Fluorite Grinding

.jpg)

On the impact of grinding conditions in the flotation of semi

2023年7月1日 We relate grinding conditions to changes in pulp chemistry and particle surface properties and assess their impact on upgrading We studied three nonsulfide ores with 2021年2月15日 In this study, to enhance the flotation of finegrained fluorite, a strategy that combines simultaneous grinding and surface modification via ballmilling and controlled gas Intensifying finegrained fluorite flotation process with a The fluorite ore beneficiation methods are gravity separation and flotation Fluorite ore gravity separation is suitable for highergrade fluorite ore blocks and particle ores with a particle size of 620mmFluorite Beneficiation Process JXSC MineralIn this study, the effect of grinding media on the flotation behavior of fluorite using sodium oleate (NaOl) as a collector was investigated via microflotation experiments, zeta potential Effect of grinding media on the flotation behavior of fluorite using

.jpg)

Fluorite Processing Methods and Flowsheet Mining

2021年6月24日 Processing of fluorite ores is the process of separating fluorite concentrate from fluorite ore Fluorite, also known as fluorspar, has a chemical composition of CaF2, which is usually symbiotic with quartz, calcite, barite, Grinding: The twostage grinding process is usually used in the grinding stage of fluorite mines The ball mill + spiral classifier are combined to form a closedcircuit ring mill, which can be ground to the required particle size 3Fluorite Flotation Process, Equipment JXSC Machinery2023年7月29日 Fluorite ore must undergo a series of crushing processes to reduce its size to obtain samples of suitable particle size Commonly used lab jaw crusher, its sturdy design and powerful motor allow it to process high Laboratory Fluorite Ore Testing Process And 2018年11月1日 In this paper, a systematic investigation was carried out on surface physicochemical properties of fluorite particles produced by ball and rod mills through such Tune surface physicochemical property of fluorite particles by

.jpg)

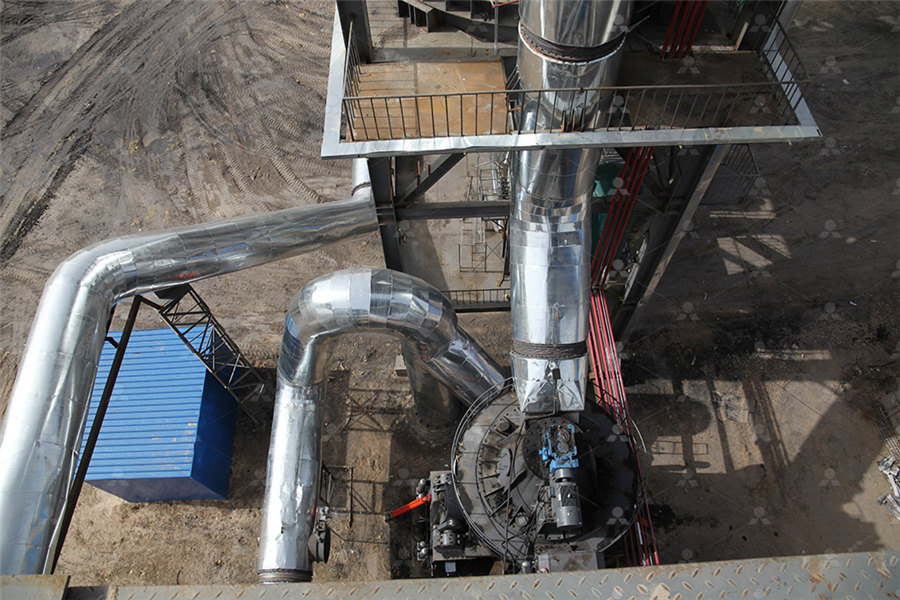

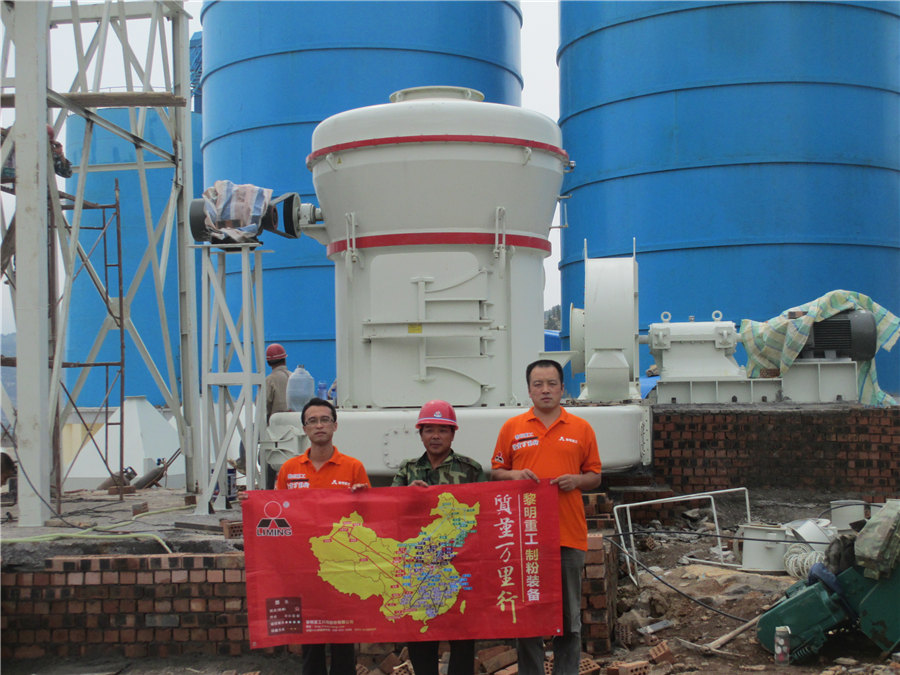

Fluorite Processing Equipment, Process Flow, Cases

2019年8月23日 Need more fluorite processing solutions? Contact us now to get more fluorite processing flowsheet PDF and get a free customize processing flow by our mining experts and engineers 【Advantages】 1 Fully crushing and 2024年11月21日 Fluorite ore beneficiation is a complex process involving various stages of extracting the fluorspar mineral from its original form The process typically involves crushing, grinding and flotation methods to separate Five Factors Affecting Fluorite Ore Beneficiation2023年7月29日 Grinding test Grind the collected fluorite ore samples to make the particles fine and uniform The ore is typically ground using a laboratory cone ball mill or other suitable grinding equipment With adjustable speed settings, Laboratory Fluorite Ore Testing Process And Characteristics of fluorite Composition: CaF₂, which contains fluorine 4867%, calcium 5133%, sometimes contain rare elements; often associated with quartz, calcite, barite and metallidesWhat Is Fluorite? Clirik Grinding Mill

.jpg)

Fluorite: Mineral information, data and localities

Fluorite has seven main crystal forms: the most common Are the cube {100}, octahedron {111} and dodecahedron {110}; these forms having fixed Miller indices); and the tetrahexahedron {hk0}, trapezohedron {h11}, trisoctahedron {hhl} and hexoctahedron {hkl} (less common to quite rare crystal forms, having variable Miller indices) Combinations of two or more of these forms are 2020年5月3日 Grinding, an essential procedure before flotation, to some extent, determines the flotation behavior of minerals In this study, the effect of grinding media on the flotation behavior of fluorite using sodium oleate (NaOl) as a collector was investigated via microflotation experiments, zeta potential measurements, scanning electron microscopyenergy dispersive spectrometry Effect of grinding media on the flotation behavior of fluorite 2023年7月23日 Every fluorine atom in humanmade molecules ultimately comes from the same mineral source: CaF 2, also known as fluorspar or fluoriteBut getting those fluorines into a form where they are usable Fluorine chemistry, hold the HF Chemical Engineering News2024年7月8日 02 Fluorite mineral processing machine for grinding and classification Entering the grinding and classification stage, the ore particles will be further ground to a monomer dissociation state As the core equipment of this stage, the ball mill significantly improves the fineness and purity of fluorite through efficient grindingHow to Choose the Fluorite Mineral Processing Machine?

Potential for Improvement of Fluorite Concentrate Quality in

2023年3月14日 Abstract The authors discuss concentration of fluorite from waste at Yaroslavskaya Mining Company The waste accumulated in the tailings storage for the long operating period contain 116–207% of fluorite Old tailings have specific process properties because the initial ore has experienced certain physicochemical treatment during primary 2023年7月1日 Fluorite flotation is the most selective towards SSSM after dry grinding and the least selective after wetconditioned grinding (Fig 17) This is probably associated with the higher R max of fluorite particles after dry grinding as well as to the higher k of SSSM particles after wet and wetconditioned grinding (Fig 16)On the impact of grinding conditions in the flotation of semi 2024年11月21日 Four common types of fluorspar (fluorite) mineral processing include: quartz fluorspar ore, calcitefluorspar ore, sulfide fluorspar type, and barite fluorspar type Skip to content The process begins by crushing and Four Common Types Of Fluorspar Mineral Processing 2024年2月1日 Once extracted from the Earth’s depths, fluorite undergoes a series of processing steps to enhance its purity and suitability for various applications: 1 Crushing and Grinding: Breaking Down the Barriers The initial step involves crushing and grinding the fluorite ore into smaller fragments, increasing the surface area forUnveiling The Secrets: How Is Fluorite Extracted From The Earth’s

.jpg)

Difference Of Metallurgical And Chemical Grade

2024年11月21日 In terms of fluorite ore beneficiation, stage grinding, stage separation, and multiple beneficiation are the main processes of fluorite ore flotation The process flow design and mining equipment configuration of the 2023年6月19日 Fluorite, also known as fluorspar, is a calcium fluoride (CaF2) mineral It is commonly found in various colors, including purple, green, blue, yellow, and colorless Fluorite is known for its cubic crystal structure and is prized for its beauty and various industrial usesFluorite Types and Beneficiation Methods JXSC Mineral2023年9月14日 The fluorite beneficiation process involves several stages, each critical for achieving optimal results These stages include exploration and resource assessment, ore sampling and characterization, laboratoryscale testing and analysis, pilotscale testing and process optimization, plant design and engineering, production and operations, and quality A Comprehensive Guide to Fluorite Beneficiation Miningpedia2024年2月28日 It starts with the extraction and crushing of the ore, followed by grinding, classification, flotation, and finally, concentration and dewatering The design must ensure that each stage is optimized for the specific characteristics of the fluorite deposit, such as its size, hardness, and purity 2 Equipment SelectionBuilding a Fluorite Processing Plant: A Comprehensive Guide

What is the difference between crushing and grinding?

2020年9月7日 Source: Guikuang By Administrator Posted: In the field of fluorite grinding, Raymond mill will be one of the most popular machines for fluorite powder grinding As a common grinding mill for fluorite powder processing, fluorite Raymond mill is an excellent high efficiency equipment2020年5月3日 Grinding, an essential procedure before flotation, to some extent, determines the flotation behavior of minerals In this study, the effect of grinding media on the flotation behavior of fluorite Effect of grinding media on the flotation behavior of fluorite Fluorite Fluorite Fluorite Introduction to fluorite Fluorite, also known as fluorspar, is the main source of fluorine in industry and one of the 20 important nonmetallic mineral raw materials in the world It is widely used in metallurgy, aluminum smelting, What Are The Uses Of Fluorite? Clirik Grinding Mill2023年5月31日 These were dry, wet, and wet conditionedground before flotation in a laboratory mechanical cell Results were evaluated with bulk and particlespecific methodologies The selectivity of the process is higher after dry grinding for the fluorite and apatite ores and irrelevant for the scheelite oreOn the impact of grinding conditions in the flotation of semi

Intensifying finegrained fluorite flotation process with a

2021年2月15日 Accordingly, thorough grinding is necessary to extract highgrade fluorite from lean ore, leading to particles with small dimensions When the particle size reduced to 37 μm, the large specific area leads to difficulties in stable operation for conventional flotation, due to ineffective attachment between millimeterscale bubbles and the tiny particles [29] 2024年7月1日 Rainbow Fluorite, often simply referred to as Fluorite, is a beautiful and highly soughtafter mineral known for its dazzling array of colors and unique crystal formations It is used for grinding, polishing, and cutting hard materials such as metals, ceramics, and glassRainbow Fluorite : Properties, Formation, Uses, Locations » The fluorite Raymond pulverizer is a grinding mill equipment that can grind minerals into 80400 mesh powder It covers a number of patented technologies and each performance index has been greatly improved, the working principle of the equipment is scientific, the machine has high operating efficiency, large capacity and low energy consumptionBuy High Quality Fluorite Grinding Mill from Manufacturer2024年4月20日 How Much Do I Need? An important question This section is a reminder for each individual piece of equipment that you can craft Of course, this only counts everything once and doesn't reference the idea that you'll likely create more than one of a few pieces in order to go along the branching trees or for Seal farmingLike a Dragon: Ishin! Walkthrough Guide GameFAQs

Fluorite lenses: Corrective capabilities beyond the limits of

While the grinding and polishing processes may seem identical for all kinds of optical glass, each stage of the fluorite lens production process requires slow, meticulous attention to detail 1 Raw materials2023年2月15日 Fluorite has a wide range of uses It is not only used industrially as a source of fluority and a smelting flux in steelmaking, but also used in the manufacture of glass, ceramic and cement Besides, Fluorite has ornamental and lapidary uses in the stone Have you ever seen a glowing fluorite?Fluorite: A Rainbow Germ That Can Glow Fote Machinery2024年2月13日 StepbyStep Guide: Transforming Rough Fluorite into a Polished Gem 1 Prepare the Fluorite: Securely mount the rough fluorite onto a dop stick or holding device to facilitate handling during the polishing process 2 Coarse Grinding: Employ a coarsegrit diamond wheel or sanding disc to remove major surface imperfections, blemishes, and How To Polish Fluorite: Unveil The Hidden Beauty Of Your Fluorite 2022年5月27日 Fluorite doesn’t seem to benefit much from going over 2000 grit before the final polish Ideally, you’ll also change the water in the bucket after each grit This avoids problems with contamination In practice, I’ve never had a problem this way and it’s a huge pain to keep refilling the bucket over and overHow to Polish Fluorite (StepByStep Guide) Rock Seeker

Flotation Behavior of Different Colored Fluorites Using Sodium

2017年9月1日 Using sodium oleate (NaOL) as a collector, the flotation characteristics of natural colorless fluorite (CF), green fluorite (GF), and purple fluorite (PF) were investigated through microflotation tests, collector adsorption measurements, and surface tension measurement The microflotation results indicated that CF had a much better flotation response than both GF The (100) plane is the most stable cleavage plane, where the coordination number of Ce atoms reduces from nine to five In contrast, fluorite crystals are attributed to a cubic crystal system Distribution of global fluorite reserves (data from the 2017 USGS 2019年8月23日 Need more fluorite processing solutions? Contact us now to get more fluorite processing flowsheet PDF and get a free customize processing flow by our mining experts and engineers 【Advantages】 1 Fully crushing and Fluorite Processing Equipment, Process Flow, Cases2024年11月21日 Fluorite ore beneficiation is a complex process involving various stages of extracting the fluorspar mineral from its original form The process typically involves crushing, grinding and flotation methods to separate Five Factors Affecting Fluorite Ore Beneficiation

.jpg)

Laboratory Fluorite Ore Testing Process And

2023年7月29日 Grinding test Grind the collected fluorite ore samples to make the particles fine and uniform The ore is typically ground using a laboratory cone ball mill or other suitable grinding equipment With adjustable speed settings, Characteristics of fluorite Composition: CaF₂, which contains fluorine 4867%, calcium 5133%, sometimes contain rare elements; often associated with quartz, calcite, barite and metallidesWhat Is Fluorite? Clirik Grinding MillFluorite has seven main crystal forms: the most common Are the cube {100}, octahedron {111} and dodecahedron {110}; these forms having fixed Miller indices); and the tetrahexahedron {hk0}, trapezohedron {h11}, trisoctahedron {hhl} and hexoctahedron {hkl} (less common to quite rare crystal forms, having variable Miller indices) Combinations of two or more of these forms are Fluorite: Mineral information, data and localities2020年5月3日 Grinding, an essential procedure before flotation, to some extent, determines the flotation behavior of minerals In this study, the effect of grinding media on the flotation behavior of fluorite using sodium oleate (NaOl) as a collector was investigated via microflotation experiments, zeta potential measurements, scanning electron microscopyenergy dispersive spectrometry Effect of grinding media on the flotation behavior of fluorite

.jpg)

Fluorine chemistry, hold the HF Chemical Engineering News

2023年7月23日 Every fluorine atom in humanmade molecules ultimately comes from the same mineral source: CaF 2, also known as fluorspar or fluoriteBut getting those fluorines into a form where they are usable 2024年7月8日 02 Fluorite mineral processing machine for grinding and classification Entering the grinding and classification stage, the ore particles will be further ground to a monomer dissociation state As the core equipment of this stage, the ball mill significantly improves the fineness and purity of fluorite through efficient grindingHow to Choose the Fluorite Mineral Processing Machine?2023年3月14日 Abstract The authors discuss concentration of fluorite from waste at Yaroslavskaya Mining Company The waste accumulated in the tailings storage for the long operating period contain 116–207% of fluorite Old tailings have specific process properties because the initial ore has experienced certain physicochemical treatment during primary Potential for Improvement of Fluorite Concentrate Quality in 2023年7月1日 Fluorite flotation is the most selective towards SSSM after dry grinding and the least selective after wetconditioned grinding (Fig 17) This is probably associated with the higher R max of fluorite particles after dry grinding as well as to the higher k of SSSM particles after wet and wetconditioned grinding (Fig 16)On the impact of grinding conditions in the flotation of semi