Operation instructions for 100x150 pendulum ore mill

46.jpg)

AIRSWEPT PENDULUM MILL SYSTEM Bradley Pulverizer

Bradley Airswept Mills combine the fine grinding action of a pendulum roller mill with air stream classifying and fluid bed drying capabilities to produce precisely sizedRtype pendulum mill is suitable for grinding noninflammable and explosive materials such as nonplastic ore, ore, metal oxides and chemical compounds with a hardness of not more than R TYPE PENDULUM MILLThe present operating instructions for the ball mills of type PM100/200 provide all the necessary information on the headings contained in the table of contents They act as a guide for the Operating Instructions Ball Mills Type PM100 / PM200 / PM100cmLoesche Automation combines cuttingedge machine technology and intelligent process control for optimum and efficient plant operation We offer our customers customised engineering PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

Pendulum Mills Verdés

They are used for crushing and grinding minerals and raw materials of various types, with different characteristics such as specific gravity, humidity, hardness, etc, obtaining high rate The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working Operation Manual: HRM1700M Vertical Roller Coal MillHere you will find operating manuals and instructions for RETSCH mills sieve shakers different languages PDF Format Download hereRetsch operating manuals operating instructionsPOITTEMILL PROCESS OF SIMULTANEOUS GRINDING AND DRYING WITH PENDULUM MILL The natural moisture in quarries or moisture resulting from industrial processing often Grinding and drying installation Poittemill Group

Ball Mill: Standard Operating Procedure PDF Mill (Grinding)

The document provides standard operating procedures for a ball mill It lists 18 steps for operating the ball mill, including connecting power, loading materials and grinding media, starting and The LM PBM1 laboratory planetary mill is universally applicable for quick dry or wet grinding of inorganic and organic samples for analysis, quality control, materials testing and mechanical PBM 1 PLANETARY BALL MILL USER MANUALBall Mill Grinding Process Handbook Free download as PDF File (pdf), Text File (txt) or read online for free This document provides guidance on ball mill grinding processes It covers topics such as ball mill design including length to Ball Mill Grinding Process Handbook2017年7月26日 We will consider an ore with a ball mill work index varying between 16 and 13, feeding into a single stage ball mill operation with one million kilowatts per day consumed power For the particular mill configuration, a performance graph, Fig (21), has been constructed according to Bond’s methodsHow Ball Mill Ore Feed Size Affects Tonnage Capacity

.jpg)

OPERATING INSTRUCTIONS FOR MILLS AND FLAKERS KoMo

Please thoroughly read these operating instructions before using the device for the first time There you will find all information for a safe operation We wish you to enjoy preparing your fine dishes Marcel and Peter Koidl 3 4 1 mill, you can put a tea bag with herbal tea or laurel leafs2015年3月14日 D) Represents the socalled Dynamic Angle of Repose (or Lift Angle) adopted during steady operation by the top surface of the mill charge (“the kidney”) with respect to the horizontal A reasonable default value for this angle is 32°, but may be easily “tuned” to specific applications against any available actual power dataCalculate a Mill’s Operating Work Index 911 MetallurgistFor all mills, have at least two people lifting and moving mill onto its final place Never lift using the hand wheel Always lift from the base of the mill or, for the D2 130 and D4 158, lay the mill down and lift from both ends The approximate weights of the machines are as follows: Micro Mill, 9kgs; Mini Mill, 16kgs; DRM 100,Instructions for Durston® HandPowered Mill Usage2015年4月15日 Discharge from each mill Feed to each classification stage Oversize from each classification stage Fines from each classification stage, k Power drawn by each mill (motor input) Motor and drive efficiency of each mill, Size of and type of grinding media used in each mill Speed in RPM for each mill Liner design and condition in each millWhat Ore Testing is Required For Mill Selection

UNDErsTaNDINg MINE TO MILL 911 Metallurgist

operations, however gains associated with integration and predictability remain absolutely relevant in these scenarios Mine to Mill is a site activity and each operation must determine which of the many Mine to Mill variants fits its needs and has the greatest potential to deliver benefitsOverloading the mill can lead to excessive wear and tear, reduced efficiency, and potential equipment damage It is crucial to follow the manufacturer's guidelines for loading to ensure safe and optimal operation 3 Startup and Operation: Once the ball mill is loaded, it can be started according to the manufacturer's instructionsBall mill operation procedures and safety precautionsIt is a new type of highefficiency and energysaving mill The fineness of the finished product can be adjusted arbitrarily between 22180μm (80600 mesh) This product is an updated product of the Rtype mill Among them, the HC1700 large vertical pendulum mill is a large Raymond mill successfully developed early in ChinaHC series pendulum mill HCM Grinding MillMRN Pendulum Roller Grinding Mill talcum, dolomite, bauxite, barite, petroleum coke, quartz, iron ore, phosphate rock, gypsum, graphite and other noninflammable and nonexplosive mineral materials with Moh’s hardness below 9 and Automatic Operation The mill's reducer is equipped with an oiltemperature detecting system and MRN Pendulum Roller Grinding Mill Zenith Crusher

.jpg)

Pendulum roller mill PM POITTEMILL / FORPLEX

The POITTEMILL pendulum roller mill is a vertical mill that works by compressing the material bed The pendulums mounted on a star wheel are driven by a vertical shaft Each pendulum is fitted with a grinding roller that rotates upon its axis Follow steps 1 3 to open the mill (p 10/ 11) Remove the two transport locking devices are positioned opposite each other and between housing and milling device Continue with the steps 5 7 (p 11 / 12) to close the mill FURTHER OPERATING INSTRUCTIONS On our homepage mockmill you will find videos containing further operating instructionsJ K OPERATING INSTRUCTIONS Mockmill 100 Mockmill 200China Pendulum Mill wholesale Type: Gold Ore Grinding Mill Motor Type: AC Motor Motor Power: 185160kw Rotationl Speed: 1719r/min It's essential to consult with a reputable supplier to determine the best option for your operation Q What advantages does Pendulum Mill MadeinChina2023年12月4日 Numerical Investigation of Vertical Roller Mill Operation Using Discrete Element Method Conference paper; First Online: 04 December 2023; pp 323–334; Cite this cement, and ceramics It is also used to grind slag and nonmetallic ores The VRM decreases the number of equipment in the grinding circuit by combining the drying Numerical Investigation of Vertical Roller Mill Operation Using

.jpg)

Vertical Milling Machine Operating Instructions

READ INSTRUCTIONS BEORE OPERATING SAETY GLASSES SHERLIE RDUCTS IC • • • ( ( • ( • 4/21/16 Vertical Milling Machine Operating Instructions General Description At first glance, a vertical mill looks similar to a drill press, but there are some important design differences; for example, the mill has a spindle that can take side loads2024年3月9日 Finally, it’s important to familiarize yourself with the operation of the chainsaw mill and any specific instructions provided by the manufacturer This will ensure that you’re using the mill correctly and safely By properly preparing for operation with a chainsaw mill, you can increase your chances of a successful milling experienceHow to Operate a Chainsaw Mill: A StepbyStep Guide for 2022年11月23日 the influence on mill efficiency and main duct wear This study provides a digital design basis for optimizing the structure and operating parameters of the pendulum mill Working process and principles of pendulum mill The pendulum mill is a powder production equipment that combines ringroller grinding with air classifying and air conveyingAdvances in Mechanical Engineering 2023, Vol 15(7) 1–14 2019年8月14日 Correct ball mill liner replacement operation can improve the use time of the ball mill and ensure the safe operation of the ball mill In order to improve the safety factor of the use of the ball mill, Xinhai Mining and dressing experts suggest that the replacement process of the entire ball mill liner should be properly guided and participated by the technicians of the ball The Ultimate Guide to Ball Mills Miningpedia

.jpg)

SOPStartup Shutdown and Operation of Cement Mills

SOPStartup shutdown and operation of Cement Mills Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free This document provides the standard operating procedure for starting up, shutting down, and operating cement mills at Anjani Portland Cement Limited It outlines the specific sequence that mill groups must be started and stopped The pendulum mill PM is a roller or horizontal mill It is the further development of the proven Raymond Mill and is suitable for fine grinding and drying soft to mediumhard ground material Application examples include clay , bentonite , barite, phosphate, coal , burnt lime , Pendulum Mill PM Neuman EsserVRM operation SOPs Free download as PDF File (pdf), Text File (txt) or read online for free The document provides standard operating procedures for grinding mills It discusses four mill operation conditions based on VRM Operation SOPs PDF Mill (Grinding) Pressure2023年7月19日 Pendulum mill is a widely used grinding equipment in powder processing industry Less indepth studies have been carried out especially for grinding efficiency and wearResearch of grinding efficiency and main duct wear of

Operation and Maint A4P 20 en PDF

OPERATION AND MAINTA4P20EN Free download as PDF File (pdf), Text File (txt) or read online for free This document is an instruction manual for operating and maintaining an Atox mill for raw meal It Observe instructions for use Repairs These operating instructions do not include repair instructions For your own safety repairs must be carried out only by Retsch GmbH or an authorised agent (service technicians) In this case please contact: The Retsch agency in your country Your supplier Retsch GmbH directly Your service address:Operating Instructions for Oscillating Mill MM 200 Fisher SciMultiple pieces of equipment were in the mills to facilitate extraction and the following account provides one with a verbatim account from Waldo Twitchell the assayer at the Vulture Mine in Arizona, of their mill operation in 1912: “The new mill was erected in 1910, at a cost of about $80,000 The capacity is about 100 tons of ore a dayWinning the Metal: Ore Mills of the West Western Mining History2018年11月21日 Blending of ore domains with different characteristics is common for operations In recent years a number of technologies have become available for online and more rapid assessment of ore and have been discussed in a recent paper by Cameron etal (2016) as an opportunity for further utilisation of minetomill (and mine to product) strategiesDynamic concepts for mine to mill operation and optimisation

.jpg)

Operating Instructions for Oscillating Mill MM400 LabWrench

Observe instructions for use Repairs These operating instructions do not include repair instructions For your own safety repairs must be carried out only by Retsch GmbH or an authorised agent (service technicians) In this case please contact: The Retsch agency in your country Your supplier Retsch GmbH directly Your service address:Observe instructions for use Repairs These operating instructions do not include repair instructions For your own safety repairs must be carried out only by Retsch GmbH or an authorised agent (service technicians) In this case please contact: The Retsch agency in your country Your supplier Retsch GmbH directly Your service address:Operating Instructions for Oscillating Mill MM400HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM ultrafine grinding mill, SBM Ore Ultrafine Grinding Mill2020年10月9日 In order to obtain the optimal operation parameters of a SAG mill, in this paper, the discrete element method (DEM) is used to simulate the breakage process of the particles by controlling three Operation Analysis of a SAG Mill under Different Conditions Based on

.jpg)

Ball Mill Grinding Process Handbook

Ball Mill Grinding Process Handbook Free download as PDF File (pdf), Text File (txt) or read online for free This document provides guidance on ball mill grinding processes It covers topics such as ball mill design including length to 2017年7月26日 We will consider an ore with a ball mill work index varying between 16 and 13, feeding into a single stage ball mill operation with one million kilowatts per day consumed power For the particular mill configuration, a performance graph, Fig (21), has been constructed according to Bond’s methodsHow Ball Mill Ore Feed Size Affects Tonnage CapacityPlease thoroughly read these operating instructions before using the device for the first time There you will find all information for a safe operation We wish you to enjoy preparing your fine dishes Marcel and Peter Koidl 3 4 1 mill, you can put a tea bag with herbal tea or laurel leafsOPERATING INSTRUCTIONS FOR MILLS AND FLAKERS KoMo2015年3月14日 D) Represents the socalled Dynamic Angle of Repose (or Lift Angle) adopted during steady operation by the top surface of the mill charge (“the kidney”) with respect to the horizontal A reasonable default value for this angle is 32°, but may be easily “tuned” to specific applications against any available actual power dataCalculate a Mill’s Operating Work Index 911 Metallurgist

.jpg)

Instructions for Durston® HandPowered Mill Usage

For all mills, have at least two people lifting and moving mill onto its final place Never lift using the hand wheel Always lift from the base of the mill or, for the D2 130 and D4 158, lay the mill down and lift from both ends The approximate weights of the machines are as follows: Micro Mill, 9kgs; Mini Mill, 16kgs; DRM 100,2015年4月15日 Discharge from each mill Feed to each classification stage Oversize from each classification stage Fines from each classification stage, k Power drawn by each mill (motor input) Motor and drive efficiency of each mill, Size of and type of grinding media used in each mill Speed in RPM for each mill Liner design and condition in each millWhat Ore Testing is Required For Mill Selectionoperations, however gains associated with integration and predictability remain absolutely relevant in these scenarios Mine to Mill is a site activity and each operation must determine which of the many Mine to Mill variants fits its needs and has the greatest potential to deliver benefitsUNDErsTaNDINg MINE TO MILL 911 MetallurgistOverloading the mill can lead to excessive wear and tear, reduced efficiency, and potential equipment damage It is crucial to follow the manufacturer's guidelines for loading to ensure safe and optimal operation 3 Startup and Operation: Once the ball mill is loaded, it can be started according to the manufacturer's instructionsBall mill operation procedures and safety precautions

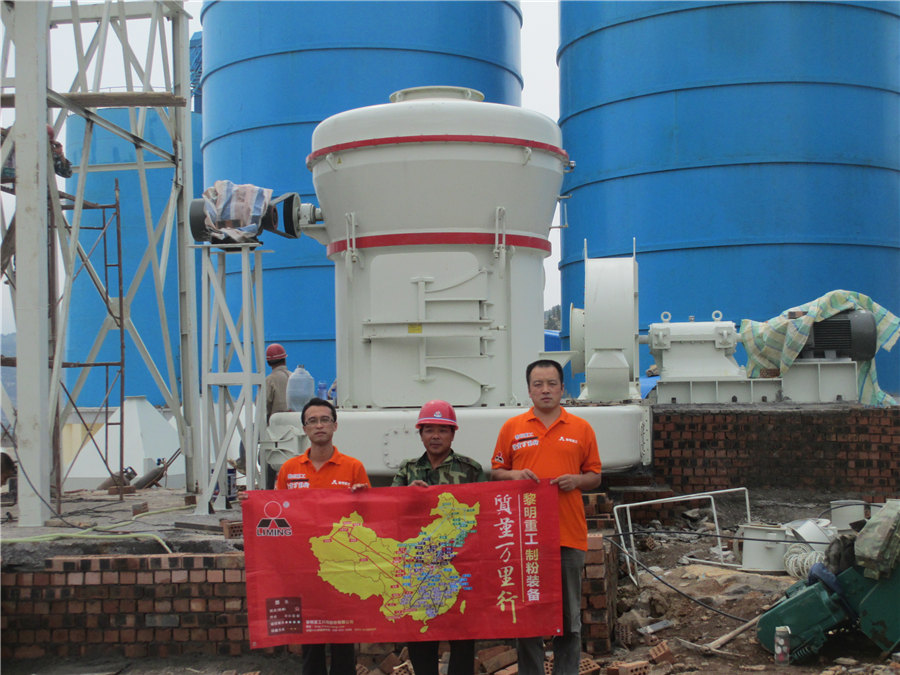

HC series pendulum mill HCM Grinding Mill

It is a new type of highefficiency and energysaving mill The fineness of the finished product can be adjusted arbitrarily between 22180μm (80600 mesh) This product is an updated product of the Rtype mill Among them, the HC1700 large vertical pendulum mill is a large Raymond mill successfully developed early in ChinaMRN Pendulum Roller Grinding Mill talcum, dolomite, bauxite, barite, petroleum coke, quartz, iron ore, phosphate rock, gypsum, graphite and other noninflammable and nonexplosive mineral materials with Moh’s hardness below 9 and Automatic Operation The mill's reducer is equipped with an oiltemperature detecting system and MRN Pendulum Roller Grinding Mill Zenith Crusher