HOME→How to do the process of tungsten ore powder processing plant, how to obtain highgrade tin concentrate

How to do the process of tungsten ore powder processing plant, how to obtain highgrade tin concentrate

.jpg)

Tungsten extractive metallurgy: A review of processes and their

2019年10月1日 The current commercial tungsten extractive metallurgy by soda/caustic soda digestion with solvent extraction or ion exchange step can use various raw materials and 2006年9月1日 To recover the tungsten and other metallic valuables from these secondary resources, various processes have been developed, such as zincmelt, cold stream, melt bath, Modern hydrometallurgical production methods for tungstenModern processing methods dissolve scheelite and wolframite concentrates by an alkaline pressure digestion, using either a soda or a concentrated NaOH solution The sodium tungstate solution obtained is purified by precipitation and Tungsten: extraction and processing Asian Metal2024年1月7日 As we discussed earlier, tungsten manufacturing involves several steps: mining the ore, extracting and concentrating tungsten from the ore, and then refining it to obtain pure tungsten Each step is crucial in transforming the How is Tungsten made: From Ore to HighTech Metal

.jpg)

Tungsten Metallurgy SpringerLink

2023年5月17日 The main raw materials used for tungsten metallurgy are wolframite concentrate and scheelite concentrate The metallurgical processes mainly include tungsten ore 2019年8月29日 The first stage is to decompose the ore or concentrate by HTSE The extracting components are sodium chloride and sodium metasilicate melts When fused with tungsten Production of Tungsten and Tungsten Carbide PowdersThe first step in the production of tungsten is to enrich tungsten from two minerals wolframite ( (Fe, Mn)WO 4) and scheelite (CaWO 4) through the leaching process The leaching residue Fundamental studies for high temperature processing of tungsten Crushing and Grinding: The raw tungsten ore is first crushed and ground to liberate the tungsten minerals from the surrounding rock Concentration: Using techniques such as gravity tungsten ore processing plant

The six main steps of iron ore processing Multotec

When iron ore is extracted from a mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS 2022年3月21日 Rareearth elements (REEs) are required for use in modern hightech applications and demand has increased significantly over the last decade 1 However, processing of REE ores poses potential hazards to human health and the environment due to challenges in the management of thorium (Th) and uranium (U) in waste products 2 If well managed, REE Processing the ores of rareearth elements MRS Bulletin2024年8月15日 A typical mineral processing plant is able to process various types of ores and mineral materials, including metal ores, nonmetallic ores, clay minerals, building materials and energy minerals Metallic ores: Gold ore, Mineral Processing Plants: What You Need to KnowA lab will find the amount of tungsten oxide in the tungsten concentrates First grade material will have at least 65% tungsten oxide Some impurities can be difficult to remove or are costly to dispose of High levels of things like arsenic or uranium are not desireable A full assay will help determine the value of the ore Purchasing Tungsten Concentrates Buffalo Tungsten

Tungsten Metallurgy SpringerLink

2023年5月17日 Dense tungsten mostly refers to tungsten rod and tungsten ingot Metal tungsten powder is the main raw material for production of dense tungsten Tungsten rod is produced by powder metallurgy process Tungsten powder is first formed in the pressed film, and then experiences hightemperature sintering in vacuum or protective atmosphere2016年3月10日 The specific gravity is 573 The mesh analysis of the final jig concentrate is as follows: Tungsten Extraction Process Summarized The ability to recover a highgrade concentrate from an initial coarse unclassified feed, with a minimum amount of slimes, is one of the outstanding features of this flowsheetTungsten Extraction Process 911Metallurgist2021年6月29日 Tungsten is recognized as a critical metal due to its unique properties, economic importance, and limited sources of supply It has wide applications where hardness, high density, high wear, and (PDF) A Review of Tungsten Resources and Potential2024年4月26日 The beneficiation process aims to increase the iron content and reduce impurities in the ore, resulting in a higherquality concentrate suitable for further processing and utilization The specific beneficiation method employed depends on factors such as the mineralogy of the ore, the presence of specific impurities, and the desired iron contentIron Ore Processing: From Extraction to Manufacturing

.jpg)

Understanding the wet decomposition processes of tungsten ore:

2022年8月1日 At present, the mainstream tungsten metallurgical process is to produce tungsten metal powder that meets the requirements of both chemical compositions and physical properties by using wolframite, scheelite, wolframitescheelite mixed ore and other valuable raw materials (Gaur, 2006; Lassner, 1995)This process can be generally divided into four main steps: 2024年1月11日 The process steps for producing tungsten powder are outlined below: Tungsten Ore Concentration The process starts with extraction of tungsten ore and concentration to WO3 levels above 65% using crushing, grinding, gravity and magnetic separation Calcination This step involves roasting the tungsten ore concentrate with organic agents at 600 Introduction to Tungsten Metal Powder Additive Manufacturing The first step in the production of tungsten is to enrich tungsten from two minerals wolframite ((Fe, Mn)WO4) and scheelite (CaWO4) through the leaching process The leaching residue usually contains a certain amount (2–5 wt%) of WO3 which is higher than that in the tungsten ore (generally less than 1 wt%) In addition, the leaching residue may also consist of other Fundamental studies for high temperature processing of tungsten 2016年5月11日 Tungsten Ore Specifications All tungsten ores require concentration to produce a marketable product Generally the WO3 content of tungsten ores is less than one percent and ores with up to 3% are considered Tungsten Metallurgy 911Metallurgist

.jpg)

Tin Ore Processing Plant JXSC Machinery

Tin(Cassiterite) ore processing refers to the process of extracting tin from ore Gravity separation, magnetic separation and flotation are mainly used to grade tin concentrate and remove other impurities In order to achieve high efficient, low Tungsten oxide can be roasted in a hydrogen atmosphere to create pure tungsten powder with water as a byproduct Tungsten powder is the starting point for tungsten mill products, including wire Now that we have pure tungsten powder, how do we make wire? 1 Pressing Tungsten powder is sifted and mixed A binder may be addedHow Tungsten Wire is Made6 天之前 Usually, there is often one or more equipment being used for processing and beneficiation tin ores, thus the finally tin concentrate can get an ideal grade and high recovery rate Below are the three beneficiaiton flow used in tin ore beneficiation Tin ore gravity Separation: In fact, most of the tin concentrates come from cassiterite depositsTin Ore Beneficiation Methods And Some PracticeCHEMICAL PROCESSING TUNGSTEN ORES AND CONCENTRATES The late K C Li, probably the world's leading authority on the extractive metallurgy of tungsten, discovered the first tungsten deposits in China, and in 1915 made the first shipment of Chinese wolfram ore to the United States This article is a survey of chemical methods used to convert impure conCHEMICAL PROCESSING TUNGSTEN ORES AND CONCENTRATES

.jpg)

82: Mining and Ore Processing Geosciences LibreTexts

Media Attributions; Metal deposits are mined in a variety of different ways depending on their depth, shape, size and grade Relatively large deposits that are quite close to surface and somewhat regular in shape are mined using openpit mine methods (Figure 815 in Section 81)Creating a giant hole in the ground is generally cheaper than making an underground 2023年8月11日 It is important to estimate the energy required in ore processing to select the most affordable and efficient energy system for the integration of renewable resources into the mining industryEstimation of Energy Consumption for Concentrate Process of Tungsten 2017年8月21日 The original tin deposits will be exhausted in several years, therefore, tinbearing secondary resources, such as tin alloy, tin anode slime, ewastes, tin slag and tinbearing tailings, will (PDF) Extraction and Separation of Tin from TinBearing 2015年7月1日 Recovery of elemental copper, bismuth, tellurium, antimony and tin from thermoelectric generators (TEGs) is vital to recover the high content of critical metals and potential risk of environmental Processes for the recovery of bismuth from ores and concentrates

Metals Production and Metal Oxides Reduction Using Hydrogen: A

2022年1月12日 Hydrogen is projected to be not only a source of clean fuel energy, but also a reducing agent for metals production in the current industrial decarbonization effort Currently, hydrogen is still not common to be used in many metals production Hydrogen is only commercially utilized in a limited number of refractory metals (ie, W, Mo) and partly utilized in 2024年11月21日 A brief history of extracting of tin from tin ores In nature, the tin ore are existing in sand or alluvial raw material, this kind tin ore called sand tin or alluvial tin, those raw material may be with stone, sand, gravel, soil, sticky How to extraction tin from tin ores JXSC Machinery2018年9月6日 This paper reviews the stateoftheart recycling of tungsten from carbide (WC) scraps and other spent alloys generated by various production and application industries With an aim of direct reuse or chemical recovery of tungsten, the reclamation of WC is commonly divided into three parts: (1) pyrometallurgy, (2) hydrometallurgy, and (3) a combined (pyro + hydro) Reclamation of tungsten from carbide scraps and spent materials 2010年8月12日 On the other hand, tin and tungsten metal prices are showing an upward trend, giving a scope to the processing of tin tungsten ores for production of these metals, which will result in their An integrated process for the recovery of tungsten and tin from

.jpg)

Beneficiation studies of tungsten ores – A review ScienceDirect

2018年8月15日 Scheelite (CaWO 4) and wolframite ((Fe, Mn)WO 4) are the only tungsten minerals mined commercially and are mainly found in five types of deposits: skarn, vein/stockwork, porphyry, disseminated and strataboundGravity concentration and flotation are the beneficiation techniques most commonly applied to scheelite ore, and gravity and/or at a number of mines around the world as it can give a high grade tin concentrate at high recovery from low grade concentrates The challenge is to find a cheap furnace and associated gas handling system The chemistry is simple –heat and melt the low grade concentrate, add carbon in some for to create a reducing atmosphere, add sulphur in someTIN ORES SOME ASPECTS OF PROCESS METALLURGY AusIMM6 天之前 A single sulfide ore is usually treated by flotation process, using crushinggrindingclassificationflotationconcentration process to select a single copper sulfide ore as copper concentrate Copper ore beneficiation process The principle of priority flotation process is: crushing and screening→grinding and classification→priority flotation of copper Copper Ore Processing Plants, Flow And Equipment2023年3月13日 The highgrade copper concentrate can be obtained by the coarse grinding, roughing, scavenging of copper ore, then grinding and concentrating of coarse concentrate Classification of copper ore Due to the different types of ore, the nature of the ore is also different, so the beneficiation process needs to be customized The specific process How to Process Copper Ore: Beneficiation Methods and Equipment

.jpg)

How is Platinum mined? Full Guide to Platinum Production

2024年9月23日 This is followed by flotation, a process that uses water and chemicals to concentrate the PGMs by making them attach to air bubbles and rise to the surface 3) Smelting The concentrated ore is then subjected to high temperatures in a smelter, where the metals are separated from the waste rock2001年1月1日 Pandey et al, (2001) processed a lowgrade scheelite ore (03 % WO 3 ) into a preconcentrate assaying 13% WO 3 The preconcentrate either can be directly utilized for extraction of tungsten (W Processing of Tungsten Preconcentrate from Low Grade Ore to When iron ore is extracted from a mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS The six main steps of iron ore processing Multotec2022年3月21日 Rareearth elements (REEs) are required for use in modern hightech applications and demand has increased significantly over the last decade 1 However, processing of REE ores poses potential hazards to human health and the environment due to challenges in the management of thorium (Th) and uranium (U) in waste products 2 If well managed, REE Processing the ores of rareearth elements MRS Bulletin

.jpg)

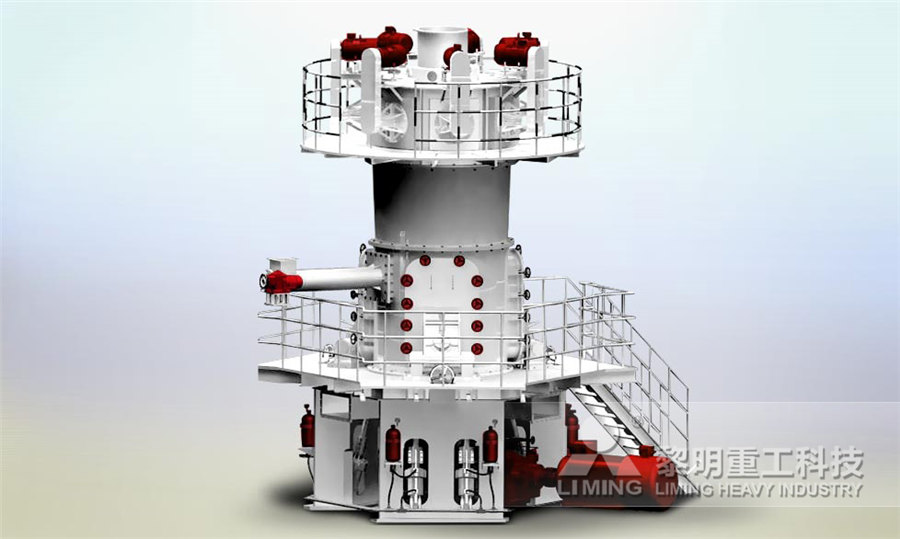

Mineral Processing Plants: What You Need to Know

2024年8月15日 A typical mineral processing plant is able to process various types of ores and mineral materials, including metal ores, nonmetallic ores, clay minerals, building materials and energy minerals Metallic ores: Gold ore, A lab will find the amount of tungsten oxide in the tungsten concentrates First grade material will have at least 65% tungsten oxide Some impurities can be difficult to remove or are costly to dispose of High levels of things like arsenic or uranium are not desireable A full assay will help determine the value of the ore Purchasing Tungsten Concentrates Buffalo Tungsten2023年5月17日 Dense tungsten mostly refers to tungsten rod and tungsten ingot Metal tungsten powder is the main raw material for production of dense tungsten Tungsten rod is produced by powder metallurgy process Tungsten powder is first formed in the pressed film, and then experiences hightemperature sintering in vacuum or protective atmosphereTungsten Metallurgy SpringerLink2016年3月10日 The specific gravity is 573 The mesh analysis of the final jig concentrate is as follows: Tungsten Extraction Process Summarized The ability to recover a highgrade concentrate from an initial coarse unclassified feed, with a minimum amount of slimes, is one of the outstanding features of this flowsheetTungsten Extraction Process 911Metallurgist

(PDF) A Review of Tungsten Resources and Potential

2021年6月29日 Tungsten is recognized as a critical metal due to its unique properties, economic importance, and limited sources of supply It has wide applications where hardness, high density, high wear, and 2024年4月26日 The beneficiation process aims to increase the iron content and reduce impurities in the ore, resulting in a higherquality concentrate suitable for further processing and utilization The specific beneficiation method employed depends on factors such as the mineralogy of the ore, the presence of specific impurities, and the desired iron contentIron Ore Processing: From Extraction to Manufacturing2022年8月1日 At present, the mainstream tungsten metallurgical process is to produce tungsten metal powder that meets the requirements of both chemical compositions and physical properties by using wolframite, scheelite, wolframitescheelite mixed ore and other valuable raw materials (Gaur, 2006; Lassner, 1995)This process can be generally divided into four main steps: Understanding the wet decomposition processes of tungsten ore: 2024年1月11日 The process steps for producing tungsten powder are outlined below: Tungsten Ore Concentration The process starts with extraction of tungsten ore and concentration to WO3 levels above 65% using crushing, grinding, gravity and magnetic separation Calcination This step involves roasting the tungsten ore concentrate with organic agents at 600 Introduction to Tungsten Metal Powder Additive Manufacturing