How is gypsum processing

Infrastructure and Construction Materials Guide —

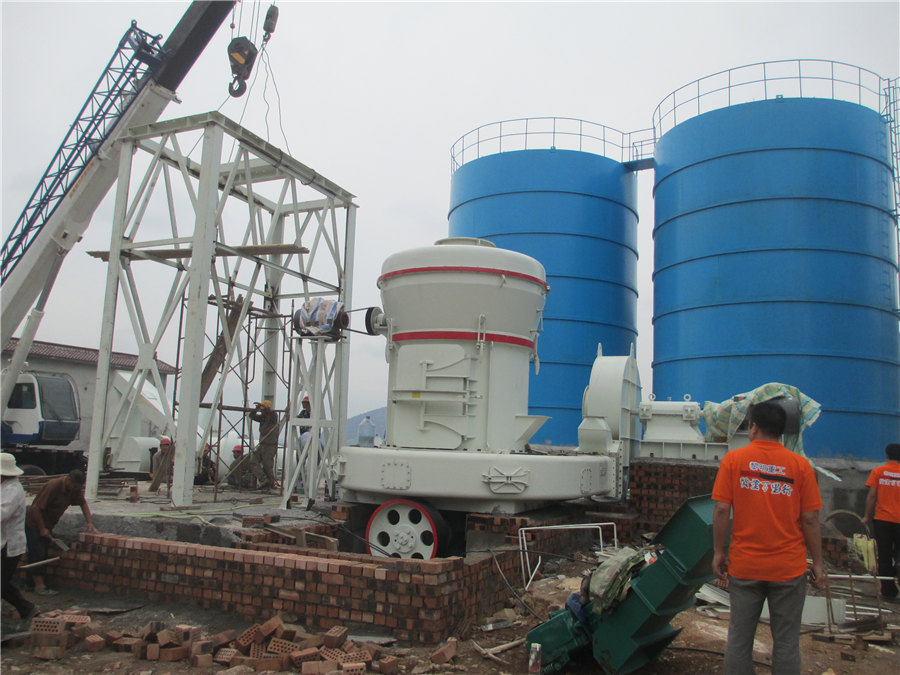

Gypsum processing can be divided into three basic steps: (1) rock preparation, (2) calcining, and (3) formulating and manufacturing This is illustrated graphically with the flow chart in Figure 1 The specifics of each step will vary with the Gypsum processing can be divided into three basic steps: (1) rock preparation, (2) calcining, and (3) formulating and manufacturing This is illustrated graphically with the flow chart in Figure 1 The specifics of each step will vary with the Infrastructure and Construction Materials Guide — 2023年9月9日 Gypsum is a naturally occurring mineral that has been used by humans for various purposes for thousands of years It is a versatile mineral with a wide range of applications in construction, agriculture, industry, and even Gypsum Properties, Formation, Uses and DepositsGYPSUM PROCESSING AND USE Gypsum is a particularly useful processed material Its main application is as a building material, mostly produced as socalled plaster of Paris for plastering walls and making decorative features in buildings However gypsum also has a diversity ofGypsum processing and use Humanitarian Library

Gypsum Minerals Education Coalition

Gypsum Gypsum is a mineral found in crystal form as well as masses called gypsum rock It is a very soft mineral and it can form very pretty, and sometimes extremely large colored crystals Massive gypsum rock forms within layers of sedimentary rock, typically found in Gypsum processing equipment differs significantly in scale and level of technology some plants produce one or two tonnes per day using lowcost manual technologies, some other plants of a thousand tonnes per day that are highly mechanized and capable of producing different types and grades of gypsum plaster or plaster boardsGypsum Mining Processing Equipment Flow Chart JXSCASTM standards govern the manufacture of gypsum board and set strict criteria for strength, water resistance, and other characteristics To produce gypsum board, crushed natural gypsum or synthetic gypsum is heated or calcined to dehydrate the feedstock Next the calcined gypsum is mixed with water and additives to form a slurry which is fedMaking Gypsum Board Gypsum AssociationGypsum is normally only screened to remove ‘fines’ (mainly mudstones), then crushed and finely ground Gypsum/Anhydrite for cement manufacture is supplied in crushed form for further fine grinding with cement clinker C Processing Natural Gypsum When Gypsum ( CaSO 4,2H 2O) is ground to a powder and heated at 150° to 165° C, threeFactsheet on: What is Gypsum?

.jpg)

What is Gypsum How Gypsum is Processed MC

Raw Gypsum is calcium sulfate dihydrate ((Ca (SO 4) 2H 2 O), also known as gypsum dihydrate, gypsum or gypsum, composition CaO (326%), Grinding, processing equipments Reply jamal Sowid says: 07/07/2021 at 21:13 Thanks for the effort and all the infoChemical Processing of Phosphate (gypsum) is also produced This byproduct gypsum is called phosphogypsum There are approximately five tons of phosphogypsum produced for every ton of phosphoric acid product produced Phosphogypsum, like natural gypsum, is Chemical Processing of Phosphate Florida Polytechnic University2015年1月1日 After starting up the Mt Cattlin mine and its processing plant producing (∼6% Li 2 O) spodumene concentrate in Western Australia for its Jiangsu lithium carbonate processing plant in China (capacity 17,000 tpa), Galaxy Resources Ltd (Australia) halted its production in July 2012, although the mine is considered still holding a total resource of 1818 Mt Li 2 O with a Lithium Production Processes ScienceDirectGypsum is normally only screened to remove ‘fines’ (mainly mudstones), then crushed and finely ground Gypsum/Anhydrite for cement manufacture is supplied in crushed form for further fine grinding with cement clinker C Processing Natural Gypsum When Gypsum ( CaSO 4,2H 2O) is ground to a powder and heated at 150° to 165° C, threeFactsheet on: What is Gypsum?

.jpg)

Gypsum Mining Method Cost 911Metallurgist

2021年2月17日 Gypsum and its products are economical materials in their respective fields Gypsum and anhydrite, particularly the latter, may be converted to ammonium sulfate fertilizer by processing with coke and 2024年11月18日 5 Bryan A Diffley: Processing Scrap Drywall Onsite In 2023, Bryan A Diffley filed a patent in the US for an onsite gypsum board recycling system that uses a portable crusher to reduce scrap drywall volume at Gypsum Recycling: An Environmental and Industrial Mineralogically identical to natural gypsum, FGD gypsum, or synthetic gypsum, is produced from gas captured within emission control systems at coal fired electric utilities An emission that would compromise air quality, sulfur dioxide (SO2) gas, is the primary contribution coal makes to FGD gypsum Utilities that produce panelgrade synthetic gypsum beneficially reuse FGD sludge FGD Gypsum Production Process2024年5月16日 By understanding the key aspects of the gypsum industry and the importance of gypsum in construction, you can lay a strong foundation for your gypsum business Conducting market research, developing a business plan, and obtaining the necessary legal requirements and permits are crucial steps to take before moving forwardThe Gypsum Board Manufacturing Process Unveiled Osum

.jpg)

How Tofu Is Processed IFT

2016年2月1日 This month’s Processing column will continue the theme of “How Is It Processed?” The column will focus on tofu, which is sometimes called “the cheese of Asia” It is a nutritious, proteinrich bean curd made by coagulating soy milk There are many different types of tofu, and they are processed in a variety of waysThe major difference in processing gypsum is that it must be dehydrated to form calcium sulfate, the major component of colored chalk This is done in a kettle, a large combustion chamber in which the gypsum is heated to between 244 and 253 How chalk is made material, making, used, processing, 2024年11月23日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by Cement Extraction, Processing, Manufacturing Britannica2023年9月7日 The soy milk is then coagulated to separate the proteins and fats from the liquid Various coagulants can be used, such as calcium sulfate (nigari), magnesium chloride (bittern), gypsum, or other natural coagulants These coagulants cause the soy proteins to bind together and form curds while leaving the liquid, or whey, behindHow is Tofu Made? (Behind the Scenes Look) World of Vegan

.jpg)

What is Gypsum? A Detailed Overview of Its Properties and Uses

Gypsum Processing Techniques Once extracted, gypsum undergoes several processing steps: Crushing and Grinding: The mined gypsum is crushed into smaller pieces and ground into a fine powder Calcination: The powdered gypsum is heated to remove water molecules, producing different forms of plaster depending on the temperature and duration of 2011年1月1日 The properties of gypsum are soft, perfect cleavage, specific gravity and low harness It's extremely soft, and can be easily scraped with a fingernail and has a Mohs hardness number of 2Gypsum: Properties, production and applications ResearchGate2016年11月7日 Typically, to produce drywall, manufacturers must first dehydrate mined gypsum into bassanite, a time and energyintensive process The study concludes by explaining that learning how gypsum and bassanite The path to gypsum is four steps long EARTH Gypsum has many unique characteristics that contribute to its popularity, and gypsum processing works to bring out these benefits for commercial use Common processing methods used to prepare gypsum for commercial use Challenges in Gypsum Processing FEECO

.jpg)

The Cement Manufacturing Process Thermo Fisher Scientific

2023年12月20日 In this process, the chemical bonds of the raw materials are broken down and then they are recombined into new compounds The result is called clinker, which are rounded nodules between 1mm and 25mm across The clinker is ground to a fine powder in a cement mill and mixed with gypsum to create cementWhile each cement plant may differ in layout, equipment, and appearance, the general process of manufacturing portland cement is the same: crushed limestone and sand are mixed with ground clay, shale, iron ore, fly ash and alternative raw materialsHow Cement is Made Portland Cement AssociationThe mixing of sulfuric acid and phosphate creates gypsum (called phosphogypsum) as a byproduct Although gypsum can be used for a variety of purposes, the EPA prevents usage of Florida’s phosphogypsum because it retains low levels of radioactivity found in the host sediments At present, phosphogypsum is piled up around the processing plantHow phosphate is mined and processedGypsum, or hydrous calcium sulfate, is a crucial mineral in the production of everything from wallboard to cement and even many consumer products, surrounding us throughout our daily lives United States gypsum production was at an estimated 20 million metric tons (Mt) of crude gypsum and 16 Mt of synthetic gypsum in 2019, allowing the US to maintain the title of world’s A Look at US Gypsum Production FEECO International Inc

.jpg)

Material Characteristics to Consider in Gypsum Processing

Even wellknown minerals such as gypsum require testing on a case by case basis to ensure quality results The following list outlines key material characteristics that affect gypsum processing 1 Abrasive Mined gypsum is a somewhat abrasive material As a result, robust equipment must be used when processing gypsum ore2024年7月9日 What is gypsum, and how is it mined? Gypsum is a soft sulphate mineral composed of calcium sulphate dihydrate, and occurs naturally in sedimentary rock Gypsum can be mined using several methods, depending on the deposit location and characteristics Openpit mining is common for nearsurface deposits, while for deeper deposits, underground mining Focus on: Gypsum, a Building Block for World Construction2023年12月7日 Silos store large quantities of the final cement powder until it’s ready for processing At processing plants, machines package the cement powder in large paper bags Workers then group bags together on pallets where they’re shrink wrapped to How Is Cement Made? StepbyStep Guide BigRentzGypsum processing can be divided into three basic steps: (1) rock preparation, (2) calcining, and (3) formulating and manufacturing This is illustrated graphically with the flow chart in Figure 1 The specifics of each step will vary with the Infrastructure and Construction Materials Guide —

Gypsum Properties, Formation, Uses and Deposits

2023年9月9日 Gypsum is a naturally occurring mineral that has been used by humans for various purposes for thousands of years It is a versatile mineral with a wide range of applications in construction, agriculture, industry, and even GYPSUM PROCESSING AND USE Gypsum is a particularly useful processed material Its main application is as a building material, mostly produced as socalled plaster of Paris for plastering walls and making decorative features in buildings However gypsum also has a diversity ofGypsum processing and use Humanitarian LibraryGypsum Gypsum is a mineral found in crystal form as well as masses called gypsum rock It is a very soft mineral and it can form very pretty, and sometimes extremely large colored crystals Massive gypsum rock forms within layers of sedimentary rock, typically found in Gypsum Minerals Education CoalitionGypsum processing equipment differs significantly in scale and level of technology some plants produce one or two tonnes per day using lowcost manual technologies, some other plants of a thousand tonnes per day that are highly mechanized and capable of producing different types and grades of gypsum plaster or plaster boardsGypsum Mining Processing Equipment Flow Chart JXSC

.jpg)

Making Gypsum Board Gypsum Association

ASTM standards govern the manufacture of gypsum board and set strict criteria for strength, water resistance, and other characteristics To produce gypsum board, crushed natural gypsum or synthetic gypsum is heated or calcined to dehydrate the feedstock Next the calcined gypsum is mixed with water and additives to form a slurry which is fedGypsum is normally only screened to remove ‘fines’ (mainly mudstones), then crushed and finely ground Gypsum/Anhydrite for cement manufacture is supplied in crushed form for further fine grinding with cement clinker C Processing Natural Gypsum When Gypsum ( CaSO 4,2H 2O) is ground to a powder and heated at 150° to 165° C, threeFactsheet on: What is Gypsum?Raw Gypsum is calcium sulfate dihydrate ((Ca (SO 4) 2H 2 O), also known as gypsum dihydrate, gypsum or gypsum, composition CaO (326%), Grinding, processing equipments Reply jamal Sowid says: 07/07/2021 at 21:13 Thanks for the effort and all the infoWhat is Gypsum How Gypsum is Processed MCChemical Processing of Phosphate (gypsum) is also produced This byproduct gypsum is called phosphogypsum There are approximately five tons of phosphogypsum produced for every ton of phosphoric acid product produced Phosphogypsum, like natural gypsum, is Chemical Processing of Phosphate Florida Polytechnic University

.jpg)

Lithium Production Processes ScienceDirect

2015年1月1日 After starting up the Mt Cattlin mine and its processing plant producing (∼6% Li 2 O) spodumene concentrate in Western Australia for its Jiangsu lithium carbonate processing plant in China (capacity 17,000 tpa), Galaxy Resources Ltd (Australia) halted its production in July 2012, although the mine is considered still holding a total resource of 1818 Mt Li 2 O with a