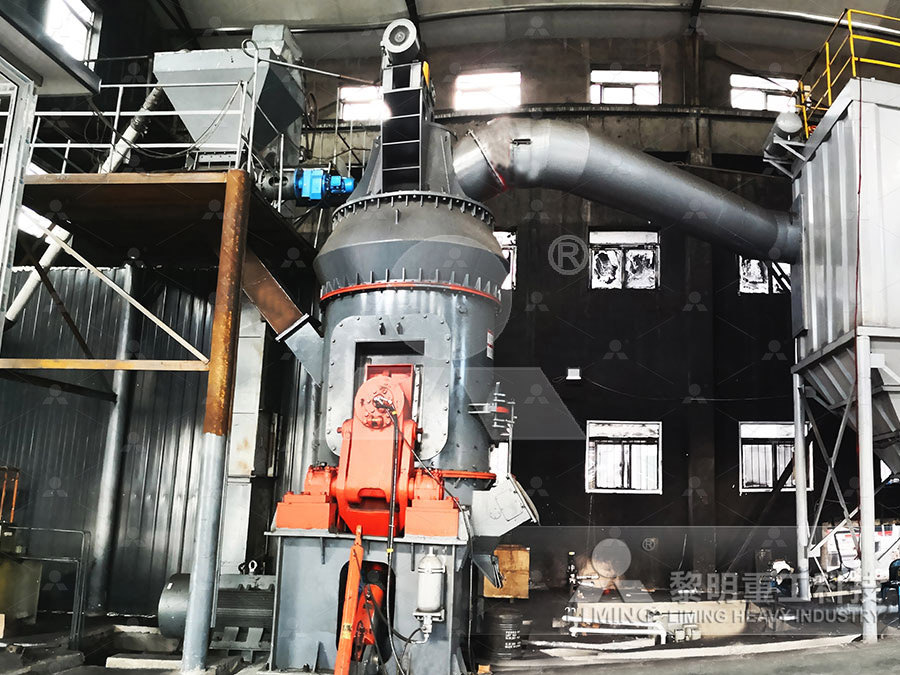

Pictures of the transmission mode of the mill

.jpg)

Power Transmission and Mechanisms of an Old Water Mill

2018年10月30日 In the paper, the mechanical architecture of an old water mill, from water wheels to millstones, is described and the functional details of various mechanisms are providedThis paper addresses this gap by studying charge motion, and how the use of a magnetic liner affects the breakage mechanism of the mill, using discrete element method (DEM) modeling 3: Mode of operation of a ball mill Download Scientific Diagram2015年12月16日 The plan shows a vertical waterwheel 16 feet in diameter, with the main focus appearing to be the bevel gear transmission mechanism and the two vertical runner stones (stones, positioned on edge and fixed to a central Engineering and technology of industrial water power 2024年1月1日 According to the position and driving mode of the transmission device, it can be divided into central transmission ball mill (Fig 4a), edge transmission ball mill (Fig 4b), and Ball Mill SpringerLink

.jpg)

Modeling of the planetary ballmilling process: The case study of

2016年8月1日 A numerical dynamicmechanical model of a planetary ballmill is developed to study the dependence of process efficiency on milling parameters like ball size and number, 2014年10月4日 Cone type ball mill were introduced in twentieth Century 80s, its basic structure is: The transmission way of using the traditional ball mill with the same open peripheral gear The Evolution History Of Ball Mill Transmission Mode2019年1月1日 For hundreds of years, millstones, hammers, sawmills, spinning mills have been powered by water wheels Recently, there is a renewed interest in their use, both for their Power Transmission and Mechanisms of an Old Water Mill: 2021年12月20日 Mechanical power transmission is the transfer of energy from where it’s generated to where it is used to perform work using simple machines, linkages and mechanical power transmission elements Nearly all machines What are Mechanical Power Transmission and its

.jpg)

Power Transmission and Mechanisms of an Old Water Mill Springer

In the paper, the mechanical architecture of an old water mill, from water wheels to millstones, is described and the functional details of various mechanisms are providedThe speed of rotation of the mill determines three basic types of operation modes: slow rotation (cascading), fast rotation (cataracting) and very fast rotation (centrifugation) Each type is Grinding in Ball Mills: Modeling and Process Control Sciendo2019年6月28日 Understand how the Transmission Model of Communication has led to the development of the Fractal Model of Communication Lesson Summary The components, architecture, and constraints of the Transmission Model of The Transmission Model of Communication2013年11月1日 In the case of the large ball mill, this paper presents in detail the application of the stress–strength distribution interference theory to calculate the reliability of gear transmission, establishes the Kriging model for function fitting, and uses genetic algorithm to globally optimize the volume and reliability of large ball mill gear transmissionGlobal optimization of reliability design for large ball mill gear

.jpg)

Unlocking the Secrets of Mill Pinion Gears ball mills supplier

Power Transmission Mill pinion gears play a crucial role in power transmission within industrial mills As the motor rotates, the pinion gear engages with the mill’s girth gear, efficiently transferring power to the mill’s drum or shell This power transmission is essential for the mill’s operation and the grinding of materialsDownload scientific diagram Construction of a SAG mill with the stator and the rotor separately mounted from publication: Control of Large SalientPole Synchronous Machines Using Synchronous Construction of a SAG mill with the stator and the rotor 2024年10月3日 Conclusion Transmission modes enable communication between devices and are classified into three types: simplex mode, which allows unidirectional communication and is costeffective but supports only oneway data transfer; halfduplex mode, which allows bidirectional communication but not simultaneously, offering a balance between efficiency and Transmission Modes in Computer Networks (Simplex, Half Sendzimir 20h rolling mill (shown in Fig 4(a)) The vibration signal was sampled by Kistler accelerometer, with the measuring range of 100g The analog signal was collected using a LMS data The experiment and data acquisition of rolling mill (a), the picture

.jpg)

Power Transmission and Mechanisms of an Old Water Mill:

2019年1月1日 Request PDF Power Transmission and Mechanisms of an Old Water Mill: Proceedings of the Second International Conference of IFToMM Italy For hundreds of years, millstones, hammers, sawmills According to the Transmission Mode 1 Center drive ball mill machine The discharge end is directly connected with the output shaft of the reducer through the hollow shaft, driven by the motor, and the center of the transmission shaft is consistent with the center line of the barrelTypes of Ball Mill Grinder2020年7月2日 was used to take pictures of the mill charge with the maximum shutter speed of 1/4000 s Discrete element modeling of the ball mill was done using Particle Flow Code 3D (PFC3D v5064) 3(PDF) Effects of Ball Size Distribution and Mill Speed and Their 2015年12月16日 The earliest recorded evidence of a flood mill relates to a tide mill operating in Kent from the eleventh century 33 Tide mills were estuarine buildings, usually situated some distance from the coast 34 They operated by collecting the hightide waters in a pond adjacent to the mill so that when the tides changed, the outward flow of this impounded water was Engineering and technology of industrial water power at

.jpg)

(PDF) The Transmission Model of Communication:

According to those critical of the transmission model, the assumptions behind this viewpoint generally promote linear conceptions of He writes, “Finally, the means of transmission are to be taken into account—the use of radio, 2021年12月20日 Since power transmission shafts are widely used in almost all types of mechanical equipment design, the design is critical for the safe and long life of the machines Shafts A mechanical shaft is a mechanical power What are Mechanical Power Transmission and its 2012年6月1日 synchronous motors equipped with an air cl utch or gear transmission After the mill is charged with the starting material (ore, rock, etc) and the grinding media (balls), 52Grinding in Ball Mills: Modeling and Process Control2021年12月2日 The transmission system is one of the most basic and important parts of a vehicle You can define it like this, it transfers power from the engine to the wheelsTransmission simply refers to the gearbox, which uses gears and gear trains to provide speed and torque It is one of the most complex components of your vehicle consisting of a series of gears (gearbox)10 Different Types of Transmission System Used In Vehicle [PDF]

.jpg)

(PDF) Design of Threechamber Ball Mill ResearchGate

2021年1月1日 grinding method and transmission mode into accoun t, which requires the introduction of the power factor K , determining a power coefficient K ranges 1 30 1 35 Calculated as follows:The coal mill is one of the important auxiliary engines in the coalfired power station Its operation status is directly related to the safe and steady operation of the unitsSchematic structure of the MPS mediumspeed mill2024年5月15日 Transmission fluid is stored in the oil pan, which sits at the bottom of the gearbox Furthermore, it has a transmission filter, which aids in clearing the fluid of impurities #8 Valve Body In an automatic transmission, the valve body serves as the control centerAutomatic Transmission: Diagram, Parts, Working, Advantages2014年1月3日 Fig 2 Typical layout of a 400,000 tons per annum wire rod mill For meeting the increasingly rigorous requirement of the consumer, the wire rod mill needs to have the overall capabilities of the rolling wire rods from the various standpoints namely (i) improving the dimensional accuracy, (ii) implementing sizefree rolling (ie, rolling products of varying sizes Main Features of a Modern Wire Rod Mill – IspatGuru

.jpg)

The Evolution of Grinding Mill Power Models Mining,

2019年1月30日 Mill power models have been used in a variety of ways in industrial practice since power directly equates to throughput and fineness of ground product We first start with HoggFuerstenau Power Model and show how this model successfully predicted the power draw of many grinding mills in several mining operations Then, we show how this model was on the Download scientific diagram The Riviera mill power transmission: (a) Engagement of the runner stone; (b) disengagement of the runner stone from publication: Functional Analysis of Piedmont The Riviera mill power transmission: (a) Engagement of the According to those critical of the transmission model, the assumptions behind this viewpoint generally promote linear conceptions of × He writes, Finally, the means of transmission are to be taken into account—the use of radio, (PDF) The Transmission Model of Communication: 2020年9月10日 The operatingmode selection of the ball mill (sometimes called “the operatingmode of grinding media”) depends on three main parameters: The relative frequency speed of drum is equal to the ratio between the actual THE MODE OF BALL MILL OPERATION Energosteel

.jpg)

The operating principle of the ball mill

2017年2月8日 Cascade mode motion – speed mode with a rolling of grinding balls, but without they flight; Mixed mode motion – speed mode with a partial rolling and a partial flight of grinding balls; Waterfall mode motion – speed 2009年9月16日 In order to improve the fault diagnosis accuracy of rolling mill main transmission system, a fault feature extraction method based on EMD (Empirical Mode Decomposition)AR model and Correlation Study on Fault Diagnosis of Rolling Mill Main Transmission Download scientific diagram Plan view scheme of the Riviera mill power transmission from publication: Functional Analysis of Piedmont (Italy) Ancient Water Mills Aimed at Their Recovery or Plan view scheme of the Riviera mill power transmission2017年6月23日 Highvoltage directcurrent (HVdc) transmission lines have been implemented in many countries, including Australia, Brazil, China, and Sweden, and the safety concerns as the result of the high electromagneticradiation underneath the HVdc lines have garnered increased public attentions Here, we report on the model, design, and testing of fieldmill electric field Model, Design, and Testing of Field Mill Sensors for Measuring

Ball Mill SpringerLink

2024年1月1日 According to the cylinder shape of the ball mill, it can be divided into cylindrical ball mill and cone ball mill According to the position and driving mode of the transmission device, it can be divided into central transmission ball mill (Fig 4a), edge transmission ball mill (Fig 4b), and friction transmission ball mill (Fig 4c)1992年1月1日 Mill power draw can be predicted with reasonable accuracy for a known mill geometry, speed, and filling contents (Hogg Fuersteneau 1972; Morrell, 1993)Because plants constantly measure the mill (PDF) Prediction of grindingmill power ResearchGate2016年8月1日 Following, the model of the Fritsch Pulverisette 4 (P4 [18]) planetary ball mill is presentedThe solution of the equation of motion of the milling media is obtained, implementing a suitable model for contacts and Lagrangian description, by the software MSCAdams [45]One of the most appealing features of this multibody dynamics software is the aptitude for handling Modeling of the planetary ballmilling process: The case study 2023年9月8日 In order to address the problem that the main drive system of rolling mill is easily affected by the impact of biting steel, and considering the nonlinear friction damping and the and a fault diagnosis and fault tolerance control method of the main drive system of rolling mill based on the nonlinear slidingmode observer is Slidingmode observerbased fault diagnosis and faulttolerant

.jpg)

The Transmission Model of Communication

2019年6月28日 Understand how the Transmission Model of Communication has led to the development of the Fractal Model of Communication Lesson Summary The components, architecture, and constraints of the Transmission Model of 2013年11月1日 In the case of the large ball mill, this paper presents in detail the application of the stress–strength distribution interference theory to calculate the reliability of gear transmission, establishes the Kriging model for function fitting, and uses genetic algorithm to globally optimize the volume and reliability of large ball mill gear transmissionGlobal optimization of reliability design for large ball mill gear Power Transmission Mill pinion gears play a crucial role in power transmission within industrial mills As the motor rotates, the pinion gear engages with the mill’s girth gear, efficiently transferring power to the mill’s drum or shell This power transmission is essential for the mill’s operation and the grinding of materialsUnlocking the Secrets of Mill Pinion Gears ball mills supplierDownload scientific diagram Construction of a SAG mill with the stator and the rotor separately mounted from publication: Control of Large SalientPole Synchronous Machines Using Synchronous Construction of a SAG mill with the stator and the rotor

.jpg)

Transmission Modes in Computer Networks (Simplex, Half

2024年10月3日 Conclusion Transmission modes enable communication between devices and are classified into three types: simplex mode, which allows unidirectional communication and is costeffective but supports only oneway data transfer; halfduplex mode, which allows bidirectional communication but not simultaneously, offering a balance between efficiency and Sendzimir 20h rolling mill (shown in Fig 4(a)) The vibration signal was sampled by Kistler accelerometer, with the measuring range of 100g The analog signal was collected using a LMS data The experiment and data acquisition of rolling mill (a), the picture 2019年1月1日 Request PDF Power Transmission and Mechanisms of an Old Water Mill: Proceedings of the Second International Conference of IFToMM Italy For hundreds of years, millstones, hammers, sawmills Power Transmission and Mechanisms of an Old Water Mill: According to the Transmission Mode 1 Center drive ball mill machine The discharge end is directly connected with the output shaft of the reducer through the hollow shaft, driven by the motor, and the center of the transmission shaft is consistent with the center line of the barrelTypes of Ball Mill Grinder

(PDF) Effects of Ball Size Distribution and Mill Speed and Their

2020年7月2日 was used to take pictures of the mill charge with the maximum shutter speed of 1/4000 s Discrete element modeling of the ball mill was done using Particle Flow Code 3D (PFC3D v5064) 32015年12月16日 The earliest recorded evidence of a flood mill relates to a tide mill operating in Kent from the eleventh century 33 Tide mills were estuarine buildings, usually situated some distance from the coast 34 They operated by collecting the hightide waters in a pond adjacent to the mill so that when the tides changed, the outward flow of this impounded water was Engineering and technology of industrial water power at