Source manufacturer water mill

.jpg)

Water Mill an overview ScienceDirect Topics

Water has been used for mechanical power generation in water mills, sawmills, and other machines for thousands of years Hydraulic turbines were developed and steadily improved Looking for surface water mill factory direct sale? You can buy factory price surface water mill from a great list of reliable China surface water mill manufacturers, suppliers, traders or plants Surface Water Mill Factory, Custom Surface Water Mill OEM/ODM 2023年3月17日 A water mill is a construction that uses the power of water to turn a wheel or turbine for the mechanical process, such as milling for flour, lumber sawing, or textile production facilities, as well as metal shaping, such Water Mills Encyclopedia MDPIYou can buy factory price water mill from a great list of reliable China water mill manufacturers, suppliers, traders or plants verified by a thirdparty inspector Source with confidence Supplier Water Mill Factory, Custom Water Mill OEM/ODM Manufacturing

From the water wheel to turbines and hydroelectricity

2017年8月1日 While in England the use of coal replaced hydropower after 1830 for cotton manufactures, water power remained the main source of energy for cotton spinning mills in China Water Mill wholesale Select 2024 high quality Water Mill products in best price from certified Chinese Sand Mill manufacturers, China Mill suppliers, wholesalers and factory on Water Mill MadeinChinaFully operational waterpowered grist mill Founded in 1767, moved 500 feet downstream to current location in 1819 According to legend, Revolutionary War British troops seized the List of watermills in the United States Wikipedia2017年3月29日 In general, the wastewater from a pulp mill is subjected to primary and secondary wastewater treatments, from which are generated the respective PPMSs that correspond to about 70% and 30% of the Pulp Mill Wastewater: Characteristics and

From the water wheel to turbines and hydroelectricity Technological

2017年8月1日 The vertical water wheel was born somewhere in the Middle East during the first century BC, as suggested by the earliest textual mention by Strabo [2] of a water mill in Mithridate's palace in Cabeira (north of presentday Turkey) Water wheels further developed to a large extent in the empires of Rome and of China during the first to third centuries ACClosedloop systems recirculate treated water within the manufacturing process, reducing the demand for freshwater intake and mitigating environmental impact Closedloop systems are designed to maximize water reuse, employing Latest Innovations Driving Water Treatment in Paper 2001年4月1日 It is observed that a number of operations can be performed by the horizontal water mill with the help of various machines, such as flour mill, rice huller oil expeller etc, while only one Evaluation of Water Mills as a Source of Renewable Energy2019年5月3日 Highquality water is vital for many industry applications, from cooling towers at a manufacturing plant to irrigation systems at a large agricultural operation Most commercial businesses and industrial plants pull water from the local municipality to power appliances and equipment, feed lawns and provide drinking water onsite However, the municipal water Producing Clean Water for Isolated Steel Mill Cooling Towers

WATER MANAGEMENT IN THE STEEL INDUSTRY worldsteel

water plays in its manufacturing operations and also its value to society Even though the steel industry uses large quantities of water, very little of that water is actually consumed as most is reused or returned to source For example, sea water is almost exclusively used in cooling operations and the lossThe Watermill A watermill is a structure that uses a water wheel to drive a mechanical process such as grinding flour, lumber or textile production, or metal shaping A water mill that generates electricity is usually called a hydroelectric power plant A Brief History The first documented use of a water mill was in the first century BC and the technology spread quite quickly across the Watermill Take a detailed look at the use of watermillsThe Galashiels Manufacturers’ Corporation, established in 1777, decided to construct a “mill lade”, a system diverting water from the Gala Water This provided a constant source of energy to drive the water wheels which in turn provided the power to operate the mill machineryThe Gala Water and Mill Lade Galashiels HeartlandWater Mill Products, Inc 2482 BROTHERWOOD CV COLLIERVILLE, TN 380178972 US 6316643210 svandewmp@gmail Water Mill Products Birdsall Hoof Care

CASE STUDY Nepal Improved Water Mills INFORSE

There are about 25,000 traditional water mills, comprising a major source of rural energy for agroprocessing across the country They have been used for centuries by the communities in the hills and mountain regions of Nepal Improved Water Mill The Improved Water Mill (IWM) is a modified version of the traditional water mill It is an2018年12月1日 Therefore, gravity water wheels can be considered attractive and competitive hydropower converters Their performance characteristics allow for the efficient exploitation of low head sites, also when the flow rate is variable Water wheels can be installed both at old mill sites and in canals for electricity generationGravity water wheels as a micro hydropower energy source: A If you’re talking about Parboiled Rice, Steamed Rice, Paddy Drying, or other Rice milling processes, much of the manufacturing process involves the use of steam or hot water created by industrial boilers As a result, selecting a boiler system for a Rice Mill should be done with cautionRice Mill Industry THERMODYNE2020年11月22日 fresh water (60 230m 3 per ton of paper production), resulting in the generation of large amounts of wastewater [1] Uma Shankar Singh , Central Pulp Paper R e s earch Institute(PDF) Characteristics and Treatment of Pulp and Paper Mill

.jpg)

Boat mills: water powered, floating factories resilience

2010年11月22日 The waterwheel was seen as the most important power source in the world, from the Middle Ages to the end of the nineteenth century When smaller streams became saturated, medieval engineers turned their attention to larger rivers, eventually leading to the development of the hydropower dams that still exists today Lesser known are the intermediate 2021年6月18日 The Water Mill is a passive generator that produces energy from water Tier Generation Rate Output Storage ; Basic : 0104 E/t 1: 32 E/t : 1 kE : 1 Generates 01 E/t per adjacent water block Recipe Usage Requires water blocks touching 14 of its' side faces Outputs energy on all sidesWater Mill [Tech Reborn]Since cane consists of about 7075% water, cane sugar mill processes more water than sugar All the water entering a mill must also leave it in one form or another The sugar industry is a major water user and wastewater producer In this work are identify the structure of the main water and wastewater circuit in a sugar manufacturing processWater and Wastewater Management in a Sugar Process SECTION 2 – GENERAL CHARACTERISTICS OF WATER SOURCES PPO WATER USERS QUALITY REQUIREMENTS 21 – WATER SOURCES AND GENERAL CHARACTERISTICS Water for PPO comes from one of two sources Surface water sources such as rivers and lakes or ground water sources such as underground wellsMILL WATER QUALITY IN THE PULP PAPER INDUSTRY:

43.jpg)

Boat Mills: Water Powered, Floating Factories LOW←TECH

2010年11月16日 Granted, boat mills are curious things Some look like paddlewheel riverboats, but in fact they are exactly the opposite A waterwheel can be used in two ways: to create energy from moving water, as is the case with the water mill, or to apply energy to water with the result of motion, as is the case with a paddlewheel boatIn the manufacturing process, pulp is introduced into a paper machine where it is shaped into a paper web and water is extracted through pressing and drying stages Pressing involves removing water from the sheet by applying force This process employs a specialized type of felt, distinct from traditional felt, to absorb the waterPulp and paper industry Wikipedia2018年5月21日 Tom Neltner, JD, Chemicals Policy Director, and Maricel Maffini, PhD, Independent Consultant Update: See June 21, 2018 QA blog on PFAS at textile mills and environmental permits Across the country, communities are grappling with how to manage contamination of drinking water by perfluorinated alkyl substances (PFASs), a class of Paper mills as a significant source of PFAS contamination, but 2019年7月29日 Mill workers using carding engines c 1800 Arkwright patented a carding engine in 1774 Carding is the process of combing out the cotton fibres, ready to be spun Once Arkwright's water frames increased the amount of cotton that could be spun, manufacturers also needed powered machines to get enough cotton ready for spinningRichard Arkwright Science and Industry Museum

.jpg)

Pulp and paper mill wastes: utilizations and prospects

2021年4月29日 Besides fly ash, sawdust from the pulp and paper mill waste is another potential source for the manufacturing of biocomposite (Zhang et al 2020) Sawdust which mainly constitutes cellulose can be used in blending for The main steps of the paper manufacturing process are raw material preparation, digestion, pulping, and bleaching (Figure 4) Raw material preparation, pulping, washing, screening, bleaching, and coating are the main pollution sources of pulp and paper mill All the production stage process water has toxicPAPER INDUSTRIES CONCERN WATER POLLUTION: A REVIEWMill owners had a range of power sources available, each with benefits and disadvantages Up until the 19th century, numerous other inventors and engine manufacturers contributed to the growth of steam power in Britain (2013) 'Tectonics, geomorphology and water mill location in Scotland, and the potential impacts of mill dam failure'Scottish water mills website National Library of ScotlandBlack Berkey ® Black Berkey® Elements address over 200+ potential contaminants commonly found in drinking water sources BUYER BEWARE How to verify the authenticity of Black Berkey® Elements and Ltd (NMCL) is the manufacturer of the Berkey water filter a line of gravityfed water filtration and purification products Berkey® Systems Berkey water filter manufacturer New Millennium Concepts, Ltd

Mill History Cromford Mills

Cromford Mills is the Northern Gateway to the Derwent Valley Mills UNESCO World Heritage Site Built in 1771 by Sir Richard Arkwright, it is the world’s first successful waterpowered cotton spinning mill and a cornerstone of the Industrial Revolution Immerse yourself in the remarkable history of Cromford Mills and discover what life was like in the 18th centuryThe stream that powers the water mill suddenly lost strength and the main wheel has stopped The water also acquired a slightly green coloration Something has happened The town is in danger because the mill will not work and the water supply is almost dry Don Yara hires the adventurers to travel upstream and discover the source of the problem250 Water Mill Elven Tower AdventuresSources of effluent in a Sugar industry Sugar is made by the processes of milling, clarification, evaporation, crystallisation and centrifugation Here are some sources which lead to the generation of effluent, which include, 1: Mill House Effluent is generated by cleaning and washing, juice leakages and spillages of mill bearing waterEffluent Treatment Plant (ETP) for Sugar Mill/IndustryCromford Mill is the world's first waterpowered cotton spinning mill, developed by Richard Arkwright in 1771 in Cromford, Derbyshire, EnglandThe mill structure is classified as a Grade I listed building [1] It is now the centrepiece of the Derwent Valley Mills UNESCO World Heritage Site, and is a multiuse visitor centre with shops, galleries, restaurants and cafesCromford Mill Wikipedia

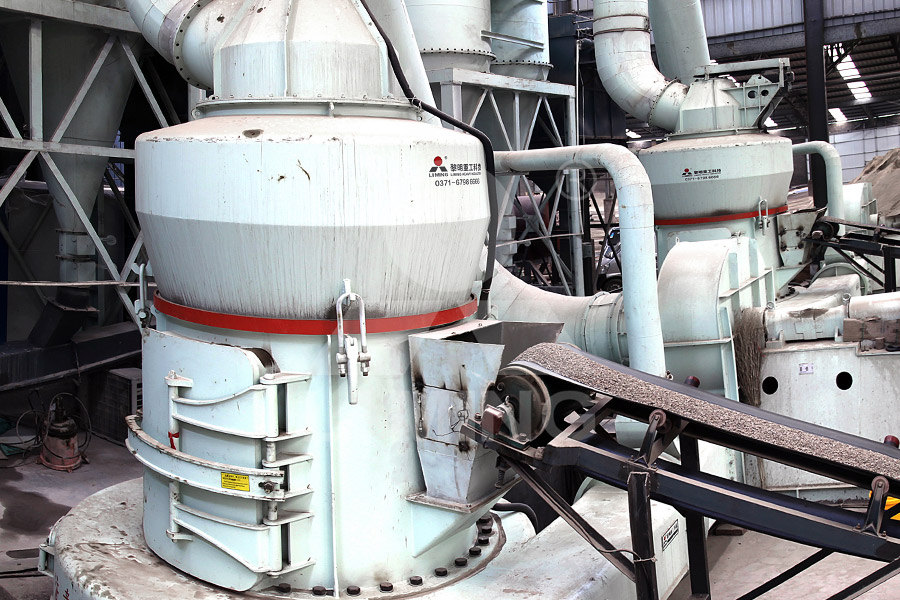

Stone Crusher Manufacturer, Water Well Drilling Rig, Ball Mill

Stone Crusher, Water Well Drilling Rig, Ball Mill manufacturer / supplier in China, offering Hydraulic DTH Blasting Core Rock Borehole Rotary Water Well Horizontal Directional Drill Drilling Rig, 300m/400m/600m/800m Portable Geotechnical Hydraulic Crawler Type Blast Borehole Mining Rock Water Well Drilling Rig Diamond Core Drilling Rig, Henan 90138mm CE ISO Rig 2017年3月29日 In general, the wastewater from a pulp mill is subjected to primary and secondary wastewater treatments, from which are generated the respective PPMSs that correspond to about 70% and 30% of the Pulp Mill Wastewater: Characteristics and 2017年8月1日 The vertical water wheel was born somewhere in the Middle East during the first century BC, as suggested by the earliest textual mention by Strabo [2] of a water mill in Mithridate's palace in Cabeira (north of presentday Turkey) Water wheels further developed to a large extent in the empires of Rome and of China during the first to third centuries ACFrom the water wheel to turbines and hydroelectricity Technological Closedloop systems recirculate treated water within the manufacturing process, reducing the demand for freshwater intake and mitigating environmental impact Closedloop systems are designed to maximize water reuse, employing Latest Innovations Driving Water Treatment in Paper

Evaluation of Water Mills as a Source of Renewable Energy

2001年4月1日 It is observed that a number of operations can be performed by the horizontal water mill with the help of various machines, such as flour mill, rice huller oil expeller etc, while only one 2019年5月3日 Highquality water is vital for many industry applications, from cooling towers at a manufacturing plant to irrigation systems at a large agricultural operation Most commercial businesses and industrial plants pull water from the local municipality to power appliances and equipment, feed lawns and provide drinking water onsite However, the municipal water Producing Clean Water for Isolated Steel Mill Cooling Towerswater plays in its manufacturing operations and also its value to society Even though the steel industry uses large quantities of water, very little of that water is actually consumed as most is reused or returned to source For example, sea water is almost exclusively used in cooling operations and the lossWATER MANAGEMENT IN THE STEEL INDUSTRY worldsteel The Watermill A watermill is a structure that uses a water wheel to drive a mechanical process such as grinding flour, lumber or textile production, or metal shaping A water mill that generates electricity is usually called a hydroelectric power plant A Brief History The first documented use of a water mill was in the first century BC and the technology spread quite quickly across the Watermill Take a detailed look at the use of watermills

The Gala Water and Mill Lade Galashiels Heartland

The Galashiels Manufacturers’ Corporation, established in 1777, decided to construct a “mill lade”, a system diverting water from the Gala Water This provided a constant source of energy to drive the water wheels which in turn provided the power to operate the mill machineryWater Mill Products, Inc 2482 BROTHERWOOD CV COLLIERVILLE, TN 380178972 US 6316643210 svandewmp@gmail Water Mill Products Birdsall Hoof CareThere are about 25,000 traditional water mills, comprising a major source of rural energy for agroprocessing across the country They have been used for centuries by the communities in the hills and mountain regions of Nepal Improved Water Mill The Improved Water Mill (IWM) is a modified version of the traditional water mill It is anCASE STUDY Nepal Improved Water Mills INFORSE