Hurricane steel mill steel slag mill rp

Comprehensive utilization of steel slag: A review ScienceDirect

2023年5月15日 Steel slag, the main solid waste in the steelmaking process, is produced more than 120 million tons annually in China Most of the steel slag was stored in the open air, 2007年3月1日 Steel slag is the main waste product in the steelmaking process Because of its chemical composition and technical properties, it can be reused as raw material in steel plants An overview of utilization of slag and sludge from steel industries2011年10月26日 Steel slag is a byproduct of the steelmaking and steel refining processes This paper provides an overview of the different types of steel slag that are generated from basic Chemical, Mineralogical, and Morphological Properties of Steel 2020年4月1日 Rapid cooled basic oxygen furnace slag (RCBOFS) is derived from a new slag process called Baosteel Slag Short Flow, which involves treating molten steel slag with Basic oxygen furnace slag: Review of current and potential uses

(PDF) Industrial uses of slag The use and reuse of iron and

2005年2月1日 Steelmakers have made attempts to reduce slag volumes in the individual unit processes and to strive towards slagless steelmaking by recycling slags internally A much 2012年2月8日 The energy potential of steel mill slags is about 026 GJ/ton of steel, which implies a worldwide estimated energy wastage of about 37010 3 TJ per year Research on Steel mill slags energy potential: the case of the steel factory of 2020年10月15日 Capturing CO 2 by steel slag (SS) via mineralization is regarded to be an excellent choice due to the high basicity of the slag In this paper, recent research on the steel Cotreatment of Waste From Steelmaking Processes: Steel Slag 2018年2月5日 This paper reviews the characteristics of steel slag and its usage The paper reviews recent developments in wellknown applications to the steel slag such as aggregate in Review on the innovative uses of steel slag for waste minimization

Hydrometallurgical Processes for the Recovery of Metals from

The state of the art for the recovery of metals from steel industry byproducts using hydrometallurgical processes is reviewed The steel byproducts are different slags, dusts, and 2004年5月14日 Steel slag is a byproduct from either the conversion of iron to steel in a basic oxygen furnace, or the melting of scrap to make steel in an electric arc furnace This paper Steel Slag—Its Production, Processing, Characteristics, and 2002年7月1日 Semantic Scholar extracted view of "Pelletizing steel mill desulfurization slag" by S Kawatra et al Use of Pelletized Slag in Concrete Masonry Units Rp Cotsworth Engineering, Materials Science 1978; This paper contains a brief description of the slag pelletizer and the external pressures which led to its developmentPelletizing steel mill desulfurization slag Semantic Scholar2012年2月8日 Slag accounts for most of the residuals or byproducts of the steel manufacturing process and represents a not inconsiderable amount of energy waste and CO2 emissions Energy recovery from steel mill slags is not actually performed because of the difficulty of the industrial implementation, but the actual demand and the incentives for new electricity generation plants Steel mill slags energy potential: the case of the steel factory of

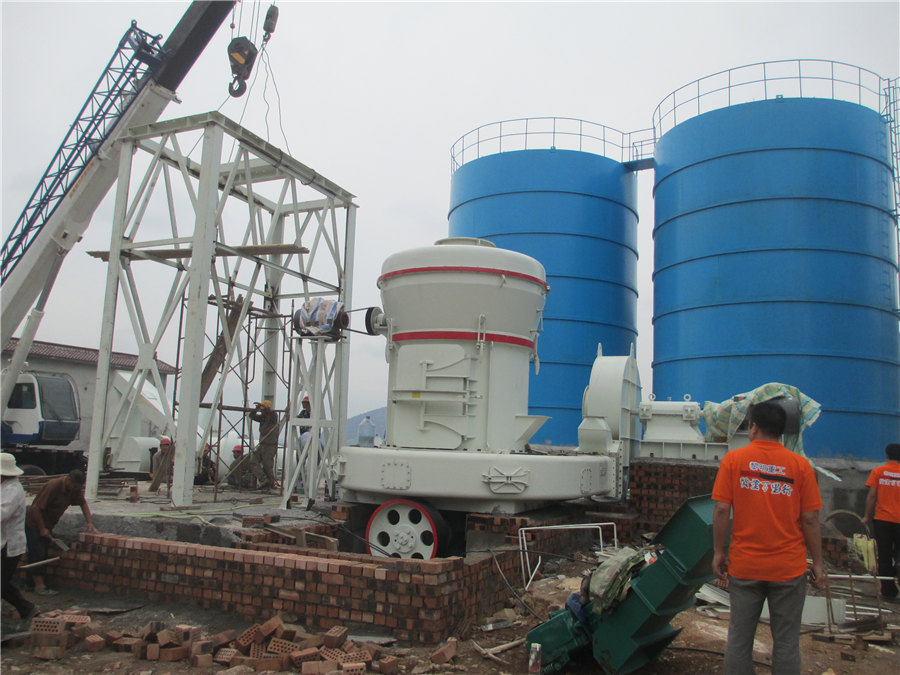

Loesche Mills for Metal Recovery and Filler Production from Steel Slag

A typical process variation for special steel slag reduction is depicted in the following flow diagram Features of the Loesche process for the complete and dry processing of steel slag Loesche Mill type LM 15200 under construction Loesche Steel slag, in addition to being a lowcost alternative to its quarriedstone counterparts, is readily available at several facilities in New Jersey and Pennsylvania The NJDEP requires that all clean fill sources be screened and tested in accordance with the Alternative and Clean Fill Guidance Document, dated December 29, 2011Steel Slag Alternative to Crushed Stone and Clean Fill SESIWhat is Slag? There are two distinct types of slag produced at the BlueScope Steel Port Kembla Site; Blast Furnace Slag and Steel Furnace (or BOS) Slag BLAST FURNACE SLAG Iron is extracted from iron ore in a blast furnace by a process known as reduction The raw materials iron ore, coke and fluxes are fed into the top of the furnaceWhat is Slag? Australian Steel Mill ServicesOnce viewed as a waste product, steel mill slag is now generally engineered to be useful byproducts Principal uses of slag include concrete and asphalt aggregates It is also extensively utilized for placement of highway shoulder berms, driveway and parking lot fills, stream bank protection, and as railroad grade ballast Slag has been used Impacts of Steel Mill Slag Leachate on the Water Quality of a

.jpg)

Magnet Associated Rare Earths in Steel Mill Slags ResearchGate

World of Metallurgy – ERZMETALL 0 (2017) No 5 273 Janina Daul et al: Magnet Associated Rare Earths in Steel Mill Slags REEinput in the slag needs to consider the natural REEPouring Molten slag from a melt pot at a steel mill The radiant heat from this was almost to much even at this distanceSteel Mill pouring Molten Slag from the melt pot YouTube2015年9月9日 steel mill slag materials resulting from the former iron and steel operations The steel mill slag material is incapable of sustaining vegetation, and the site has been vacant since the 1970s (Fig 1); however, parks and residential and commercial development are planned for the site The slag will need to be capped with topsoilGreening a Steel Mill Slag Brownfield with Biosolids and ACSESS2018年2月5日 Piles of steel slag, a solid waste generated from the iron and steel industry, could be seen due to no utility found for the past century Steel slag has now gained much attention because of its new applications The properties of slag greatly influence its use and thus had got varied applications The chemical composition of steel slag varies as the mineral composition Review on the innovative uses of steel slag for waste minimization

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

Indiana steel mill fire blamed on slag being dumped on water

2018年11月7日 EAST CHICAGO, Ind (AP) — A steel company is blaming a fire at a northwestern Indiana mill on slag being dumped onto an area containing water The fire Monday afternoon injured a worker and sent smoke billowing from ArcelorMittal's steel mill along Lake Michigan in East Chicago ArcelorMittal says in a statement that the injured worker was 2018年1月1日 The flexural strength has slightly decreased for the partially replacement of steel slag and mill scale slag by adding as coarse aggregate and the mechanical properties of 30% partially Experimental study on behavior of concrete by partially replacing 2016年1月21日 As a result of this growing environmental awareness, steel slag is now highly regarded as a recycled material that can reduce environmental impact due to its resourceconservation and energysaving properties What’s Steel Slag: The Incredible, Upcycable Byproduct of 2023年10月25日 Friday, October 20th, was groundbreaking day for Nucor Steel’s mill in Mason County The event was a big deal US Senators Joe Manchin and Shelley Moore Capito were among the Guinness record setting 545plus to take shovelinhand at the ceremony The steel sheet mill at $27 billion is the largest investment in the history of NucorNucor Steel Breaks Ground for New Mill Hurricane Breeze

Steel Train Dumping Liquid Molten Slag

2015年1月9日 The steel making process produces the waste byproduct of slag In this clip, the Bethlehem Steel Works shows how it’s done!Taking the slag from the steel mill on special “slag cars” which act as giant ladles and dumping the contents into the slag pit The slag cars generally have two ladles (or buckets) per car and are dumped electronically2015年5月22日 Slags, Steel Making 100 6 Other Substances in the product which may present a health or environmental hazard, or which have been assigned occupational exposure limits, are detailed below Please see Section 8 of SDS for more details Contains: Dust may contain >1% crystalline silica and/or manganese (inherent in the slag)STEEL MAKING SLAGMetallurgical Equipment Slag Pots for Steel Mill Applic [] Skip to content Leading supplier of high alloy castings and forgings Leading supplier of high alloy castings and forgings Office Hours 9:0018:00 {Sun:Closed} WeChat ID / Number 0086131 7966 3014 Us sales@ebcastworld Home;Metallurgical Equipment Slag Pots /Slag Ladles for Steel MillThe main challenge of the steel industry for the next decade is the steel production transformation process, starting in Europe The CO 2 intensive blast furnace/basic oxygen furnace (BOF) route will be substituted by a combination of Direct Reduced Iron (DRI), based on natural gas, later on “green” hydrogen, with an Electric Arc Furnace (EAF) or a Submerged Arc Furnace (SAF), The steel production transformation process in Europe: New slag

.jpg)

(PDF) Iron and Steel Slags ResearchGate

2017年3月5日 In the USA, steel slag is currently sold and used for various applications, pre could be quite signi fi cant for an individual steel mill [84] References 12011年1月1日 Steel slag is a byproduct of the steelmaking and steel refining processes This paper provides an overview of the different types of steel slag that are generated from basicoxygenfurnace (BOF Chemical, Mineralogical, and Morphological Properties of Steel SlagSteel furnace slag steel scrap processing mill scale debris handling Seatac Steel Mill Recycling Services is located in Seattle, WA and is a supplier of Slag FIND A SUPPLIER: GET A QUOTE: INDUSTRYNET BLOG: ABOUT INDUSTRYNET: MARKETINGSeatac Steel Mill Recycling Services Seattle, WA Slag2007年3月1日 The various solid wastes in the form of slags and sludges that are emerged from steel plants are blast furnace slag, blast furnace flue dust and sludge, Linz–Donawitz (LD) converter slag, LD sludge, LD dust, mill scale, mill sludge, acetylene sludge, etc The solids and liquid wastes generated from a steel plant are shown in Table 1An overview of utilization of slag and sludge from steel industries

.jpg)

Slag pit blast at East Chicago steel mill being probed

EAST CHICAGO, Ind (AP) — The state of Indiana is investigating a slag pit explosion at a northwestern Indiana steel mill, it said Tuesday The explosion Sunday in a raw materials section of the sprawling ClevelandCliffs Indiana Harbor West mill on the Lake Michigan shoreline “was caused by rainwater meeting the hot slag,” the Indiana Department of Environmental 2012年3月27日 Pueblo's steelmaking past shines in the subtle colors of jewelry being created today Frances "BeBe" Burns and Turner Ray are collaborating on Blast Furnace Gems, which are bracelets, necklacSteel mill slag shows its true colors Pueblo ChieftainAs a result of its many years of activity in electric arc furnaces and oxygen steel plant, FUSIREF has developed activities covering slag management, transport, processing and recycling This enables it to diversify its activities while remaining true to its core business, and to pool its services across a wider area of operationSteel mill slag processing Fusiref2024年2月9日 Algoma Steel Group Inc suffered another incident at its steel mill in Sault Ste Marie, Ontario, this week In the late evening of Wednesday, Feb 7, there was an incident at the north casthouse of its blast furnace complex, the steelmaker said in a statement on FridayAnother incident hits Algoma Steel mill Steel Market Update

Research on the Properties of Steel Slag with Different MDPI

2024年3月28日 To promote the resource utilization of steel slag and improve the production process of steel slag in steelmaking plants, this research studied the characteristics of three different processed steel slags from four steelmaking plants The physical and mechanical characteristics and volume stability of steel slags were analyzed through density, water 2016年1月1日 GEOTECHNICAL CHARACTERISTICS OF INDUSTRIAL WASTE SLAG AND SLUDGE FROM SMEDEREVO STEEL MILL, SERBIA January 2016; Journal of Environmental Protection and Ecology 17(2):512522; Authors:GEOTECHNICAL CHARACTERISTICS OF INDUSTRIAL WASTE SLAG 2023年3月12日 Mediterranean countries experience a large production of olive oil, thus generating huge quantities of nonbiodegradable vegetation waters The discharge of these effluents into aquatic environments seriously affects the quality of surface waters This study investigated the potential use of carbon steel slag (SS) as an adsorbent and improver for Efficient Removal of Tannic Acid from Olive Mill Wastewater Using 2002年7月1日 Request PDF Pelletizing steel mill desulfurization slag Hot metal desulfurization slag is a highmetallic iron content slag produced at a typical steelmaking facility and is currently Pelletizing steel mill desulfurization slag Request PDF

.jpg)

Pelletizing steel mill desulfurization slag Semantic Scholar

2002年7月1日 Semantic Scholar extracted view of "Pelletizing steel mill desulfurization slag" by S Kawatra et al Use of Pelletized Slag in Concrete Masonry Units Rp Cotsworth Engineering, Materials Science 1978; This paper contains a brief description of the slag pelletizer and the external pressures which led to its development2012年2月8日 Slag accounts for most of the residuals or byproducts of the steel manufacturing process and represents a not inconsiderable amount of energy waste and CO2 emissions Energy recovery from steel mill slags is not actually performed because of the difficulty of the industrial implementation, but the actual demand and the incentives for new electricity generation plants Steel mill slags energy potential: the case of the steel factory of A typical process variation for special steel slag reduction is depicted in the following flow diagram Features of the Loesche process for the complete and dry processing of steel slag Loesche Mill type LM 15200 under construction Loesche Loesche Mills for Metal Recovery and Filler Production from Steel SlagSteel slag, in addition to being a lowcost alternative to its quarriedstone counterparts, is readily available at several facilities in New Jersey and Pennsylvania The NJDEP requires that all clean fill sources be screened and tested in accordance with the Alternative and Clean Fill Guidance Document, dated December 29, 2011Steel Slag Alternative to Crushed Stone and Clean Fill SESI

What is Slag? Australian Steel Mill Services

What is Slag? There are two distinct types of slag produced at the BlueScope Steel Port Kembla Site; Blast Furnace Slag and Steel Furnace (or BOS) Slag BLAST FURNACE SLAG Iron is extracted from iron ore in a blast furnace by a process known as reduction The raw materials iron ore, coke and fluxes are fed into the top of the furnaceOnce viewed as a waste product, steel mill slag is now generally engineered to be useful byproducts Principal uses of slag include concrete and asphalt aggregates It is also extensively utilized for placement of highway shoulder berms, driveway and parking lot fills, stream bank protection, and as railroad grade ballast Slag has been used Impacts of Steel Mill Slag Leachate on the Water Quality of a World of Metallurgy – ERZMETALL 0 (2017) No 5 273 Janina Daul et al: Magnet Associated Rare Earths in Steel Mill Slags REEinput in the slag needs to consider the natural REEMagnet Associated Rare Earths in Steel Mill Slags ResearchGatePouring Molten slag from a melt pot at a steel mill The radiant heat from this was almost to much even at this distanceSteel Mill pouring Molten Slag from the melt pot YouTube

.jpg)

Greening a Steel Mill Slag Brownfield with Biosolids and ACSESS

2015年9月9日 steel mill slag materials resulting from the former iron and steel operations The steel mill slag material is incapable of sustaining vegetation, and the site has been vacant since the 1970s (Fig 1); however, parks and residential and commercial development are planned for the site The slag will need to be capped with topsoil2018年2月5日 Piles of steel slag, a solid waste generated from the iron and steel industry, could be seen due to no utility found for the past century Steel slag has now gained much attention because of its new applications The properties of slag greatly influence its use and thus had got varied applications The chemical composition of steel slag varies as the mineral composition Review on the innovative uses of steel slag for waste minimization