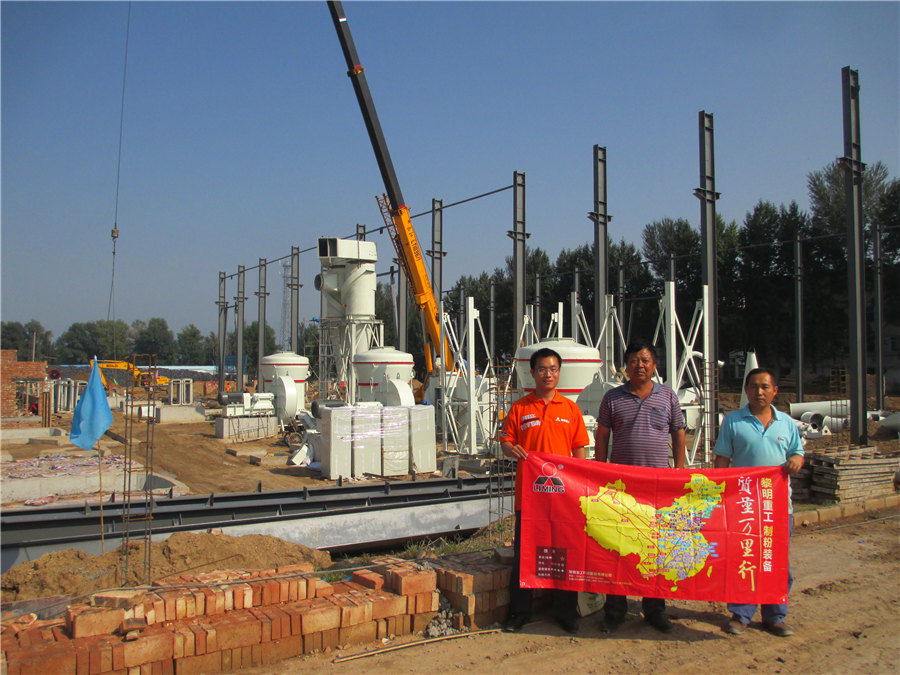

Internet marketing of grinding mill

.jpg)

The Grinding Mills Market Boom: Key Drivers, Market Value, and

2 天之前 The Grinding Mills Market Size was valued at USD 25 Billion in 2023 and is expected to reach USD 35 Billion by 2031, growing at a 45% CAGR from 2024 to 2031 The report 2024年11月14日 Grinding mills are crucial equipment used in industries ranging from mining and cement manufacturing to chemicals, food, and pharmaceuticals These mills are designed to Grinding Mill Market Innovations, Key Trends, and Growth2023年3月15日 Grinding mills have become indispensable in various industries such as food processing, mining, and construction due to their versatility and efficiency This article aims to explore the history, types, and importance of The Evolution and Importance of Grinding Mills in From precrushers for the comminution of coarse materials to jet and ball mills for ultrafine grinding: Hosokawa Alpine offers mills for a wide range of fineness levels The mill type that is best suited to your application depends not only on Grinding Hosokawa Alpine

.jpg)

Grinding mills for mining and minerals processing

Browse Metso's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs Our pioneering innovations in horizontal grinding mills technology offer exceptional performance and Leading sales and marketing intent data, database and data enrichment providers and technology solutions for the mining industryCrushers, Breakers and Grinding Mills Mining TechnologyGrinding mills and pulverizers transform course materials into finer shards or granules Mills and pulverizers move materials through various devices that use pressure and blades to grind it There are several types of grinding mills and Grinding Mills and Pulverizers Information GlobalSpecWe specialize in the supply of new grinding mills Our designs are completed using modern FEA design techniques and 3D simulation packages This ensures that our clients receive Global Suppliers of New Refurbished Grinding Mills NCP

.jpg)

How grinding mill design changed over the last 30 years

2020年6月3日 Grinding mills are some of the most important equipment in mines, processing over a few thousand tons of ore every hour It is not uncommon to see these days that a single 2024年8月8日 Grinding media, pivotal for the efficacy of the ball milling process, come in various materials, each offering unique characteristics and advantages tailored to specific applications Ceramic Balls: Composed of materials like Ball Mill Success: A StepbyStep Guide to Choosing 2016年11月7日 In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 Grinding Mills Common Types 911Metallurgist2022年4月25日 After that first installation experiment, carried out in the US in a 4 x 20’ Ball Mill, at the Nipissing Mine in Ontario, Canada, Trelleborg went on to patent the first Mill linings in 1953 and after thorough tests applied for Mill liners: grinding out a legacy Mining Technology

Understanding the operation of grinding mills in the mining and

Ball mills are the most commonly used type of grinding mill They work by rotating a cylinder containing lead balls, called grinding media, at speeds of up to 700 revolutions per minute The ore is fed into the mill and as the cylinder rotates, the balls crush and grind the ore, 2023年4月23日 High mill filling reduces the grinding rate because the collision zone would be saturated Deniz [71] in his dry ball mill studies investigated the impacts of media filling on the kinetic break(PDF) Grinding Media in Ball MillsA Review ResearchGate2018年8月17日 Extreme temperatures, impact velocity, mill load, grinding media, ore types, and applications are some of the factors to be considered while installing new linersGrinding Mills — Types, Working Principle ApplicationsThe hammers accelerate the grain into breaker plates lining the housing of the mill Next, the grain encounters a changeable screen with a “close tolerance” gap between it and the rotating hammers Unique to hammer mill grinding is that material must pass through the screen to exit the mill This guarantees the final product maximum sizeDistillery Milling Efficiency Stedman Machine Company

MTW Trapezium Grinding Mill Zenith Crusher

MTW Trapezium Grinding Mill Features More Compact Structure The structure is more compact, occupying smaller floor area to reduce project investments Ecofriendly Production MTW Mill is equipped with a professional dust remover, so the operation is quite friendly to the surrounding environment Longer Service LifeLUM Ultrafine Vertical Mill LUM Ultrafine Vertical Grinding Mill sets grinding, drying, classifying and transportation as a whole and takes little space High Content of End Products; Intelligent Control; Easier Maintenance; Capacity: 315t/hLUM Ultrafine Vertical Grinding Mill Zenith Crusher2021年8月27日 Marketing is all about reaching your target audience at the right place and at the right time With more than 48 billion people using the internet today, internet marketing is one of the easiest What is Internet Marketing? Your Guide to Today’s Online Marketing2017年6月2日 Autogenous grinding (AG) and semiautogenous grinding (SAG) mills use the material to be ground as the grinding media Autogenous grinding mills use larger rocks to impact and break smaller rocks as the mill rotates How it Works: Crushers, Grinding Mills and Pulverizers

.jpg)

Gorilla Marketing Gorilla Mill Gorilla Mill

“People refer to tissues as Kleenex® – meaning, they use the brand name to refer to what is now a ubiquitous item We want Gorilla Mill to be synonymous with high performance drills / end mills, so we reinforce that message throughout our 2017年10月3日 Share with Facebook; Share with Twitter; Share with Google+; Share with LinkedIn; Posted: October 3, 2017 Grinding Mills Types, Working Principle Applications The purpose of this article is to explain the usage of Grinding Mill Types, Working Principle A crushing plant delivered ore to a wet grinding mill for further size reduction The size of crushed ore (F 80) was 40 mm and the SG 28 t/m 3 The work index of the ore was determined as 122 kWh/t A wet ball mill 1 m × 1 m was chosen to grind the ore down to 200 micronsGrinding Mill an overview ScienceDirect TopicsSeller Details DirectorMarketing (AME) Mr Alok Tiku Address 406, Kalpataru Plaza, Chincholi Bunder Road, Malad (West), Mumbai, Maharashtra, , IndiaExporter of Grinding Mill from Mumbai by GLONET MARKETING

Grinding Mill an overview ScienceDirect Topics

Grinding Mills Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 71 Introduction Grinding is the last stage in the comminution process where particles are reduced in size by a combination of impact and abrasion, either dry, or more commonly, in suspension in waterLABORATORY GRINDING MILL Model MBO1 Grinding chamber 160 mm in alloy steel Consists of 3armed rotor and grooved stator Drive power 11 kW with 3000 rpm speed for maximum grinding efficiency 3 mini Circular sieves (10, 15, 20 mm) External Dimensions 25x60x60 cm (WxHxD) Packing dimensions (WxDxH) 30x65x71 cm, 5560 kg Technical Datasheet Laboratory Grinding Mill Labopoliswhere T is the grinding time to reach a certain median particle size, K is a constant that depends upon the material being processed, the type of media and the particular mill being used, D is the diameter of the media, and N is the shaft rpm This equation shows that total grinding time is directly proportional to media or ball diameter and inversely proportional to the square root of Solids Choose the Right Grinding Mill Chemical ProcessingPDF On Jan 16, 2013, Gheorghe Voicu and others published Grinding Characteristics of Wheat in Industrial Mills Find, read and cite all the research you need on ResearchGateGrinding Characteristics of Wheat in Industrial Mills

.jpg)

The Influence of the Grinding Media Diameter on Grinding

2024年6月14日 The grinding process plays a crucial role in industry, allowing for the reduction of particle sizes of raw materials and substances to the required fineness—either as a finished product or for further technological processes The high demand for micro and nanopowders or suspensions is associated with the high energy consumption of the milling process Therefore, With a RETSCH grinding mill you can rely on more than a century of experience and the best of German engineering technology You will receive a product that is longlasting, reliable and engineered with an eye for detail Watch our company video and learn more about our solutions, profile and philosophyGrinding Mills for reliable size reduction tasks RETSCHSUPPLY, INSTALLATION, COMMISSIONING OF THE WORLD'S LARGEST GRINDING MILL by Alan Boughey Project Engineering Manager Newcrest Mining Ltd Australia Vytas Svalbonas Director of Engineering Technologies SUPPLY, INSTALLATION, COMMISSIONING OF THE FPJO, a joint venture between engineering firms Fluor and Petrosea, will be responsible for the construction of a third semiautogenous grinding (SAG) mill This mill will be located adjacent to the existing milling facilities at the Grasberg minerals district, which includes openpit and underground minesFluorPetrosea JV to construct grinding mill at Indonesia’s

A Review of the Grinding Media in Ball Mills for Mineral

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as The Vertical Grinding Mill is now CEapproved For very fine grinded coffee on our Diamant Vertical mills, we can supply the mills with special coffee stones in the size 400 mm and 500 mm Our mill in size 400 mm is available in a special version for milling oily products for example mustard – it must be dry and not wetDiamant Vertical Grinding Mill Engsko1992年1月1日 Most mathematical grinding mill models, including those in JKSimMet and the Morrell (1993) power model define filling as that of the cylindrical section assuming a smooth cylindrical shape(PDF) Prediction of grindingmill power ResearchGate2020年6月3日 The design of such grinding mills is extremely critical, requiring sophisticated software tools, proprietary calculation worksheets, and experienced technical engineers and drafters This blog will review how the mill design process has changed over the last 30 years While most of the changes have been positive, new issues and problems have risen in the How grinding mill design changed over the last 30 years

.jpg)

MTM MediumSpeed Grinding Mill Zenith Crusher

MTM MediumSpeed Grinding Mill Features Upgraded Structure The innovative change of the spring connection structure not only reduces shock of large materials on the aixs and bearing, but also enhances crushing strength of rollers Energysaving Production Its electricity consumption is lower than that of ball mill of the same level by over 60%2023年10月16日 International Sales Marketing Manager Currently with JSW Steel 14+ years of experience SAG Ball consumption is average at 500 g/t while Ball Mill grinding media 65 mm balls usage is 250 g/tUnderstanding the Science Art of Grinding Media Selection in 2024年8月8日 Grinding media, pivotal for the efficacy of the ball milling process, come in various materials, each offering unique characteristics and advantages tailored to specific applications Ceramic Balls: Composed of materials like Ball Mill Success: A StepbyStep Guide to Choosing 2016年11月7日 In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 Grinding Mills Common Types 911Metallurgist

Mill liners: grinding out a legacy Mining Technology

2022年4月25日 After that first installation experiment, carried out in the US in a 4 x 20’ Ball Mill, at the Nipissing Mine in Ontario, Canada, Trelleborg went on to patent the first Mill linings in 1953 and after thorough tests applied for Ball mills are the most commonly used type of grinding mill They work by rotating a cylinder containing lead balls, called grinding media, at speeds of up to 700 revolutions per minute The ore is fed into the mill and as the cylinder rotates, the balls crush and grind the ore, Understanding the operation of grinding mills in the mining and 2023年4月23日 High mill filling reduces the grinding rate because the collision zone would be saturated Deniz [71] in his dry ball mill studies investigated the impacts of media filling on the kinetic break(PDF) Grinding Media in Ball MillsA Review ResearchGate2018年8月17日 Extreme temperatures, impact velocity, mill load, grinding media, ore types, and applications are some of the factors to be considered while installing new linersGrinding Mills — Types, Working Principle Applications

.jpg)

Distillery Milling Efficiency Stedman Machine Company

The hammers accelerate the grain into breaker plates lining the housing of the mill Next, the grain encounters a changeable screen with a “close tolerance” gap between it and the rotating hammers Unique to hammer mill grinding is that material must pass through the screen to exit the mill This guarantees the final product maximum sizeMTW Trapezium Grinding Mill Features More Compact Structure The structure is more compact, occupying smaller floor area to reduce project investments Ecofriendly Production MTW Mill is equipped with a professional dust remover, so the operation is quite friendly to the surrounding environment Longer Service LifeMTW Trapezium Grinding Mill Zenith CrusherLUM Ultrafine Vertical Mill LUM Ultrafine Vertical Grinding Mill sets grinding, drying, classifying and transportation as a whole and takes little space High Content of End Products; Intelligent Control; Easier Maintenance; Capacity: 315t/hLUM Ultrafine Vertical Grinding Mill Zenith Crusher2021年8月27日 Marketing is all about reaching your target audience at the right place and at the right time With more than 48 billion people using the internet today, internet marketing is one of the easiest What is Internet Marketing? Your Guide to Today’s Online Marketing