iron ore raw material supply and the operation requirements of concentrate production in blast furnace, blast furnace production has developed from the earliest direct feeding of iron ore to the feeding of clinker such as sinter and pellet, and gradually developed into a series of process steps before ironmaking such as coking, sintering, 2022年3月17日 Behiry, A E A EM 2013 “Evaluation of steel slag and crushed limestone mixtures as subbase material in flexible pavement in reactions of alumbased water treatment residual with steel slag” Waste Manage 84 2019 “Expansive soil modified by waste steel slag and its application in subbase layer Steel Slag for Roadway Construction: A Review of Material the cosmelting slag to provide a basis for the cosmelting of high lead slag with gypsum sludge 2 Experimental 21 Materials and reagents In this study, high lead slag as the experimental raw material was synthesized from PbO, ZnO, SiO 2, Fe 2O 3, CaO, and Fe powder [21], and the reagents were all analytically pure After the raw materialsUtilization and detoxification of gypsum sludge by replacing limestone 2004年5月1日 For example, steel slag from steel production is an abundant byproduct material in the USA, China, Australia and some European countries [87,91](PDF) Steel Slag and Waste Management ResearchGate

Treatments and Recycling of Metallurgical Slags IntechOpen

2018年11月7日 Steelmaking plants continuously strive to reduce the environmental load in the steelmaking process, resulting in the recycling of energy, water, and other byproducts In this chapter, techniques for the treatment and recycling of metallurgical slags are described Metallurgical slags are considered secondary raw materials and are used or added during the 2024年3月13日 It is added to the blast furnace during the production process to remove impurities and facilitate the formation of slag The slag helps in the removal of impurities like sulfur and phosphorus from the molten iron 2 Raw Material: Limestone is used as a raw material in the production of iron and steelLimestone—A Review with Special Reference to the Iron and Steel 2023年1月1日 After being subjected to various cooling temperatures and material recovery processes, the waste slag material can be processed into different size ranges Its use and disposal are limited as it includes around 6–12 % harmful elements such as chromium oxide and could release dangerous chromium compounds into the surroundingsUtilization of steel slag waste as construction material: A reviewBlasting, drilling and scaling out limestone from the Earth requires the right equipment—and when it comes to reducing the size of that limestone material, it’s no different Williams Patent Crusher is committed to designing and Limestone Mills Limestone Crushers Pulverizers

Highpurity recycling of hematite and Zn/Cu mixture from waste smelting

2020年6月3日 Smelting slag is a typical hazardous waste generated in the smelting and metallurgy industry 1,2 Slag contains high concentrations of heavy metals, such as Cu, Zn, Cr and Ni, which are harmful if 2022年11月1日 Until now, relevant scholars have done a lot of works on the environmental assessment of various recycling technologies of steel slag For instance, Qian et al (Qian et al, 2021) adopt Bacillus Mucilaginosus (BM) to absorb carbon dioxide to promote the carbonization of dead burned lime and pared with traditional cement, Carbonized steel slag as a Life cycle assessment of melting reduction treatment for iron and 2018年12月1日 Environmental issues have increased the importance of recycling and management of the byproducts of smelting and mining wastes The Center for Sustainable Resource Processing (CSRP) supported by the Australian government evaluated various waste streams produced by the mineral industry from technical, economic, and environmental aspectsApplicability of gold tailings, waste limestone, red mud, and 2024年7月17日 Jaw Crusher Jaw crushers use the compressive and bending action of a fixed jaw plate and a movable jaw plate to crush materials of various hardnesses When the two jaw plates come together, the material is crushed; when the plates move apart, material smaller than the discharge opening is released from the bottom The crushing action is Types of Crushers: Choosing the Right One for Each Stage

(PDF) Reductivesulfurizing smelting treatment of smelter slag

2017年1月1日 Hughes 2000) Reductive sulfurizing smelting of slag with added CaO has been found conducive to Co recovery (Li et al 2018b) Treatment in slag cleaning furnaces does give rise to dust formation 2016年5月16日 Reduce, reuse, and recycle are important techniques for waste management These become significant for improving environmental and economic condition of industries Integrated steel industries are generating huge amounts of steel slag as waste through the blast furnace and Linz–Donawitz (LD) process Presently, these wastes are disposed by dumping in Sustainable Approaches for LD Slag Waste Management in Steel 2018年12月1日 The meltinghomogenization temperature (T mh ) is very near the melting point; the hold time is 1560 min [19,20] In contrast, the fiberforming viscosity (V ff ) of continuous fibers is higher Applicability of gold tailings, waste limestone, red mud, and 2018年12月1日 Increasing concerns about environmental issues have led to more attention being paid to the recycling of mining wastes and smelting byproducts In the present study, the utilization of gold tailings, waste limestone, red mud, and ferronickel slag was investigated for producing continuous glass fibersTo verify the applicability of the downdrawing process, the Applicability of gold tailings, waste limestone, red mud, and

.jpg)

Particle size distribution of raw materials including limestone

Download scientific diagram Particle size distribution of raw materials including limestone powder, tailing A, tailings B, and cement from publication: Effect of Incorporating Waste Limestone