Road calcium carbonate crushing method

Research Review: Dust Control on Gravel Roads: Traditional

the magnesium or calcium chloride solutions Prewetting is critical for dust control materials, (eg, chlorides) to soak into the gravel section a couple inches deep Chlorides follow the water into the gravel and once in place they draw moisture out of the air The water pulled from the air Microbial induced carbonate precipitation (MICP) technology is a method to insitu repair the microcracks and micropores of recycled concrete aggregates via inducing the deposition of Mechanical properties and repairing mechanism of recycled 2024年9月25日 The combined method resulted in a reduction of RCAs by 347% and 361% in the water absorption and crushing index Above combined method effectively solved the A practical enhancing method of recycled concrete aggregates via 2020年7月20日 The results indicate that HEAB follows a twostage curing method of “160 °C, 2 h + 60 °C, 4 d”, while WEAB adopts a onestage curing method of “120 °C, 5 h”, both of which Microbiologically Induced Calcite Precipitation biocementation,

Evaluating the crushing characteristics of recycled construction

2021年3月1日 In this study, experiments and numerical simulations were conducted to evaluate the crushing characteristics of the CDW, consisting of three main components, ie, gravel, 2024年7月2日 This study focuses on a novel type of coldmixed and coldlaid asphalt mixture pavement material, along with its production method The process begins by recycling existing Road surface coldmixed coldlaid recycled carbonreduced 2021年11月9日 The SEM results showed that the calcium carbonate (C a C O 3) produced by MICP treatment can coat and bond grains and fill voids, which is more apparent in the upper Mechanical Performance of Biotreated Sandy Road Bases2017年3月15日 Calcium carbonate is produced over time by concrete carbonation An ATG analysis could confirm this statement Then, the surfaces of the bigger grain size fractions Influence of Crushing Conditions on Recycled Concrete

.jpg)

Chemical Extraction and Mechanical Crushing Method for Fine

2010年10月20日 Calcium extraction would be effective in promoting the separation of hydrated cement from aggregates The aggregate component, mainly composed of SiO2, does not Through the applied processes of carbonation, concrete aggregate is exposed to an increased CO2 concentration and the CO2 reacts with the cement phase of the concrete aggregate Methodology: Carbon Sequestration Through Accelerated 2021年9月14日 Over a wide range of industries, different functions require different particle size distributions of ground calcium carbonate powders That is the reason why particle sizing is a vital step for (PDF) Measuring the Particle Size Distribution of 2024年10月30日 A carbon–sulfur byproduct material called Blowdown (B) has recently been considered as a possible alternative to calcium carbonate (CaCO3) as a mineral filler This article studied the impact of acrylonitrile–butadiene–styrene (ABS) polymer on densegraded (DG) mixtures with two different types of filler: CaCO3 and Bwaste, which is an alternative filler Evaluation of Rutting, Cracking, and Fatigue Characteristics of

.jpg)

The Application of NanoCalcium Carbonate in the Technology of

2022年7月31日 This article explores the methods of preparing nanocalcium carbonate and petroleum pitch, understands the characteristics of the two materials, and then draws two methods of mixing nanocalcium 2016年9月1日 Calcareous sand is a calciumrich soil with calcium carbonate (CaCO 3 ) content exceeding 90% predominantly caused by marine organisms widely distributed in the South China Sea [8,3, 35]Fractal crushing of carbonate sands under impact loading2024年7月17日 The need for highquality calcium carbonate has resulted in the formation of several specialized factories, mainly in Gujarat Importance of Calcium Carbonate in Industries Calcium Carbonate’s multiple positive characteristics make it useful in a variety of businesses Here are a few significant applications:Calcium Carbonate Manufacturers in Gujarat Girnar Industries2023年9月28日 A calcium carbonate processing plant is a facility where calcium carbonate is processed and produced for various industrial applications The specific processes and equipment used in a calcium carbonate processing plant may vary depending on the source of calcium carbonate (such as limestone or marble) and the desired end product specificationsExploring Different Grinding Mills for Calcium Carbonate Processing

.jpg)

Guide to Calcium Carbonate Grinding: Mills, Tips, and Uses

2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the mill Grinding: Use a bucket elevator to send the crushed small pieces of calcium carbonate to the silo, then use a vibrating feeder to send them fier requires crushing using other methods Accordingly,in this study, an attempt has been made to use a cheaper and more efficient way to produce calcium carbonate The ball mill crusher is the primary apparatus for pulverizing calcium carbonate rock By rotating the mill, the steel pellets inside the apparatus cause calcium carbonate to beMoisture Sensitivity of Hot Mix Asphalt Modified with Micronized Get Price [] APPLICATION METHODS CALCIUM CHLORIDE AS A DUST precautions used in method #1 and #2 5 Apply the calcium to the full width evenly wet grinding mills for ground calcium carbonate Aug; rock crushing companies in te as quarry of calcium corbonate in uae; No416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China Zip calcium mining methods Welcome to Tables Thyme2023年1月1日 The traditional treatment method is to soak the recycled aggregates in a mixture of ureaseproducing bacteria, urea and calcium source, and the generated calcium carbonate can cover the surface and the pores of the recycled aggregates through the effects of gravity and adsorption (Wang et al, 2017; Feng et al, 2020; Zhan et al, 2020; Zhao et al, 2021)Physical and mechanical properties of recycled aggregates

.jpg)

How to Choose a Calcium Carbonate Grinding Mill

The choice of grinding mill machine is related to the quality of the final ground calcium carbonate powder, so how to choose the right calcium carbonate grinding equipment has also become a concern for many customers This article will 2024年1月19日 With the recognised reactive role of calcium carbonate in PC, there is a growing interest in harnessing various forms of calcium carbonate to enhance the performance of different cement typesMaximising the benefits of calcium carbonate in sustainable 2023年12月7日 There are two main types of calcium carbonate: natural and synthetic Natural calcium carbonate is mined from the earth, while synthetic calcium carbonate is produced from limestone or other calciumrich materials What is the steps in the Calcium Carbonate 2024年10月14日 Rutting is a significant form of pavement distress that arises from irreversible strains accumulating along wheel paths, directly impacting pavement safety This research investigates the effectiveness of nanocarboncoated micronized calcium carbonate powder as a modified filler to mitigate rutting, utilizing numerical methods via finite element software The Impact of NanocarbonCoated Calcium Carbonate on Asphalt

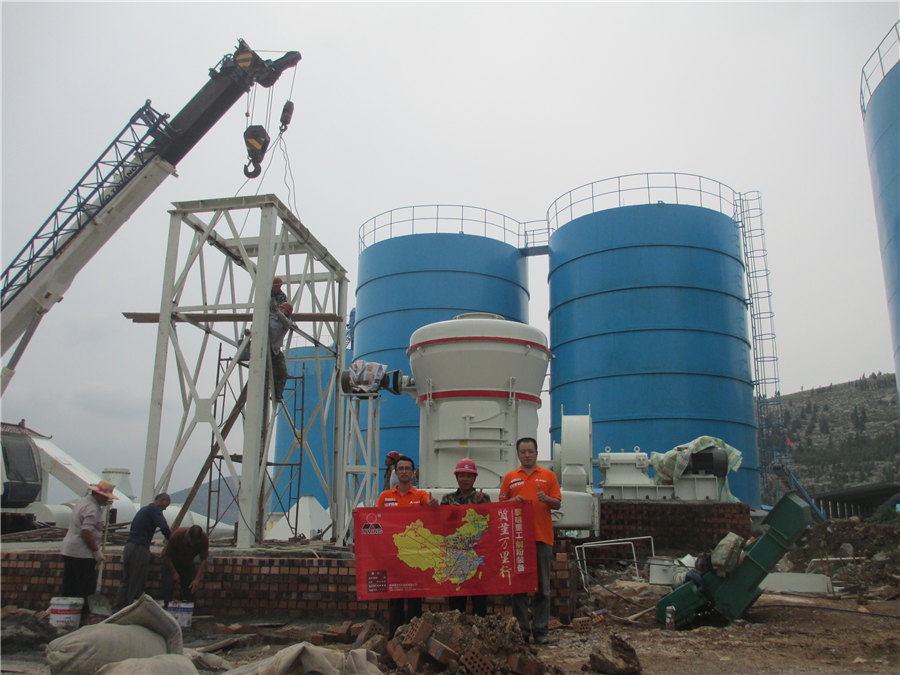

Ground Calcium Carbonate Production Plant In Sichuan

2024年6月14日 Welcome to our stateoftheart Ground Calcium Carbonate Production Plant in Sichuan, ChinaIn this plant, the HGM ultrafine mill and CLUM vertical mill play the most important roles Here, we meticulously transform raw calcium carbonate materials into ultrafine powder, employing advanced technology and precise methodsProducts are manufactured by means of crushing, milling, screening drying and air classification McGraths Limestone erected a modern state of art plant in 2007 for production of high specification calcium carbonates We are accredited to FEMAS Standards and ISO Integrated Management System View markets where Calcium Carbonate products can be RoadSurfacing, Concrete, Stone, Calcium Carbonate Products: 2024年3月22日 Carbonation treatment of RCA is a process in which carbon dioxide in the environment reacts with calcium hydroxide and hydrated calcium silicate in the adherent mortar to form calcium carbonate precipitates [16], [17]Lu et al [18] found by dry carbonation that the microhardness of ITZ of RCA increased significantly after carbonation, and the compressive Evaluation of techniques for enhancing recycled concrete based stabilisation with microbial carbonate precipitation in Australian road base materials Carbonate producing ureolytic strains of bacteria were isolated from Western Australian soil Sand samples with a cement dosage of 7% have been subjected to microbial precipitation The calcium carbonate crystals formedSustainable Road Bases with Microbial Carbonate Precipitation

Review Accelerated carbonation of steel slag: A review of methods

2024年1月12日 The concept of mineral carbonation for reducing CO 2 emissions was first proposed by Seifritz in 1990 [12]Mineral carbonation is considered as a promising largescale CO 2 storage application technology [13]As a raw material for mineral carbonation, steel slag has advantages such as proximity to CO 2 emission sources, significant cost savings in 2016年8月7日 A simulation method for microbial cemented sand (MCS) based on the TwoDimensional Particle Flow Code (PFC 2D) has been developed in this studySustainable Road Bases with Microbial Carbonate Precipitation2022年11月1日 Limestone Calcium Carbonate Limestone is a carbonate sedimentary rock that is often composed of the skeletal fragments of marine organisms such as coral, foraminifera, and molluscs Its major materials are Calcium Carbonate Products South Queensland US Calcium oversees and operates the extraction and processing of a large, proven supply of limestone located in Custer, County, Idaho Adjacent to Highway 93 between Arco and Mackay, Idaho, we cover a large amount of acreage that Calcium Mine US Calcium United States

MICROBIAL INDUCED CALCIUM CARBONATE PRECIPITATION (MICCP) FOR ROAD

These calcium carbonate bonds are present in three crystalline forms in nature – aragonite, valerite and calcite The most stable form is calcite, which presents under the trigonal or rhombohedral crystalline structure (Portugal et al, 2020) Figure 1: Process of Calcium Carbonate Precipitation by Urease Positive Bacteria2016年8月1日 Some carbonates, such as Precipitated Calcium Carbonate (PCC), have industrial applications and may provide sufficient economic incentive for sequestering CO2 should the product be a marketable Production of carbon negative precipitated calcium carbonate from Heavy calcium carbonate is a calcium carbonate powder material produced by mechanical crushing method using calcite, chalk, marble and other ores as raw materials It has the characteristics of wide source of raw materials, high whiteness, low oil absorption value, good applicability and low priceNews Calcium powder processing machinery and equipment 2024年4月30日 1 Different source Calcium carbonate light is chemically synthesized calcium carbonate, also known as precipitated calcium carbonate It is produced by calcining limestone raw materials to produce lime and carbon dioxide, generating calcium carbonate precipitates, which are dehydrated, dried, and crushed, or by the double decomposition reaction of sodium Calcium carboante heavy calcium carbonate light food grade

.jpg)

[Retracted] The Application of Nano‐Calcium Carbonate in the

2022年7月31日 211 Application of NanoCalcium Carbonate in Plastics In terms of plastic processing and manufacturing [], ordinary calcium carbonate products can only be used as general fillers, but in addition to being used as fillers, modified calcium carbonate also functions as an active agent [] and a strengthening agent []At the same time, the amount of plastic 2024年9月25日 The combined method resulted in a reduction of RCAs by 347% and 361% in the water absorption and crushing index Above combined method effectively solved the negative impact of MG on properties the precipitation crystals on the surface of enhanced RCAs induced by different types of bacteria were both composed of calcium carbonateA practical enhancing method of recycled concrete aggregates via 2010年10月20日 Calcium extraction would be effective in promoting the separation of hydrated cement from aggregates The aggregate component, mainly composed of SiO2, does not react with carbonic acid and would be recovered as the solid phase on filtration Dissolved calcium can be recovered as calcium carbonate under low CO2 pressure conditionsChemical Extraction and Mechanical Crushing Method for Fine 2023年6月1日 The prepreg method consists of two types: one is to increase the bacterial concentration of defects within the RCAs by way of prepreg bacterial solution, which leads to an increase in the rate of calcium carbonate synthesis at the defect locations [28]; the other is to increase the calcium ion content within the RCAs by way of prepreg calcium ion rich solution Changing the soaking method of microbially induced calcium carbonate

.jpg)

(PDF) Measuring the Particle Size Distribution of

2021年9月14日 Over a wide range of industries, different functions require different particle size distributions of ground calcium carbonate powders That is the reason why particle sizing is a vital step for 2024年10月30日 A carbon–sulfur byproduct material called Blowdown (B) has recently been considered as a possible alternative to calcium carbonate (CaCO3) as a mineral filler This article studied the impact of acrylonitrile–butadiene–styrene (ABS) polymer on densegraded (DG) mixtures with two different types of filler: CaCO3 and Bwaste, which is an alternative filler Evaluation of Rutting, Cracking, and Fatigue Characteristics of 2022年7月31日 This article explores the methods of preparing nanocalcium carbonate and petroleum pitch, understands the characteristics of the two materials, and then draws two methods of mixing nanocalcium The Application of NanoCalcium Carbonate in the Technology of 2016年9月1日 Calcareous sand is a calciumrich soil with calcium carbonate (CaCO 3 ) content exceeding 90% predominantly caused by marine organisms widely distributed in the South China Sea [8,3, 35]Fractal crushing of carbonate sands under impact loading

Calcium Carbonate Manufacturers in Gujarat Girnar Industries

2024年7月17日 The need for highquality calcium carbonate has resulted in the formation of several specialized factories, mainly in Gujarat Importance of Calcium Carbonate in Industries Calcium Carbonate’s multiple positive characteristics make it useful in a variety of businesses Here are a few significant applications:2023年9月28日 A calcium carbonate processing plant is a facility where calcium carbonate is processed and produced for various industrial applications The specific processes and equipment used in a calcium carbonate processing plant may vary depending on the source of calcium carbonate (such as limestone or marble) and the desired end product specificationsExploring Different Grinding Mills for Calcium Carbonate Processing2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the mill Grinding: Use a bucket elevator to send the crushed small pieces of calcium carbonate to the silo, then use a vibrating feeder to send them Guide to Calcium Carbonate Grinding: Mills, Tips, and Usesfier requires crushing using other methods Accordingly,in this study, an attempt has been made to use a cheaper and more efficient way to produce calcium carbonate The ball mill crusher is the primary apparatus for pulverizing calcium carbonate rock By rotating the mill, the steel pellets inside the apparatus cause calcium carbonate to beMoisture Sensitivity of Hot Mix Asphalt Modified with Micronized

.jpg)

calcium mining methods Welcome to Tables Thyme

Get Price [] APPLICATION METHODS CALCIUM CHLORIDE AS A DUST precautions used in method #1 and #2 5 Apply the calcium to the full width evenly wet grinding mills for ground calcium carbonate Aug; rock crushing companies in te as quarry of calcium corbonate in uae; No416 Jianye Road, South Jinqiao Area, Pudong, Shanghai, China Zip 2023年1月1日 The traditional treatment method is to soak the recycled aggregates in a mixture of ureaseproducing bacteria, urea and calcium source, and the generated calcium carbonate can cover the surface and the pores of the recycled aggregates through the effects of gravity and adsorption (Wang et al, 2017; Feng et al, 2020; Zhan et al, 2020; Zhao et al, 2021)Physical and mechanical properties of recycled aggregates