High quality mbf medium speed coal mill

中国能建黎明重工设备公司英文站 Mechanical Products

2024年11月5日 The new generation SXJ series highefficiency planetary gearbox developed independently and manufactured by BPEG is a transmission equipment, specially designed for 2019年4月15日 With more than forty year experiences in designing and manufacturing at coal mill, SHMP is able to supply all types of mediumspeed coal mill to 50MW15000MW power 上海电气上重碾磨特装设备有限公司MPG medium speed coal mill is designed according to the principle of high speed, large roll diameter and high loading force Compared with other types of medium speed coal mills, it has MPG Medium Speed Coal Mill NHIDual inlet dual outlet steel ball mills have advantages of high rate of continuous operation, rapid response in a wide load range, low coal to air ratio and low maintenance And the machine is Coal Mill Coal Fired Power Generation Shanghai Electric

.jpg)

Vertical Coal Mill Power Generation Equipment Shanghai Electric

On the basis of retaining the advantages of RP grinders and absorbing the structural characteristics of MPS and MBF coal grinders, the HP mediumspeed coal grinder has been 2017年8月1日 MPStype medium speed coal mills are widely used in the thermal power plants in China They are designed and manufactured by the German company Babcock This kind of Modeling of a medium speed coal mill ScienceDirectThe Raymond Bowl Mill is considered the finest vertical roller mill available for pulverizing coal The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and Raymond Bowl Mill designed and built for flexibility QlarThis study takes the Mill Parter Ship (MPS)type mediumspeed coal mill of the 350 MW coalgenerating electricity set of CHN Energy Changyuan Wuhan Qingshan CoGengeration Co, Research on the construction of digital twin virtual model of coal

Modeling of a medium speed coal mill ResearchGate

2017年5月1日 Simulation results indicate that the model effectively represents the midhigh process of coal mill dynamics and can be used to estimate the key parameters in coal mills, The BTM is a lowspeed mill that primarily grinds coal by impact and attrition The VRM is a medium speed mill that grinds coal by compression and, because of the low coal inventory in A Comparison of Three Types of Coal Pulverizers Babcock Powermodification to its MB mill predecessor Shortly thereafter, DBW became the first licensee of Gebruder Pfeiffer in Europe for coal applications This particular mill was chosen because of DBW's successful track record not only in their worldwide installation of 6 to 100 TPH MPS coal mills since the early 1960s but alsoWorldProven Coal Pulverizer Technology Debuts in the US2017年5月1日 Download Citation Modeling of a medium speed coal mill The obtained highquality model identification confirms the correctness of the presented methodModeling of a medium speed coal mill ResearchGate

Review of control and fault diagnosis methods applied to coal mills

2015年8月1日 Schematic of mill control for (a) low speed mills and (b) medium speed mills The controls included are – (1) coal flow control, (2) air flow control and (3) outlet temperature control Download: Download fullsize image; Fig 5 SAMA Nomenclature [11] – (a) PID controller (b)Bias with automanual station (c) Signal processing symbolsThis study takes the Mill Parter Ship (MPS)type mediumspeed coal mill of the 350 MW coalgenerating electricity set of CHN Energy Changyuan Wuhan Qingshan CoGengeration Co, Ltd in China as the research object, and proposes to establish a more accurate and effective virtual model of digital twin of coal mill with online updating capability based on the existing workResearch on the construction of digital twin virtual model of coal mills2017年8月1日 In this study, the lumped parameter modeling method is adopted with the following assumptions: 1) the parameters of the medium in the coal mill are uniform; 2) the media in the coal mill are incompressible; 3) the parameters of the medium in the coal mill change along the axial direction only; 4) the change in the flow power in the coal mill is ignored; 5) the coal Modeling of a medium speed coal mill ScienceDirectThe versatile MPS vertical mill – with a fine tradition of quality grinding Highest flexibility with constant product quality, highquality wear materials and sophisticated service concepts, MPS 200 BK coal mill, Krimzement Bakhchisarayski, Ukraine MPS 3070 BK coal mill, Jaypee Cement Balaji, Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

.jpg)

MPS ZGM Coal MillGrinding Equipment YingYong Machinery

The mediumspeed coal mill can handle different types and quality of coal, which can adapt to different coal supply and production needs Energy Efficient and Low Cost Our ZGM MPS coal vertical mill uses highefficiency pulverizing technology to Highspeed coal mill: Its rotating speed range is 5001,500 r/min Commonly used highspeed coal mills include fan coal mills and hammer coal mills Among all coal mills, cylindertype steel ball coal mill is widely favored because of its good adaptability to all kinds of coal, strong drying ability, simple structure, high reliability, and easy maintenanceAirSwept Coal Mill of High Quality Fote Machinery2017年8月1日 On the basis of the literature above, a nonlinear dynamic model of a MPS (Mill Parter Ship)type medium speed coal mill is proposed in this study based on its mass and energy balance Highefficiency coalfired power plants development and perspectives[J] Energy, 31 (10) (2006), pp 14371445Modeling of a medium speed coal mill ScienceDirect2011年8月1日 Pulverizers prepare raw fuel by grinding it to a desired fineness and mixing it with the just the right amount of air before sending the mixture to boiler burners for combustion In Part I of Pulverizers 101: Part I POWER Magazine

.jpg)

Modeling of a medium speed coal mill Semantic Scholar

2017年8月1日 Semantic Scholar extracted view of "Modeling of a medium speed coal mill" by Yaokui Gao et al Skip to search form Skip to main content Skip to account menu Semantic Highefficiency coalfired power plants development and perspectives J Bugge S Kjær R Blum Engineering, Environmental Science 2006; 2822020年4月2日 The different mill has different PC pipe corners, and with different length and high level This case indicates and measures the changes of boiler parameters due to different mill in serviceAnalysis of the Coal Milling Operations to the Boiler 4 Selection method According to the coal quality and working conditions provided by users, the type selection calculation of Beijing electric power equipment plant is mainly based on DL/T51452002 "Technical specification ZGM type Mediumspeed Rolling coal millpower Foster Wheeler provides replacement parts and maintenance services for vertical spindle roller mills used to pulverize coal Their parts and upgrades help reduce maintenance costs and improve mill performance They offer rotating airports, highchrome rollers, ceramic rollers, and other parts and upgrades to increase wear life and reduce required maintenance With over MBF Coal Pulverizers Foster Wheeler PDF Scribd

.jpg)

“Blueprint” Your Pulverizer for Improved Performance

coal pipes and burner nozzle sizes is essential for the best furnace performance Furthermore, remember that there will be minor variation in mill capacity, fuel quality, and mill inlet airflow rates that must be considered when sizing the pulverizer throat flow area The vertically flowing air must be of sufficient velocity to susThe mediumspeed coal mill system is mainly composed of raw coal bunker, coal feeder, coal mill, primary fan, sealing fan, hot and cold air regulating valves View in fulltext Similar The structure of MPS mediumspeed coal mill system2023年5月8日 These include high motor amperage, high or low outlet temperature, high or low inlet temperature, coal spillage, coal plugging, and selfcombustion The disturbance occurs because it operates using LowRank Call (LRC) coal with high moisture, causing the changing in the operating pattern of the coal pulverizer mill, such as the coal flow rate setting and primary airCoal pulverizer mill system modeling for failure simulationThe coal mill can also grind petroleum coke and anthracite down to a fineness below 5% +90 micromillimeters (mm) when coupled with a variable speed mill motor No sticky situations The ATOX® Coal Mill can grind and dry raw coal with up to 25 percent moisture levelATOX® Coal Mill FLSmidth Cement

SHPHGLXP VSHHGFRDOPLOO ResearchGate

Journal of Physics: Conference Series PAPER OPEN ACCESS)DXOWDQDO\VLVDQGRSWLPL]DWLRQWHFKQRORJ\RI+3ERZOW\SHPHGLXP VSHHGFRDOPLOO To cite this article: Dou Jie 2021 J Phys: Conf Ser 2005 [2] Mei Z F, Chen M and Xu M F 2016 Flow field in the upstream circular primary air duct of medium speed mills: numerical simulation and optimization design Thermal Power Generation 45 99105 113 Google Scholar [3] Gu Z E, Lin G R and Zhu B G 2016 Retrofit of PA Flow Measuring Device at 600MW Boiler Coal Mill Inlet Power System Engineering 32 Mixing Characteristics and Flow Fields Optimization of Primary Air Medium speed coal mill is suitable for grinding bituminous coal, With highquality innovative products, reasonable prices, perfect aftersales service and good reputation, we have won the recognition and praise of tens of thousands Mediumspeed coal mill wearresistant ceramic linerdefined nonlinear system and two actual fault cases of a mediumspeed coal mill Compared with the traditional methods, the experimental results demonstrate the effectiveness of the proposed methodA novel multimode Bayesian method for the process monitoring

High Speed Hammer Mills Meteor Hammer Mills

Williams' Meteor High Speed Hammer Mills, also referred to as Meteor Hammer Mills, are characterized by high hammertip speed to permit a fine product or to obtain specific characteristics in the finished productThis type of high speed Generally, the outlet temperature of the mediumspeed coal mill is controlled at 100 to 120 degrees Celsius The material processed by the mediumspeed mill barrel is particles of various sizes and hardnesses These materials move inside the mediumspeed mill, constantly causing friction, scouring and impact on various parts of the mediumspeed The cylinder of the mediumspeed coal mill is lined with wear Coal Vertical Roller Mill (VRM) for Grinding Stone, Find Details and Price about High Quality Vertical Rollers Mill Vertical Coal Vertical Roller Mill (VRM) is an air swept, mediumspeed, Grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a ball mill Application Coal Vertical Roller Mill (VRM) for Grinding Stone High Quality foster wheeler mbf coal pulverizer service manual Foster Wheeler – Coal Mills Foster Wheeler’s Global Power Group offers advanced Coal Mills Since its introduction in 1927 140 sold in the last 10 years Foster Wheeler Coal Pulverisor Crusher Mills

Coal mill model considering heat transfer effect on mass

2021年8月1日 The optimal control system of coal mills should respond effectively and quickly to the changes of plant load and coal quality which will decrease the combustion efficiency of coal However, extremely high outlet temperature will make Modeling of a medium speed coal mill Powder Technol, 318 (2017), pp 214223 View PDF 2 Raw coal properties – Hardgrove index and moisture level 3 Pulverized coal fineness The raw coal is fed into a rotating bowl via a center feed pipe The rate of coal feed is normally determined automatically by a combustion control system, taking into account the MW demand on the unit, coal quality, and the number of coal pulverizers in Bowl Mill Coal Pulverizer COAL HANDLING PLANTS2010年3月9日 The invention provides a mediumspeed coalmill directfiring pulverizing combustion system for burning highmoisture lignite, which can dry and burn highmoisture lignite The system consists of a mediumspeed coal mill, a pulverized coal concentrator and a burner The system can adopt a primary air rate of over 40 percent to meet the drying capability of the Mediumspeed coalmill directfiring pulverizing combustion Wall Fired Burners Tangential Burners Ball Mills Vertical Mills • Coal Nozzles • Adjustable Nozzle Tips • Liners • Roller Assemblies • Coal Inlets • Coal Nozzles • Conveyors • Classifier Upgrades • Inner Sleeves • Tilt Upgrades • Trunnion Bearings • Airports • Register Components • Damper Box Upgrades • Classifiers • Plungers • Bull amp; Pinion Gears MBF Coal Pulverizers Foster Wheeler studylib

WorldProven Coal Pulverizer Technology Debuts in the US

modification to its MB mill predecessor Shortly thereafter, DBW became the first licensee of Gebruder Pfeiffer in Europe for coal applications This particular mill was chosen because of DBW's successful track record not only in their worldwide installation of 6 to 100 TPH MPS coal mills since the early 1960s but also2017年5月1日 Download Citation Modeling of a medium speed coal mill The obtained highquality model identification confirms the correctness of the presented methodModeling of a medium speed coal mill ResearchGate2015年8月1日 Schematic of mill control for (a) low speed mills and (b) medium speed mills The controls included are – (1) coal flow control, (2) air flow control and (3) outlet temperature control Download: Download fullsize image; Fig 5 SAMA Nomenclature [11] – (a) PID controller (b)Bias with automanual station (c) Signal processing symbolsReview of control and fault diagnosis methods applied to coal mills This study takes the Mill Parter Ship (MPS)type mediumspeed coal mill of the 350 MW coalgenerating electricity set of CHN Energy Changyuan Wuhan Qingshan CoGengeration Co, Ltd in China as the research object, and proposes to establish a more accurate and effective virtual model of digital twin of coal mill with online updating capability based on the existing workResearch on the construction of digital twin virtual model of coal mills

Modeling of a medium speed coal mill ScienceDirect

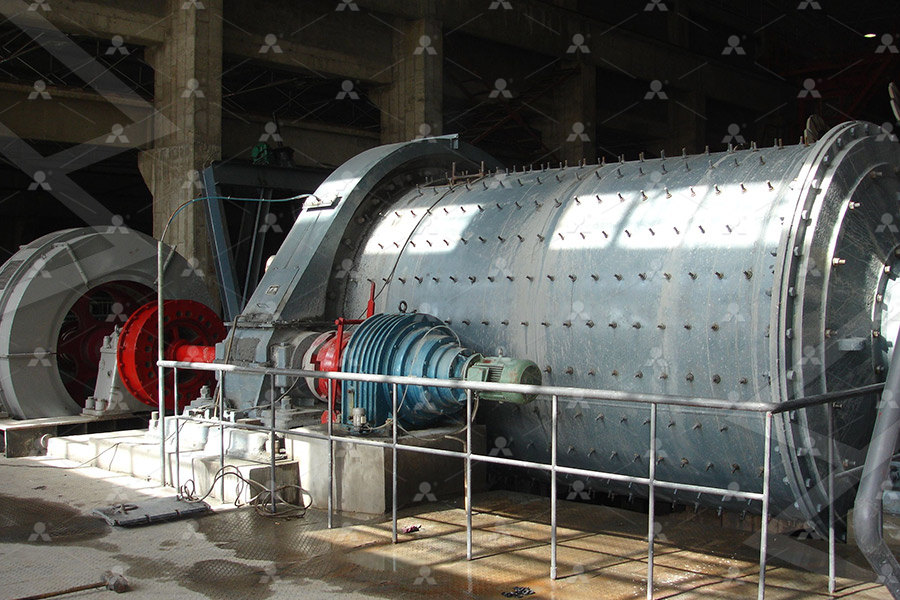

2017年8月1日 In this study, the lumped parameter modeling method is adopted with the following assumptions: 1) the parameters of the medium in the coal mill are uniform; 2) the media in the coal mill are incompressible; 3) the parameters of the medium in the coal mill change along the axial direction only; 4) the change in the flow power in the coal mill is ignored; 5) the coal The versatile MPS vertical mill – with a fine tradition of quality grinding Highest flexibility with constant product quality, highquality wear materials and sophisticated service concepts, MPS 200 BK coal mill, Krimzement Bakhchisarayski, Ukraine MPS 3070 BK coal mill, Jaypee Cement Balaji, Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsThe mediumspeed coal mill can handle different types and quality of coal, which can adapt to different coal supply and production needs Energy Efficient and Low Cost Our ZGM MPS coal vertical mill uses highefficiency pulverizing technology to MPS ZGM Coal MillGrinding Equipment YingYong MachineryHighspeed coal mill: Its rotating speed range is 5001,500 r/min Commonly used highspeed coal mills include fan coal mills and hammer coal mills Among all coal mills, cylindertype steel ball coal mill is widely favored because of its good adaptability to all kinds of coal, strong drying ability, simple structure, high reliability, and easy maintenanceAirSwept Coal Mill of High Quality Fote Machinery

.jpg)

Modeling of a medium speed coal mill ScienceDirect

2017年8月1日 On the basis of the literature above, a nonlinear dynamic model of a MPS (Mill Parter Ship)type medium speed coal mill is proposed in this study based on its mass and energy balance Highefficiency coalfired power plants development and perspectives[J] Energy, 31 (10) (2006), pp 143714452011年8月1日 Pulverizers prepare raw fuel by grinding it to a desired fineness and mixing it with the just the right amount of air before sending the mixture to boiler burners for combustion In Part I of Pulverizers 101: Part I POWER Magazine