Process formula of fly ash crushing station

How to Process Fly Ash and What Is It Used for? Fote Machinery

Depending on the discharge method, there are dry fly ash and wet fly ash Dry fly ash is sold well as an admixture for cement production The wet fly 展开2021年9月1日 Fly ash (FA) is the principal industrial waste byproduct from the burning of solid fuels FA is a powdery solid that is constituted mostly of unburned carbon (UC), metal oxides Fly ash properties, characterization, and applications: A review2006年1月1日 A pelletization process is used to manufacture artificial lightweight coarse aggregate using fly ash Pelletization depends on the size of particles and their distribution, the Influence of pelletization process on the properties of fly ash 2021年9月2日 Crushing strength of individual pellet was estimated using a compression testing machine (ring type unconfined compression test apparatus) and crushing strength (σ) of fly Study on the Production Factors in the Process of Production and

.jpg)

Effect of Crushing Process Parameters on Quality of Fly Ash

2024年3月1日 abrasion values) of the fly ash aggregate were not much affected by crushing process parameters The findings of this study will help in optimizing the crushing operation of Artificial aggregates can be manufactured from fly ash from various processes such as sintering, hydrothermal treatment and cold bondingFlyash is proven to exhibit geopolymer properties Production of Pelletized Fly Ash Aggregates by Geopolymerisation2023年2月20日 This paper is aimed at providing a comprehensive overview of advances in the mechanical processing of fly ash and fly ashderived materials, in addition to highlighting the A critical review on mechanochemical processing of fly ash and fly In this process, fly ash and bottom ash are mixed in the form of slurry, which cannot be used for the production of cement (2) The physiochemical properties of the fly ash are influenced by State of the art review on physiochemical and engineering

.jpg)

Fly Ash properties, characterization, and applications: a review

2021年7月1日 Fly ash (FA) is the principal industrial waste byproduct from the burning of solid fuels FA is a powdery solid that is constituted mostly of unburned carbon (UC), metal oxides 2021年9月2日 An optimization study was carried out for the sustainable production of coarse aggregates from fly ash and alkaline solution, considering the combined effect of alkaline Study on the Production Factors in the Process of Production and 2010年4月20日 Similarly 3 fly ash concrete beams were cast using fly ash aggregates obtained from cement fly ash propor tions 125:875, 15:85, 175:825, 20:80 and 225:775 for ages of concrete 7 days and 28 Study on Utilization of Fly Ash Aggregates in 790 The Effect of Fly Ash Based Geopolymer Aggregate Using Crushing and Pelletization Methods on the Mechanical Properties of Concrete pellets depended on the amount of activator usedThe Effect of Fly Ash Based Geopolymer Aggregate Using Crushing

Fly ash processing process flow, fly ash equipment and

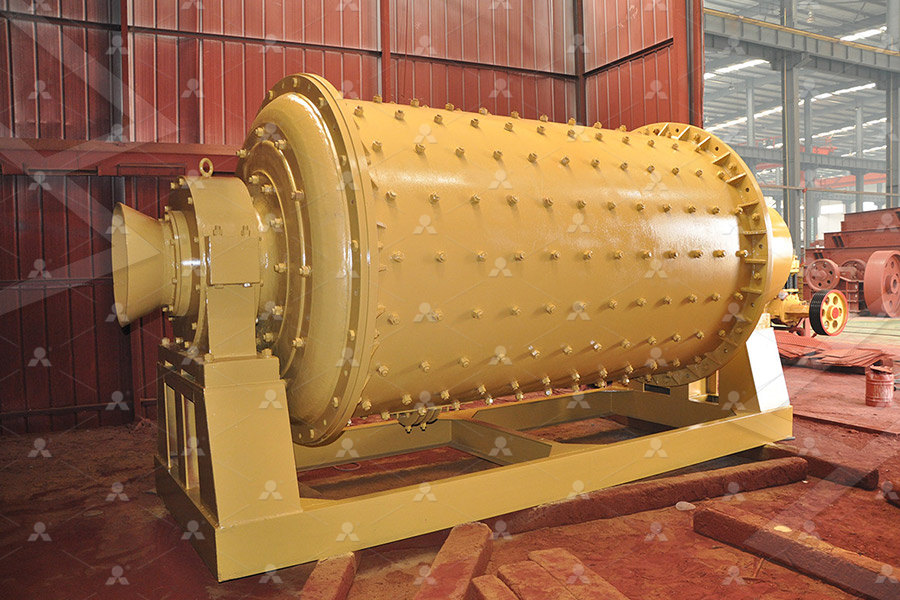

Fly Ash Processing Equipment: Baghouse filters or electrostatic precipitators for fly ash collection Drying and grinding machines for conditioning fly ash (rotary dryer, fluidized bed dryer, ball mill, vertical mill) Silos and storage containers for fly ash storage Pneumatic conveyors and other material handling equipment for fly ash handlingProduction of fly ash artificial aggregates by geopolymerisation using optimum factors and analysis of physical and mechanical properties of the produced aggregates III Materials and Methods 31 Materials 311 Fly Ash Class F fly ash is collected from North Chennai Power Plant station, Athipattu, Tamil Nadu Fly ash isProduction of Pelletized Fly Ash Aggregates by Geopolymerisation2016年11月1日 Fly ash is one of the most common waste materials created by burning of coal It is composed of smaller particles, consisting mainly of aluminosilicateglass, mullite and quartz, which are (PDF) Laboratory testing of fly ash ResearchGate2019年6月29日 The perfect combination for manufacturing a fly ash brick is 70/30 fly ash with 15% of fine aggregate and 5% of gypsum can give a better fly ash which is better in modularity, higher in strength The combination ratio of 3% 5% of cement in flyash can give a compressive strength of 518% 63% respectively which is generally more than that as compared to Class Study of Compressive Strength of FlySH Brick – IJERT

.jpg)

Fly Ash – Properties, Types, Mechanism and Uses

As fly ash contains pozzolanic materials components which reach with lime to form cementatious materials Thus Fly ash is used in concrete, mines, landfills and dams Chemical Composition of Fly Ash The chemical composition of fly ash depends upon the type of coal used and the methods used for combustion of coal2024年10月25日 This study analyzed environmental impacts and economic feasibility to evaluate whether recycling fly ash, which has rarely been addressed in previous studies, as a raw material for lightweight aggregates can be a sustainable waste management alternative This study presents a comparative analysis of three disposal scenarios: landfill disposal, recycling Recycling Fly Ash into Lightweight Aggregate: Life Cycle MDPI2024年1月30日 materials such as fly ash that contain a high volume of silicon and aluminum elements as a building block for the geopolymermade aggregates Moreover, the characteristics of these aggregates can further be improved by combining fly ash with sand during the production process It is important to further emphasize that fly ash isThe Effect of Fly Ash Based Geopolymer Aggregate Using Crushing 2018年4月30日 Salt River Materials Group (SRMG) is to remove or 'harvest' fly ash from an onsite landfill at the Colorado Generating Station owned by Salt River Project (SRP) SRMG, a supplier of portland and masonry cements, will invest additional capital dollars in beneficiation equipment to process the previously landfilled ash, resulting in a long term supply of ASTM SRMG to reclaim fly ash at Colorado Generating Station

.jpg)

COMPRESSIVE STRENGTH OF FLY ASH BRICKS IRJET

The cost of fly ash cement brick goes up as the cement is costly compared to the fly ash The use of fly ash for manufacturing of bricks is useful as it is economical and ecofriendly REFERENCES N Bhanumathidas and NKalidas, Fly ash: The resource for construction industry‘, April 2003 ,The Indian Concrete Journal, PP 9971004 (KN)2015年4月1日 China has ranked first in the coal fly ash emission in the world The multipurpose use of the fly ash from power plant waste is always an important topic for the Chinese environmental protection, which has drawn the concern of the government, scientific research departments, manufacturing enterprises and industry experts This paper introduces an New technology and application of brick making with coal fly ash2022年1月26日 Formation of Fly Ash Fly ash is formed during the coal burning process in the boiler Fly ash material solidifies while in suspension in the exhaust gases and is collected by electrostatic precipitators or filter bags Since the What is Fly Ash? Physical and Chemical Properties of 2019年5月23日 524 Composition of Fly Ash Particles The fly ash particles are composed of a mixture of various particles Therefore, the quality of fly ash mainly depends on the composition of various particles, and the quality is affected by the change in composition []Scanning electronic microscope (SEM) observation shows that fly ash includes spherical particles, slag particles, Comprehensive Utilization of Fly Ash SpringerLink

.jpg)

Chapter 1 Fly Ash An Engineering Material Fly Ash Facts for

2017年6月27日 Coarse ash particles, referred to as bottom ash or slag, fall to the bottom of the combustion chamber, while the lighter fine ash particles, termed fly ash, remain suspended in the flue gas Prior to exhausting the flue gas, fly ash is removed by particulate emission control devices, such as electrostatic precipitators or filter fabric baghouses (see Figure 11)2022年1月1日 These tests revealed that the technical properties of building materials, such as standard consistency, commencement of setting process, end of setting process and constancy of volume, as Performance assessment of flyash aggregates in concrete2024年2月20日 A novel process for the production of angularshaped high strength fly ash aggregates from an energetic, and environmental perspective is presented in this paper and compared with the production of natural aggregates This study is significant because there is an increasing demand for aggregates and no published research addressing the environmental Comparative environmental life cycle assessment of artificial fly ash Also, an empirical formula has been developed for coal fly ash ( Fisher et al 1976) as: The mineral composition of coal fly ash from burning of lignite, subbituminous, bituminous or anthracite Major elemental composition of coal fly ash Download Table

Lightweight aggregates made from fly ash using the coldbond process

2017年4月19日 Aggregates made from fly ash have been developed by means of the coldbonding process, with the addition of Portland cement as a binder at (10, 20, and 30) % of mass fractions, and by pouring the 2017年1月1日 About 112 billion tons of solid waste that is dumped every year in landfills and releases toxic chemicals in the soil, water, and air It further pollutes more than 280 billion tons of parative study on compressive strength of fly ash concrete2020年8月10日 Various effects of process parameters (fly ashtowater ratio, stirring method, ultrasonication, and size classification) were designed to examine the cenosphere recovery yield in comparison(PDF) Separation Process and MicrostructureChemical 2024年2月26日 Fly ash (FA) is a waste product of the thermal coal manufacturing process It is pozzolanic that have the properties of binding materials which get polymerized under high temperature with an Estimation of compressive strength of waste concrete utilizing fly ash

.jpg)

Manufacturing Process Of Fly Ash Bricks PPT

2016年5月3日 Manufacturing Process Of Fly Ash Bricks Download as a PDF or view online for free 5% Total Formula of Material 100% 4 Types Of Fly Ash Bricks Flyash – Sand Lime Bricks Cold Bonded Lightweight Flyash 2019年7月1日 Coal bottom ash (BA)red clay (RC or simply clay), dredged soil (DS)BA, coal fly ash (FA)red clay, DSFA were used as samples for the PI measurement From the comparison of clay bodies with BA Stabilization of Clay Soils Using Fly Ash ResearchGateInternational Journal of Science and Research (IJSR) ISSN (Online): 23197064 Impact Factor (2012): 3358 Volume 3 Issue 10, October 2014 ijsrThe Effect of Barite Content on Anti Radiation ResearchGatefly ash is always preferred for sintering process and class C fly ash for coldbonding process [3] Efficiency of pellet depends on the fineness value of fly ash [4] Also, the research study showed that the effects of binder material did not result in the change in chemical composition but enhanced the microstructure of the aggregate therebyCHARACTERIZATION ON THE STRENGTH PROPERTIES OF PELLETIZED FLY ASH

.jpg)

A Review of Ecofriendly Bricks by Using Fly Ash ResearchGate

2018年4月25日 Fly ash is a waste material of coal firing thermal plants and its accumulation near power plants causes severe pollution problems Therefore, its utilization as a raw material for brick making 101 FlyAsh Brick After Being Casted: with silica of fly ash that forms calcium silicate hydrates(CSH) that binds the ingredients to firm brick and act as a binder material The superior quality of bricks is highly dependable on the quality of fly ash are being taken(12) The process of manufacturing of fly ash Brick asStudy of Compressive Strength of FlySH Brick2017年5月1日 Alumina extraction from coal fly ash (CFA) by Na 2 CO 3 activationacid leaching method could make Al 2 O 3 and SiO 2 in CFA achieve high value utilization simultaneously, which shows wide application prospects The large consumption of Na 2 CO 3, however, limits its industrial applicationA novel process of alumina extraction from coal fly ash by “Pre Novel process of alumina extraction from coal fly ash by pre 2013年1月1日 Crushing strength of lightweight aggregates depends on the efficiency of production, type of binder used and size of the aggregate formed Fly ash based slag pellets were produced in the present Crushing strength properties of furnace slagfly ash blended

Study on Utilization of Fly Ash Aggregates in

2010年4月20日 Similarly 3 fly ash concrete beams were cast using fly ash aggregates obtained from cement fly ash propor tions 125:875, 15:85, 175:825, 20:80 and 225:775 for ages of concrete 7 days and 28 790 The Effect of Fly Ash Based Geopolymer Aggregate Using Crushing and Pelletization Methods on the Mechanical Properties of Concrete pellets depended on the amount of activator usedThe Effect of Fly Ash Based Geopolymer Aggregate Using Crushing Fly Ash Processing Equipment: Baghouse filters or electrostatic precipitators for fly ash collection Drying and grinding machines for conditioning fly ash (rotary dryer, fluidized bed dryer, ball mill, vertical mill) Silos and storage containers for fly ash storage Pneumatic conveyors and other material handling equipment for fly ash handlingFly ash processing process flow, fly ash equipment and Production of fly ash artificial aggregates by geopolymerisation using optimum factors and analysis of physical and mechanical properties of the produced aggregates III Materials and Methods 31 Materials 311 Fly Ash Class F fly ash is collected from North Chennai Power Plant station, Athipattu, Tamil Nadu Fly ash isProduction of Pelletized Fly Ash Aggregates by Geopolymerisation

.jpg)

(PDF) Laboratory testing of fly ash ResearchGate

2016年11月1日 Fly ash is one of the most common waste materials created by burning of coal It is composed of smaller particles, consisting mainly of aluminosilicateglass, mullite and quartz, which are 2019年6月29日 The perfect combination for manufacturing a fly ash brick is 70/30 fly ash with 15% of fine aggregate and 5% of gypsum can give a better fly ash which is better in modularity, higher in strength The combination ratio of 3% 5% of cement in flyash can give a compressive strength of 518% 63% respectively which is generally more than that as compared to Class Study of Compressive Strength of FlySH Brick – IJERTAs fly ash contains pozzolanic materials components which reach with lime to form cementatious materials Thus Fly ash is used in concrete, mines, landfills and dams Chemical Composition of Fly Ash The chemical composition of fly ash depends upon the type of coal used and the methods used for combustion of coalFly Ash – Properties, Types, Mechanism and Uses2024年10月25日 This study analyzed environmental impacts and economic feasibility to evaluate whether recycling fly ash, which has rarely been addressed in previous studies, as a raw material for lightweight aggregates can be a sustainable waste management alternative This study presents a comparative analysis of three disposal scenarios: landfill disposal, recycling Recycling Fly Ash into Lightweight Aggregate: Life Cycle MDPI

The Effect of Fly Ash Based Geopolymer Aggregate Using Crushing

2024年1月30日 materials such as fly ash that contain a high volume of silicon and aluminum elements as a building block for the geopolymermade aggregates Moreover, the characteristics of these aggregates can further be improved by combining fly ash with sand during the production process It is important to further emphasize that fly ash is2018年4月30日 Salt River Materials Group (SRMG) is to remove or 'harvest' fly ash from an onsite landfill at the Colorado Generating Station owned by Salt River Project (SRP) SRMG, a supplier of portland and masonry cements, will invest additional capital dollars in beneficiation equipment to process the previously landfilled ash, resulting in a long term supply of ASTM SRMG to reclaim fly ash at Colorado Generating Station