Raw lime quick lime mill cement

.jpg)

Rotary Kiln Lime Production AGICO CEMENT

Application: Active lime production, quick lime production AGICO Rotary Lime Kilns are specifically designed for efficient, energysaving, and environmentally friendly lime production1 Lime:Quick Lime is a configuration of lime which is produce by the removal of chemical component (calcium carbonate CaCo3) by heating process of raw stone The heating LIME AS CONSTRUCTION MATERIAL: PROCESS APPLICATIONQuicklime lumps are ground and classified in Pfeiffer MPS vertical roller mills The fineness of the white fine limes can be set within wide limits (006 to 01 mm) In downstream Pfeiffer lime hydrators, water is added to quicklime, thus Quicklime preparation Gebr PfeifferAGICO CEMENT has rich experience in designing and constructing active lime production lines In the past 20 years, we have successfully built more than 100 lime kiln projects, large and small, at home and abroad The kiln types Active Lime Production Line AGICO Cement Plant

Impact of quicklime reactivity and origin on Autoclaved

2011年1月1日 Quicklime is a key component of Autoclaved Aerated Concrete (AAC), with typical quicklime contents of order 15 wt% in Europe It is the mostly used source of calcium oxide that eventually endsLimestone is the most common raw material used to produce lime, although other calcareous materials such as marble, coral and shells are also used With largescale excavation of any Lime An Introduction2023年7月19日 There are three main types of lime: quicklime, slaked or hydrated lime and hydraulic lime Each type of lime has its own unique properties and applications in construction [3] QUICKLIME, also known as calcium LIME: Everything you need to know to get startedMarkets Outlook of quick lime Quicklime, also known as calcium oxide, is produced by calcining minerals with a high calcium content such as limestone, chalk, and dolomite at temperatures ranging from 900 to 1100°C It serves as Lime Calcination Plant Lime Kiln Plant Output:

Active Lime Production Line AGICO Cement Plant

Optimize your lime production with AGICO Cement comprehensive lime production line Cement Mill; Vertical Roller Mill; Cement Mill Separator; Steel Balls for Ball Mill; Others Menu Toggle Minimum particle size of raw 2019年3月27日 In this study, Lime sludge from recovery section of the paper mill is used in concrete in its asreceived condition and in calcined condition to partially substitute cementPaper Mill Lime Sludge Valorisation as Partial Substitution of Cement Moreover, drying oven is used to remove the free water (moisture) in a raw material like Lime stone, Pumice, and Sand stone except Gypsum at 105 C for one hour Raw mill, Coal Mill and Cement mill drying; Heating and power generation; Speed of Clinker Cooling Rapid cooling prevents growth of crystals and its size; Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENTAbstract: This research aims to investigate the effect of free lime and lime saturation factor on grindability of cement clinker Cement is a powdered substance that develops strong adhesive and cohesive properties when mixed with water Cement production involves a number of processes, these include; Preparation of raw materials,Effect of Free Lime and Lime Saturation Factor on Grindability of

.jpg)

Quick Lime Super Cement Manufacturing Co

We produce quicklime lumps with high calcium content and with a specification of available lime more than 910% having unburnt portion less than 400% With the raw material from RAK, being the only one with the Italian kiln and the wellqualified team the quality has been superior to all the competition in the region With the raw []Quicklime reacts with water, generating a great amount of heat We distinguish softburnt lime, mediumburnt lime, and hardburnt lime In the construction industry, quicklime is added to mortar It can also be used as a drying or neutralizing agent, as fertilizer lime and for the production of lime mortar and lime plasterQuicklime preparation Gebr Pfeiffer221 Manufacturing of Cement The raw materials for manufacturing of Portland cement are : (i) Calcareous material – limestone or chalk ground into a fine consistency in ball mill Cement and Lime and converted into slurry by addition of water (iii) The slurry is tested for correct composition and sprayed on to theUNIT 2 CEMENT AND LIME Cement and Lime eGyanKoshLime Saturation Factor (LSF) is the ratio of the actual amount of lime in raw meal/clinker to the theoretical lime required by the major oxides (SiO 2, Al 2 O 3 and Fe 2 O 3) in the raw mix or clinkerIt is practically impossible to complete the reaction to 100%, in a reactor like rotary kiln, therefore there will always be some unreacted lime (CaO f) known as free limeLime Saturation Factor Cement Plant Optimization

.jpg)

The Quality Requirements For Active Lime You Should Know

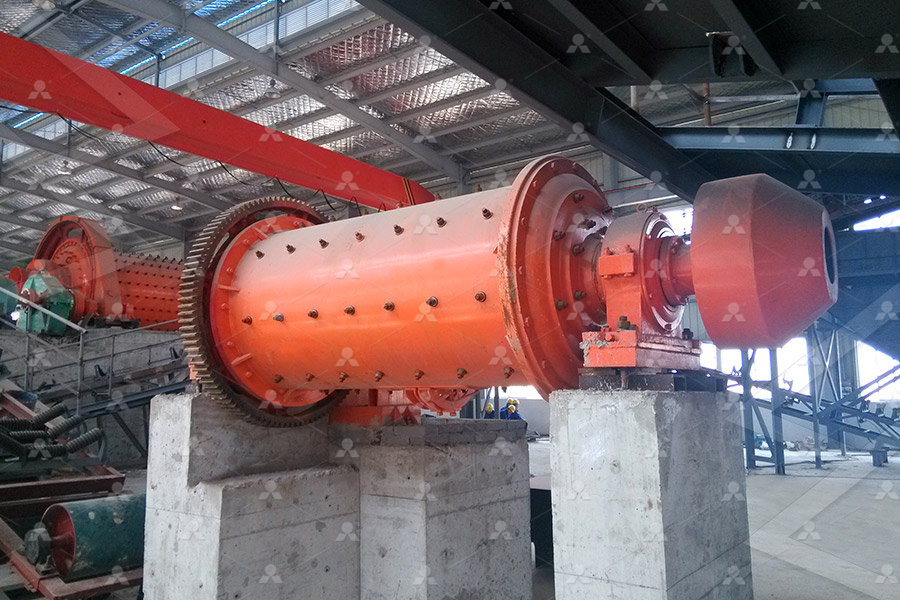

2023年11月11日 vertical lime kiln and rotary lime kiln are two types of lime kiln commonly used in active lime production line A rotary kiln can directly calcinate 10–50 mm of finegrade limestone so that most of the limestone below 40mm can be used, saving a lot of mining costs every year and extending the mining life of the mine2021年1月1日 The control of the raw mill feed before the raw mill and the raw meal after the mill is still indispensable Because of the complexity and the significance of the control process, various automated systems are available for sampling and analysing the raw mix as well as for adjustment of the mill weight feeders according to the raw meal chemical modules in mill outlet Influence of raw meal composition on clinker reactivity and cement Quicklime is produced by our company through the thermal decomposition of limestone During this process, the limestone is heated to high temperatures, causing it to decompose into quicklime and carbon dioxide Quicklime has a range of potential applications, including its use as a raw material in the production of cement, glass, and steelQuicklime RCI LimeWide product range: For meeting various requirements from different clients, our cement mill range from cement ball mill, vertical cement mill, Raymond mill, coal mill in cement plant, etc Strong production ability : AGICO CEMENT has a Cement Mill Cement Ball Mill Vertical Cement Mill

Everything you need to know about cement Materials Preparation and Raw

Finish grinding of this type with a roller press has been successfully used in the cement industry for grinding raw meal, blast furnace slag, and quicklime the analysis of free lime in Brundick, H, “Drying and grinding of extremely moist cement raw materials in the Loesche mill,” ZKG International, No2, 1998, pages 6471 AGICO Cement supplies cement equipment for cement raw material production as you need, such as cement mill, cement crusher, onestop turnkey project, welcome to contact! Skip to content +86 Preparation Of Cement Raw Material Cement Mill, Cement The main difference to cement mill operation is the need to dry rawfeed and assure transport of stightly moist materialwithin a mill Analysis of the coarse (+901Jm) fraction may be limerich or, more likely,silicarich, relative to the total sample but should show constant biasRaw milling and blending INFINITY FOR CEMENT EQUIPMENTRaw meal homogenization is the most important process link of the four, accounting for 40% of the homogenization task It is an important factor to support the balanced and stable working performance of preheaters and kilns, and plays an important role in improving the output and quality of cement clinkerCement Raw Meal Homogenization Process in The Cement

.jpg)

Application of Vertical Roller Mill in Cement Production

In the raw meal grinding process, VRMs are used to grind the raw materials used in cement production, such as limestone, clay, and silica After being crushed and processed in crushers,the raw materials are fed into the VRM through the center of the rotating table, where they are ground to powders by the rollersAnnular Shaft Kiln Production Capacity: 200 – 600 t/d Heat Consumption: 930980 kCL/kg Lime Activity: >350mL Application: Active lime production, quick lime productionAnnular Shaft Kiln Lime Kiln Solution from AGICO CEMENTThe cement raw material mixtures are ground, dried, and classified in the Pfeiffer vertical roller mill For drying the material, hot gases are directed into the mill Product fineness can be adjusted within a wide range (0063 to 02 mm)Raw mills for all requirements Gebr PfeifferTailored Lime Calcination Solutions: Optimized Customized CAPACITY: 200~1500T/HFUEL: Coal Gas, Natural Gas, and Pulverized CoalEQUIPMENT: Jaw Crusher+Raymond mill+Rotary Kiln/Vertical Kiln+Cooler+Bucket Lime Calcination Plant AGICO Cement Plant

Modeling and Simulation study on Cement Raw Mill Process

Keywords: Process control, raw mill, cement plant, oxide composition 1 Introduction The cement manufacturing process begins with mining for raw materials, including limestone This clinker is a Ferrari cement with a low heat of hydration Lime Saturation Factor (LSF) Lime Saturation Factor (LSF) is the maximum amount of Calcium oxide 2011年2月21日 Cement Download as a PDF or view online for free 4 PORTLAND CEMENT COMPOSITION Lime (CaO) 6066% Excess reduces strength and make cement disintegrate and in less amount reduces strength Cement PPT SlideShare• Slaking process of lime: Generally nonhydraulic or quick lime is employed for Slaking of lime The Process of blending lime in water is called slaking The utmost temperature reached through the exothermic (heat producing) reaction of quicklime with water is a good indicator of the quality of the lime Optimal slakingLIME AS CONSTRUCTION MATERIAL: PROCESS APPLICATIONLearn about the raw mill in cement plants and the basic raw materials used in cement manufacturing Discover our efficient cement manufacturing process Contact us for more info! Amrit Support About Amrit Support; Services; Activities; Corporate Raw Mill in Cement Plant Cement Manufacturing Raw Materials

Influence of raw meal composition on clinker reactivity and cement

2021年4月1日 In this study we have chosen raw meal samplers with variable levels of Lime Saturation Factor LSF in order to evaluate possible interactions between LSF of the raw meal and clinker reactivityOur bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It is affordable to install and cost effective to operate over your cement plant’s lifetimeOK™ Raw and Cement MillAGICO CEMENT can undertake 2001500 t/d lime calcination plant EPC project, and cover feasibility study report, design, Raw Mill; Vertical raw mill; Disc pelletizer; Clinker Production Cement kiln; Rotary Kiln; Overburning rate of quicklime (%) < 57: Quick lime consumption(t/t) 18: CO 2 concentration in flue gas (%) 42: Soot Lime Production Line Active Lime Production Line Cement PlantLime Slaking Process It is combined with grinding equipment and a powder separator to form a hydrated lime production lineThe quick lime block of about 3 cm is processed by the grinding equipment into powder, then it can pass through the lime slaker, and repeatedly stirred and reacted with water for up to 1520 minutes to make a powdered hydrated lime product with Lime Slaker cementmillequipment

.jpg)

Lime Calcination Plant Lime Kiln Plant Output:

Markets Outlook of quick lime Quicklime, also known as calcium oxide, is produced by calcining minerals with a high calcium content such as limestone, chalk, and dolomite at temperatures ranging from 900 to 1100°C It serves as Optimize your lime production with AGICO Cement comprehensive lime production line Cement Mill; Vertical Roller Mill; Cement Mill Separator; Steel Balls for Ball Mill; Others Menu Toggle Minimum particle size of raw Active Lime Production Line AGICO Cement Plant2019年3月27日 In this study, Lime sludge from recovery section of the paper mill is used in concrete in its asreceived condition and in calcined condition to partially substitute cementPaper Mill Lime Sludge Valorisation as Partial Substitution of Cement Moreover, drying oven is used to remove the free water (moisture) in a raw material like Lime stone, Pumice, and Sand stone except Gypsum at 105 C for one hour Raw mill, Coal Mill and Cement mill drying; Heating and power generation; Speed of Clinker Cooling Rapid cooling prevents growth of crystals and its size; Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT

.jpg)

Effect of Free Lime and Lime Saturation Factor on Grindability of

Abstract: This research aims to investigate the effect of free lime and lime saturation factor on grindability of cement clinker Cement is a powdered substance that develops strong adhesive and cohesive properties when mixed with water Cement production involves a number of processes, these include; Preparation of raw materials,We produce quicklime lumps with high calcium content and with a specification of available lime more than 910% having unburnt portion less than 400% With the raw material from RAK, being the only one with the Italian kiln and the wellqualified team the quality has been superior to all the competition in the region With the raw []Quick Lime Super Cement Manufacturing CoQuicklime reacts with water, generating a great amount of heat We distinguish softburnt lime, mediumburnt lime, and hardburnt lime In the construction industry, quicklime is added to mortar It can also be used as a drying or neutralizing agent, as fertilizer lime and for the production of lime mortar and lime plasterQuicklime preparation Gebr Pfeiffer221 Manufacturing of Cement The raw materials for manufacturing of Portland cement are : (i) Calcareous material – limestone or chalk ground into a fine consistency in ball mill Cement and Lime and converted into slurry by addition of water (iii) The slurry is tested for correct composition and sprayed on to theUNIT 2 CEMENT AND LIME Cement and Lime eGyanKosh

Lime Saturation Factor Cement Plant Optimization

Lime Saturation Factor (LSF) is the ratio of the actual amount of lime in raw meal/clinker to the theoretical lime required by the major oxides (SiO 2, Al 2 O 3 and Fe 2 O 3) in the raw mix or clinkerIt is practically impossible to complete the reaction to 100%, in a reactor like rotary kiln, therefore there will always be some unreacted lime (CaO f) known as free lime2023年11月11日 vertical lime kiln and rotary lime kiln are two types of lime kiln commonly used in active lime production line A rotary kiln can directly calcinate 10–50 mm of finegrade limestone so that most of the limestone below 40mm can be used, saving a lot of mining costs every year and extending the mining life of the mineThe Quality Requirements For Active Lime You Should Know