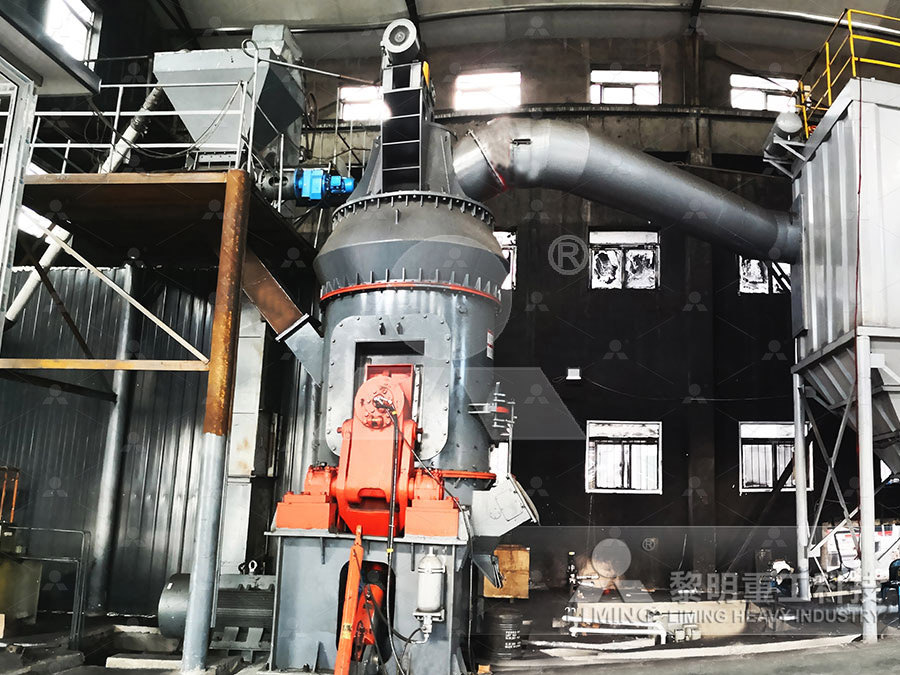

Raw mill hydraulic oil station

quadropol® thyssenkrupp Polysius Grinding Technologies

Finally, the raw mill product is the supplier for the kiln, means also responsible for the clinker quality A technical reliable solution within the production process includes our sepol® high Indirect and therefore gentle cooling processes are often preferable to direct Fines CoolerLoesche Automation combines cuttingedge machine technology and intelligent process control for optimum and efficient plant operation We offer our customers customised engineering PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTSVertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one It can be widely used in cement, electric power, metallurgy, chemical industry, nonmetallic Vertical raw mill Cement Plant

.jpg)

水泥厂常见设备英文名称 搜狐

2017年2月21日 油站 oil station 复位 reset 空气炮 air cannon 低温 low temp 电梯 lift 生料磨 raw mill 速度开关 speed switch 球磨 ball mill 磨辊 roller 水泥磨 cement mill 磨盘 disc This document is an instruction manual for operating and maintaining an Atox mill for raw meal It provides general information about the construction and operation of the mill, including the Operation and Maint A4P 20 en PDF MillHydraulic solutions by INTEGRAL HYDRAULIK are used for the raw material and hard crushing industry, eg coal crushers or cement mills An application example is a clinker cooler with Raw material crushing industryIn raw cement freestanding roller grinding oil terminal process, when through the mill chamber wind path to control temperature and pressure to meet requirements, that is ready to launch Design and Realization Of Roller Mill Control System ResearchGate

.jpg)

OK™ RAW MILL

• Simple hydraulic or hydropneumatic spring system • Drive systems Along with FLSmidth’s proven highefficiency RAR separator, the OK raw mill also incorporates the best VRM Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller mill for raw Application p rocess materialsThe vertical pregrinding mill is primarily composed of the electric motor, speed reducer, grinding wheel, grinding roller, hydraulic system, and the lubrication system The feeding material is Vertical PreGrinding Mill PENGFEI GroupSIMEC HOP series high pressure hydraulic oil press can extrude the cocoa butter out from the cocoa liquor The oil press consists of hydraulic pressure station, hydraulic cylinder, double raw material barrels, control cabinet and body To Make Cocoa Butter with Hydraulic Oil Press

Cement Mill, Vertical Raw Mill, Hydraulic System IQ Oil

Cement Mill, Vertical Raw Mill # 4, Hydraulic System 1 2 Oil Type: ISO VG 68, Tellus68 Capacity: 2 x 1,680 Liters THE PROBLEM Holcim Philippines Bulacan Plant is doing a quarterly machine condition monitoring through oil analysis On May 15, 2012, they found out that the oil in the Hydraulic System 1 2 on Raw Mill #4 was heav2018年10月1日 Prioress Mill Raw Water Pumping station (RWPS) is located in Rhadyr, near Llancayo, Monmouthshire, on the south bank of the River Usk It abstracts at a rate of up to 318 ML/day, and is the primary supply to Prioress Mill Raw Water Pumping Station (2018)Type: palm fruit/bench oil pressing, making machines Processing Material: Palm fruit Processing Capacity: 5120TPH Palm Oil Mill Plant Flow Chart Introduction: 1Palm oil mil process of bunch reception: as palm fruit unloading, cleaning, storage platform during palm oil mill processing, all hydraulic segmented discharge Palm oil mil bunch receptionPALM OIL MILL MACHINEthyssenkrupp is one of the few fullrange suppliers for the cement industry – from individual machines, all the way up to complete cement plants, and this since decades The market requirement is easy to define Present kiln lines have capacities of up to 10,000 tons per day Kiln lines of 12,000 tons per day were already built by polysius ® technologyquadropol® thyssenkrupp Polysius Grinding Technologies

Combination Digester And Hydraulic Press Systems In Traditional

TechnoServe Inc brought the digester, hydraulic press and spindle press into a rural community together with the business management training to create smallscale palm oil processing enterprises However there were engineering problems with plant layout and matching the throughput of machine componentsFeasibility Analysis of Investment in Palm Oil Processing Plant: Investment in palm oil processing plant has a stable and broad market development prospects, mainly reflected in the palm oil processing raw materials sufficient, large market demand, and large profit margins 1 Palm Fruit Raw Materials are SufficientPalm Oil Pressing MachineOK mill – the name says it all A complete size range, including the largest VRM available for raw grinding, ensure the ability to meet all possible capacity requirements in a single mill even for the hardest materials The wellknown reputation of the OK mill as a reliable machine that is easy to operate and maintain continues with the OK raw OK™ RAW MILLPalm Oil press station: Separate palm fruit and kernel, and oil press machine can obtain CPO (crude palm oil) and palm kernel The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production Process flow of palm oil pressing processing line:PALM OIL PRESSING STATION Palm Oil Factory

.jpg)

LT40WIDE Hydraulic Portable Sawmill WoodMizer USA

Professional portable sawmill with complete hydraulic log handling, gas/diesel power, 91m log diameter,64m log length, and production up to 13m³/hrThe OK™ Mill was originally designed for cement grinding In 2017 we released the OK™ vertical roller mill for raw materials grinding The OK™ Mill’s modular design comes with unique flexibility, showcasing parts commonality, where OK™ Raw and Cement MillPDF On Apr 8, 2019, Azam Akhbari and others published A study of palm oil mill processing and environmental assessment of palm oil mill effluent treatment Find, read and cite all the research (PDF) A study of palm oil mill processing andType: palm fruit/bench oil pressing, making machines Processing Material: Palm fruit Palm Oil Mill Plant Flow Chart Introduction: 1Palm oil mil process of bunch reception: as palm fruit unloading, cleaning, storage platform during palm oil Palm Oil Processing Machines Palm Oil Mill Machines

.jpg)

HYDRAULIC MILL Tri County Hardwood Floors

HYDRAULIC MILL: The Turner Hydraulic Mill comes standard with most all of our best options It features a box tube subframe, log bunks spaced every 24" apart, hydraulic back stops, log loaders, bull dog leveling jacks, power head lift, hydraulic controls, and a remote mounted off to the side of the machine as to not interfere with board handlingThis document is a user manual for a hydraulic station used in a cement plant It provides instructions on general provisions, safety considerations, product nameplate information, working principles, technical specifications, maintenance, quality assurance, troubleshooting, and reference drawings The hydraulic station is used to control the descent of a retaining wheel Rotary Kiln Hydraulic Oil Station User ManualThe Horomill used as a raw mill is claimed to combine the effectiveness of the vertical roller mill and the roller press with a very low pressure drop in the circuit It is also expected to offer some advantage in handling raw materials containing a higher percentage of quartz in comparison to vertical roller mills (Buzzi, 1997)Everything you need to know about cement Materials Preparation and Raw Atox Raw Mill: 36: Hydraulic Pump Station: Atox Raw Mill: Elswitch XS1M30MA250: 1: Atox Raw Mill: Strainer UCSE1219 212F: 1: Atox Raw Mill: Pump 74 cc PVH74 QIC Atox Raw Mill: Flowmeter UCC 26: 1: Atox Raw Mill: Oil level switch LS600550NO10: 1: Atox Raw Mill: Oil level switch LS600500NO10: 1: Atox Raw Mill: Temperatur ATOX125 ATOX135 ATOX155 ATOX175 Raw Coal Vertical Roller Mill

Hydraulic Oil Press Machine:Unlock Efficiency and Quality

Now, the most widely used sesame oil making machine is Screw Oil Press Machine, Hydraulic Oil Press Machine, Stone Mill Sesame Oil Fully automatic hydraulic oil press uses the oil pressure produced by the pump station to generate pressure between the piston and the top, so that the raw materials between the piston and the top are pressed Norwood Sawmills is the leading global manufacturer of portable sawmills and mobile forestry equipment with an industry leading 85+ innovative patentsNorwood Sawmills Global Leader in Portable Sawmills 1 Station Bunch Reception: as palm fruit unloading, cleaning, storage platform during palm oil mill processing, all hydraulic segmented discharge 2Palm Oil Mill Stations NoakMechCooks HD3238 portable sawmill Hydraulic mill at the right price! The HD3238 portable sawmill is built upon the heavy duty frame construction found in our manual MP32 sawmill model which incorporates 6x3x3/16" main frame HD3238 Hydraulic Portable Sawmill Cook's Saw Store

.jpg)

Palm Oil Pressing Station Palm Oil Mill Machine Leading

Palm Oil press station: Separate palm fruit and kernel, and oil press machine can obtain CPO (crude palm oil) and palm kernel The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production Process flow of palm oil pressing processing line:PENGFEI vertical pregrinding mill avails of forced lubrication method, The hydraulic oil station employs advanced followup control system to offer continuous inspection on the equipment operation When used for cement raw material and cement clinker pregrinding, the pregrinding machine can increase production capacity by 100% Vertical PreGrinding Mill PENGFEI GroupThe working principle of hydraulic system of vertical mill grinding equipment are as follows: the hydraulic device is mainly to raise and lower the grinding roller and setting, when lifting the grinding roller, hydraulic oil in the hydraulic cylinder can be a through the oil pump, switching valve into the cylinder, the cylinder because add hydraulic oil caused pressure increases, so the Hydraulic System Vertical Roller Mill Operation StudyModeavailable for raw grinding, ensure the ability to meet all possible capacity requirements in a single mill even for the hardest materials The wellknown reputation of the OK mill as a reliable machine that is easy to operate and maintain continues with the OK raw mill In addition to the roller design features, the OK mill retains the abilityOK RAW AND CEMENT MILL

.jpg)

Circulating Oil Systems: What You Should Know Machinery

The oil is collected from the bearing, as suggested by the name “circulating oil system” The oil is filtered and cooled (if necessary) while passing through the lubrication system The path the oil follows is shown in Figure 2 It begins with the oil coming into the reservoir through piping connected to an overflow port at the bearingIf you want to make RAW oil here is your Skip to content With more than 15 year of palm oil mill hydraulic application field expreriance, we can provide our service for many famous brand such Bosch Rexroth, STATION DIGESTER AND PRESS ~ Palm Oil Industrial Engineeringhydraulic palm oil mill screw press in nepalfeatures of our hydraulic oil press machine produce highquality health care oil / edible oil: it is designed for manufacturing high quality edible oil and health care oil, such as sesame oil (toasted sesame oil and cold press sesame oil), walnut oil, pineseed oil, peanut seed oil, peanut oil, almond oil etc; 100% physical oil pressing process: zero damage to the nutrient component ofkolkata hydraulic press oil mill hydraulic oil press for sesameSIMEC HOP series high pressure hydraulic oil press can extrude the cocoa butter out from the cocoa liquor The oil press consists of hydraulic pressure station, hydraulic cylinder, double raw material barrels, control cabinet and body To Make Cocoa Butter with Hydraulic Oil Press

.jpg)

Cement Mill, Vertical Raw Mill, Hydraulic System IQ Oil

Cement Mill, Vertical Raw Mill # 4, Hydraulic System 1 2 Oil Type: ISO VG 68, Tellus68 Capacity: 2 x 1,680 Liters THE PROBLEM Holcim Philippines Bulacan Plant is doing a quarterly machine condition monitoring through oil analysis On May 15, 2012, they found out that the oil in the Hydraulic System 1 2 on Raw Mill #4 was heav2018年10月1日 Prioress Mill Raw Water Pumping station (RWPS) is located in Rhadyr, near Llancayo, Monmouthshire, on the south bank of the River Usk It abstracts at a rate of up to 318 ML/day, and is the primary supply to Prioress Mill Raw Water Pumping Station (2018)Type: palm fruit/bench oil pressing, making machines Processing Material: Palm fruit Processing Capacity: 5120TPH Palm Oil Mill Plant Flow Chart Introduction: 1Palm oil mil process of bunch reception: as palm fruit unloading, cleaning, storage platform during palm oil mill processing, all hydraulic segmented discharge Palm oil mil bunch receptionPALM OIL MILL MACHINEthyssenkrupp is one of the few fullrange suppliers for the cement industry – from individual machines, all the way up to complete cement plants, and this since decades The market requirement is easy to define Present kiln lines have capacities of up to 10,000 tons per day Kiln lines of 12,000 tons per day were already built by polysius ® technologyquadropol® thyssenkrupp Polysius Grinding Technologies

Combination Digester And Hydraulic Press Systems In Traditional

TechnoServe Inc brought the digester, hydraulic press and spindle press into a rural community together with the business management training to create smallscale palm oil processing enterprises However there were engineering problems with plant layout and matching the throughput of machine componentsFeasibility Analysis of Investment in Palm Oil Processing Plant: Investment in palm oil processing plant has a stable and broad market development prospects, mainly reflected in the palm oil processing raw materials sufficient, large market demand, and large profit margins 1 Palm Fruit Raw Materials are SufficientPalm Oil Pressing MachineOK mill – the name says it all A complete size range, including the largest VRM available for raw grinding, ensure the ability to meet all possible capacity requirements in a single mill even for the hardest materials The wellknown reputation of the OK mill as a reliable machine that is easy to operate and maintain continues with the OK raw OK™ RAW MILLPalm Oil press station: Separate palm fruit and kernel, and oil press machine can obtain CPO (crude palm oil) and palm kernel The adoption of double screw and hydraulic oil press machine can greatly improving working efficiency during palm oil production Process flow of palm oil pressing processing line:PALM OIL PRESSING STATION Palm Oil Factory

LT40WIDE Hydraulic Portable Sawmill WoodMizer USA

Professional portable sawmill with complete hydraulic log handling, gas/diesel power, 91m log diameter,64m log length, and production up to 13m³/hr