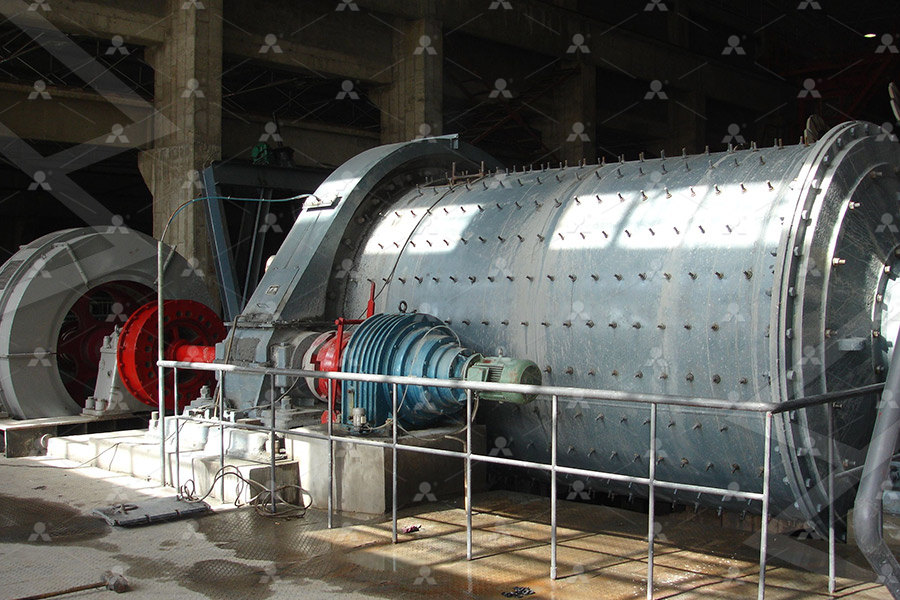

Shanlu coal mill lining

.jpg)

Shandong Shanlu Heavy Industry Technology Co LTD

Our company can customize production lines for customers based on their original ore grade, output, product standards, and other requirements Annual production can be achieved from The service content of Shanlu Heavy Industry is: High purity quartz sand production line, photovoltaic quartz sand production line, float (flat) glass sand production line, quartz plate Shandong Shanlu Heavy Industry Technology Co, LtdShanlu Heavy Industry, professional quartz sand engineering technology equipment service providers, focusing on light sand production line, float (plate) glass sand production line, plate Company ProfileShandong Shanlu Heavy Industry Technology Co2022年12月1日 Determination of the causeandeffect relationship regarding the wear of the lining (beater) of a coal beater mill is presented The type and state of the material used for the The wear mechanism of mill beaters for coal grinding madeup

Mill liners Metso

We offer fit for purpose liners for all types of mills, including SAG mills, AG mills, ball mills, rod mills, and pebble mills Our liners are designed to fit the specific requirements of each mill, taking into account factors such as mill size, speed, Our Ball Mill Lining Capability : We can fabricate the Nihard Ball Mill Lining as per your material and your sizes We’d like to help select suitable material grade for your Ball Mill Lining as per your specific working conditionBall Mill Lining for Coal Mill EB CastworldAbstract: Three kinds of roll sleeves and liners of different materials used successively in ZGM113GI medium speed coal mill are introduced The chemical composition and casting 三种不同材质磨煤机的辊套和衬板使用情况 EB specializes in production of CrMo Alloy Steel Mill Liners For Coal Mills for 20 years The material includes ASTM A532, AS2027, BTMCr20Mo, BTMCr26MoCrMo Alloy Steel Mill Liners For Coal Mill EB Castworld

.jpg)

Coal Mill Liners for Coal Plants EB Castworld

EB specializes in production of Coal Mill Liners for Coal Plants for 20 years The material includes ASTM A532, AS2027, BTMCr20Mo, BTMCr26Mohighlighted the significance of correct mill liner selection Liners protect the mill shell from wear and transfer energy to the grinding charge, and a careful balance is required to optimise these The Selection and Design of Mill Liners 911 Metallurgist2015年8月6日 There are basically two groups of Grinding Mill Liners Ones with a HIGH PROFILE and those with a LOW PROFILE will be protected with an abrasion resistant resilient surface under compression and that the remaining Grinding Mill Liners 911Metallurgist: shanlu @ csuchicago Crerar Library 343 5730 S Ellis Ave, Chicago, IL 60637 CV: Bio: Publications 2025 You Only MemLiner: Lining up Tracing and Application for a FarMemoryFriendly Runtime Chenxi Wang, Haoran Ma, Shi Liu, Yifan Qiao, Jonathan Eyolfson, Christian Navasca, Shan Lu, Harry XuShan Lu, go Department of Computer Science

WEAR ANALYSIS OF VERTICAL COAL MILL PLATE ResearchGate

2022年11月1日 Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining 2021年1月27日 Update By the Shan Human Rights Foundation January 27, 2021 Burma Armylinked coal mining expansion in wartorn northern Shan State Summary During the past year, the Mandalaybased conglomerate Ngwe Yi Pale and the Burma Army have expanded their coal mining operations in wartorn northern Shan State, destroying farmlands, worsening water and Blackening our Future: Burma Armylinked coal mining expansion Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining The layout of the coal mill with a rotary classifierChina Ball Mill Rubber Lining wholesale Select 2024 high quality Ball Mill Rubber Lining products in best price from certified Chinese Milling Machine manufacturers, Ball Mill suppliers, 99% High Alumina Ceramic Wear Lining for Bucket Wheel and Coal Mill US$ 5761 / kg 1000 kg (MOQ) ZIBO QIMINGXING NEW MATERIAL INCORPORATED CO, LTDBall Mill Rubber Lining MadeinChina

ATOX® Coal Mill FLSmidth Cement

Our ATOX® Coal Mill has large rollers with great grinding capability of virtually all types of raw coal The rollers work harmoniously with a highlyefficient separator and feed sluice to consistently and reliably deliver coal meal to your desired fineness and moisture level2020年1月27日 Figure 2: Cascadingimpact action in a SAG mill Rubber and composite mill lining systems In the past, grinding mills were typically lined with cast metal linings of varying steel or iron alloys, and lining system selection was typically driven by level of Key considerations when selecting a mill lining systemEB specializes in production of Coal Mill Liner BTMCr15Mo for 20 yearsThe material includes ASTM A532,AS2027,BTMCr20Mo,BTMCr26Mo Skip to content Leading supplier of high alloy castings and forgings SAG Ball Mill Rubber Lining SupplierCoal Mill Liners for Coal Plants EB CastworldRunning state and heat treatment of coal mill liner After the material of coal mill lining has passed the ordinary high manganese steel, the strengthened high manganese steel, the alloy white pig iron and so on stage, the middle low alloy steel lining board has obtained the very good developmentLow and medium alloy steel liner material adding alloy element Cr, Mo, V, Ti, Ato Coal Mill Liner

132 Loesche Mills For Solid Fuels Coal Mill E 2016

132 Loesche Mills for Solid Fuels Coal Mill E 2016 Free download as PDF File (pdf), Text File (txt) or read online for free Loesche has been involved in processing solid fuels since 1925 Some key events include delivering their first coal mill in 1927 and introducing hydraulic systems in 1961 Their mills are distinguished by grinding without metal contact, suitability for 2010年5月1日 Request PDF CFD modeling of MPS coal mill with moisture evaporation Coal pulverizers play an important role in the functioning and performance of a PCfired boiler The main functions of a CFD modeling of MPS coal mill with moisture evaporation2022年11月30日 Request PDF The wear mechanism of mill beaters for coal grinding madeup from high manganese cast steel Determination of the causeandeffect relationship regarding the wear of the lining The wear mechanism of mill beaters for coal grindingOur customers strive for safety, productivity, and efficiency in their mineral processing operations That’s why we offer a diverse range of mill lining solutions, including steel and rubbercomposite liners, each solution is designed to meet application requirements across various conditionsMill Liners Bradken

ball mill linings Capabuild

quartz sand dry ball mill with rubber lining Nov 23, ;32;Ball mill A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing Less wear takes place in rubber lined millsJYOTI INNOVISION PVT LTD is the Manufacturer, Supplier and Exporter of Ball Mill Lining Bricks from Ahmedabad, Gujarat, India We are ahead in wear resistant technology Call Us Request A Quote Home Page; Coal Mill Cone Coal Mill Cone; Slag Chutes With Liner Slag Chutes With Liner; Dust Blower Casing Dust Blower Casing Ball Mill Lining Bricks Manufacturer in Ahmedabad, Gujarat Best Mill liners are an essential component in grinding mills, providing a protective surface to minimize wear and extend the lifespan of the mill In this article, we will explore what mill liners do, their importance, and the different types available Mill liners are protective components that shield the interior of a grinding mill from the abrasive forces generated by grinding media and oreWhat Does Mill Liner Do? ball mills supplier1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLS

Technical specifications of vertical roller coal mill

Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining Relines South Africa’s multiskilled workforce is experienced in providing rubber lining installations and repair work on mills Due to the rubber lining being a critical component of the mill lining system, we provide the tools, materials and expertise Mill Relining Relines South AfricaChina Mill Lining wholesale Mining Machine, Thermal Power Plant, Coal Yard Material: Chromium Carbide Type: Wear Resistant Plate Wear Layer Thickness: +05/05mm Model Number: HP100400 1 / 6 Favorites High Manganese Steel Casting WearResistant Ball Mill Liner High WearResistant Rubber Lining Mill Lining MadeinChina2018年9月1日 Variation of the damage index of concrete lining after coal mine fire 5 Conclusions In order to study the effect of coal mine fire on the damage of concrete lining, an indoor model experiment was carried out in a 1/10 reducedscale Nondestructive testing and temperature distribution of coal

.jpg)

Solutions for Wear Protection in Mining and Processing Industry

Plant Components Material for lining SAG mill Transfer chutes, spout feeders KALCAST, KALOCER, KALCOR Ball mill Spout feeders, lining KALCAST Highly wear resistant KALOCER pipes for handling Hydraulic conveying pipes integrated in a coal preparation ore sludge to be installed in a mine in the Far East plant in North America The pipes have China Alumina Mill Lining wholesale Select 2024 high quality Alumina Mill Lining products in best price from certified Chinese Hot Strip Mill manufacturers, Aluminium Mill suppliers, 99% High Alumina Ceramic Wear Lining for Bucket Wheel and Coal Mill US$ 5761 / kg 1000 kg (MOQ) ZIBO QIMINGXING NEW MATERIAL INCORPORATED CO, LTDAlumina Mill Lining MadeinChinaMill Lining THOR – R mill liners are manufactured from specially formulated rubber compounds, which are blends of Natural and Synthetic rubbers The T800 rubber formulation series have proved its robustness over time, through installations across a wide range of Ball Mill Lining Thejo AustraliaWhat are the most common types of mill liners? The most common types of mill liners include steel liners, rubber liners, composite liners, and magnetic liners Mill liners play an essential role in the mining and milling industry, protecting the mill’s internal components from wear and damage caused by the grinding processWhat Are Mill Liners? ball mills supplier

Effect of mill outlet temperature on the coal moisture content

Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining 2022年8月10日 According to the running characteristics of vertical coal mill, KINGCERA has designed different wearresistant lining plates for coal mill barrel and coal mill shell The coal mill liner can be Mediumspeed coal mill wearresistant ceramic plate Composite Nicr4600 Liners for Coal Mills Wear Resistance Lining Plate HJMT ® wear resistance liner plates is made of highpurity ultrafine alumina powder as the main raw material, combined with optimized formula, after isostatic pressed, and sintered at a high temperature of 1530℃ Wear resistant ceramic plates are usually installed in the wear area of some material conveying Nicr4600 Liners for Coal Mills Wear Resistance Lining Plate2020年1月27日 Figure 2: Cascadingimpact action in a SAG mill Rubber and composite mill lining systems In the past, grinding mills were typically lined with cast metal linings of varying steel or iron alloys, and lining system selection was typically driven by level of Key considerations when selecting a mill lining system

.jpg)

Grinding Mill Liners 911Metallurgist

2015年8月6日 There are basically two groups of Grinding Mill Liners Ones with a HIGH PROFILE and those with a LOW PROFILE will be protected with an abrasion resistant resilient surface under compression and that the remaining : shanlu @ csuchicago Crerar Library 343 5730 S Ellis Ave, Chicago, IL 60637 CV: Bio: Publications 2025 You Only MemLiner: Lining up Tracing and Application for a FarMemoryFriendly Runtime Chenxi Wang, Haoran Ma, Shi Liu, Yifan Qiao, Jonathan Eyolfson, Christian Navasca, Shan Lu, Harry XuShan Lu, go Department of Computer Science2022年11月1日 Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining WEAR ANALYSIS OF VERTICAL COAL MILL PLATE ResearchGate2021年1月27日 Update By the Shan Human Rights Foundation January 27, 2021 Burma Armylinked coal mining expansion in wartorn northern Shan State Summary During the past year, the Mandalaybased conglomerate Ngwe Yi Pale and the Burma Army have expanded their coal mining operations in wartorn northern Shan State, destroying farmlands, worsening water and Blackening our Future: Burma Armylinked coal mining expansion

The layout of the coal mill with a rotary classifier

Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining China Ball Mill Rubber Lining wholesale Select 2024 high quality Ball Mill Rubber Lining products in best price from certified Chinese Milling Machine manufacturers, Ball Mill suppliers, 99% High Alumina Ceramic Wear Lining for Bucket Wheel and Coal Mill US$ 5761 / kg 1000 kg (MOQ) ZIBO QIMINGXING NEW MATERIAL INCORPORATED CO, LTDBall Mill Rubber Lining MadeinChinaOur ATOX® Coal Mill has large rollers with great grinding capability of virtually all types of raw coal The rollers work harmoniously with a highlyefficient separator and feed sluice to consistently and reliably deliver coal meal to your desired fineness and moisture levelATOX® Coal Mill FLSmidth Cement2020年1月27日 Figure 2: Cascadingimpact action in a SAG mill Rubber and composite mill lining systems In the past, grinding mills were typically lined with cast metal linings of varying steel or iron alloys, and lining system selection was typically driven by level of Key considerations when selecting a mill lining system

Coal Mill Liners for Coal Plants EB Castworld

EB specializes in production of Coal Mill Liner BTMCr15Mo for 20 yearsThe material includes ASTM A532,AS2027,BTMCr20Mo,BTMCr26Mo Skip to content Leading supplier of high alloy castings and forgings SAG Ball Mill Rubber Lining SupplierRunning state and heat treatment of coal mill liner After the material of coal mill lining has passed the ordinary high manganese steel, the strengthened high manganese steel, the alloy white pig iron and so on stage, the middle low alloy steel lining board has obtained the very good developmentLow and medium alloy steel liner material adding alloy element Cr, Mo, V, Ti, Ato Coal Mill Liner