Slag grinding production line

.jpg)

slag grinding plant CHAENG

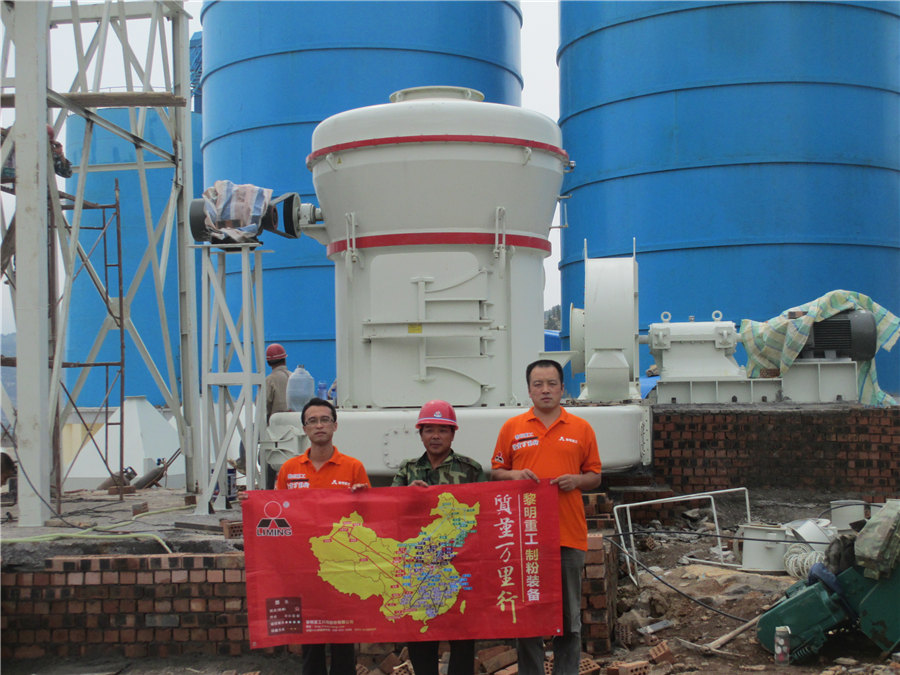

CHAENG is a cement industry equipment manufacturer with more than 60 years of experience, can provide not only slag grinding equipment, but also complete turnkey solutions for grinding blast furnace slag (GGBS) production Equipment: GRMS Slag Vertical Mill Grinding Material: CHAENG (Great Wall Machinery) can undertake 20 tons 15 million tons of Blast furnace slag/Steel slag/Nickel slag/Manganese slag powder production EPC projects Up to now, Slag CHAENGThe slag grinding production line is a production system specially used to process slag and make slag powder Slag, as a byproduct in the industrial production process, can be converted into Slag Grinding Production Line TAYMACHINERYGroundgranulated blastfurnace slag (GGBS or GGBFS) is obtained by quenching molten iron slag (a byproduct of iron and steelmaking) from a blast furnace in water or steam, to produce a glassy, granular product that is then GGBS Production LineChina Henan Zhengzhou Mining

Slag Grinding Plant

Slag Grinding Plant CHAENG (Great Wall Machinery) can undertake 20 tons 15 million tons of Blast furnace slag/Steel slag/Nickel slag/Manganese slag powder production EPC projects Up Steel slag below 5mm enters the grinding system and is ground by the GRMSS series steel slag vertical roller mill The produced steel slag powder has a specific surface area of 400500 Steel Slag Grinding Plant CHAENGWe can provide a variety of mill systems suitable for granulated ground blastfurnace slag (GGBS) grinding, including open circuit and closed circuit systems with ball mill as the core equipment, vertical roller mill (VRM) systems, and GGBS Production Line Slag Mill for Slag Powder Process Description CHAENG can undertake EPC turnkey services for slag / steel slag / nickel slag / manganese slag powder production line with an annual output of 200,0001,500,000 Slag grinding plant Xinxiang Great Wall Machinery Co, Ltd PDF

Superfine Slag Powder Production Line FTM Machinery

Superfine slag powder production line has the advantages like low noise; uniform abrasion of grinding ring and grinding roller; low energy consumption; low failure rate and so on, and is widely used to crush materials in metallurgy, building materials, 2024年1月31日 This study develops an intelligent datadriven approach for optimising slag grinding systems Slag grinding exhibits complex nonlinear dynamics that challenge control The proposed system Li X, Jia C, et al Tracking control of slag powder production process based on adaptive dynamic programming Acta Automatica Sinica 2016; 24:Intelligent process control system for predicting operating Advantages 1 Starting from customer needs to avoid project investment waste caused by design Optimize the overall layout of the production line according to specific conditions, so that the process is simple, smooth, compact, reasonable and beautiful, so as to reduce the floor space and reduce the consumption of pipes, cables, etcslag grinding plant CHAENGAfter the research of Xinxiang Great Wall Machinery Industry Waste Residue Powder Research Center, CHAENG can provide 200,0001,500,000t/a nickel slag production line project +79nickel slag production line CHAENG

Steel Slag Grinding Plant CHAENG

Aiming at the characteristics of steel slag, CHAENG proposes a 200,000 to 15 million tons per year turnkey service plan for the comprehensive utilization of steel slag, which uses vertical roller mills as the main grinding equipmentThe dryprocess steel slag production process does not need to consume precious water resources After the steel slag is crushed, rod milled, and magnetically separated, the slag steel can be selfgrinding to obtain grade A and B scrap steel The iron content of the slag powder can reach more than 55%Steel slag recycling crushing and grinding production lineSlag Vertical Mill Production Line from ZKCorp engages the advantages of simple process flow, highefficiency of grinding, great drying capacity, efficient Powderclassifying, easilyadjustable outputting size, low noise and electricityconsumption, small mill consumption, high degree of automation, low running expense, which make it suitable for small and middle plant ownerGGBS Production LineChina Henan Zhengzhou Mining 300 t/d Cement Production Line 300t/d cement production line designed by Great Wall machinery, fully learns from the lessons and experiences of more than 20 years of NSP production line design, advanced vertical roller mill grinding system and DCS automatic control system; 3000 t/d Cement Production Line Xinxiang Great Wall Machinery provides turnkey basis service Cement Production Line

Slag Grinding Plant Great Wall

GGBFS Production Line Slag Grinding Plant; Slag Grinding Plant Application: Cement Plant: Annual Output: 200,0001,000,000 tons: Power Consumption: 3545 kWh/t: Blaine Fineness: Investment powder production line with considerable economic benefit and high return on investment, usually 13 years can recover the cost High efficiency, energy 2023年12月26日 As we all know, the dryprocess cement production line is commonly used in the cement industry The new type of dryprocess cement production process includes four main sections: Prehomogenization of raw materials, homogenization of raw materials, clinker firing, cement grinding, etc Raw material conveying system The raw material, including limestone, 6 Cement Equipment For Dryprocess Cement Production LineSlag Vertical Mill Production Line from ZKCorp engages the advantages of simple process flow, highefficiency of grinding, great drying capacity, efficient Powderclassifying, easilyadjustable outputting size, low noise and electricity Slag Grinding PlantProcess Description CHAENG can undertake EPC turnkey services for slag / steel slag / nickel slag / manganese slag powder production line with an annual output of 200,0001,500,000 tons So far, CHAENG has established successfully more than 100 slag production lines in the worldSlag grinding plant Xinxiang Great Wall Machinery Co, Ltd

.jpg)

Production Line

Slag Grinding Plant CHAENG (Great Wall Machinery) can undertake 20 tons 15 million tons of Blast furnace slag/Steel slag/Nickel slag/Manganese slag powder production EPC projects Up to now, CHAENG has constructed more than 100 slag grinding production lines at home and aBuy slag grinding units from a reliable supplier The vertical mills are stable and durable Costeffective production of fine GGBS! ASK Price! Skip to content Menu A GGBS production line main includes slag feeding equipment, a bucket elevator, a dust collector, a slag vertical mill, a powder separator, a fan, a funnel, Slag Grinding Plant GGBS Plant One Stop Solution CNBM Slag Grinding Plant GGBS(Granulated Blastfurnace Slag) Guangxi Huayan 2x600t/d lime production line; PTIndoferro t/a nickel slag grinding plant EPC project; Great Wall Machinery GGBS Plant with 600,000 t/a Capacity; Hot GGBS Plant, GGBFS Production Line CHAENG Great WallNickel Slag Grinding Plant Materials: Nickel Slag Main Equipment: GRMSS Slag Vertical Mill Matching Equipment: belt feeder + vibrating screen + slag vertical mill + hot stove + dust collector + finished product warehouse Steel Slag Grinding Plant Materials: Steel slag Main equipment: GRMSS Steel Slag Vertical Mill Applications: Roads, building materials, soil amendments, Cement Production Line CHAENG

Production line case

Panzhihua, Sichuan 450,000t/a Steel Slag Grinding Plant In order to produce highquality steel slag micropowder, a company in Sichuan decided to cooperate with CHAENG to build a general contracting project for a steel slag micropowder production line Recently, Slag has become an important mixing material of cement, grind ability of slag is very poor In general, the slag powder is processed by the slag grinding plant in advance, and slag powder will be sent into the cement plant for making slag cement, so it is particularly important to select the appropriate slag grinding plantSlag Cement Production Line Blast Furnace Slag Cement MakingGGBS Production Line Introduction: GGBS is granulated blast furnace slag, ground to very high fineness While grinding the slag, the fineness will be as per Blaine>4,200 cm2/gram The initial moisture of 15% in the slag will be reduced to 05% in the processGGBS PlantSlag Grinding Mill cementmillequipment2021年12月5日 The working principle of the copper slag processing production line is to use the physical characteristics of the ductility of the metal copper The metal copper and the waste slag are separated by crushing, grinding, screening, etc, using a very simple working principle from The extraction of metallic copper from copper slag has significant effect, low investment, low Copper Slag Processing Production Line Flow Henan Forui

.jpg)

Development Trend Analysis of Cement Production Line

2023年11月21日 we will introduce the development trends of cement production lines and explore their impact on the cement industry AGICO CEMENT can offer a series of cement plant upgrade solutions for you, Slag Grinding Plant 2024年1月31日 Additionally, machine breakdowns often pose threats to the safety of workers Consequently, it is crucial to optimise the control of slag grinding systems, whether from a system optimisation control or safety Intelligent process control system for predicting CHAENG can undertake the 2001500t/d active lime production line EPC, including the the reach report, civil engineering, designing, equipment, installation and debugging +79active lime production line CHAENG2023年10月19日 Ultrafine slag grinding production line for cement In late July 2023, Guangxi Guigang Hengyao steel Co, Ltd successfully completed the production and acceptance cementgrindingplantWhat is a ultrafine slag grinding plant? ultrafine slag grinding

.jpg)

Slag Grinding line mining processing machine XKJ Group

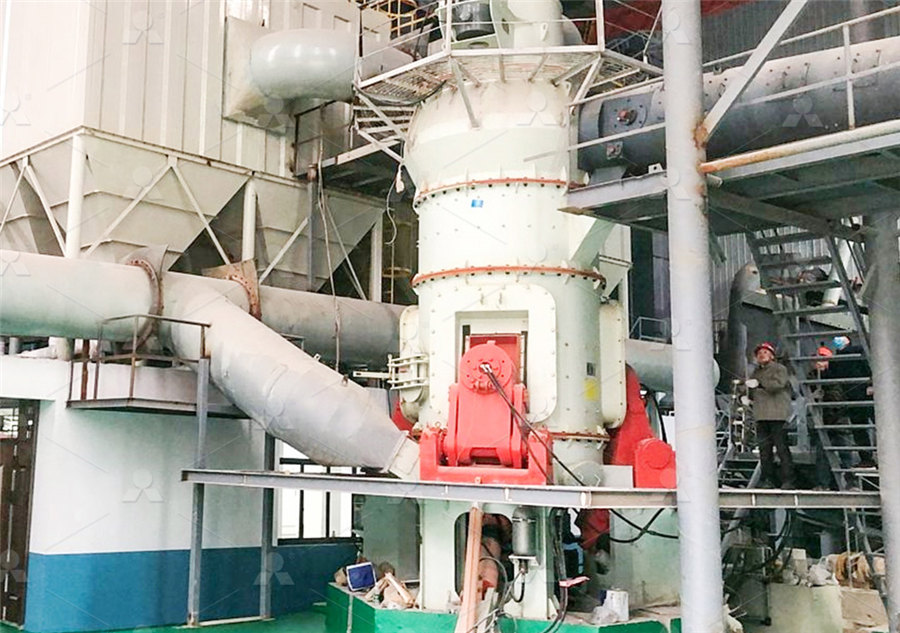

Vertical roller mill is the core equipment of the slag powder production line, the solid waste slag powder produced in the process of steel production is grinded into the high fine slag powder with high valueadded, which not only solves the problem of solid waste disposal in iron and steel enterprises, but also brings new profit growth point for the enterprises2016年5月31日 CHAENG (Great Wall Machinery) can undertake 20 tons 15 million tons of Blast furnace slag/Steel slag/Nickel slag/Manganese slag powder production EPC projects Up to now, CHAENG has constructed more than 100 slag grinding production lines at home and abroad Process DescriptionSlag Grinding Plant2008年3月3日 Grinding slag for cement replacement requires only about 25% of the energy needed to manufacture normal Portland cement Without the use of granulated material the total volume of slag produced could not be viably or economically utilised in other processes, such as aggregate for example, and would inevitably go to landfill as in the pastEfficient and reliable handling of GBFS and GGBFS at grinding Coarse particles are returned to the mill for further grinding, which forms a socalled closed circuit Structure 1 Classifying liners are used to keep larger steel balls at the feed end for breaking large particles, and retain smaller steel balls at the discharge end for fine grinding This grinding method improves efficiency 2Slag Mill

Clinker Grinding Unit CHAENG

Slag Grinding Plant Steel slag grinding plant Active lime production line Cement Grinding Station Cement production line Sandstone production line Case Production line case Steel casting case Equipment case Media Room News Gallery Special coverage PDF download Video Contact us : WeChat:+79 WhatsApp AGICO is a trustable manufacturer of gypsum board production lines We can offer gypsum board making machines, and we are also responsible for the whole gypsum board production line design, manufacturing, Slag Grinding Plant Mini Cement Plant Before you send inquiry Please provide us with project information as much as possible:Gypsum Board Manufacturing Plant Plasterboard Production LineSuperfine slag powder production line has the advantages like low noise; uniform abrasion of grinding ring and grinding roller; low energy consumption; low failure rate and so on, and is widely used to crush materials in metallurgy, building materials, Superfine Slag Powder Production Line FTM Machinery2024年1月31日 This study develops an intelligent datadriven approach for optimising slag grinding systems Slag grinding exhibits complex nonlinear dynamics that challenge control The proposed system Li X, Jia C, et al Tracking control of slag powder production process based on adaptive dynamic programming Acta Automatica Sinica 2016; 24:Intelligent process control system for predicting operating

slag grinding plant CHAENG

Advantages 1 Starting from customer needs to avoid project investment waste caused by design Optimize the overall layout of the production line according to specific conditions, so that the process is simple, smooth, compact, reasonable and beautiful, so as to reduce the floor space and reduce the consumption of pipes, cables, etcAfter the research of Xinxiang Great Wall Machinery Industry Waste Residue Powder Research Center, CHAENG can provide 200,0001,500,000t/a nickel slag production line project +79nickel slag production line CHAENGAiming at the characteristics of steel slag, CHAENG proposes a 200,000 to 15 million tons per year turnkey service plan for the comprehensive utilization of steel slag, which uses vertical roller mills as the main grinding equipmentSteel Slag Grinding Plant CHAENGThe dryprocess steel slag production process does not need to consume precious water resources After the steel slag is crushed, rod milled, and magnetically separated, the slag steel can be selfgrinding to obtain grade A and B scrap steel The iron content of the slag powder can reach more than 55%Steel slag recycling crushing and grinding production line

.jpg)

GGBS Production LineChina Henan Zhengzhou Mining

Slag Vertical Mill Production Line from ZKCorp engages the advantages of simple process flow, highefficiency of grinding, great drying capacity, efficient Powderclassifying, easilyadjustable outputting size, low noise and electricityconsumption, small mill consumption, high degree of automation, low running expense, which make it suitable for small and middle plant owner300 t/d Cement Production Line 300t/d cement production line designed by Great Wall machinery, fully learns from the lessons and experiences of more than 20 years of NSP production line design, advanced vertical roller mill grinding system and DCS automatic control system; 3000 t/d Cement Production Line Xinxiang Great Wall Machinery provides turnkey basis service Cement Production LineGGBFS Production Line Slag Grinding Plant; Slag Grinding Plant Application: Cement Plant: Annual Output: 200,0001,000,000 tons: Power Consumption: 3545 kWh/t: Blaine Fineness: Investment powder production line with considerable economic benefit and high return on investment, usually 13 years can recover the cost High efficiency, energy Slag Grinding Plant Great Wall2023年12月26日 As we all know, the dryprocess cement production line is commonly used in the cement industry The new type of dryprocess cement production process includes four main sections: Prehomogenization of raw materials, homogenization of raw materials, clinker firing, cement grinding, etc Raw material conveying system The raw material, including limestone, 6 Cement Equipment For Dryprocess Cement Production Line