Pictures of gypsum ore grinding process

.jpg)

Gypsum Manufacturing Process Gypsum Processing Equipment

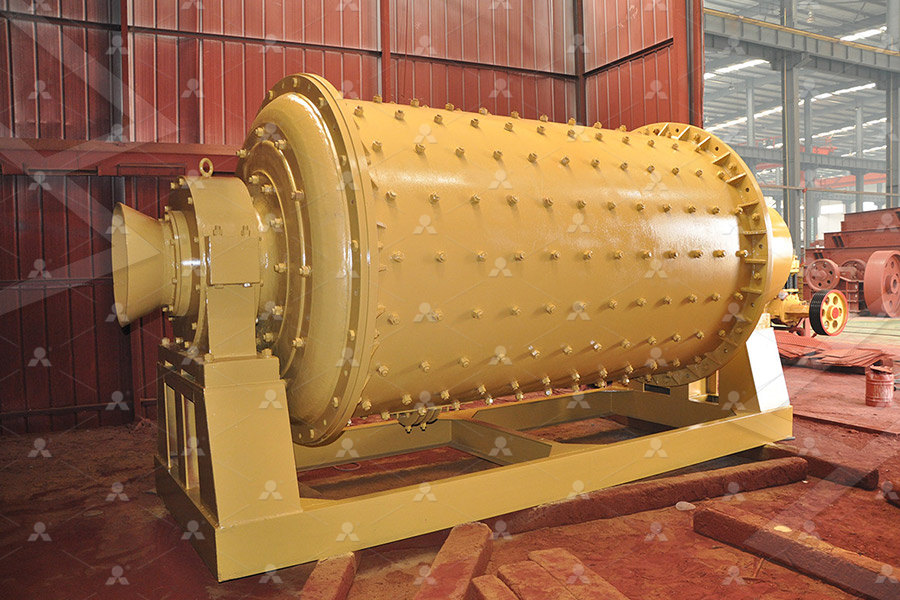

2023年11月13日 Grinding Process: Gypsum ore is fed into the grinding mill, where it is subjected to mechanical forces that crush and grind the ore into a fine powder The size of the At some gypsum plants, drying, grinding, and calcining are performed in heated impact mills In these mills hot gas contacts gypsum as it is ground The gas dries and calcines the ore and 1116 Gypsum Manufacturing US EPA2016年4月1日 In this study, batch grinding tests of gypsum ore were performed using a ball mill to investigate the effects of grinding parameters such as mill speed, ball filling ratio, ball size An experimental study on the ultrafine grinding of gypsum ore in a Pfeiffer GK gypsum calcining kettle In this process, the natural gypsum is first fed to a Pfeiffer MPS mill where the material is dried and simultaneously ground to the required fineness for Grinding and calcining of gypsum with Pfeiffer grinding plants

CLIRIK gypsum grinding mill for gypsum powder production process

2021年8月4日 CLIRIK gypsum grinding mills are specialized in the production process of 303000 mesh gypsum powder The gypsum powder production process is obtained by grinding 2023年11月13日 1 Crusher: Gypsum ore is initially crushed into smaller pieces in a crusher to reduce its size for further processing 2 Grinding Mill: After crushing, the gypsum ore is often ground into a fine powder using a grinding mill The grinding process further reduces the size of the gypsum particles 3 Rotary Kiln or Fluidized Bed Calciner: The calcination process, where Gypsum Manufacturing Process Gypsum Processing Equipment2024年1月23日 The production process of gypsum includes three processes: gypsum stone crushing, calcination, and grinding Firstly, the jaw crusher or impact crusher crushes the gypsum raw ore to around 30 millimeters Then Gypsum Powder Grinding And Processing Plant The post Five Stages of Gypsum Production Process appeared first on PermuTrade Thankfully, the next steps are much easier as they require crushing, sieving, grinding, and heating the ore The result is highquality Five Stages of Gypsum Production Process

Upgrade Your Process: 3 Best Gypsum Powder Mills

2024年9月26日 Complete gypsum grinding process flow: 1 Gypsum ore is processed by jaw crushers and hammer crushers to reduce the particle size to below 25 mm 2 Next, different types of grinding mills are used for fine grinding 3 After classification by a powder selector, 2021年8月4日 CLIRIK gypsum grinding mills are specialized in the production process of 303000 mesh gypsum powder The gypsum powder production process is obtained by grinding natural dihydrate gypsum ore (green gypsum) or industrial byproduct gypsum (desulfurized gypsum, phosphogypsum, etc) through a special mill and heating and calcining at a certain CLIRIK gypsum grinding mill for gypsum powder production processIn the process of gypsum production and processing, a gypsum powder ultrafine grinding mill is indispensable Generally speaking, the process of the gypsum production line is as follows: first, crush the gypsum ore to meet the particle size requirements of the mill; then use the ultrafine mill for grinding treatment; then enter the boiling furnace for heating treatment, and finally do store Gypsum Powder Ultrafine Grinding MillDOI: 101016/JPOWTEC201512027 Corpus ID: ; An experimental study on the ultrafine grinding of gypsum ore in a dry ball mill @article{kszolu2016AnES, title={An experimental study on the ultrafine grinding of gypsum ore in a dry ball mill}, author={Bilge {\"O}ks{\"u}zoğlu and Metin Uçurum}, journal={Powder Technology}, year={2016}, An experimental study on the ultrafine grinding of gypsum ore

Gypsum Properties, Formation, Uses and Deposits Geology

2023年9月9日 Gypsum is a naturally occurring mineral that has been used by humans for various purposes for thousands of years It is a versatile mineral with a wide range of applications in construction, agriculture, industry, and even art In this introduction, we'll explore the definition and composition of gypsum2018年6月18日 Pretreatment of ores to improve energy efficacy of grinding has been explored for decades However, many of these techniques are still at developmental stages and a review has been presented in Ore Pretreatment Methods for Grinding: Journey and Prospects2022年8月31日 Dear Colleagues, The grinding process, as a primary stage of ore/raw material processing, is a necessary operation in beneficiation plants It not only provides the appropriate particle size for subsequent separation operations but also enables the liberation of valuable minerals from the gangueGrinding Modeling and Energy Efficiency in Ore/Raw Material 2015年12月1日 Öksüzoglu and Uçurum [27] studied the ultrafine grinding of gypsum ore in a dry ball mill In their grinding tests, the mill speed was varied from 50 to 90% of the critical speed for gypsum oreAn experimental study on the ultrafine grinding of gypsum ore

.jpg)

Resistance to Grinding and Cement Paste Performance of Blends

2021年4月19日 Grinding of finished cement is performed in a single stage, intergrinding materials with very different grindabilities This intergrinding process has many different interactions among the different components of the finished cement In a context of developing more sustainable and less energy intensive processes, it is important to understand the 2016年5月7日 Potash occurs in soft deposits generally associated with sodium chloride and varying amounts of clay slime, which because of its colloidal character, complicates the beneficiation process Potash ores generally contain 20 to 40 percent KCL with the balance being NaCl and a small amount of clay slime, the latter usually in the order of 1 to 1½%Potash Flotation Process 911MetallurgistWhen iron ore is extracted from a mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushingThe six main steps of iron ore processing Multotec2021年2月1日 clinker grinding process does control by the content of sulfur trioxide (SO 3) in the cement produced The higher SO 3 content in cement indicates that the gypsum composition is also high(PDF) Optimization of Gypsum Composition Against Setting Time

.jpg)

What is Gypsum How Gypsum is Processed MC

The raw material of gypsum powder is natural gypsum ore, and the production process of gypsum powder is mainly divided into 5 stages: crushing, screening, grinding, calcination, storage and transportation Crushing: The mined gypsum ore raw material enters 2016年4月1日 Because it is well known that the specific surface area is increased as the particle size becomes small, the L* color parameter value of gypsum ore increased from 9575 to 9738, while the b* value decreased from 251 to 183 due to the grinding processAn experimental study on the ultrafine grinding of gypsum ore 2023年7月10日 Cement manufacturing is a significant industrial activity that plays a vital role in the construction sector However, the process of cement production is associated with various environmental Cement Manufacturing Process and Its Environmental Impact2023年6月12日 Iron oxide copper gold ore refers to the symbiosis of copper ore and gold ore in gold ore in some form Its amount is about 10 million to 4 billion tons IOCG ore contains copper with a grade of 02% to 5% and gold with a content of 01 to 141 grams per ton8 Types of Gold Ore Properties and Ways to Process

.jpg)

Effect of gypsum on the setting time ResearchGate

Gypsum is one of the additive raw materials added to the clinker grinding process that regulate the binding time of cement or commonly known as a retarder2023年2月15日 14 subclasses of gypsum ore Fibrous plaster is milky white or wax yellow, with a fibrous structure It's often in the form of veins, nets, lenses or thin interlayers together with gypsum and anhydrite layers The bluegray What Are the Types of Gypsum Ore and Their Gypsum production process Gypsum ore, from quarries and underground mines, is crushed and stockpiled near a plant Asneeded, the stockpiled ore is further crushed and screened to about 50 millimeters (2 inches) in diameter If the Five stages of gypsum production process Samim Gypsum powder is a product made by processing natural gypsum ore or industrial byproduct gypsum into fine powder through a series of physical and chemical treatment processes, such as crushing, grinding, calcination, etc Gypsum powder has a wide range of uses and can be used in many fields such as building materials, chemicals, medicine, agriculture, etc Usually, the Gypsum Powder Production Line Hongji Mining Machinery

.jpg)

Copper ore crushing equipment and beneficiation process

The copper ore processing and production process mainly includes three processes: crushing, grinding and beneficiation In the crushing process, the threestage closedcircuit crushing is more modern and suitable for highhardness copper ore crushing, and can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding efficiency;gypsum sector, supplying its fi rst mills to the sector in 1963 It is one of the technical leaders in this fi eld, introducing its gypsum grinding and calcining mills in the late 1990s Th ere are 49 MPS VRMs references for gypsum grinding and drying, plus 30 MPS VRMs for gypsum calcining Th ey are very fl exible, whichGLOBAL GYPSUM: GRINDING Gebr Pfeiffer2023年8月8日 To extract phosphorus from phosphate rock, Ftmmachinery will explain to you the process flow of phosphate rock and the equipment we can provide, from the four stages of crushing grinding flotation – dehydration Stage 1: Crushing Phosphate rock is transported to the raw ore bin and enters the jaw crusher through the vibrating feederPhosphate Rock Processing: 6 Useful Ways and 4 Stages2023年7月20日 (2) Various working parameters of grinding mill, including fraction of critical speed for grinding mill, filling rate for grinding mill, grinding concentration, grinding cycle load, etc (3) And grinding material properties, including ore grindability, feeding particle size, etc Huge energy and steel consumption in ore grinding process greatly affect the subsequent separation Ore Grinding SpringerLink

.jpg)

A Process of Setting up an Industrial Plant ResearchGate

A Process of Setting up an Industrial Plant (Gypsum plant as a case study) A Thesis Submitted in Partial Fulfillment of the Requirementsgypsum and limestone occurring during Portland cement finish grinding and develop a model to predict blends resistance to grinding as a function of the volume fraction of each component The aim is to develop a method to aid in finding the optimum blend that can yield the lowest energy consumption without requiring process modificationsResistance to Grinding and Cement Paste Performance of Blends Grinding, for example in a ball, rod, or hammer mill, is necessary if the gypsum is to be used for high quality plasterwork or for moulding, medical, or industrial applications Unlike with other cements, such as lime and Ordinary Portland Cement, special mills for mineral grinding may not be required and the relatively soft gypsum could be pulverised in agricultural millsGypsum Mining Processing Equipment Flow Chart JXSC2023年11月13日 1 Crusher: Gypsum ore is initially crushed into smaller pieces in a crusher to reduce its size for further processing 2 Grinding Mill: After crushing, the gypsum ore is often ground into a fine powder using a grinding mill The grinding process further reduces the size of the gypsum particles 3 Rotary Kiln or Fluidized Bed Calciner: The calcination process, where Gypsum Manufacturing Process Gypsum Processing Equipment

.jpg)

Gypsum Powder Grinding And Processing Plant

2024年1月23日 The production process of gypsum includes three processes: gypsum stone crushing, calcination, and grinding Firstly, the jaw crusher or impact crusher crushes the gypsum raw ore to around 30 millimeters Then The post Five Stages of Gypsum Production Process appeared first on PermuTrade Thankfully, the next steps are much easier as they require crushing, sieving, grinding, and heating the ore The result is highquality Five Stages of Gypsum Production Process2024年9月26日 Complete gypsum grinding process flow: 1 Gypsum ore is processed by jaw crushers and hammer crushers to reduce the particle size to below 25 mm 2 Next, different types of grinding mills are used for fine grinding 3 After classification by a powder selector, Upgrade Your Process: 3 Best Gypsum Powder Mills2021年8月4日 CLIRIK gypsum grinding mills are specialized in the production process of 303000 mesh gypsum powder The gypsum powder production process is obtained by grinding natural dihydrate gypsum ore (green gypsum) or industrial byproduct gypsum (desulfurized gypsum, phosphogypsum, etc) through a special mill and heating and calcining at a certain CLIRIK gypsum grinding mill for gypsum powder production process

.jpg)

Gypsum Powder Ultrafine Grinding Mill

In the process of gypsum production and processing, a gypsum powder ultrafine grinding mill is indispensable Generally speaking, the process of the gypsum production line is as follows: first, crush the gypsum ore to meet the particle size requirements of the mill; then use the ultrafine mill for grinding treatment; then enter the boiling furnace for heating treatment, and finally do store DOI: 101016/JPOWTEC201512027 Corpus ID: ; An experimental study on the ultrafine grinding of gypsum ore in a dry ball mill @article{kszolu2016AnES, title={An experimental study on the ultrafine grinding of gypsum ore in a dry ball mill}, author={Bilge {\"O}ks{\"u}zoğlu and Metin Uçurum}, journal={Powder Technology}, year={2016}, An experimental study on the ultrafine grinding of gypsum ore 2023年9月9日 Gypsum is a naturally occurring mineral that has been used by humans for various purposes for thousands of years It is a versatile mineral with a wide range of applications in construction, agriculture, industry, and even art In this introduction, we'll explore the definition and composition of gypsumGypsum Properties, Formation, Uses and Deposits Geology 2018年6月18日 Pretreatment of ores to improve energy efficacy of grinding has been explored for decades However, many of these techniques are still at developmental stages and a review has been presented in Ore Pretreatment Methods for Grinding: Journey and Prospects

Grinding Modeling and Energy Efficiency in Ore/Raw Material

2022年8月31日 Dear Colleagues, The grinding process, as a primary stage of ore/raw material processing, is a necessary operation in beneficiation plants It not only provides the appropriate particle size for subsequent separation operations but also enables the liberation of valuable minerals from the gangue