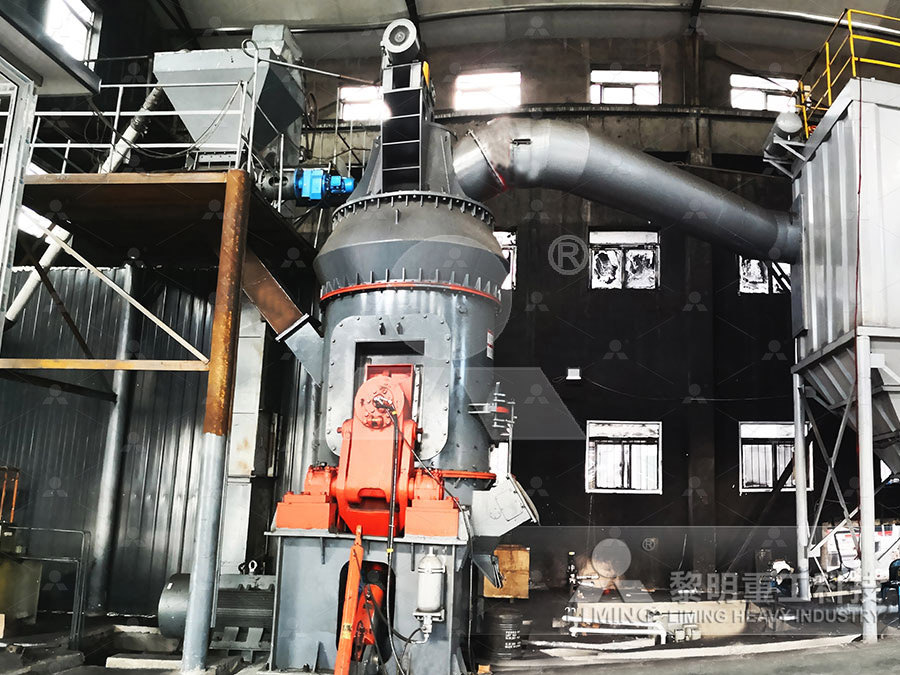

Ore Grinding Mill Working Environment

.jpg)

Ore Grinding SpringerLink

2023年7月20日 Moist grinding, a special grinding method, is used to prepare pellets for smelting According to the grinding medium features, ore grinding is mainly classified into ball grinding process, rod grinding process, and autogenous grinding process Ore grinding process falls A crushing plant delivered ore to a wet grinding mill for further size reduction The size of crushed ore (F 80) was 40 mm and the SG 28 t/m 3 The work index of the ore was determined as Grinding Mill an overview ScienceDirect Topics2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the A Review of the Grinding Media in Ball Mills for Mineral Processing operation (1) Structure parameters of grinding mill, including its specifications, model, aspect ratio, ore discharging method, and liner form (2) Various working parameters of grinding mill, Ore Grinding Methods and Process of Ore Grinding

Ultra Fine Grinding A Practical Alternative to Oxidative Treatment

In pit blasting, primary crushing, secondary crushing, SAG and ball milling are all able to exploit natural fracture planes in the ore allowing breakage along these features2017年9月1日 The objective of this work is to assess the influence of fine grinding in ball mills and stirred mills on valuable mineral liberation and particle shape characteristics of UG2 ore, a Fine grinding: How mill type affects particle shape characteristics 2022年8月31日 The main concern in ore beneficiation and processing plants is producing the desired product size with the lowest possible energy consumption It has been estimated that grinding consumes up to 4% of global electrical Grinding Modeling and Energy Efficiency in Ore/Raw Testwork was undertaken to develop a flowsheet that would maximise gold recovery from an ore containing 3 g/t Au and high levels of arsenic Treatment of the sulphide ore involves gravity Flowsheet Development of A Refractory Gold Ore To Minimise

.jpg)

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE

2019年4月16日 This paper brings together two separate studies, in which the vertical roller mill was used to grind two different precious metal ores, an epithermal gold deposit hosted in quartz vein from2018年8月17日 SemiAutogenous Mills/ SAG Mills (primary grinding mill) — these mills use grinding balls with forces of attrition, impact, and abrasion between grinding balls and ore particles that result in Grinding Mills — Types, Working Principle The significance of grinding environment on the flotation of UG2 ores CJ GREET Magotteaux Australia A large body of work exists discussing the impact of grinding media on mineral flotation Generally, the work indicates that a change to a less electrochemically active grinding environment has positive benefits on downstream processingThe significance of grinding environment on the flotation of UG2 oresThe significance of grinding environment on the flotation of UG2 ores CJ GREET Magotteaux Australia A large body of work exists discussing the impact of grinding media on mineral flotation Generally, the work indicates that a change to a less electrochemically active grinding environment has positive benefits on downstream processingThe significance of grinding environment on the flotation of UG2 ores

.jpg)

CLUM Ultrafine Vertical Grinding Mill

CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultrafine industrial ore grinding equipment that integrates grinding, grading, powder collection and conveying +年6月3日 The principal method of grinding in a Tower mill is attrition (scrubbing of particles off material being ground), with the possibility of some shearing and 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Tower Mill Operating Work IndexTower Mill Operating Work Index 911MetallurgistWet pan mill equipment reduces dust generation, improves the working environment, and helps to evenly mix and refine materials; it uses the lubrication of water to reduce energy consumption and improve grinding efficiency; by adjusting the grinding time and the parameters of the grinder, the crushing fineness of the material can be controlled to meet the needs of different industries; it Wet Pan Mill Gold Mining Wet Pan Mill Ore Grinding Find your ore mill easily amongst the 42 products from the FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding chemical industry, etc, it has two ore grinding Compare this product Remove from comparison tool ball grinding millOre mill, Ore grinding mill All industrial manufacturers

Grinding Modeling and Energy Efficiency in Ore/Raw Material

2022年8月31日 The order of influencing factors of the two ores is as follows: grinding time > filling ratio > grinding concentration For Tongkeng ore, the optimized grinding conditions are grinding time 54 min, grinding concentration 67% and filling ratio 35% For Gaofeng ore, the optimized grinding conditions are grinding time 38 min, grinding 2018年6月18日 Demand for energyefficient grinding pretreatment methods will grow in the future considering the depletion of highgrade resources and stringent environmental constraints related to reject disposalOre Pretreatment Methods for Grinding: Journey and ProspectsType of Mill Typical Lower Grind Size P80 µm Power Intensity kW/m3 Ball Mill 75 20 Tower Mill 20 40 UFG Mill 5 280 Two basic types of UFG mills are available, the vertical stirred mill and the horizontal stirred mill Both use rotating stirrers within a stationary mill shell to impart kinetic energy to a fine media charge (usually sand)Ultra Fine Grinding A Practical Alternative to Oxidative 2021年9月23日 The barite industrial ultrafine grinding mill is a lowenergy, highefficiency nonmetallic ore milling equipment It can process ultrafine powder of 1503000 mesh It is often used for grinding more than 100 kinds of non Barite Industrial Ultrafine Grinding Mill SBM

.jpg)

Impact on Grinding Mill Design of Recent New Discoveries

2021年1月18日 includes a Bond Ball Mill Work Index test on SAG ground ore from the first stage of the test a heavy steel chamber and grinding in a semiautogenous environment The results are totally different Paper for the SME, Tucson, AZ, September, 2009 Page 3 of 9 2019年4月16日 Conference: Applying a Successful Technology from the Cement Industry: Advantages of Grinding Ore in a VerticalRollerMill; At: Antalya, Türkey(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE The Autogenous Mill, also known as AG Mill, is a type of grinding mill used in the mining industry This machine uses ore and rock itself as grinding media to perform its job Unlike other types of mills that use steel balls or rods for grinding materials, the Autogenous Mill relies on the material being ground to break itself into smaller piecesUnderstanding the SAG Mill in Copper Ore Mining Processapplied sciences Article Grinding Kinetics Adjustment of Copper Ore Grinding in an Innovative Electromagnetic Mill Marta WołosiewiczGłab˛ 1,*, Paulina Pieta˛ 1, Dariusz Foszcz 1, Szymon Ogonowski 2 ID and Tomasz Niedoba 1 1 Department of Environmental Engineering and Mineral Processing, Faculty of Mining and Geoengineering, AGH University of Science and Grinding Kinetics Adjustment of Copper Ore Grinding in an

.jpg)

Processing of Magnetite Iron Ores–Comparing Grinding Options

Ore grade Drop weight index (DWi) % FeT 322 kWh/m3 111 Ore specific gravity 340 Concentrate specific gravity 430 t/m3 201 kWh/t 172 Bond rod mill work index (BRWi) kWh/t 177 Bond crushing work index (BCWi) Bulk density Bond ball mill work index (BBWi) Bond abrasion index (BAi) 03 kWh/t 206 Point load index (PLI) MPa 148 Unconfined compressive 2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plant2021年6月17日 PDF It is a wellknown fact that the value of the Bond work index (wi) for a given ore varies along with the grinding size In this study, a Find, read and cite all the research you need on (PDF) Variability Study of Bond Work Index and Grindability Index Vertical Roller Mill Working Principle low wear, long life, environmental protection and energy saving, simple operation, intelligent control system, easy maintenance, and the fineness can be freely adjusted between 150 Illite ore industrial grinding mill machine can grind illite into powder up to 3000 mesh, including ultrafine Vertical Roller Mill SBM Ultrafine Powder Technology

Grinding Mills and Their Types IspatGuru

2015年4月9日 Grinding Mills and Their Types satyendra; April 9, 2015; 12 Comments ; autogenous grinding, ball mill, grinding mills, hammer mill, rod mill, roller mill, SAG,; Grinding Mills and Their Types In various fields of the process industry, reduction of size of different materials is a basic unit operation2015年4月15日 Bond rod mill grindability tests at 10 or 14 mesh for Work Index For each ball mill grinding step, a Bond ball mill grindability test for Work Index at one mesh size coarser than the desired 80% passing size and at the mesh What Ore Testing is Required For Mill SelectionThe ball mill operates by crushing, grinding, and mixing ores through the action of steel balls rotating inside the mill When the cylindrical mill rotates, the ores are carried along with the steel balls It is through the process of mutual collisions, friction, and wear that the ores are ground down to the desired particle sizeThe role of ball mill in iron ore processing Grinding Milloperation (1) Structure parameters of grinding mill, including its specifications, model, aspect ratio, ore discharging method, and liner form (2) Various working parameters of grinding mill, including fraction of critical speed for grinding mill, filling rate for grinding mill, grinding concentration,grindingcycleload,etc(3)AndgrindOre Grinding Methods and Process of Ore Grinding

Grinding Mill Liners 911Metallurgist

2015年8月6日 Noise: Noise control is becoming a major factor in the workplace and rubber mill liners result in a quieter environment, particularly in primary mills with larger grinding media Tight Seal : Because rubber liners can be produced to relatively close tolerances and rubber is deformable, a rubber liner system is designed as a tight liner2024年1月12日 How Overflow Type Ball Mill Works Material Feed: The raw material is fed into the mill at one end and travels through the mill by rotation The feed enters the mill at a specific rate, ensuring a controlled grinding process; Grinding Process: As the mill rotates, the grinding media crushes and grinds the material into a fine powder The wet conditions enhance the Wet Overflow Type Ball Mill and ApplicationsGrinding Mills: Ball Mill Rod Mill Design PartsCommon types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed herePhotographs of a glass ended laboratory ball mill show Grinding Mills 911MetallurgistOre pretreatment methods for grinding: journey and prospects Veerendra Singh a, Prashant Dixit , R Venugopalb, and K Bhanu Venkatesha aResearch and Development Department, Tata Steel, Jamshedpur Ore pretreatment methods for grinding: journey and prospects

.jpg)

Processing of Magnetite Iron Ores–Comparing Grinding Options

2009年1月1日 Bond ball mill work index (BBWi) kWh/t 172 ore mining, Ministry of Environment and Forest, Government of India characterized by a subsequent circuit of rod and ball mill grinding2022年8月24日 The method allows capturing variations in mill filling and mill speed, whereas effects such as ball size distribution and solids concentrations require conducting batch tests incorporating their Multicomponent modeling and simulation of the Minas Rio iron ore 2018年8月17日 SemiAutogenous Mills/ SAG Mills (primary grinding mill) — these mills use grinding balls with forces of attrition, impact, and abrasion between grinding balls and ore particles that result in Grinding Mills — Types, Working Principle The significance of grinding environment on the flotation of UG2 ores CJ GREET Magotteaux Australia A large body of work exists discussing the impact of grinding media on mineral flotation Generally, the work indicates that a change to a less electrochemically active grinding environment has positive benefits on downstream processingThe significance of grinding environment on the flotation of UG2 ores

The significance of grinding environment on the flotation of UG2 ores

The significance of grinding environment on the flotation of UG2 ores CJ GREET Magotteaux Australia A large body of work exists discussing the impact of grinding media on mineral flotation Generally, the work indicates that a change to a less electrochemically active grinding environment has positive benefits on downstream processingCLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultrafine industrial ore grinding equipment that integrates grinding, grading, powder collection and conveying +17CLUM Ultrafine Vertical Grinding Mill2016年6月3日 The principal method of grinding in a Tower mill is attrition (scrubbing of particles off material being ground), with the possibility of some shearing and 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Tower Mill Operating Work IndexTower Mill Operating Work Index 911MetallurgistWet pan mill equipment reduces dust generation, improves the working environment, and helps to evenly mix and refine materials; it uses the lubrication of water to reduce energy consumption and improve grinding efficiency; by adjusting the grinding time and the parameters of the grinder, the crushing fineness of the material can be controlled to meet the needs of different industries; it Wet Pan Mill Gold Mining Wet Pan Mill Ore Grinding

Ore mill, Ore grinding mill All industrial manufacturers

Find your ore mill easily amongst the 42 products from the FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding chemical industry, etc, it has two ore grinding Compare this product Remove from comparison tool ball grinding mill2022年8月31日 The order of influencing factors of the two ores is as follows: grinding time > filling ratio > grinding concentration For Tongkeng ore, the optimized grinding conditions are grinding time 54 min, grinding concentration 67% and filling ratio 35% For Gaofeng ore, the optimized grinding conditions are grinding time 38 min, grinding Grinding Modeling and Energy Efficiency in Ore/Raw Material 2018年6月18日 Demand for energyefficient grinding pretreatment methods will grow in the future considering the depletion of highgrade resources and stringent environmental constraints related to reject disposalOre Pretreatment Methods for Grinding: Journey and ProspectsType of Mill Typical Lower Grind Size P80 µm Power Intensity kW/m3 Ball Mill 75 20 Tower Mill 20 40 UFG Mill 5 280 Two basic types of UFG mills are available, the vertical stirred mill and the horizontal stirred mill Both use rotating stirrers within a stationary mill shell to impart kinetic energy to a fine media charge (usually sand)Ultra Fine Grinding A Practical Alternative to Oxidative