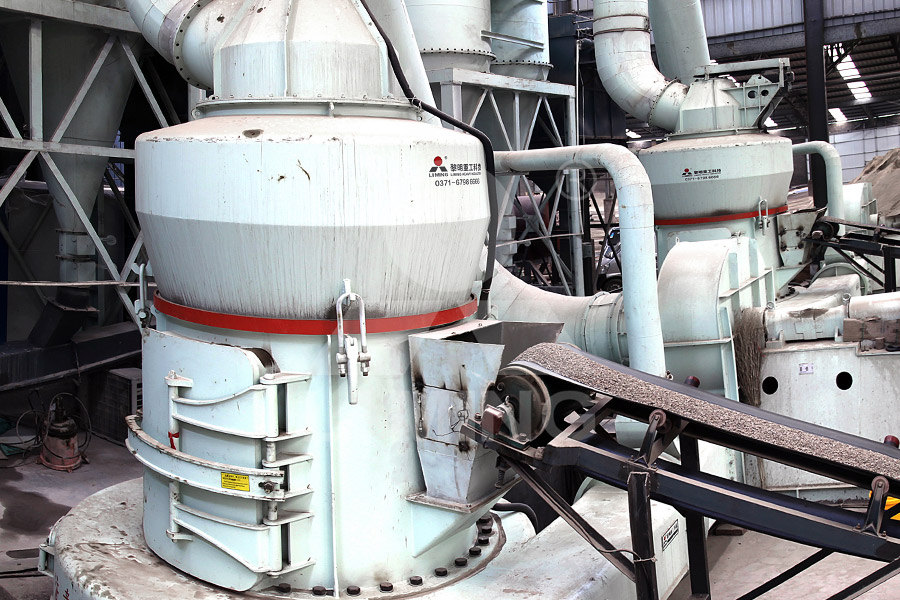

Zeolite high fine vertical mill

.jpg)

HIGmill high intensity grinding mill Metso

The Metso HIGmill™ is an advanced, energyefficient fine and ultrafine grinding solution that utilizes proven technology With the tall, narrow, vertical body arrangement, grinding media is evenly distributed and mineral particles remain Vertical roller mill have outstanding performance in many nonmetal fields, fully demonstrating the "advanced charm" of highefficiency milling, environmental protection and low carbon For Clirik CLUM Zeolite Vertical Roller MillZeolites vertical roller mills mainly consists of main unit, classifier, powder collector, dust cleaner, blower, muffler, soundproof room, crusher, bucket elevator, storage hopper, and vibrating feederZeolites vertical roller mills, vertical mill machineThe combined beadmilling and postmilling recrystallization yielded nanozeolites with high crystallinity The nanosized powders showed higher ionexchange properties for zeolite A and Topdown Tuning of Nanosized Zeolites by Beadmilling and J

Synthesis of Highly Active Nanozeolites Using Methods of

2021年7月7日 There are two approaches to nanozeolite preparation: direct chemical synthesis [28–30] and highenergy mechanical milling of commercially available zeolites in planetary and 2021年1月22日 Almost all reports showed that in the solventfree process assisted by milling pretreatment it was possible to obtain zeolites with crucial properties desirable for catalytic applications: high crystallinity, low Milling Activation for the SolventFree Synthesis of Zeolites with high external surface area allow diffusing reactants greater access to catalytically active sites, which has lead to interest in the preparation of nanozeolites In this study, a topdown approach has been used, first milling the Fabrication of Fine Zeolite with Improved Catalytic 2016年7月5日 Herein we present a facile methodology to prepare zeolite nanocrystals, where milling and recrystallization can be performed in situ A milling apparatus specially designed to Pioneering In Situ Recrystallization during Bead Milling: A Top

.jpg)

Vertical Mill Shanghai Zenith Company

The LM Vertical Grinding Mill, launched by ZENITH, integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by centralized Production of coarse powder and general fine powder above 45um, stable operation, high cost performance and high noise Ring roller mill: 2um content is about 20% or more, the highest fineness is 810um, middle and highend CLUM Ultrafine Vertical Grinding Mill2021年7月28日 The ultrafine vertical roller mill is suitable for mass production, and the fineness of the finished powder can reach 3000 meshes It can grind solid ores into a fine powder, such as marble, talc, calcite, calcium carbonate, Dolomite Grinding Mill SBM Ultrafine Powder 2021年7月22日 Vertical wet stirring mill equipment is mainly divided into mixing mill (tower mill) and sand mill The barrel of the stirring mill is thicker and the spindle angular velocity is lower The grinding medium can be either a sphere Vertical wet stirring millVertical wet stirring mill

Vertical raw mill pradeep kumar PPT Free Download SlideShare

2013年5月15日 • 21 vertical roller mill vibration is too large: (1) Feed uneven, when the mixture into the vertical roller mill over the powder, the vertical roller mill's loading rate, leading to the vertical roller mill on the thin material, and even disc direct contact with the roller,resulting in mechanical milling; when into the vertical roller mill multimaterial mixture materials for the The ground particles exhibited massive size reduction where the volume moment diameter of 556 μm was reached within 600 s Aggregation of fine particles was very pronounced when it was ground for 600 s due to high surface energy Aggregation of fine particles caused the ground particles to exhibit polymodal particle size distributionMicronization of zeolite in vibration mill AcademiaIntorduction of Ultra Fine Vertical Roller Mill Brand: Clirik Model: CLUM Application: Micro powder vertical roller mil l are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under 7(the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon Ultra Fine Vertical Roller MillUltra Fine Vertical Roller Mill 2010年11月15日 The aim of this work was to examine the performance of a vertical subsurface constructed wetland system in treating olive mill wastewater (OMW) The experimental pilot scale wetlands consisted of PVC reactors, some filling materials such as gravel, sand, and zeolite and the natural wetland vegetation including Typha latifolia and Cyperus alternatifolius Performance evaluation on the treatment of olive mill waste water

.jpg)

Kinetics of fine wet grinding of zeolite in a steel ball mill in

The variation of specific rates of breakage (Si) of zeolite with mill diameter (D) is shown in Fig 8, ie as the mill diameter increases, the Si values for dry and wet grinding of zeolite also increase The effect of rotational speed of the mill on the Si values of zeolite is shown in Fig 9Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill; Fine Grinding Mill (Centrifugal Roller Mill) Kurimoto Roller Mill; Batch Type Highspeed Planetary Mill Kurimoto High G; Horizontal Grinding Mill Overflow Type, Gratedischarge Type, and Compartment Type Ball Mill; Horizontal Coarse Grinding Mill Rod MillVertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill HLM series vertical mill is a largescale, highyield, HLM ultra fine vertical mill; Specifications Capacity(t/h) Pulverized coal fineness The raw coal moisture Pulverized coal moisture Main motor power(kW) HLM1200M 6—10 R008=515% ≤15% ≤15% 110132 Energysaving and Efficient Vertical Roller Mill Fote MachineryCLUM ultrafine vertical mill is a new type of ultrafine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging Capacity: 0245 t/h Max feeding size: 30mm CLUM Ultrafine Vertical Mill

Vertical Mill Shanghai Zenith Company

The LM Vertical Grinding Mill, launched by ZENITH, integrates five functions of crushing, grinding, powder selection, drying and material conveying It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protectionDOI: 101016/JMINPRO200810006 Corpus ID: ; Kinetics of fine wet grinding of zeolite in a steel ball mill in comparison to dry grinding @article{Ozkan2009KineticsOF, title={Kinetics of fine wet grinding of zeolite in a steel ball mill in comparison to dry grinding}, author={A Ozkan and Meftuni Yekeler and M Calkaya}, journal={International Journal of Kinetics of fine wet grinding of zeolite in a steel ball mill in 2022年11月30日 There are many grinding equipment required for limestone powder grinding, such as ball mill, Raymond mill, ultrafine powder mill, etc To achieve a fineness of 1000 meshes, the general grinding equipment is really not enough, and ultrafine vertical grinding is required There are two kinds of machines or ultrafine powder millsCLIRIK ultrafine grinding millindustrial grinding mill, vertical The ultrafine powder vertical roller mill produced by Vsunny are applicable to the processing of dry powder The content of 2μm fine powder is 10%60% (tested by Malvern 2000 particle size laser analyzer), VSLM series grinding mill adopts imported high chromium rare earth alloy steel which has good quality and is wear resistantUltrafine Powder Vertical Roller Mill Powder Grinding Mill

.jpg)

Kinetics of Fine Wet Grinding of Zeolite in A Steel Ball Mill in

2009年2月1日 Batch wet grinding of zeolite was studied with emphasis on a kinetic study in a laboratory size steel ball mill of 200 mm diameter The breakage parameters were determined by using the single 2023年2月21日 2 Roller mills: Roller mills use a series of rotating rollers to crush and grind zeolite crystals into a fine powder The size and spacing of the rollers can be adjusted to control the particle size of the powder Roller mills are typically used for largescale production and can produce a relatively narrow particle size distributionHow To Make Zeolite Powder?Highquality ultra fine powder vertical roller mill manufacturer Tongli Ultrafine Powder Vertical Mill is particularly suitable for ultrafine grinding of nonmetallic minerals, including ultrafine calcium carbonate powder (fineness can reach 25 microns), limestone, barite, calcite, kaolin, gypsum, bauxite and graphite Its production capacity can reach 1030 tons per hour to meet the Ultra fine Vertical Roller Mill CEMENTLVertical stirred mills are a fine grinding equipment that covers advantages of low rotation speed, high reliability and long life cycle The significant advantages that the vertical stirred mills have over the ball mills are smaller size, less auxiliary equipment required, more simple system and more options of processing methodsVertical Stirred Mill Mineral Processing Equipment CITIC HIC

CLUM Series Ultrafine Vertical Roller Mill

Generally produce 45um thick body; ultrafine ball mill can produce 10um powder; ceramic ball mill has high whiteness and the lowest iron content Good grain, spherical It is suitable for a wide range of materials, a wide range of particle size of the finished product, a wide selection of grinding media, high energy consumption and high noiseInformation on UBE Machinery's UBE Vertical Mill HOME PRODUCTS UBE Vertical Mill UBE biomass, ceramics, and fiber materials, various fields needs pulverization technology for reducing these materials into fine particles UBE UBE Vertical Mill UBE Machinery Corporation, Ltd2023年3月21日 Application of ultrafine vertical mill in the processing and production of ultrafine heavy calcium Considering the diversified needs of heavy calcium powder products, the “CLUM ultrafine vertical mill + secondary (or tertiary)” classification process is often used in the design of vertical grinding powder engineering systems There are two reasons:The advantages of ultrafine vertical mill in the processing and Independent research and development of Ultrafine vertical roller mill used Adopt multihead powder separator, SBM classifier perfect solved the particle cutting point height rate of screening questions, compared with the traditional Ultrafine vertical roller mill SBM Ultrafine Powder

Barite Ultrafine Vertical Roller Mill

Barite ultrafine vertical roller mill is an industrial vertical grinding mill that can grind nonmetallic ore into fine powder The mill has a high production capacity, high fine powder content, high degree of automation, convenient maintenance, long service life, environmental protection, and energysaving, and is an ideal equipment for largescale production of ultrafine powder2022年8月10日 3 3253000 mesh, choose ultrafine vertical roller mill Ultrafine vertical mill is also a common equipment for kaolin grinding, it is mainly suitable for ultrafine powder processing of nonflammable and explosive brittle materials with What equipment is used for kaolin grinding?What equipment is The coal vertical mill, also referred to as the vertical roller coal mill, is an advanced equipment developed by our company It combines modern technology with our extensive experience in powder manufacturing This coal pulverizer efficiently integrates coal grinding and drying, providing highperformance and energysaving featuresHighEfficiency Vertical Coal Mill Enhancing Coal PulverizationMounted High Shear Mixers Reliability The Greerco Homogenizer series offers a full range of tank mounted, high shear mixers from laboratory to production scale The design exceeds the high quality standards necessary to achieve optimal process results and withstand the rigors of difficult processes that require high shear mixingGreerco™ High Shear Mixers NOV

(PDF) Performance Comparison of the Vertical and ResearchGate

2023年2月23日 Francis, B Scaleup and Operations of a Vertical Stirred Mill, Master’s Thesis, The University of British Columbia, Vancouver, BC, Canada, 2014 Minerals 2023 , 13 , 315 16 of 年1月15日 Semantic Scholar extracted view of "Kinetics of fine wet grinding in a laboratory ball mill" by M Therefore, the grinding properties of natural zeolite were studied with the emphasis Expand 13 Save A simulation study of Differences in dry and wet grinding with a high solid concentration of coking coal using a Kinetics of fine wet grinding in a laboratory ball mill2022年11月1日 Under certain defined industrial conditions, zeolite molecular sieves should have high CO 2 adsorption capacity in addition to high mechanical strength, Virtual materialization of BFZM internal channels e) Horizontal/vertical section of monolithic zeolite S 1 represents the total area of horizontal section, Construction of high performance binderfree zeolite monolithProduction of coarse powder and general fine powder above 45um, stable operation, high cost performance and high noise Ring roller mill: 2um content is about 20% or more, the highest fineness is 810um, middle and highend CLUM Ultrafine Vertical Grinding Mill

.jpg)

Dolomite Grinding Mill SBM Ultrafine Powder

2021年7月28日 The ultrafine vertical roller mill is suitable for mass production, and the fineness of the finished powder can reach 3000 meshes It can grind solid ores into a fine powder, such as marble, talc, calcite, calcium carbonate, 2021年7月22日 Vertical wet stirring mill equipment is mainly divided into mixing mill (tower mill) and sand mill The barrel of the stirring mill is thicker and the spindle angular velocity is lower The grinding medium can be either a sphere Vertical wet stirring millVertical wet stirring mill 2013年5月15日 • 21 vertical roller mill vibration is too large: (1) Feed uneven, when the mixture into the vertical roller mill over the powder, the vertical roller mill's loading rate, leading to the vertical roller mill on the thin material, and even disc direct contact with the roller,resulting in mechanical milling; when into the vertical roller mill multimaterial mixture materials for the Vertical raw mill pradeep kumar PPT Free Download SlideShareThe ground particles exhibited massive size reduction where the volume moment diameter of 556 μm was reached within 600 s Aggregation of fine particles was very pronounced when it was ground for 600 s due to high surface energy Aggregation of fine particles caused the ground particles to exhibit polymodal particle size distributionMicronization of zeolite in vibration mill Academia

.jpg)

Ultra Fine Vertical Roller MillUltra Fine Vertical Roller Mill

Intorduction of Ultra Fine Vertical Roller Mill Brand: Clirik Model: CLUM Application: Micro powder vertical roller mil l are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under 7(the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon 2010年11月15日 The aim of this work was to examine the performance of a vertical subsurface constructed wetland system in treating olive mill wastewater (OMW) The experimental pilot scale wetlands consisted of PVC reactors, some filling materials such as gravel, sand, and zeolite and the natural wetland vegetation including Typha latifolia and Cyperus alternatifolius Performance evaluation on the treatment of olive mill waste water The variation of specific rates of breakage (Si) of zeolite with mill diameter (D) is shown in Fig 8, ie as the mill diameter increases, the Si values for dry and wet grinding of zeolite also increase The effect of rotational speed of the mill on the Si values of zeolite is shown in Fig 9Kinetics of fine wet grinding of zeolite in a steel ball mill in Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill; Fine Grinding Mill (Centrifugal Roller Mill) Kurimoto Roller Mill; Batch Type Highspeed Planetary Mill Kurimoto High G; Horizontal Grinding Mill Overflow Type, Gratedischarge Type, and Compartment Type Ball Mill; Horizontal Coarse Grinding Mill Rod MillVertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill

.jpg)

Energysaving and Efficient Vertical Roller Mill Fote Machinery

HLM series vertical mill is a largescale, highyield, HLM ultra fine vertical mill; Specifications Capacity(t/h) Pulverized coal fineness The raw coal moisture Pulverized coal moisture Main motor power(kW) HLM1200M 6—10 R008=515% ≤15% ≤15% 110132