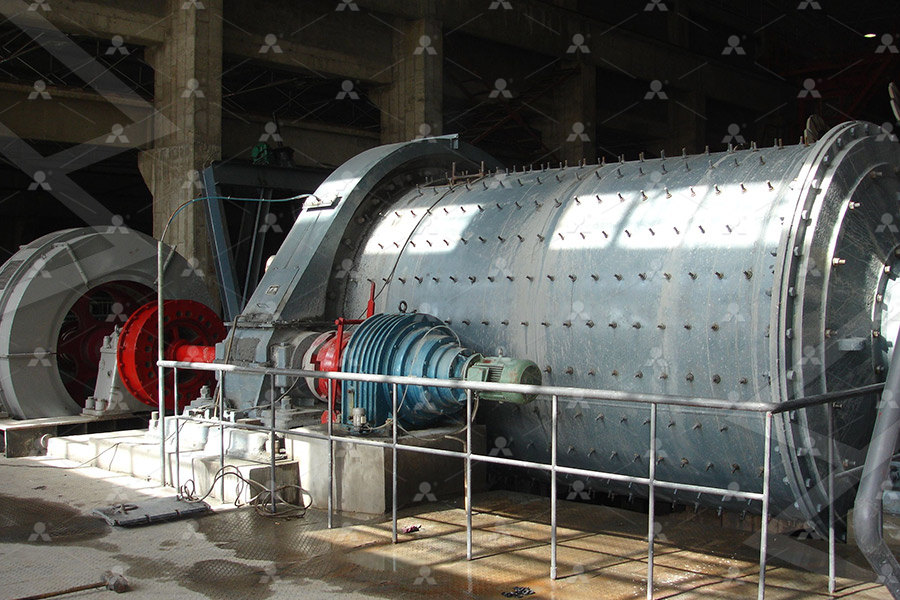

Slag powder making process Slag powder making process Slag powder making process

.jpg)

Processing and Reusing Technologies for Steelmaking Slag

Steelmaking slag is subjected to the following four process es: ① solidify and cooling of the hot molten slag, ② crushing and magnetic separation treatment of the slag to recover the metal iron,The objective of this study was to reduce the stockpile of steel slag, which is a solid waste generated in the steelmaking process, and promote the resource utilization of steel slag powderSteel Slag — Its Production, Processing, Characteristics, and 2020年7月1日 Slag powder is a process with characters of multivariables, strongly coupling and nonlinearity The material layer thickness plays an important role in the process It can reflectAnalysis and multiobjective optimization of slag The complete utilization process of steelmaking slag has been developed, in which Fe and P were recovered and slag products such as cement or aggregates, phosphate fertilizer, and the hot Development of the Complete Utilization Process of Steelmaking

.jpg)

Basic Oxygen Steelmaking Slag: Formation, Reaction,

Basic oxygen steelmaking (BOS) slag, a product of hot metal element (eg, Si, Mn, Fe, P) oxidation and flux (eg lime, dolomite) dissolution, plays a critical role in the production of highquality crude steel, although its behavior inside the 2004年5月14日 Steel slag is a byproduct from either the conversion of iron to steel in a basic oxygen furnace, or the melting of scrap to make steel in an electric arc furnace This paper Steel Slag—Its Production, Processing, Characteristics, and Schematic drawings of the continuous casting process (a) showing ladle, tundish and mould and secondarycooling and (b) of halfsection of the mould showing that mould powder added to Structure and Properties of Slags Used in the Continuous Casting Abstract: Dumping the slag into vertical mill, granulated blast furnace slag powder is finally got by the crushing, grinding and separation in the vertical mill The whole process is a nonlinear, Modeling and analysis of material layer thickness in slag powder

Analysis and multiobjective optimization of slag powder process

Slag powder process is introduced • Objectives and affecting factors of slag powder process are analyzed • The models are established by using the generalized regression neural network • 2018年1月30日 1 Introduction Steel slag is a byproduct of steel manufacturing []Approximately 160 kg of steel slag is generated per ton of steel produced []The common chemical compounds in steel slag are SiO 2, CaO, Fe 2 O 3, Al 2 O Applications of Steel Slag Powder and Steel Slag Superfine slag powder production line is also called ultrafine slag micro powder plant or superfine slag powder making plant Superfine slag powder production line is used to crush non flammable materials of which Mohs hardness is no more than seven degree and water content is Superfine Slag Powder Production Line FTM Machinery2022年11月11日 Steel slag is generally regarded as a supplementary cementitious material in cementbased materials, which is conducive to the realization of the goal of carbon peak and carbon neutralization However, the Laboratory Preparation and Performance

Different carbon treatments for steel slag powder and their

2022年8月15日 Steel slag powder is the waste slag produced in the steelmaking process, and its emissions account for about 15%–20% of crude steel production in China (Shi et al, 2022a; Shi, 2004; Wang et al, 2011)However, a large amount of steel slag cannot be effectively utilized, which resulting in a large amount of steel slag stockpiled (Li et al, 2021)2024年11月1日 Cement is a key ingredient in many construction materials and plays an essential role in modern construction (Gagg, 2014)However, the extraction and processing of raw materials for cement production not only put a heavy burden on natural resources, but also lead to environmental pollution and energy consumption (Rodrigues and Joekes, 2011, Xu et al, 2015)Dynamic mechanical properties and microstructure of ultrafine slag 2013年4月12日 Fig 3 Steelmaking slag Aging treatment Since the flux added to refine the steel forms a component of the steelmaking slag It is particular significance that CaO and MgO contained in the flux remain partly inactive and reside in the slag or crystallize while the slag is solidified and cooledSteelmaking Slag IspatGuru2017年3月28日 The principle of the process of using synthetic slag consists in making a contact on a large surface between the liquid steel and a slag having a composition selected to ensure an advanced steel deoxidation and desulphurization Design of synthetic slag Slag design in secondary metallurgy is crucial for the performance in steelmakingSynthetic Slag for Secondary Steelmaking – IspatGuru

.jpg)

Steel slag superfine powder production process Google Patents

Steel slag tailings, as steelmaking solid waste, owing to it is difficult, is presently mainly thrown asideMinority steel Factory can reclaim small amounts ferrum after fine grinding, and using fine grinding powder as concrete admixture, adopts in this way Fine grinding powder after process is big as concrete admixture not only granularity, specific surface area is little, and ferrum oxide Effect of grinding method on properties of steel slag powder: DUAN Siyu 1, LI Xi 2, MA Zhuohui 1, LIAO Hongqiang 1, CHENG Fangqin 1: 1 State Environment Protection Key Laboratory of Efficient Utilization Technology of Coal Waste Resources, Institute of Resources and Environmental Engineering, Shanxi University, Taiyuan , China; 2 Shanxi Architectural Effect of grinding method on properties of steel slag powder2024年6月5日 Ferronickel slag is the solid waste slag produced by smelting nickel–iron alloy After grinding ferronickel slag into powder, it has potential chemical activity It can partially replace cement and reduce the amount of cement, and is conducive to environmental protection The mechanical properties of soil cement were investigated through the compressive strength test Performance of Ferronickel Slag Powder Soil Cement under2017年2月16日 PDF Sintering is a thermal agglomeration process that is applied to a mixture of iron ore fines, recycled ironmaking products, fluxes, slagforming (PDF) Iron Ore Sintering: Process ResearchGate

Dynamic mechanical properties of ferronickel slag

2023年11月10日 The materials used in the SHPB tests are silty sand, cement, FSMP, granulated blast furnace slag, and purified water The silty sand used in this experiment, shown in figure 1, was obtained from the foundation pit of a 2024年9月15日 Steel slag possesses high contents of silicate minerals, oxides, and inherent alkalinity, enabling it to exhibit excellent carbonation performance and CO 2 sequestration capacity [4], [5], [6] Carbonation enhances the soundness and pozzolanic activity of steel slag, making it a promising supplementary cementitious materialSteel slag powderCO2 contact state in static or rotary process of 2024年9月15日 In this process, selecting a filling rate of slag powder of 100 % in the device, a rotation speed of 05 rad/s, and a ventilation time of 1 h can achieve a carbon fixation rate about 10 % At this point, the duration of gasslag powder contact is approximately 126 min, in which, the average diameter of 90 % slag particles is 5935 μmSteel slag powderCO2 contact state in static or rotary process of 2016年9月15日 Ladle slag, currently an underutilized crystalline metallurgical residue, was studied for use as a precursor for alkali activation An activating solution containing sodium silicate and potassium hydroxide was used in activating the slag with varying compositional ratios in order to optimize the compressive strength Ladle slag is commonly regarded as having limited Alkali Activation of Ladle Slag from SteelMaking Process

.jpg)

Recycled Kambara reactor slag powder as a sustainable stabilizer

2024年7月30日 Raw materials and mixtures preparation KR slag is a residual byproduct from a blast furnace used in the ironmaking process The characteristics of the material are obtained through a complex treatment involving crushing plants, screening, and removal of metallic fractions from the slag generated during pig iron desulfurization2023年2月22日 Granulated blast furnace slag (GBFS) is a glassy calciumaluminum silicate coproduct with latent hydration activity produced during the blast furnace ironmaking process [21]When the GBFS is in contact with water, a layer of calciumdeficient aluminosilicate protective film would be formed rapidly on the surface, and only a small amount of calcium ions and Hydration superposition effect and mechanism of steel slag powder 2024年5月25日 This study investigated the influences of ultrafine fly ash (UFA) and ultrafine slag powder (USL) on the compressive strengths, autogenous shrinkage, phase assemblage, and microstructure of magnesium potassium phosphate cement (MKPC) The findings indicate that the aluminosilicate fractions present in both ultrafine fly ash and ultrafine slag participate in the Influence of Ultrafine Fly Ash and Slag Powder on Microstructure 2023年5月21日 The results illustrate that the incorporation of steel slag powder can significantly delay the setting time and improve the flowability of AAMUHPC, making it possible for engineering applicationsEffects of Steel Slag Powder Content and Curing Condition on the

Effects of Steel Slag Powder Content and Curing Condition on the

2023年5月21日 The accumulation of steel slag and other industrial solid wastes has caused serious environmental pollution and resource waste, and the resource utilization of steel slag is imminent In this paper, alkaliactivated ultrahighperformance concrete (AAMUHPC) was prepared by replacing ground granulated blast furnace slag (GGBFS) powder with different 2023年6月27日 Steel slag powder and construction waste have received widespread attention for their resource utilization as solid waste This article uses steel slag powder and recycled concrete aggregates to prepare controlled lowstrength materials (CLSM) The study investigates the influence of steel slag powder replacing cement and recycled aggregates on the Effect of Steel Slag Powder on the Performance of Controlled Low 2017年12月15日 The chemical components of ferronickel slag primarily include SiO 2, MgO, CaO, Al 2 O 3, and Fe 2 O 3 [8], [11] and the crystalline minerals in ferronickel slag include enstatite, forsterite, and diopside [12]The content of amorphous minerals in ferronickel slag is usually greater than 50% [13]Ferronickel slag powder exhibits pozzolanic activity and hence is Characteristics and reactivity of ferronickel slag powder2021年7月1日 Lithium slag (LS) powder is a potential supplementary cementitious material due to its large content of active aluminosilicate minerals To clarify the properties of LS powder as a supplementary cementitious material, the ionic dissolution properties of LS powder and the hydration properties and kinetic process of blended cement containing LS powder were Hydration properties and kinetic characteristics of blended

Preparation of Reactive Powder Concrete Using Fly Ash and Steel Slag Powder

Steel slag is the steelmaking industry waste, which contains a certain amount of cement clinker mineral, such as C 2S and C 3S Therefore, steel slag is a potential mineral admixture for concrete industry However, due to high content of CaO, MgO and other ingredients, steel slag may have negative effect on the volume stability of concrete2023年10月15日 Steel slag is an industrial byproduct arisen from the steel manufacturing process, the amount of which is estimated to be about 12–20% of total steel production [1, 2]In 2022, statistics show that 1013 billion tons of steel were manufactured in China in which approximately 0162 billion tons of steel slag was producedInfluence of steel slag powder on the characteristics of 2002年4月1日 Otherwise, pozzolans that do not have suitable fineness will raise undesirable situations, such as decreasing the strengthgaining speed and delaying the setting start time in cementEffect of superfine slag powder on cement propertiesRecently, Slag has become an important mixing material of cement, grind ability of slag is very poor In general, the slag powder is processed by the slag grinding plant in advance, and slag powder will be sent into the cement plant for making slag cement, so it is particularly important to select the appropriate slag grinding plantSlag Cement Production Line Blast Furnace Slag Cement Making

.jpg)

Laboratory Preparation and Performance Characterization of Steel Slag

2022年11月11日 By calculation from Equation (1) [22], the alkalinity coefficient of the steel slag is 222, which is higher than 18 lower than 25 This means that this kind of steel slag belongs to the 2023年11月23日 The alkaliactivated curing of LF slag in the presence of metakaolin facilitates the curing at room temperature, making the process energyefficient 59 Lancennotti et al studied alkaliactivated LF slag using NaOH and SiO 2 /Na 2 O cured in moisture for their compressive strength performance 130 Ladle Furnace Slag: Synthesis, Properties, and Applications2019年5月23日 The steel slag is divided into converter (basic oxygen furnace, BOF) slag and electric arc furnace (EAF) slag according to the steel making process that is used, and EAF slag is divided into oxidizing slag and reducing slag steel slag fine powder that is of over 80mesh standard sieve is taken as the standard, and for this, Comprehensive Utilization Technology of Steel Slag2018年1月30日 1 Introduction Steel slag is a byproduct of steel manufacturing []Approximately 160 kg of steel slag is generated per ton of steel produced []The common chemical compounds in steel slag are SiO 2, CaO, Fe 2 O 3, Al 2 O Applications of Steel Slag Powder and Steel Slag

.jpg)

Superfine Slag Powder Production Line FTM Machinery

Superfine slag powder production line is also called ultrafine slag micro powder plant or superfine slag powder making plant Superfine slag powder production line is used to crush non flammable materials of which Mohs hardness is no more than seven degree and water content is 2022年11月11日 Steel slag is generally regarded as a supplementary cementitious material in cementbased materials, which is conducive to the realization of the goal of carbon peak and carbon neutralization However, the Laboratory Preparation and Performance 2022年8月15日 Steel slag powder is the waste slag produced in the steelmaking process, and its emissions account for about 15%–20% of crude steel production in China (Shi et al, 2022a; Shi, 2004; Wang et al, 2011)However, a large amount of steel slag cannot be effectively utilized, which resulting in a large amount of steel slag stockpiled (Li et al, 2021)Different carbon treatments for steel slag powder and their 2024年11月1日 Cement is a key ingredient in many construction materials and plays an essential role in modern construction (Gagg, 2014)However, the extraction and processing of raw materials for cement production not only put a heavy burden on natural resources, but also lead to environmental pollution and energy consumption (Rodrigues and Joekes, 2011, Xu et al, 2015)Dynamic mechanical properties and microstructure of ultrafine slag

Steelmaking Slag IspatGuru

2013年4月12日 Fig 3 Steelmaking slag Aging treatment Since the flux added to refine the steel forms a component of the steelmaking slag It is particular significance that CaO and MgO contained in the flux remain partly inactive and reside in the slag or crystallize while the slag is solidified and cooled2017年3月28日 The principle of the process of using synthetic slag consists in making a contact on a large surface between the liquid steel and a slag having a composition selected to ensure an advanced steel deoxidation and desulphurization Design of synthetic slag Slag design in secondary metallurgy is crucial for the performance in steelmakingSynthetic Slag for Secondary Steelmaking – IspatGuruSteel slag tailings, as steelmaking solid waste, owing to it is difficult, is presently mainly thrown asideMinority steel Factory can reclaim small amounts ferrum after fine grinding, and using fine grinding powder as concrete admixture, adopts in this way Fine grinding powder after process is big as concrete admixture not only granularity, specific surface area is little, and ferrum oxide Steel slag superfine powder production process Google PatentsEffect of grinding method on properties of steel slag powder: DUAN Siyu 1, LI Xi 2, MA Zhuohui 1, LIAO Hongqiang 1, CHENG Fangqin 1: 1 State Environment Protection Key Laboratory of Efficient Utilization Technology of Coal Waste Resources, Institute of Resources and Environmental Engineering, Shanxi University, Taiyuan , China; 2 Shanxi Architectural Effect of grinding method on properties of steel slag powder

.jpg)

Performance of Ferronickel Slag Powder Soil Cement under

2024年6月5日 Ferronickel slag is the solid waste slag produced by smelting nickel–iron alloy After grinding ferronickel slag into powder, it has potential chemical activity It can partially replace cement and reduce the amount of cement, and is conducive to environmental protection The mechanical properties of soil cement were investigated through the compressive strength test