Principle of threecavity prepowder vertical grinding fine sand powder equipment

Grinding for food powder production ScienceDirect

2013年1月1日 Three grinding principles known as the energysize reduction principle, the population balance principle and the dynamic principle have been formulated for industrial scaleup2023年6月1日 Since the sample size was drastically reduced, which introduced powder flow measurements into pharmaceutical preformulation stages, this method can be applied to A concise summary of powder processing methodologies for flow 2014年1月1日 The basic principle of SHS consists of the development of an exothermic reaction (eg, redox, oxidation, thermal decomposition) in a loose or green compact powder (A+B Powder Processing of Bulk Components in Manufacturing2003年12月10日 In this paper, we examine the powder transfer process, a typical stage in the manufacture of multilevelled components in the powder metallurgy (PM) industry Both Experimental and numerical investigations of powder transfer

.jpg)

Sand grinder and sand grinding method for grinding powder

The Ginding process of realizing according to the sand mill of aforesaid wet grinding powder, it is characterized in that: motor drives large belt wheel to rotate by Vtype band, driveThree main principles govern the size reduction of solid particles: Impact, compression and shear Mechanicalimpact grinding mills utilize the impact principle of grinding; either impacting a ADVANCES IN POWDER PROCESSING TECHNOLOGIES FOR LUMSeries Ultra fine vertical grinding mill is an advanced mill which combining our company’ several years of millproducing experiences, It is designed and researched based on vertical LUM SERIES ULTRAFINE GRINDING MILLGranulation is a process involving particle size enlargement and is a complex process controlled by various mechanisms such us: wetting, nucleation, agglomeration and consolidation, Case Study 2: Ceramic Powder Processing

.jpg)

Review on preparation technology and properties of spherical

2024年3月21日 This paper provides a comprehensive review of the principles, advantages, and disadvantages of three widely used preparation technologies for spherical powders: gas The principle of Attritor dry grind processing is achieved by an expanded moving bed of media This condition is described as kinematic porosity The dry particles are subjected various Attrition Dry Milling In Continuous And Batch Modes Union 2018年4月1日 The process of preparing the presses was carried out using the powder method, by mixing the three powders, which are the base of zirconia with percentages of (94,91,88,85,82)%, silicon as a A review of current techniques for the evaluation of June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process:

.jpg)

Sand Mill Franli Machine

The speed of feeding is controlled by the feeding pump The grinding media of this equipment are generally divided into zirconia beads, glass beads, zirconium silicate beads, etc Performance classification: horizontal sand mill, vertical 2021年5月5日 The following application of Grinding Machine are: The Grinding Machine is used in various industries for grinding The first and foremost industry where this machine is used in Manufacturing Industry The Grinding Machine is used for finishing the cylindrical and flat surfaces In other words, we can say it is used for grinding various materialsGrinding Machine: Definition, Parts, Working Principle, Operation The Ultrafine Grinding Mill, also known as a Micro Powder Grinding Mill or Ultra Fine Powder Grinding Machine, is a highefficiency and lowconsumption grinding mill that is widely used in the powder processing of various materials Bellian Mining Machinery offers a range of Ultrafine Grinding Mills, including the Ultrafine Vertical Mill and Fine Powder Mill Grinder, designed to Ultrafine Grinding Mill, Micro Powder Grinding Mill Bellian Milling apparatus is as the important process equipment of the industries such as coating, chemical industry, grinding materials and grinding tool, pharmacy, food, to develop based on ball mill mostly, along with the continuous progressive of technology upgrades, no matter ball mill is to grind principle, or fineness of grind and application all little identical with sand millThe type of Sand grinder and sand grinding method for grinding powder

How to Choose the Right Sand Mill and Grinding Media

The media and materials to be ground should be selected according to what you want to produce The horizontal nanosand mill is an interval separation device so that the material and the grinding medium can be separated and operated; as long as the design of the nanosand mill is reasonable, the production efficiency is very good; check the convenience of changing 4 Multiple measures to save operating costs Machine each part adopts International brand Classifier wheels of the vertical roller mill are made from wearresistance materials, thermal treatment technology are adopted, ensuring long service life; the wear parts of grinding wheels and grinding discs are made from wearresistance alloy, which ensures long service life under RF1100 Vertical Roller Mill for Making Talc Powder, Calcium Forming: In the forming stage of the P/M process, the loose powder is pressed into engineered shape in order to achieve the required part with a specific density and density distribution The forming stage can be established via two different routes, broadly classified as; ‘cold’ compaction and ‘hot’ compaction The cold compaction forming stage can be accomplished using different Mixing of Powder an overview ScienceDirect Topics2023年10月10日 Vertical mill: It can directly produce 325600 mesh calcium carbonate micro powder (basic demand) products, and can also be used with other ultrafine grinding equipment to prepare ultrafine calcium carbonate products Ball mill: It is the main equipment of a largescale calcium carbonate production lineTypical processes and equipment for ultrafine grinding of

.jpg)

How to choose the right vertical sand mill

2023年1月9日 1 The temperature of the slurry at the pre scattered stage is not high, but once the horizontal sand mill began, the temperature of the slurry in the grinding cavity exceeds the protection temperature, so that the sand mill was 2017年5月19日 Grinding is an essential operation in cement production given that it permits to obtain fine powder which reacts quickly with water, sets in few hours and hardens over a period of weeks i Overview of cement grinding: fundamentals, 2018年3月1日 In the article questions of mechanical grinding up to nanosize of building powder materials are considered In the process of mechanoactivation of the composite binder, active molecules of cement Processing equipment for grinding of building powders2014年1月1日 The determination of powder compressibility: (a) compressibility of CuNi water atomized particles (Courtesy of Dr Adriana SORCOI, Technical University of ClujNapoca, Romania); (b) tool sets: 1 punch, 2 die with cylindrical or rectangular cavity, 3 green compact, 4 base support, (c) cylindrical cavity die, (d) rectangular cavity diePowder Processing of Bulk Components in Manufacturing

.jpg)

DeepL翻译:全世界最准确的翻译 DeepL Translate

即时翻译文本完整的文档文件。为个人和团队提供准确的翻译。每天有数百万人使用DeepL进行翻译。vertical sand mill A vertical sand mill is a wet ultrafine grinding equipment, which is developed from a ball mill Widely used in pigment dispersion and grinding in the ink production process Vertical sand mills are classified in different ways: l According to the structure and shape of the stirring shaft, it can be divided into disc type Sand Mill FLEThe LM Vertical Grinding Mill, launched by ZENITH, integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protectionVertical Mill Shanghai Zenith Company•Virtually any metal can be made into powder form •Three principal methods by which metallic powders are commercially produced 1 Atomization 2 Chemical 3 Electrolytic •In addition, mechanical methods are occasionally used to reduce powder sizesPowder Metallurgy PDF

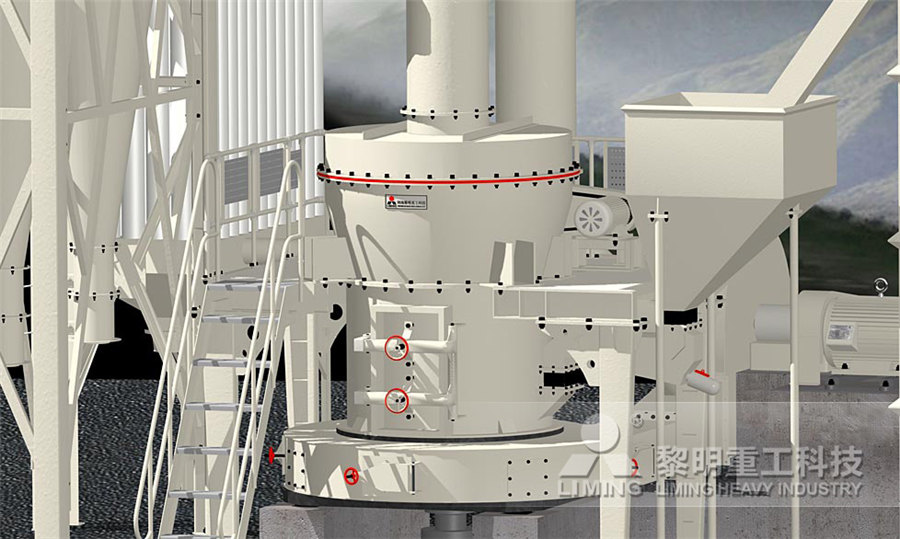

LUM Ultrafine Vertical MillVertical Powder GrinderClirik

Based on nearly 20 years mill research and operation experience, LUM Ultrafine Vertical Mill has been developed as the equipment for ultrafine powder grinding and separation Its production introduces talents in ultrafine powder production and machine manufacturing industry, and absorbs the technologies and experience of ultrafine vertical mills from Germany, Japan and fine grinding, versatility and safety Available with various interchangeable grinding media, this mill offers unsurpassed high energy, onepass size reduction It ensures a controlled size reduction with a high degree of fineness, typically grinding with a milled particle size range D50 of 100μ to 20μ A full range of models are available to Powder Processing Equipment Systems Qlar2021年6月16日 To further examine the durability properties of glass powder cementitious sand, this study uses glass powder of 100–200 mesh and 200–500 mesh to create cementitious sand samples, replacing 10% Evaluation of the Pozzolanic Activity of Glass Powder 2 Working Principle of Vertical Grinding Mill The Vertical Grinding Mill working principle is simple and begins with the jaw crusher crushing the raw material to the required size The crushed material is then added to the hopper (situated Vertical Grinding Mill: How it Works, Application And

.jpg)

HGM Micropowder Grinding Mill Fine Grinding Mill Grinding

HGM series ultra fine powder grinding mill is a new type of mining equipment for making micro powders with threering rollers It is used to grind limestone, Barite, Calcite, and Gypsum2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and energetic 2023年3月15日 SBM has launched the LM Vertical Grinding Mill which integrates five functions of crushing, grinding, Vertical Finepowder Mill Series Models and parameters: LM130XGX: LM150XGX: LM170XGX: LM190XGX: Vertical Pregrinding Mill Series Models and parameters: LM150Y: LM170Y: LM190Y: LM250Y: LM340Y: Plate diameter (mm) 1500:LM Vertical Grinding Mill SBM Mill Crusher2022年7月1日 The effects of superfine grinding on apparent structure, physicochemical properties, and functional characteristics of three kinds of mushroom (Lentinus edodes, Hericium erinaceus, and Cordyceps The effect of superfine grinding on physicochemical properties of three

Metallography of powder metallurgy parts Struers

Recommendations for grinding polishing powder metallurgy parts As a basic principle, when grinding, fine grinding and polishing powder metals, you should use the same procedures as for ingotbased specimens of the same material Plane grinding Plane grinding large volumes of materials (>150 HV) can be done on a diamond grinding disc Product Introduction After absorbing advantages from foreign superfine vertical mills and considering analysis of domestic customers' needs, Longyi makes targeted improvements on existing vertical mill's technology to develop a newtype vertical mill fit for grinding super fine powder for nonmetallic mineralsUltra Fine Powder Vertical Processing Grinding Mill Machine2021年11月25日 Nonmetallic mines, metal mines, and fuel mines are called the three pillars of the materials industry The use of nonmetallic minerals depends on the degree of deep processing, including ultrafine grinding, ultrafine grade, fine purification and surface modification, among which effective ultrafine grinding is the prerequisite and guarantee for various deep Ultrafine grinding of nonmetallic minerals ALPA Powder EquipmentBrief Introduction HGM Ultra fine grinding mill (also called micro powder mill, superfine powder grinding mill, ultra fine powder grinder) is designed by SBM RD department on the basis of multiple innovations and testing It has been proved by thousands of customers that our ultra fine powder grinder has outstanding features, stable quality, easy operation, and maintenanceUltra Fine Grinding Mill SBM Ultrafine Powder Technology

.jpg)

A review of current techniques for the evaluation of

2018年4月1日 The process of preparing the presses was carried out using the powder method, by mixing the three powders, which are the base of zirconia with percentages of (94,91,88,85,82)%, silicon as a June 2022; ARCHIVE Proceedings of the Institution of Mechanical Engineers Part C Journal of Mechanical Engineering Science 19891996 (vols 203210) 236(2):1107(PDF) A comprehensive review on the grinding process: The speed of feeding is controlled by the feeding pump The grinding media of this equipment are generally divided into zirconia beads, glass beads, zirconium silicate beads, etc Performance classification: horizontal sand mill, vertical Sand Mill Franli Machine2021年5月5日 The following application of Grinding Machine are: The Grinding Machine is used in various industries for grinding The first and foremost industry where this machine is used in Manufacturing Industry The Grinding Machine is used for finishing the cylindrical and flat surfaces In other words, we can say it is used for grinding various materialsGrinding Machine: Definition, Parts, Working Principle, Operation

.jpg)

Ultrafine Grinding Mill, Micro Powder Grinding Mill Bellian

The Ultrafine Grinding Mill, also known as a Micro Powder Grinding Mill or Ultra Fine Powder Grinding Machine, is a highefficiency and lowconsumption grinding mill that is widely used in the powder processing of various materials Bellian Mining Machinery offers a range of Ultrafine Grinding Mills, including the Ultrafine Vertical Mill and Fine Powder Mill Grinder, designed to Milling apparatus is as the important process equipment of the industries such as coating, chemical industry, grinding materials and grinding tool, pharmacy, food, to develop based on ball mill mostly, along with the continuous progressive of technology upgrades, no matter ball mill is to grind principle, or fineness of grind and application all little identical with sand millThe type of Sand grinder and sand grinding method for grinding powder The media and materials to be ground should be selected according to what you want to produce The horizontal nanosand mill is an interval separation device so that the material and the grinding medium can be separated and operated; as long as the design of the nanosand mill is reasonable, the production efficiency is very good; check the convenience of changing How to Choose the Right Sand Mill and Grinding Media4 Multiple measures to save operating costs Machine each part adopts International brand Classifier wheels of the vertical roller mill are made from wearresistance materials, thermal treatment technology are adopted, ensuring long service life; the wear parts of grinding wheels and grinding discs are made from wearresistance alloy, which ensures long service life under RF1100 Vertical Roller Mill for Making Talc Powder, Calcium

Mixing of Powder an overview ScienceDirect Topics

Forming: In the forming stage of the P/M process, the loose powder is pressed into engineered shape in order to achieve the required part with a specific density and density distribution The forming stage can be established via two different routes, broadly classified as; ‘cold’ compaction and ‘hot’ compaction The cold compaction forming stage can be accomplished using different 2023年10月10日 Vertical mill: It can directly produce 325600 mesh calcium carbonate micro powder (basic demand) products, and can also be used with other ultrafine grinding equipment to prepare ultrafine calcium carbonate products Ball mill: It is the main equipment of a largescale calcium carbonate production lineTypical processes and equipment for ultrafine grinding of