Pyrolysis carbon black grinding mill cost performance

RECOVERED CARBON BLACK Hosokawa Alpine

After pyrolysis, an intermediate process step is required The carbon black granules are precrushed and prepared for the fine grinding stage using a magnet/metal separator For fine A second way is Pyrolysis, which generates oil, gas, steel and recovered Carbon Black (rCB) as fi nal products Especially the rCB can be used to replace the virgin Carbon Black in various Process Technology for recovered Carbon Black (rCB) Grinding2022年9月30日 Recycling carbon black grinding mills (pyrolysis carbon black mills) include Raymond mills, pendulum mills, vertical mills, and ultrafine vertical mills If the rCB of 80325 mesh is processed within 20 tons in one hour, it is recommended to choose an economical pulverizer ( Raymond mill , pendulum pulverizer )Recovered Carbon Black rCB Processing Grinding Mill Machines2024年3月6日 costeffectiveness and environmental friendliness of tire pyrolysis Carbon black from pyrolysis is frequently incinerated with other hazardous wastes, presenting a significant obstacle to the widespread adoption of tire pyrolysis technology globally Given the global quantity of waste tires, developing an economically and ecologiRecycling of LowQuality Carbon Black Produced by Tire Pyrolysis

Recycling of LowQuality Carbon Black Produced by

2024年1月11日 Pyrolysis is a promising way to reuse of waste tires However, the carbon black generated in the process is often contaminated with various pyrolysis products This study aims to recycle lowquality recycled carbon Carbon black grinding machine is for process crude carbon black produced from tire/plastic pyrolysis process to fine powder used for carbon black required products This grinding machine is mainly used to pulverize various nonflammable and unexplosive materials less than 93scale Moh’s hardness and 6% humidity, in the industries of glass, rubber, pesticide, ceramic, paint, Carbon black grinding machineAuxiliary Equipment2022年3月9日 black”, “carbon activation”, and “carbon demineralization” The importance of this subject can be inferred by the increasing number of publications over the yearsProduction and Upgrading of Recovered Carbon Black from the Pyrolysis Waste Tyre Pyrolysis Plant for Carbon black Application field:Waste Tyre Pyrolysis Plant to make pyrolysis carbon black, oil, fuel, etc Type:Waste Tyre Pyrolysis Plant for Carbon black Capacity:120 tone per furnace Live Chat Carbon black grinding mill/grinder mill Application field:Designed for carbon black super fine grinding, to solve the problem of cabon black light charactercarbon black processing machine, tyre pyrolysis carbon black grinding

.jpg)

carbon black processing machine, tyre pyrolysis carbon black grinding

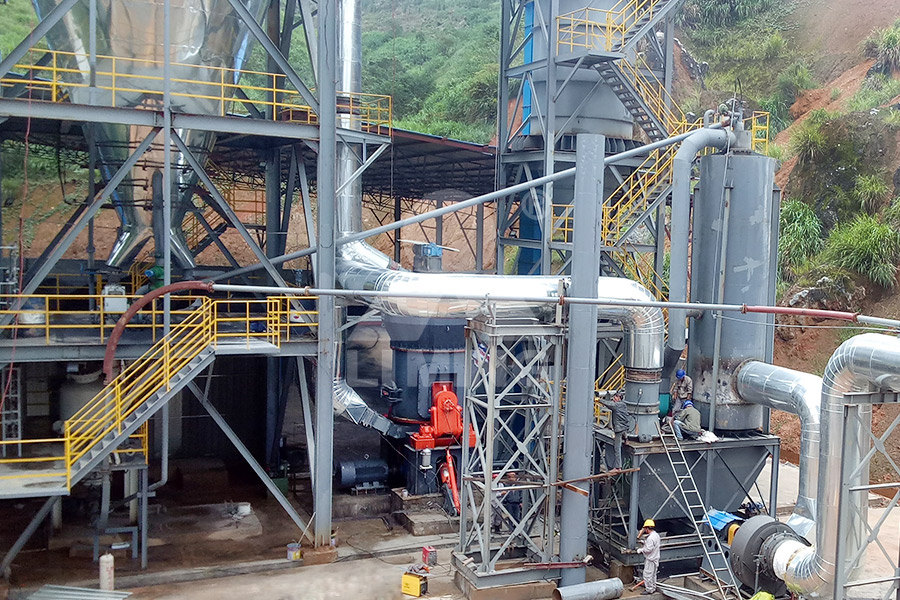

Carbon Black Production Line Energysaving, Lowconsumption and High Cost Performance Rati [] Carbon black grinding mill can increase the market value of carbon black to the most part and increase the competitivenessBeston carbon black processing plant is used for deep processing carbon black from waste tyre/plastic/rubber pyrolysis, biomass garbage, construction material grinding and so on The plant is also called carbon black grinding machine, which grinds the carbon black to a smaller, finer grainThese kinds of carbon black are more exquisite and have higher reinforcing performanceCarbon Black Processing Plant Process Carbon Black from Tyres2019年8月30日 The pyrolysis carbon black (CBp) from waste tires accounts for more than 35% of pyrolysis products Its poor reinforcing ability and low additional value limit heavily the wide application of Pyrolytic preparation and modification of carbon black recovered 2020年11月1日 Recycling of waste tire by pyrolysis to recover carbon black: A laboratorysized tworoll mill of modern engineering was employed for mixing and preparation of the rubber compounds Catalytic effect of dopants on microstructure and performance of MCMBderived carbon laminations Carbon (2004), 101016/jcarbon200311010 Recycling of waste tire by pyrolysis to recover carbon black

(PDF) Mechanical properties of pyrolysis carbon black

2023年9月28日 The carbon black material used as reinforcing filler in tires was recovered by vacuum pyrolysis at a temperature of 500°C and a total pressure of 20 kPa2024年1月1日 In this study, the production behavior, characters, and mechanism of carbon black from pyrolysis of natural rubber (NR), butadiene rubber (BR), and styrenebutadiene rubber (SBR) were investigated The yield of carbon black was increased from 208%–244% to 479%–567% with the increase of pyrolysis temperature from 1100 to 1300°CCarbon black production characteristics and mechanisms from pyrolysis 2019年8月30日 The medium temperature pyrolysis process using a fixedbed reactor at atmospheric pressure was utilised to recover carbon black from motorcycle and Barriocanal C, Alvarez R (2012) Pyrolysis of a waste from Pyrolytic preparation and modification of carbon 2024年6月14日 After grinding with the carbon black super mill, the particle size becomes more uniform, If grinding is to optimize the performance of carbon black, (RCB) produced from the pyrolysis of waste tires or other carboncontaining waste has emerged Compared to traditional virgin carbon black (VCB) from fossil fuels, Carbon Black Processing: Turning Soot into Industrial Gold

.jpg)

Performance Analysis of Common Industrial Carbon Black Grinding Mills

The carbon black overpressure trapezoidal mill is mainly suitable for grinding various nonferrous metals in building materials, chemical industry, metallurgy, mining, abrasives, refractory materials, ceramics, steel, thermal power, coal and other industries with Mohs hardness below 9 and humidity below 6% Flammable and explosive mineral materials, the fineness of the finished Especially the rCB can be used to replace the virgin Carbon Black in various applications Most important is the fineness of the rCB, which determines the final use To reach the fineness required, NETZSCH offers machines which meet the specific requirements of recovered Carbon Black to achieve the highest performance with the finest cutsRecovered Carbon Black NETZSCH Grinding DispersingTo further process the carbon black from tyre pyrolysis, (also called carbon black grinding machine) Skip to content Menu Home; Project Cases Rotating Speed of Main Mill: 160r/min: 150r/min: 130r/min: The final Size: 325mesh: 325mesh: Carbon Black Processing Plant/Machine for Sale Beston Group 1About Conductive Carbon Black 2Development of Conductive Carbon Black 21 Particle Size of Carbon Black 22 Structure of Carbon Black 23 Roughness of Carbon Black 24 Surface Volatiles of Carbon Black 25 Ash and Moisture 3Carbon BlaWhat is The Role of Carbon Black in Lithium Batteries?

.jpg)

Klean Industries: Clearing up the Tire Pyrolysis Carbon Black

The recovered carbon black accounts for 60% of the return on investment, so advanced nano carbon refining equipment is the key to a profitable business model The Klean Team has been involved in building and operating commercial tire pyrolysis plants since the 1980s and are experts in the field of carbon black upgrading and manufacturingThe pyrolysis of entire tires or tire shreds first produces coarse recovered Carbon Black, which must be ground for further use Typically, the following requirements must be met when grinding rCB: low energy consumption; particle size distribution of 4 40 µm (d97) recovered Carbon Black, highperformance battery storage systems and recovered Carbon Black: Neuman EsserFind cost effective technology solutions; Staff Recruitment Increase performance of pyrolysis reactor up to 400%; Featured Service Technology Evaluation Efficient Fine Grinding of Recovered Carbon Black with Fluidized Bed Jet Mills Efficient Fine Grinding of Recovered Carbon Black with2023年12月14日 Türkiye Pyrolysis Carbon Black Grinding Line Project Review 14/12/2023 admin Five application scenarios of carbon black powder HGM100LII ultrafine grinding mill, and went to South Korea to help build the Türkiye Pyrolysis Carbon Black Grinding Line Project

Production and Upgrading of Recovered Carbon Black

2022年3月9日 Increasing awareness regarding fossil fuel dependence, waste valorization, and greenhouse gas emissions have prompted the emergence of new solutions for numerous markets over the last decades The tire industry is 1Carbon Black Classfication 11 Furnace Black 12 Channel Black 13 Thermal Black 2The Difference in Application 21 Rubber Carbon Black 22 Color Black 3Mill Recommendation 31 Crusher 32 MillClassfication and Application of Carbon BlackCarbides of silicon, tungsten, boron and titanium, are among the hardest known materials, and are used as abrasives in cutting and grinding tools Carbon black is used as the black pigment in printing ink, automotive finishes, and laser printer toner Carbon black is also used as a filler in rubber products such as tires and in plastic compoundsCarbon Micronization : Jet Pulverizer2024年11月26日 Notch Consulting’s forecast for carbon black demand in 2029 is estimated at 187 million tons (following the increasing tire production) Using the same intensity rate, GHG emission associated with the Carbon Black industry would increase by 136 million tons to Sustainable Carbon Black produced from endoflife tires pyrolysis

Production and Upgrading of Recovered Carbon Black from the Pyrolysis

Moreover, the transformation of pyrolysis oil into carbon black is deemed to be a sustainable route for rCB production Hu C Catalytic FeP decorated carbon black as a multifunctional conducting additive for highperformance lithiumsulfur batteries Carbon 2021;172:96–105 doi: 101016/jcarbon202009094 [Google Scholar] 64Carbon black grinding mill yield is related to the price mainly lies in the different equipment performance, which means the production cost is different and the price customize is also different What should be noted is that although the price is high the comprehensive profits it brings is also high, therefore we should choose the appropriate grinding mill on the basis of Is the Output of Carbon Black Grinding Mill Related to the Price?2020年11月1日 The demineralized recovered carbon black obtained from both acids together with a reference carbon black (N550) were characterized by elemental and proximate analyses, surface area, ash composition by XRF, and morphology by SEM and TEM A comprehensive surface chemistry analysis by FTIR and TPDNH 3 was also conductedRecycling of waste tire by pyrolysis to recover carbon black Specially, after several years of research and testing, we have a mature carbon black production line The carbon black production line includes carbon black pyrolysis plant, tyre pyrolysis carbon black grinding, carbon black refining equipment, carbon black grinding mill, carbon black pellet making machine, carbon black briquetting machine, oil distillation machine, etccarbon black processing machine, tyre pyrolysis carbon black grinding

.jpg)

Recovered Carbon Black rCB Processing Grinding Mill Machines

2022年9月30日 Recycling carbon black grinding mills (pyrolysis carbon black mills) include Raymond mills, pendulum mills, vertical mills, and ultrafine vertical mills If the rCB of 80325 mesh is processed within 20 tons in one hour, it is recommended to choose an economical pulverizer ( Raymond mill , pendulum pulverizer )2024年3月6日 costeffectiveness and environmental friendliness of tire pyrolysis Carbon black from pyrolysis is frequently incinerated with other hazardous wastes, presenting a significant obstacle to the widespread adoption of tire pyrolysis technology globally Given the global quantity of waste tires, developing an economically and ecologiRecycling of LowQuality Carbon Black Produced by Tire Pyrolysis2024年1月11日 Pyrolysis is a promising way to reuse of waste tires However, the carbon black generated in the process is often contaminated with various pyrolysis products This study aims to recycle lowquality recycled carbon Recycling of LowQuality Carbon Black Produced by Carbon black grinding machine is for process crude carbon black produced from tire/plastic pyrolysis process to fine powder used for carbon black required products This grinding machine is mainly used to pulverize various nonflammable and unexplosive materials less than 93scale Moh’s hardness and 6% humidity, in the industries of glass, rubber, pesticide, ceramic, paint, Carbon black grinding machineAuxiliary Equipment

.jpg)

Production and Upgrading of Recovered Carbon Black from the Pyrolysis

2022年3月9日 black”, “carbon activation”, and “carbon demineralization” The importance of this subject can be inferred by the increasing number of publications over the yearsWaste Tyre Pyrolysis Plant for Carbon black Application field:Waste Tyre Pyrolysis Plant to make pyrolysis carbon black, oil, fuel, etc Type:Waste Tyre Pyrolysis Plant for Carbon black Capacity:120 tone per furnace Live Chat Carbon black grinding mill/grinder mill Application field:Designed for carbon black super fine grinding, to solve the problem of cabon black light charactercarbon black processing machine, tyre pyrolysis carbon black grinding Carbon Black Production Line Energysaving, Lowconsumption and High Cost Performance Rati [] Carbon black grinding mill can increase the market value of carbon black to the most part and increase the competitivenesscarbon black processing machine, tyre pyrolysis carbon black grinding Beston carbon black processing plant is used for deep processing carbon black from waste tyre/plastic/rubber pyrolysis, biomass garbage, construction material grinding and so on The plant is also called carbon black grinding machine, which grinds the carbon black to a smaller, finer grainThese kinds of carbon black are more exquisite and have higher reinforcing performanceCarbon Black Processing Plant Process Carbon Black from Tyres

Pyrolytic preparation and modification of carbon black recovered

2019年8月30日 The pyrolysis carbon black (CBp) from waste tires accounts for more than 35% of pyrolysis products Its poor reinforcing ability and low additional value limit heavily the wide application of 2020年11月1日 Recycling of waste tire by pyrolysis to recover carbon black: A laboratorysized tworoll mill of modern engineering was employed for mixing and preparation of the rubber compounds Catalytic effect of dopants on microstructure and performance of MCMBderived carbon laminations Carbon (2004), 101016/jcarbon200311010 Recycling of waste tire by pyrolysis to recover carbon black