Conical ore mill principle Conical ore mill principle Conical ore mill principle

How it Works The Conical Mill Project

The Conical Mill is believed to boost the efficiency of grinding by 27 times The mill works on a principle of automatic segregation of balls by size which allows for continuous grinding with no need for chambers2019年7月28日 Senieer offers highquality co mill (conical mill, comill, cone mill) for the global market The company supplies different models including movable comills, laboratory comills, and conical mills available integrated with high Co Mill, Conical mill, Comill, Cone Mill: Pharmaceutical 2017年3月8日 The conical mill, or what is more commonly known as the Hardinge mill, is one of those inventions which, if not fathered by actual necessity, was at least induced by the desire Hardinge Conical Mill – Grinding Efficiency Compared 911 Cone mills (also known as a conical mill or conical screen mill) are machines commonly used for milling processes in the pharmaceutical, food and related industries A cone mill offers numerous benefits over alternative milling Hanningfield I Cone Mills

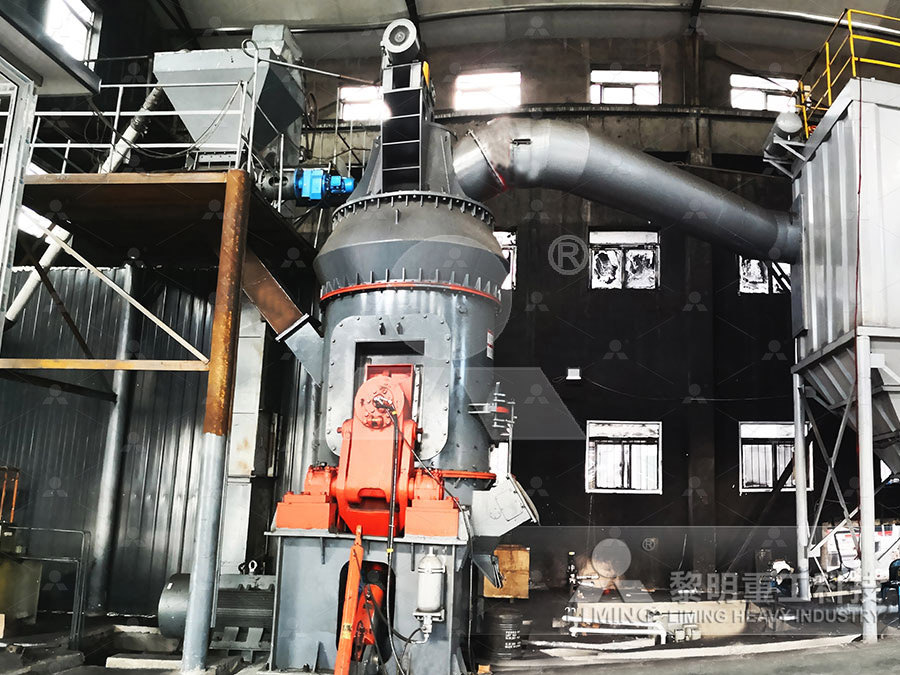

Hardinge Conical Ball Mill 911Metallurgist

2015年12月23日 The Conical Mill is now being used in all parts of the World, having substituted these latter types of machines in the grinding of ores and other materials Hardinge Conical Ball Mills are used to do the work of any Generally used for reducing material to a particle size as low as 180µm (80 mesh) a cone mill produces less dust and heat than alternative forms of milling The gentle grinding action and quick discharge of correctly sized particles ensure Cone Mill Conical Milling Machine for Size ReductionTongli Conical Ball Mill is a highefficiency grinding equipment Its unique 1520° inclination conical cylinder design effectively increases the grinding area by about 30% The builtin spiral Conical Ball Mill CEMENTL312 Operation principle The ball mill is a cylindrical drum (or cylindrical conical) turning around its horizontal axis It is partially filled with grinding bodies: cast iron or steel balls, or even flint Ball Mill an overview ScienceDirect Topics

Conical Mills (UnderDriven) Gansons

The UniMill Useries (M05U, M10U, M20U, M30U) utilises the current industry standard underdriven conical mill design, featuring a gearboxdriven impeller, rotating inside a screen This principle achieves comminution by compression or shearing of the particles between the impeller and surface of the screenA conical mill (or conical screen mill) is a machine used to reduce the size of material in a uniform manner It is an alternative to the hammermill or other forms of grinding millsAs the name implies, the conical mill varies in diameter from where the feed enters to where the product exits The conical mill operates by having the product being fed into the mill by gravity or vacuum A Conical mill WikipediaConical ball mill is a common ball grinding mill in mineral processing production Conical ball mill can grind all kinds of ores and other materials, not only can be used as a pregrinding machine for pregrinding, but also as a grinding Conical Ball Mill for Sale Wet Dry Conical Ball 2017年2月13日 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatmentBall Mills 911Metallurgist

All About Conical Mill

2020年9月11日 Conical Mill Working Principle The cone mill operates on the principle of rubbing force by cone blades and rotating the substance within a selected cone screen to get the required size after reduction First of all, the material is fed into the machine through the coneWorking Principle of Co Mills Bombay Engineering offers highquality co mill (conical mill, comill, cone mill) for the global market The company supplies different models including movable comills, laboratory comills, and conical mills available integrated with high shear mixer granulator, lifting columns, etc The Co Mill is used for a wide range of products and applicationsCo Mill, Conical mill, Comill, Cone Mill The Bombay Engg2012年6月1日 The mill is driven by a girth gear bolted to the shell of (ore, rock, etc) and the grinding media (balls this paper we provide a brief survey of the basic principles in modeling of the Grinding in Ball Mills: Modeling and Process ControlA conical mill is a specialized machine designed for the precise size reduction of various materials It involves a rotor known as an impeller that rotates inside a conical screen The material is fed into the cone mill machine, where it is reduced to the desired particle size primarily through impact, attrition, compression, and shearingConical Mill: Perfect for Size Reduction Aishin

Conical Mill , Co mill , Cone Mill Machine Shree Bhagwati

Cone mill can have an output speed of 15 kg – 150 kg per hour for the simpler versions 1003000kg/hr for the most advanced version series of the cone mill machine, mills are available with a wide range of screen and impeller tooling, helping to achieve the various required final particle sizes and throughputsConical mills are typically suitable for size reduction down to The conical ball mill is a commonly used ball mill grinder in industrial production It can realize the dry grinding and wet grinding of various ores and other grindable materials It is widely used in the beneficiation, building materials industry, Conical Ball Mill For Sale – Industrial Wet Dry 2020年3月20日 What is a Conical Mill? Conical milling (or cone milling) is one of the most common methods of milling in pharmaceutical manufacturing and associated industries In pharmaceutical production, Conical mills are typically How to Increase Productivity with Conical Milling2024年2月4日 This cone mill is different from the previous one you just read about It has increased throughput with 50 % more capacity than the other conventional cone mills It uses centrifugal force for milling and sifting Cone Mills SaintyTec

.jpg)

Conical Ball Mill CostEffective Conical Ball Mill

The Cone ball mill is the key equipment for crushing materials after they are crushed Widely used in cement, silicate products, new building materials, refractory materials, chemical fertilizers, ferrous and nonferrous metal beneficiation, glass ceramics, and other production industries, for wet grinding of various ores and other grindable materials2020年9月18日 For over 4 decades Quadro has been refining and improving conical milling equipment and technology It has become one of the most common methods used for powder processing in the pharmaceutical, chemical and food industries for size reduction, deagglomeration and delumping Due to these years of experience, we have the largest How to select a Conical MillThe working principle of a conical ball mill is based on impact and attrition Here’s a stepbystep outline of its operation: 1 Material to be ground is fed into the mill’s drum through a hopper The quantity of material and grinding media (balls) are adjusted based on the specific requirements of the milling process 2Lab conical ball mill description Hengcheng Mining Equipment HARDINGECONICALMILL FOREWORD TheHardingeConicalMillisadaptabletosomanypurposes,and itsde velopmenthasbeensorapid,thatawidedemandhasarisenforinformationasto THE HARDINCE CONICAL MILL Archive

.jpg)

Conical Mills (UnderDriven) Hanningfield

The UniMill Useries (M05U, M10U, M20U, M30U) utilises the current industry standard underdriven conical mill design, featuring a gearboxdriven impeller, rotating inside a screen This principle achieves comminution by compression or shearing of the particles between the impeller and surface of the screenA conical mill, also known as a conical screen mill or Comil, is a versatile machine used for particle size reduction, and granulation The name “conical” comes from the shape of the rotor and stator, which resemble a cone This design is particularly effective for the uniform size reduction of dry materials and wet granulation processesEverything You Need to Know About Conical Mills: Operations For instance, when processing iron ore, the use of a conical ball mill can increase the fineness index (80% less than 74 microns) by up to 15% This means that the material is ground more finely and more consistently, which can be crucial for subsequent processing stepsConical Ball Mill CEMENTLA mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are Mill (grinding) Wikipedia

Conical Ball Mill And Design Manufacturer Tongli Machinery

Mill Shell: The foundation of the conical ball mill, the mill shell, is a cylindrical structure made of premiumgrade steel Tongli heavy machinery is equipped with a large annealing furnace of 65x65x20m and a 65x65x20m large sandblasting room, which can conduct overall heat treatment and sandblasting on the ball mill to ensure the service life and appearance of the 2023年6月7日 Operating principle of dry autogenous mill: as shown in Fig 2a, the small grains from the feeding end evenly fall along surface A and into the center of the cylinder, and then spread sidewaysThe big grains have strong kinetic energy and are inclined to Autogenous Mill SpringerLinkThe Hanningfield UniMill BSeries (MIOB, M20B, M30B, M60B) utilises the current industry standard overdriven conical mill design, featuring a beltdriven impeller, rotating inside a screen (600 inclusive screen angle) This principle achieves comminution by compression and shearing of the particles between the impeller and surface of the Conical Mills (OverDriven) GansonsThe UniMill conical screen mill draws upon Hanningfield´s wealth of experience in size reduction for the process industries Conical screen or conemilling is ideal for achieving a fine, uniform particle size By combining high throughput and high efficiency, the low energy UniMill is perfect for the pharmaceutical, food, chemical and consumer goods industriesConical Screen Mills

.jpg)

Ball Mill an overview ScienceDirect Topics

where Ω E is the energycorrected ball wear rate, g per kWh, d R is the diameter of the largest balls in the mill (the recharge size), mm, K d E is the linear wear rate of balls, µm per kWh t −1, Ai is the Bond abrasion index determined in a laboratory test (unitless), F 80 is the feed 80% passing size of the ore, µm, and pH is the water acid/base measurement of the mill pulpElHARDINGECONICALMILL Fig I TheHardingeConicalMill TheHARDINGEMILL istheinventionofMrHWHardinge,a ConsultingEngineerofoverthirtyfiveyears THE HARDINCE CONICAL MILL2024年1月19日 The distinctive feature of the conical ball mill is its conical shape, which promotes efficient and uniform grinding Operators should familiarize themselves with the mill’s internal structure, including the conical sections, cylindrical sections, and feed and discharge openings Before operation, ensure the mill is correctly installed and How To Operate A Hardinge Conical Ball MillThe Quadro ® Comil ® Heritage Revolutionary milling technology has stood the test of time The Comil ® (Cone Mill) has advanced since its initial design over 30 years ago, but remains widely recognized as a leading milling technology, typically used for the following applications: Sizing wet granulated particles before drying; Sizing dry granules before the tableting stageQuadro Comil High Efficiency Milling

05 TO 15 TPH SMALL SCALE MINER’S BALL MILL

Ball Mill Capacity Table SMALL HARDINGE CONICAL BALL MILL The Hardinge Conical Ball Mill has been widely used with outstanding success in grinding many materials in a wide variety of fields The conical mill operates on the principle of an ordinary ball mill with a certain amount of classification within the mill itself, due to its shapeThe UniMill Useries (M05U, M10U, M20U, M30U) utilises the current industry standard underdriven conical mill design, featuring a gearboxdriven impeller, rotating inside a screen This principle achieves comminution by compression or shearing of the particles between the impeller and surface of the screenConical Mills (UnderDriven) GansonsA conical mill (or conical screen mill) is a machine used to reduce the size of material in a uniform manner It is an alternative to the hammermill or other forms of grinding millsAs the name implies, the conical mill varies in diameter from where the feed enters to where the product exits The conical mill operates by having the product being fed into the mill by gravity or vacuum A Conical mill WikipediaConical ball mill is a common ball grinding mill in mineral processing production Conical ball mill can grind all kinds of ores and other materials, not only can be used as a pregrinding machine for pregrinding, but also as a grinding Conical Ball Mill for Sale Wet Dry Conical Ball

.jpg)

Ball Mills 911Metallurgist

2017年2月13日 In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rod mill or ball mill, the ore in order to liberate the minerals In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment2020年9月11日 Conical Mill Working Principle The cone mill operates on the principle of rubbing force by cone blades and rotating the substance within a selected cone screen to get the required size after reduction First of all, the material is fed into the machine through the coneAll About Conical MillWorking Principle of Co Mills Bombay Engineering offers highquality co mill (conical mill, comill, cone mill) for the global market The company supplies different models including movable comills, laboratory comills, and conical mills available integrated with high shear mixer granulator, lifting columns, etc The Co Mill is used for a wide range of products and applicationsCo Mill, Conical mill, Comill, Cone Mill The Bombay Engg2012年6月1日 The mill is driven by a girth gear bolted to the shell of (ore, rock, etc) and the grinding media (balls this paper we provide a brief survey of the basic principles in modeling of the Grinding in Ball Mills: Modeling and Process Control

Conical Mill: Perfect for Size Reduction Aishin

A conical mill is a specialized machine designed for the precise size reduction of various materials It involves a rotor known as an impeller that rotates inside a conical screen The material is fed into the cone mill machine, where it is reduced to the desired particle size primarily through impact, attrition, compression, and shearingCone mill can have an output speed of 15 kg – 150 kg per hour for the simpler versions 1003000kg/hr for the most advanced version series of the cone mill machine, mills are available with a wide range of screen and impeller tooling, helping to achieve the various required final particle sizes and throughputsConical mills are typically suitable for size reduction down to Conical Mill , Co mill , Cone Mill Machine Shree Bhagwati