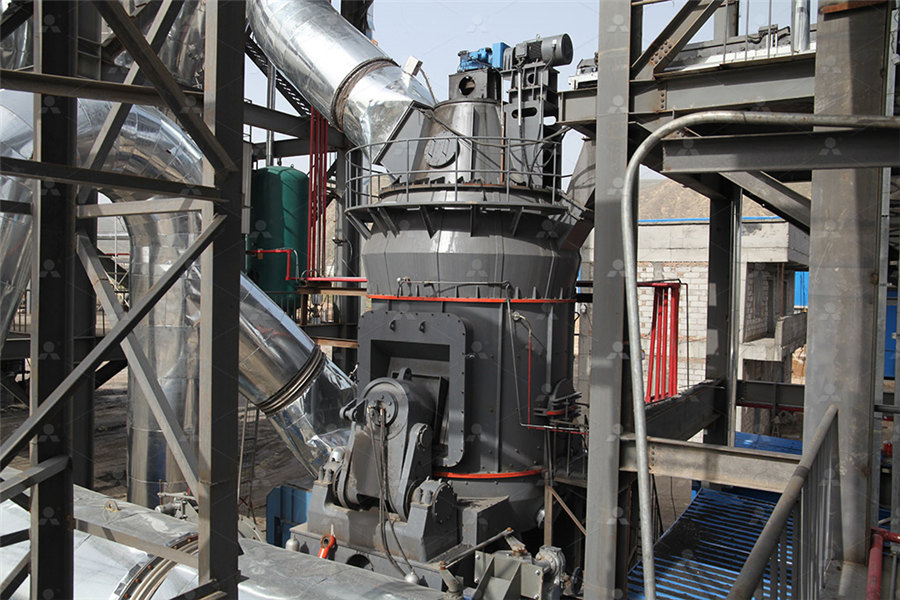

4 060 coal mill

.jpg)

LOESCHEMILLS

The Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications (LM 122 D to LM 202 D), with table diameters from 1,200 to 2,000 Our ATOX® Coal Mill is a compact vertical roller mill that can grind almost any type of raw coal The coal mill utilises compression and shear force generated between the large rollers and the ATOX® Coal Mill FLSmidth CementEquipped with the higheficiency RAKM dynamic separator, the ATOX coal mill will grind any type of coal to the required fineness at the highest eficiency When provided with a variable speed ATOX COAL MILLvertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

.jpg)

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

MPS vertical mill from Pfeiffer is the ideal allrounder Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, and many other materialsThe Raymond Bowl Mill is considered the finest vertical roller mill available for pulverizing coal The typical Raymond bowl mill system is designed to simultaneously dry, pulverize, and Raymond Bowl Mill designed and built for flexibility QlarMills are mechanical devices used to break different types of solid materials in small pieces by grinding, crushing or cutting In pulverised coalfired power plants, a pulveriser coal mill grinds Coal Mill an overview ScienceDirect Topics2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical An investigation of performance characteristics and energetic

An investigation of performance characteristics and energetic

2020年8月12日 In a power plant, the coal mill is the critical equipment, whose effectiveness impacts the overall power plant efficiency Uniform coal feeding mass flow rate and required The document is a technical manual that describes a coal mill CO gas analyzing system It provides instructions for installing, operating, and maintaining the system The system samples gas from a coal mill outlet, pumps it to a measuring chamber with an infrared gas analyzer, and is able to detect carbon monoxide levels to monitor for fires in the mill The manual covers Coal Mill CO Analyzer Codel Manual2008年6月1日 In this study, performance evaluation, modelling and simulation of airswept coal ball mill grinding circuit is presented Ball mill in the circuit was modelled based on the Whiten's (1972 Performance analysis, modelling and simulation of dry The ATOX mill will grind and dry coal containing more than 20% moisture in one operation The possibility of customersupplied parts, along with the low civil costs that accompany compact mill installation, add to the excellent economy of the ATOX coal mill Working principles The raw coal enters the mill via a rotary sluice and feed chuteATOX COAL MILL

(PDF) MPS mills for coal grinding ResearchGate

2014年1月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on Retsch Vibratory Disc Mill RS 200, 220230 V, 50/60 Hz The Vibratory Disc Mill RS 200 is suitable for the extremely quick, lossfree and reproducible grinding of mediumhard, brittle and fibrous materials to analytical finenessRetsch Vibratory Disc Mill RS 200, 14060,00€Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, MPS 200 BK coal mill, Krimzement Bakhchisarayski, Ukraine MPS 3070 BK coal mill, Jaypee Cement Balaji, India MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, CroatiaCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills2020年4月7日 PDF Monitoring and diagnosis of coal mill systems are critical to the security operation of power plants The traditional datadriven fault diagnosis Modeling of Coal Mill System Used for Fault Simulation

Sectional view of MBF coal mill Download Scientific Diagram

A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup Previous Post Next Post Contents1 COAL PREPARATION AND FIRING11 INTRODUCTION12 2COAL RESERVES13 CHARACTERISATION OF COALS BY CHEMICAL131 31 Major components132 32 Minor Components14 4CHARACTERISATION BY PHYSICAL AND MECHANICAL PROPERTIES141 41 Coal Storage142 42 Variation of Physical and COAL PREPARATION AND FIRING INFINITY FOR CEMENT EQUIPMENTPart of what marks Magotteaux out as a leader in vertical coal mill technology is our ongoing commitment to making things better for power station managers and other users of milled coal today After all, our impressive Expand range of wear parts for vertical mills did not simply come about by accident, we identified an area we thought we could bring technological Vertical Coal Mill Magotteauxdescription 1/4" 1 deg taper sq em 3fl 125" tip dia pricing 111 $3301; 1224 $3157; 2549 $3014; 50100 $2870; quantity on hand usa: 41 uk: call usEnd Mills Standard Length GARR TOOL

.jpg)

(PDF) ANALISA PENYEBAB KENAIKAN VIBRASI PADA

2022年10月24日 ANALISA PENYEBAB KENAIKAN VIBRASI PADA BELT CONVEYOR (42 BC 06) DI AREA COAL MILL DI PABRIK II PT SEMEN BATURAJA TBK October 2022; Authors: Astri Gaja Astri GajaPage 3 Lib Istruzioni 060 apollo 23022007 17:09 Pagina 4 Mod 060 QUICK MILL Page 4 Lib Istruzioni 060 apollo 23022007 17:09 Pagina 5 Mod 060 INDICE: PREMESSA CARATTERISTICHE TECNICHE NORME DI SICUREZZA DESCRIZIONE COMPONENTI INSTALLAZIONE MACINATURA CAFFÈ PULIZIA, RIPARAZIONE O MANUTENZIONE QUICK MILL 060 USER MANUAL Pdf Download ManualsLibOur ATOX® Coal Mill has large rollers with great grinding capability of virtually all types of raw coal The rollers work harmoniously with a highlyefficient separator and feed sluice to consistently and reliably deliver coal meal to your desired fineness and moisture levelATOX® Coal Mill FLSmidth Cement2017年8月1日 This paper presents a coal mill model that considers the effect of coal moisture on its accuracy This mathematical model is derived through the analysis of mass flow, heat exchange, and energy transferring balances in which all heat input into or output from the coal mill are calculated quantitatively to reduce the number of unknown parameters that need to be Modeling of a medium speed coal mill ScienceDirect

S060 Steam Shunter Derail Valley Wiki

The S060440 Steam Shunter is a threeaxle coalfired steam locomotive designed for shunting duties Compared to the DE2, it has a lower top speed, higher workload, and around double the load ratingIt was released in build 95 The S060 is found in small, remote stations, such as the forest stations, but also at the farm and steel mill2022年7月26日 Aiming at the typical faults in the coal mills operation process, the kernel extreme learning machine diagnosis model based on variational model feature extraction and kernel principal component analysis is offered Firstly, the collected signals of vibration and loading force, corresponding to typical faults of coal mill, are decomposed by variational model Fault Diagnosis of Coal Mill Based on Kernel Extreme Learning2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and energetic 2020年4月2日 : Fuel and firing system purposely to deliver light fuel oil or coal as one of the primary elements of fuel in an ideal condition for combustion to take place in the boiler combustion chamberAnalysis of the Coal Milling Operations to the Boiler

Modeling and Parameter Identification of Coal Mill

2009年9月20日 A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup 2 The hot air is used for transportation of the recirculating coal within the mill and also for transporting the coal from the pulverizer to the furnace As the coal is continuously reduced in size, the smaller/lighter particles are swept from the Bowl Mill Coal Pulverizer COAL HANDLING PLANTSAnthracite Rice Coal is The Mill's smallsized coal that is good for automatic stokers that are mechanically fed Rice Coal 3/16" 5/16" similar to a pencil eraser Nut (Chestnut) Coal 13/16" 1 5/8" similar to a golf ball+ Stove Coal 1 5/8" 2 7/16" Close to a baseball size Anthracite Coal Fact SheetAnthracite Rice Coal – The MillEpilux 5 Coal Tar Epoxy Steel : Remove grease, oil and other contaminants preferably by using Bison Degreasing Solvent Blast clean to a 060 Mar Berger House,129 Park Street, Kolkata Phone: (033) 2229 9724 (5 lines) / 2249 (4 lines) Fax: 91332249 9729 / Call us +91 98250 27368 Nilkamal Paints Hardware

.jpg)

What is a Coal Grinding Mill

Coal grinding mills are essential components of power plants, responsible for converting raw coal into fine coal powder that is essential for efficient combustion in power plant boilers Coal grinding mills can also be used to grind biomass and other alternative fuels, providing a more sustainable and renewable energy source for power generationIt takes as little as 14 kg (3 lbs) of pulverised coal in 28 m3 (1,000 ft3) of air to form an explosive mixture Since a large boiler burns over 40 kg (88 lbs) a danger that any residual coal left within the mill will oxidise, and may explode as the mill is restarted The Millwatch system is COAL HANDLING SAFETY2022年12月1日 Schematic drawing of the MWk 12 mill (FPM SA Mikołów, Poland) Download : Download highres image (138KB) Download : Download fullsize image; Fig 2 Plates of highmanganese cast steel used for mill lining and beaters of a coal grinding mill: a) inner (IP) and middle plates (MP), b) outer plates (OP) Download : Download highres image The wear mechanism of mill beaters for coal grinding madeup The raw material of coal powder is coal with various hardness, and it drying in the coal mill grinding process to obtain finished coal powder which can be efficiently burned Coal ball mills are widely used in the cement industry and thermal power generation industry, and are also suitable for metallurgical industry, chemical industry, sugar industry and other fieldsCoal Ball Mill Grinding for Different Kinds of Pulverized Coal

Coal Mill CO Analyzer Codel Manual

The document is a technical manual that describes a coal mill CO gas analyzing system It provides instructions for installing, operating, and maintaining the system The system samples gas from a coal mill outlet, pumps it to a measuring chamber with an infrared gas analyzer, and is able to detect carbon monoxide levels to monitor for fires in the mill The manual covers 2008年6月1日 In this study, performance evaluation, modelling and simulation of airswept coal ball mill grinding circuit is presented Ball mill in the circuit was modelled based on the Whiten's (1972 Performance analysis, modelling and simulation of dry The ATOX mill will grind and dry coal containing more than 20% moisture in one operation The possibility of customersupplied parts, along with the low civil costs that accompany compact mill installation, add to the excellent economy of the ATOX coal mill Working principles The raw coal enters the mill via a rotary sluice and feed chuteATOX COAL MILL2014年1月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on (PDF) MPS mills for coal grinding ResearchGate

.jpg)

Retsch Vibratory Disc Mill RS 200, 14060,00€

Retsch Vibratory Disc Mill RS 200, 220230 V, 50/60 Hz The Vibratory Disc Mill RS 200 is suitable for the extremely quick, lossfree and reproducible grinding of mediumhard, brittle and fibrous materials to analytical finenessGrinding of coal, petcoke, clay, limestone, quicklime, gypsum, MPS 200 BK coal mill, Krimzement Bakhchisarayski, Ukraine MPS 3070 BK coal mill, Jaypee Cement Balaji, India MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, CroatiaCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills2020年4月7日 PDF Monitoring and diagnosis of coal mill systems are critical to the security operation of power plants The traditional datadriven fault diagnosis Modeling of Coal Mill System Used for Fault SimulationA control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup Sectional view of MBF coal mill Download Scientific Diagram

COAL PREPARATION AND FIRING INFINITY FOR CEMENT EQUIPMENT

Previous Post Next Post Contents1 COAL PREPARATION AND FIRING11 INTRODUCTION12 2COAL RESERVES13 CHARACTERISATION OF COALS BY CHEMICAL131 31 Major components132 32 Minor Components14 4CHARACTERISATION BY PHYSICAL AND MECHANICAL PROPERTIES141 41 Coal Storage142 42 Variation of Physical and