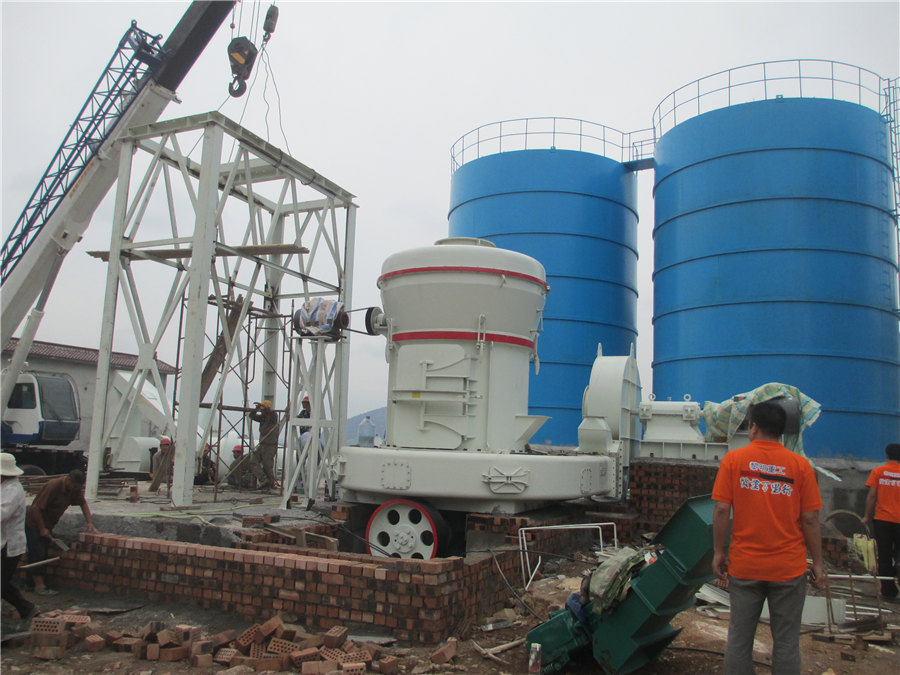

Water slag micro powder factory

Effect of Iron Tailings and Slag Powders on Workability

2021年7月25日 Water quenched slag powder is an important mineral admixture for concrete S95 slag powder produced by a factory in Hebei Province is adopted in the test The basic performance indexes are shown in Table 1 The coarse 2023年1月1日 The raw materials of AASC include slag, fine aggregate, coarse aggregate, water, alkali activator, and admixture The most common slag is ground granulated blast furnace slag Hydration Characteristics and Microstructure of AlkaliActivated 2023年3月22日 In this paper, the influence of water glass types, the modulus of water glass, the alkali content, the water consumption, and plant fibers on the mechanical strengths of alkali Mechanical Strengths of AlkaliActivated Blast Furnace Slag 2023年12月11日 The composite micronized powder is prepared by using blast furnace slag (BFS), waterquenched manganese slag (WQMS), manganese tailing slag (MTS) and Preparation and Performance of UltraFine High Activity

.jpg)

(PDF) Effect of Crsolidified/stabilized Waterquenched Slag on

2023年11月8日 Chromium in the mineral slag micropowder exists either in solid solution within the glass network structure or in the form of spinel phase, significantly reducing its leaching 2021年9月24日 These studies show that the steel slag can be a mineral admixture of cement or concrete for applications that can tolerate slow strength development if hydrated with SCPS BOF Steel Slag: Critical Assessment and Integrated Approach for 2020年11月1日 Slag powder process is introduced Objectives and affecting factors of slag powder process are analyzed The models are established by using the generalized Analysis and multiobjective optimization of slag powder process2023年11月29日 Wet granulation is a potential method to develop artificial aggregates In this paper, the granulation of recycled alkaliactivated slag powders with different particle size (d Recycling alkali activated slag into artificial aggregate: Influence of

Comprehensive utilization of steel slag: A review ScienceDirect

2023年5月15日 On this basis, steel slag and slag composite micro powder (SSCM) technology was proposed, which realized the high added value and utilization rate of steel slag in Research shows that when iron tailings powder is mixed with slag powder, concrete has relatively good mechanical properties (Wu and Liu, 2018; Han et al, 2019), and its hydration rate is very Effect of Iron Tailings and Slag Powders on Workability and Superfine slag powder production line is also called ultrafine slag micro powder plant or superfine slag powder making plant Superfine slag powder production line is used to crush non flammable materials of which Mohs hardness is no more than seven degree and water content is Superfine Slag Powder Production Line FTM MachineryA total of 35% water consumption can increase the flexural and compressive strengths by 338% and 327% Keywords: water glass; alkaliactivated; blast furnace slag powder; mechanical strengths Mechanical Strengths of AlkaliActivated Blast Furnace Slag Powder

.jpg)

(PDF) Effect of Iron Tailings and Slag Powders on

2021年7月1日 Water quenched slag powder is an important mineral S95 slag powder produced by a factory in Hebei Province is adopted in the test compressive strength and age of iron tailings micropowder2023年5月15日 Steel slag is the main solid waste generated in the steelmaking process, accounting for 15 to 20% of crude steel output [1]China's crude steel output in 2021 was 1035 billion tons [2], more than half of the global crude steel output (19505 billion tons) [3], and the steel slag output exceeded 120 million tonsIn contrast, the comprehensive utilization rate of Comprehensive utilization of steel slag: A review ScienceDirecta Corresponding author: Preparation of ultrafine iron phosphate micropowder from phosphate slag Fangjing Sun1,2, Yi Zhang1, Jiawei Zhang1, Xixi Yan1, Xiaoyu Liu1,2, Lijun Wang1,2,a 1School of Environmental and Materials Engineering, Shanghai Polytechnic University, Shanghai , P R China; 2Research Center of Resource Preparation of ultrafine iron phosphate micropowder from phosphate slag2020年7月1日 The slag grinding system is the core of the slag powder control system, which con sists of batching station, conveyor belt, vertical mill, hot gas generator , dust collector and product warehouseAnalysis and multiobjective optimization of slag powder

.jpg)

Characteristics of Recycled Micro Powder Produced Using

Characteristics of Recycled Micro Powder Produced Using Construction Waste Jinjin Shi1,2,3(B),MiaoXu1,3, Yingbiao Wu1,2,3, and Jinyan Liu1,2 1 Cangzhou Municipal Engineering Company Limited, Cangzhou , China 2 Hebei Province Road Materials and Technology Engineering Technology Research Center, Cangzhou , China 3 Hebei Industrial 2024年7月28日 The cement industry is known for being highly energyintensive and a significant contributor to global CO2 emissions To address this environmental challenge, this study explores the potential of using the waste materials of steel slag (SS) and eggshell powder (ESP) as partial replacements for cement in alkaliactivated mortars (AAMs) production, activated by NaOH Optimizing AlkaliActivated Mortars with Steel Slag and Eggshell Powder2018年1月1日 In this experiment, ultrafine iron phosphate micropowder was prepared by hydrothermal method which used phosphate slag as an iron source The effects of reaction temperature, surfactants type and Preparation of ultrafine iron phosphate micropowder from phosphate slagShanghai Jianye Heavy Industry is a longterm exporter of mobile crusher, jaw crusher, impact crusher, high pressure grinder mill and so on, which is a production and sales of machinery and equipment company!Mobile CrusherJaw CrusherImpact CrusherShanghai Jianye

Effectiveness of waste steel slag powder on the strength

Request PDF On Apr 1, 2020, Lei Lang and others published Effectiveness of waste steel slag powder on the strength development and associated micromechanisms of cementstabilized dredged sludge 2021年8月1日 Steel slag micro powder is steel slag after special process grinding, is a byproduct in the process of steel production This paper studied the basic mechanical properties and crack control (PDF) Effect of Polyvinyl FiberSteel Slag Powder on Mechanical Shanghai Jianye Heavy Industry is a longterm exporter of mobile crusher, jaw crusher, impact crusher, high pressure grinder mill and so on, which is a production and sales of machinery and equipment company!Mobile CrusherJaw CrusherImpact CrusherShanghai Jianye 2023年7月19日 In the range of ratios of water to slag powder from 026 to 028, the above three strengths were relatively high, and the compressive shear bonding strength was the highest when the ratio of water (PDF) Mechanical Properties of SlagBased Geopolymer

.jpg)

Effectiveness of waste steel slag powder on the strength

2020年4月20日 Effectiveness of waste steel slag powder on the strength development and associated micromechanisms of cementstabilized dredged sludge which makes it have strong hydraulicity When reacted with water, the pH of waste steel slag can achieve 10–12 the microcrack and pores were also clearly found in Fig 16 (c), 2023年7月1日 Steel slag powder (SSP) was selected as an inorganic micro powder filler instead of limestone powder (LSP) to prepare asphalt mastic in this paper cement, and hydrated lime can improve the water sensitivity of concrete The optimum amount of SSP as a replacement is recommended to be 25 % of the total volume of fillersCreep and fatigue properties of asphalt mastic with steel slag powder Water quenched slag powder is an important mineral admixture for concrete S95 slag powder produced by a factory in Hebei Province is adopted in the test The basic performance indexes are shown in Table 1 compressive strength and age of iron tailings micropowder concrete, Effect of Iron Tailings and Slag Powders on Workability and 2017年2月15日 Adesanya et al [20] extended the setting time by adding micro silica powder; to transform a PC plant in a AAB factory; of 002CeO2@SGMs were slag (30 g), 17 M water glass (12 Preparation of drying powder inorganic polymer cement based

.jpg)

Development of Cementing Material of Fine FullTailings Filling by Slag

2018年10月11日 By the end of 2012, the stockpiled quantity of nickel copper slag of Jinchuan Mine in China was 33×107 t, and 25×106 t is yielded every year2024年1月13日 The objective of this study is to explore the feasibility of developing environmentally friendly green rollercompacted concrete (RCC) by utilizing locally available materialsMechanical properties and microstructure of roller compacted 2018年1月30日 1 Introduction Steel slag is a byproduct of steel manufacturing []Approximately 160 kg of steel slag is generated per ton of steel produced []The common chemical compounds in steel slag are SiO 2, CaO, Fe 2 O 3, Al 2 O Applications of Steel Slag Powder and Steel Slag 2019年12月1日 Totally, seven selfcompacting ground copper slag concrete (SCGCSC) mixtures were made with a fixed water–powder ratio of 051 in which a portion of the cement was replaced by GCS in weight Utilization of micro copper slag in SCC subjected to

Adsorption Removal of Organophosphates from Water by Steel Slag

2024年11月3日 Organophosphates are a type of emerging environmental contaminant, which can be removed effectively by adsorption Here, modified steel slag was examined for its adsorptive performance in the removal of hydroxyethylidene diphosphonic acid (HEDP) from water Compared to acid (553%, maximum removal rate) and base (855%) modification, high We at Gulf Minerals Chemicals LLC value what nature has to offer in its vast bouquet of Resources We obtain those resources in raw form, from various parts of the world where they originateGulf Minerals Chemicals2023年6月27日 Steel slag powder and construction waste have received widespread attention for their resource utilization as solid waste This article uses steel slag powder and recycled concrete aggregates to prepare controlled lowstrength materials (CLSM) The study investigates the influence of steel slag powder replacing cement and recycled aggregates on the Effect of Steel Slag Powder on the Performance of Controlled Low Steel slag is one of the main solid wastes in steel plants, with considerable discharge The recycling of steel slag has become the focus of social attention The micropowder processing scheme using steel slag vertical roller mill can provide an effective way for the recycling of steel slag HCMilling(Guilin Hongcheng) provides customers with professional micropowder Introduction To The Way Of Steel Slag Recycling The Micropowder

R)8OC`6F[ZIB.jpg)

Study on Compressive Strength and Water Permeability of Steel Slag

2019年4月13日 The steel slag used in the test was taken from the water quenching slag of a steel plant without magnetic separation, which was taupe powder with a density of about 264 g / cm 22023年1月1日 powder, the “ micro aggregate effect ” of phosphate slag powder fi lls the gaps of cement particles [16] However, the phosphate slag itself has a slowsetting effect, making the increase in Preparation of High Activity Admixture from Steel Slag, Phosphate Slag 2020年9月17日 The basic mechanism of micropowder in refractory castables is filling and lubricationThe micro powder can be used to fill the gap between aggregate and powder, reducing the amount of water used After the molded body removes water, there are fewer holes left, which can increase the bulk density and reduce the apparent porosityWhat are the Functions of MicroPowder in Refractory Castables?2020年2月26日 The present investigation is mainly focused on the effect of copper slag (CS) on micro, macro, and flexural characteristics of geopolymer concrete (GPC)(PDF) Effect of Copper Slag on Micro, Macro, and Flexural

.jpg)

Superfine Slag Powder Production Line FTM Machinery

Superfine slag powder production line is also called ultrafine slag micro powder plant or superfine slag powder making plant Superfine slag powder production line is used to crush non flammable materials of which Mohs hardness is no more than seven degree and water content is A total of 35% water consumption can increase the flexural and compressive strengths by 338% and 327% Keywords: water glass; alkaliactivated; blast furnace slag powder; mechanical strengths Mechanical Strengths of AlkaliActivated Blast Furnace Slag Powder 2021年7月1日 Water quenched slag powder is an important mineral S95 slag powder produced by a factory in Hebei Province is adopted in the test compressive strength and age of iron tailings micropowder(PDF) Effect of Iron Tailings and Slag Powders on 2023年5月15日 Steel slag is the main solid waste generated in the steelmaking process, accounting for 15 to 20% of crude steel output [1]China's crude steel output in 2021 was 1035 billion tons [2], more than half of the global crude steel output (19505 billion tons) [3], and the steel slag output exceeded 120 million tonsIn contrast, the comprehensive utilization rate of Comprehensive utilization of steel slag: A review ScienceDirect

.jpg)

Preparation of ultrafine iron phosphate micropowder from phosphate slag

a Corresponding author: Preparation of ultrafine iron phosphate micropowder from phosphate slag Fangjing Sun1,2, Yi Zhang1, Jiawei Zhang1, Xixi Yan1, Xiaoyu Liu1,2, Lijun Wang1,2,a 1School of Environmental and Materials Engineering, Shanghai Polytechnic University, Shanghai , P R China; 2Research Center of Resource 2020年7月1日 The slag grinding system is the core of the slag powder control system, which con sists of batching station, conveyor belt, vertical mill, hot gas generator , dust collector and product warehouseAnalysis and multiobjective optimization of slag powder Characteristics of Recycled Micro Powder Produced Using Construction Waste Jinjin Shi1,2,3(B),MiaoXu1,3, Yingbiao Wu1,2,3, and Jinyan Liu1,2 1 Cangzhou Municipal Engineering Company Limited, Cangzhou , China 2 Hebei Province Road Materials and Technology Engineering Technology Research Center, Cangzhou , China 3 Hebei Industrial Characteristics of Recycled Micro Powder Produced Using 2024年7月28日 The cement industry is known for being highly energyintensive and a significant contributor to global CO2 emissions To address this environmental challenge, this study explores the potential of using the waste materials of steel slag (SS) and eggshell powder (ESP) as partial replacements for cement in alkaliactivated mortars (AAMs) production, activated by NaOH Optimizing AlkaliActivated Mortars with Steel Slag and Eggshell Powder

Preparation of ultrafine iron phosphate micropowder from phosphate slag

2018年1月1日 In this experiment, ultrafine iron phosphate micropowder was prepared by hydrothermal method which used phosphate slag as an iron source The effects of reaction temperature, surfactants type and Shanghai Jianye Heavy Industry is a longterm exporter of mobile crusher, jaw crusher, impact crusher, high pressure grinder mill and so on, which is a production and sales of machinery and equipment company!Mobile CrusherJaw CrusherImpact CrusherShanghai Jianye