Cement vertical mill structure diagram

.jpg)

Vertical roller mill for raw Application p rocess materials

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Loesche is launching its new LMMaster for advanced vertical roller mill (VRM) control This automation solution stabilises the VRM to allow operation with lower vibration It also optimises FOR VERTICAL ROLLER MILLS LoescheThe quadropol® vertical roller mill by thyssenkrupp Industrial Solutions takes a holistic approach to modern grinding systems in terms of its simple and compatible design Describing the key VERTICAL ROLLER MILLS A holistic VRM approach2023年7月4日 Structure diagram of vertical roller mill Working principle: the motor drives the grinding table to rotate through the reducer, the material falls into the center of the grinding Roller Mill SpringerLink

.jpg)

Schematic of raw vertical roller mill circuit in the Ilam

Download scientific diagram Schematic of raw vertical roller mill circuit in the Ilam cement plant from publication: Modeling of energy consumption factors for an industrial cementThe core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and most efficient PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTSContribute to sbm2023/sbm development by creating an account on GitHubsbm/sbm cement plant vertical mill structure diagrammd at main UBE Machinery Corporation Ltd, Japan to manufacture supply stateoftheart UBE Vertical Roller Mills for grinding applications related to Raw material, Coal, Clinker and Slag The mill VERTICAL ROLLER MILLS AMCL

.jpg)

SikaGrind® for vertical roller mills

Expressed as inclination of the particle size distribution according RRSB, cements from ball mills generally have a rather low slope [n’] In a VRM the grinding takes place by pressure and 2017年9月11日 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the circuit to(PDF) Performance Evaluation of Vertical Roller Mill in 2022年5月9日 By initiating a CL for an industrial cement vertical roller mill SHAPXGBoost could provide higher accuracy for VRMCL structure than conventional based on the following diagram Modeling of energy consumption factors for an industrial cement What Is A Cement Ball Mill The cement ball mill is a kind of cement grinding millIt is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical, and electric Cement Ball Mill Cement Grinding Machine

.jpg)

Raw Mill – Raw Mill In Cement Plant AGICO Cement

AGICO Cement Vertical Mill AGICO Cement Ball Mill Cement Vertical Mill Grinding System Cement vertical mill, also called roller mill, is another raw mill commonly used in cement pared with the cement ball mill, it has a CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS In a ball mill, the particles are ground by repeated impact forces The material usually needs more than 20 minutes of grinding from mill entrance to outlet, with uncountable impacts take place on this way Depending on the efficiency of the separatorPicture: Loesche GmbH, Germany CEMENT SikaGrind® FOR VERTICAL ROLLER MILLThe cement raw materials (lime, silica and iron ore) enter the circuit through two apron feeders The raw materials are crushed in a hammer crusher to D 95 of 80mm The raw materials are mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The vertical roller mill grinds the marital to D 85 of 90µmModeling and simulation of vertical roller mill using population Vertical roller mill manufacturers Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding materialIt integrates grinding, drying, separation, and conveying in one machine The equipment is widely used in many industries such as cement, electric power, metallurgy VRM In Cement Plant Maximize Energy Saving CNBMSINOMA

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has The annual production capacity reaches 150,000 tons of equipment and structure parts and 20,000 tons of casting parts EPC project: the vertical cement mill or the cement roller press system Instability of kiln dust mixing: kiln ash is part of Raw mill Cement PlantVertical cement mill has high grinding efficiency and low power consumption (20% – 30% less than ball mill) The granularity of the feeding material is larger(VRM cement mill is 80mm120mm, cement ball mill is less than or equal to 30mm)Vertical Cement Mill Cement Clinker Grinding Equipment in Cement Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plantVertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one It can be widely used in cement, electric power, metallurgy, chemical industry, nonmetallic ore, and other industriesVertical raw mill Cement Plant

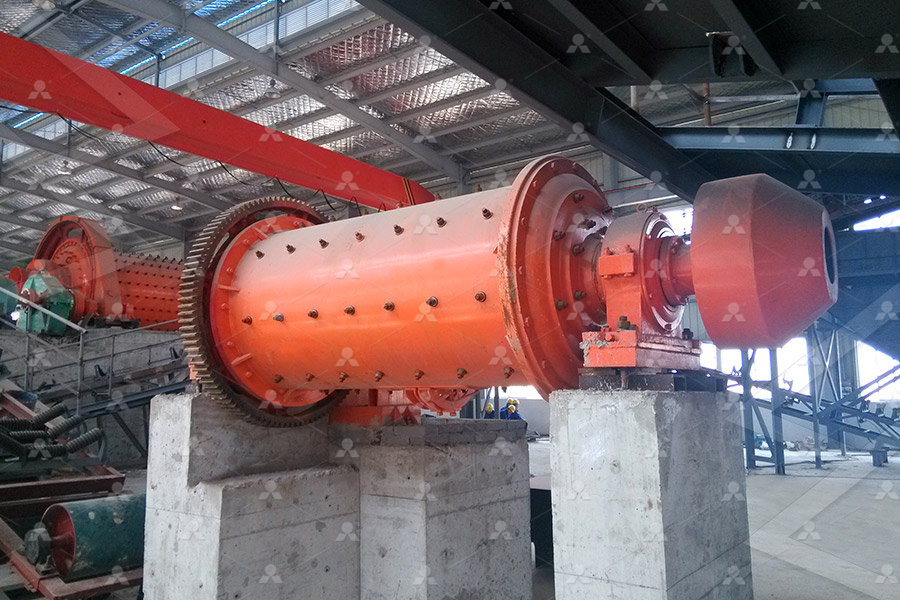

EVERY COMPONENT OF BALL MILL DETAILED

EVERY COMPONENT OF BALL MILL DETAILED EXPLAINED To Download this post + all manuals and books and Excel sheets and all notes I collected over my 23 years of experiance in Cement industry click here now Transmission Stage: two stages, power double split structure; three stages, parallel gears+ power double split structure Rated Power: 800 – 8,000 kW Applications Applied to industries such as cement processing, coal and mines etc, the gearboxes are used for tube mill to grind materials such as ore, coal sheets or cement clinker01 NGC Gears2 VERTICAL ROLLER MILLS INTERNATIONAL CEMENT REVIEW SEPTEMBER 2021 played by the mill foundation, which has been optimised to reduce vibrations2 Built to last The mill foundation, ie, the basic block with its four concrete pylons, is responsible for the smooth running of the mill The roller units and mill housing are notVERTICAL ROLLER MILLS A holistic VRM approachVertical Roller Mill 1 Rotary Lock 2 Separator 3 Chute 4 Roller 5 Swing UMseries Cement / Slag Mill Models with details of structural Cement Grinding Coal Mill UM Series 2 Rollers 3 Rollers UMseries Coal Mill Models with details of structural dimension, product throughputs and driving power (approx Values) Roller Arrangement A B HVERTICAL ROLLER MILLS AMCL

.jpg)

(PDF) Performance Evaluation of Vertical Roller Mill in Cement

2017年9月11日 PDF In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg the model structure was focused on using separate breakage tests for By initiating a CL for an industrial cement vertical roller mill (VRM), this study conducted a novel strategy to explore relationships between VRM monitored operational variables and their Schematic operation principle of a verticalrollermillThe large vertical mill has complicated structure and tens of thousands of parts, which is a critical grinding equipment for slag and cinder As large vertical mill always works in severe Vertical mill and its schematic diagram: (a) vertical mill and (b Download scientific diagram The layout of the coal mill with a rotary classifier from publication: An investigation of performance characteristics and energetic efficiency of vertical roller The layout of the coal mill with a rotary classifier

.jpg)

Vertical Shaft Kiln AGICO Cement Plant

The vertical shaft kiln (VSK), or vertical kiln, is a kind of industrial equipment used to calcinate cement clinker It is often used in small and mediumsized cement plants for cement production With the continuous development of cement production technology, the shaft kiln in many regions of the world has been replaced by the rotary kiln , a more advanced cement clinker calcination 2024年1月1日 The basic structure of the vertical roller mill with vertical arrangements comprises the engine body, the grinding table device, and the driving device A centering structure for determining the rotation center is set between the body and the grinding table device, and a rotary guide rail is arranged at the bottom of the grinding table, which can be rotated and supported Roller Mill SpringerLinkDownload scientific diagram Schematic of raw vertical roller mill circuit in the Ilam cement plant from publication: Modeling of energy consumption factors for an industrial cement vertical Schematic of raw vertical roller mill circuit in the Ilam Shaft kiln, also known as vertical kiln, vertical shaft kiln, is a vertical and fixed clinker firing equipmentThe raw meal ball with coal is fed into cement kiln from the kiln crown, and raw meal ball moves from top to bottom, air move from Shaft Kiln, Vertical Shaft Kiln, Vertical Kiln Cement

Leading Steel building SupplierXinguangzheng Steel

Qingdao Xinguangzheng steel structure company undertakes the construction of structural strength laboratory, trial production repid reaction center and UAV assembly and commissioning laboratory The total area is 42075 square Download scientific diagram The VRM grinding circuit at Ilam cement plant from publication: Modeling and simulation of vertical roller mill using population balance model There are few studies The VRM grinding circuit at Ilam cement plantVertical roller mill vs ball mill for cement grinding: Comparison the advantages and disadvantages of these two types of mills Vertical roller mill vs ball mill for cement grinding: Comparison the advantages and disadvantages of these two types of mills TO Download this post and all the books and excel sheets and my personal notes and presentations I collected about cement Vertical Roller Mill (VRM) INFINITY FOR CEMENT EQUIPMENTDownload scientific diagram Operation of vertical roller mill circuit from publication: An approach to measuring and modelling the residence time distribution of cement clinker in vertical Operation of vertical roller mill circuit Download Scientific Diagram

.jpg)

VRM Differential Pressure V/s Mill Feed PID Loop

Download scientific diagram VRM Differential Pressure V/s Mill Feed PID Loop from publication: Increase productivity of vertical roller mill using seven QC tools Cement sector in india is Airswept coal mill is the main equipment of cement plant, also called coal mill in cement plant, used for grinding and drying various hardness of coal, crushing the coal briquette into pulverized coalIt is the important auxiliary equipment of pulverized coal furnace The airswept coal mill runs reliably, can work continuously, also has a large production capacity and less energy Coal Mill In Cement Plant, Airswept Coal Mill Coal Mill80 mm e raw materials were mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) e raw vertical roller mill has four rollers, 3000 KW main drive, 48 m table diameter Modeling of energy consumption factors for an industrial cement the capacity of grinding and drying of mill The grindability affects the capacity of grinding, type of mill and roller pressure The capacity of the mill is calculated Using G K * D 251 Where, G is capacity of the mill, K1 is roller mill coefficient and D is table diameter 2 PROCESS CONTROL OF VRM The conventional control system of VRMPROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL

.jpg)

Modeling of energy consumption factors for an industrial cement

2022年5月9日 By initiating a CL for an industrial cement vertical roller mill SHAPXGBoost could provide higher accuracy for VRMCL structure than conventional based on the following diagram What Is A Cement Ball Mill The cement ball mill is a kind of cement grinding millIt is mainly used for grinding the clinker and raw materials of the cement plant, and also for grinding various ores in metallurgical, chemical, and electric Cement Ball Mill Cement Grinding MachineAGICO Cement Vertical Mill AGICO Cement Ball Mill Cement Vertical Mill Grinding System Cement vertical mill, also called roller mill, is another raw mill commonly used in cement pared with the cement ball mill, it has a Raw Mill – Raw Mill In Cement Plant AGICO Cement CEMENT SikaGrind® FOR VERTICAL ROLLER MILLS In a ball mill, the particles are ground by repeated impact forces The material usually needs more than 20 minutes of grinding from mill entrance to outlet, with uncountable impacts take place on this way Depending on the efficiency of the separatorPicture: Loesche GmbH, Germany CEMENT SikaGrind® FOR VERTICAL ROLLER MILL

Modeling and simulation of vertical roller mill using population

The cement raw materials (lime, silica and iron ore) enter the circuit through two apron feeders The raw materials are crushed in a hammer crusher to D 95 of 80mm The raw materials are mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The vertical roller mill grinds the marital to D 85 of 90µmVertical roller mill manufacturers Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding materialIt integrates grinding, drying, separation, and conveying in one machine The equipment is widely used in many industries such as cement, electric power, metallurgy VRM In Cement Plant Maximize Energy Saving CNBMSINOMAvertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTSThe annual production capacity reaches 150,000 tons of equipment and structure parts and 20,000 tons of casting parts EPC project: the vertical cement mill or the cement roller press system Instability of kiln dust mixing: kiln ash is part of Raw mill Cement Plant

.jpg)

Vertical Cement Mill Cement Clinker Grinding Equipment in Cement

Vertical cement mill has high grinding efficiency and low power consumption (20% – 30% less than ball mill) The granularity of the feeding material is larger(VRM cement mill is 80mm120mm, cement ball mill is less than or equal to 30mm)Vertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plantVertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one It can be widely used in cement, electric power, metallurgy, chemical industry, nonmetallic ore, and other industriesVertical raw mill Cement Plant