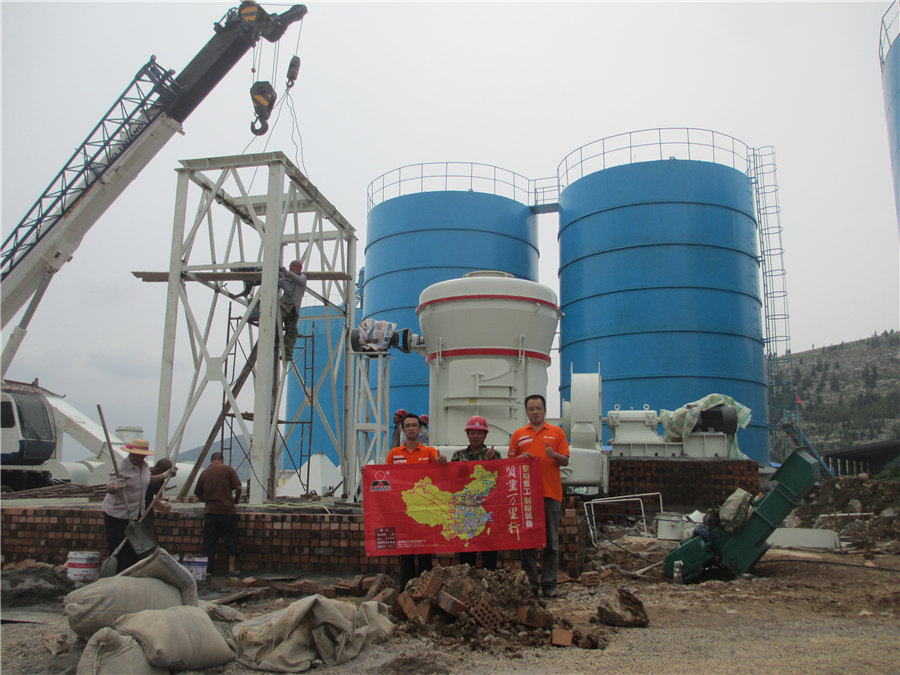

Ounuo coal gangue ore mill

.jpg)

Opportunities, challenges and modification methods of coal

2024年9月7日 The direct application of raw coal gangue faces challenges of low active beneficial ingredients, inadequate water and fertilizer retention, presence of potentially toxic elements, resulting in limited efficacy and environmental contamination2024年2月1日 Based on the source and distribution of coal gangue (CG) in China, this study introduces the current situation of CG storage in China and the problems existing in the Representative coal gangue in China: Physical and chemical 2024年6月4日 Coal gangue is a kind of blackgray rock with lower carbon content and harder than coal in the process of coal formation It is produced in the process of coal bed deposition Characteristics of Coal Gangue and Present Situation and Prospect 2024年1月18日 Coal gangue refers to the waste or byproduct produced when coal is extracted from coal mines These wastes usually include coal gangue (without valuable crushed coal and gangue), rocks, soil, and other minerals Coal Gangue: Composition, Processing, Use And

Synergistic Utilization of Basic Oxygen Furnace Slag and Coal

2024年10月25日 The comprehensive utilization of basic oxygen furnace (BOF) slag and coal gangue has always been a significant research interest in alleviating environmental pollution 2024年7月12日 Coal gangue (CG), which accounts for about 10–20 % of coal output, is a kind of solid waste generated during the coal mining and washing processes According to Fig 2, the Review Highcapacity utilization of coal gangue as supplementary 2023年8月31日 Coal gangue is a waste byproduct generated during coal mining and processing It is harder than coal, has a lower carbon content, and its main components are SiO 2 and Al 2 O 3 Coal gangue has become a significant How to Recycle and Process Coal Gangue: 7 Effective 2012年7月2日 This paper provides an overview on the current status of power generation in China using coal gangue The government regulation towards the use of coal gangue for (PDF) Power Generation from Coal Gangue in China

How To Effectively Use Coal Gangue?

2021年10月13日 Coal Gangue Pulverizer Raymond Mill Finished product fineness: 80325 mesh Production capacity: 15100t/h It is suitable for the processing of more than 300 kinds of highfine powder materials in nonflammable and explosive mineral, chemical, construction and other industries with Mohs hardness not greater than 7 and humidity below 6%21 Experimental materials The chemical composition of the coal gangue and iron ore tailings used in the test is shown in Table 1 The coal gangue was crushed to 2 mm and then ground by a ball mill, after that the fineness of the Effects of Heat Treatment System on Mechanical coal gangue and iron ore tailings 1400X muffle furnace (the calcination temperature was 800 The chemical composition of the coal gangue and iron ore tailings used in the test is shown in Table 1 The coal gangue was crushed to 2 mm and then ground by a ball mill, after that the fineness of the coal gangue was 008 mm, and the residueEffects of heat treatment system on mechanical strength and 2019年12月1日 The accumulation of considerable coal gangue not only occupies a great deal of land resource, but also results in serious environmental problems, eg, soil pollution, air pollution, and geologic hazards (Stracher and Taylor, 2004)The heat continues to accumulate during the accumulation process, which leads to spontaneous combustion with the oxidization of coal Comprehensive utilization and environmental risks of coal gangue: A

.jpg)

Characterization and acid leaching of rare earth elements in coal

2024年3月6日 The conical ball mill (XMQ–Ф240 × 90 A) was used, the filling medium was steel ball, was used to characterize major minerals and the distribution of REY in the coal gangue The microstructure of raw ore and roasting products was analyzed using a mercury intrusion porosimeter (MIP, Auto Pore V 9600 20300, America)2013年9月1日 Request PDF Liberation characteristics of coal middlings comminuted by jaw crusher and ball mill The associated minerals make coal middlings possess a relatively high ash content Subsequent Liberation characteristics of coal middlings comminuted by 2016年6月2日 Before the event of ore dressing, crude ores were shipped directly to the smelters, or the refineries, with the shipper paying the freight and treatment 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Mineral Processing and Ore Mineral Processing and Ore Dressing 911Metallurgist2016年3月30日 In book: Encyclopedia of Iron, Steel, and Their Alloys (pppp 10821108) Chapter: i) Direct Reduced Iron: Production; Publisher: CRC Press, Taylor and Francis Group, New York(PDF) i) Direct Reduced Iron: Production ResearchGate

.jpg)

High Performance Mtw178 Grinding Mill Coal Ore Granite

High Performance Mtw178 Grinding Mill Coal Ore Granite Riverstone Gangue 4 Roller High Pressure Raymond Grinding Mill Prices US$2,600009,80000: 1 Set (MOQ) Product Details Customization: Available: Type: Raymond Mill: Motor Type: AC Motor: Start Order Request Contact Supplier Chat Shipping 2016年8月1日 Kaolinite as an aluminumrich clay mineral is widely distributed in kaolin, coal gangue and mill tailings, etc Herein, alumina extraction from the lowgrade kaolin was explored via multistage (PDF) Conversion of coal gangue into alumina ResearchGate2020年3月17日 ABSTRACT Glassceramics with high strength and lightweight were developed by comprehensively utilizing coal gangue and clay This work optimized the many processing parameters including the rate of using coal gangue, coal gangue to clay ratio, mineralizers, and process of forming and sintering Using coal gangue of 75% and coal gangue to clay ratio of Glassceramics fabricated by efficiently utilizing coal gangueThe gangue – ore components of no commercial value – must be removed before processing XRD finds typical gangue species, silica and alumina that originate from quartz, clay, mica, feldspar, or carbonates They may be removed in the Iron Ore Mineralogy Bruker

.jpg)

Evolution mechanism of pore structure in sintered coal gangue

2023年10月1日 Coal gangue (CG) is a solid waste produced during coal mining The annual emission of CG worldwide is about 1 billion tons, and is usually piled up in a large area and difficult to utilize [[1], [2], [3]]Valuation and reuse of coal mine waste is an alternative approach to solving the mine waste problem2016年2月1日 In this paper a new type of autoclaved aerated concrete (ACC) was developed using coal gangue (CGC) and iron ore tailings (ITOs) The material compositions, calcination temperatures of the coal Preparation and properties of autoclaved aerated concrete using coal Extraction (CRC ORE) has been involved in research and onsite development to extend established Mine to Mill practice by focusing on optimising metal extraction across the whole value chain Branded Grade EngineeringTM, this work has a particular focus on gangue rejection at coarse scales, for example blasting, screening and sortingUNDErsTaNDINg MINE TO MILL 911 Metallurgist2020年4月14日 The coal gangue sample was separated to reduce coal content based on the density by calculating volume and weight of the ores The other raw materials used for this study include PI cement (CEM I 425 N), gypsum, and limestone with their chemical component and were shown in Table 1 Identification and Activation of Coal Gangue and Performance

.jpg)

Activation Mechanism of Coal Gangue and Its Impact on the

2022年9月15日 Coal gangue is one of the industrial solid wastes that may harm the human body through the ecosystem for a long time Using coal gangue in geopolymer preparation can effectively reduce cement output and meet the sustainability requirements In this paper, the physical and chemical characteristics, including the heavy metal content, of coal gangue from 2024年4月5日 The coal gangue with a kaolinite content of more than 80% is called coal series kaolinite (CSK) (Gao et al, 2010)CSK resources in China are abundant, with a prospective reserve of more than 20 billion tons, but highquality ores are in short supply (Shen and Ma, 2016; Shen et al, 2009)Highquality CSK is usually used to prepare calcined kaolin at high Cementitious properties of coalbased metakaolin prepared from coal 4The data processing system adopts high integration AI algorithm to achieve millisecond operation rate and high processing capacity of ore dressing recognition rate Which can increase ore recognition ability and accuracy, improve ore separation accuracy and make the separator is suitable for many kinds of oresXRT Sorting Intelligent Dry Type Coal and Mineral Ore Separator2024年5月3日 Therefore, utilizing large quantities of iron ore tailings and coal gangue as primary raw materials for nonsintering ceramsite production carries substantial environmental benefits In this study, we prepared nonsintering ceramsite using solid waste coal gangue, iron ore tailings, and fly ash as primary raw materials, with quicklime, gypsum, cement, NaOH, and aluminum Preparation and alkali excitation mechanism of coal gangueiron ore

Study on the modification effect and mechanism of tailings

2023年1月30日 Based on the problems of high carbon emission and high cost of traditional mining methods and filling materials, the tailings powder modified Coal Ganguebased Cementitious Backfill Material (CGCBM) was used for paste filling mining In this study, the samples were prepared with different tailings powder content and different curing ages The 2024年2月28日 Scientific Reports Study on the macro–micro evolution of compaction characteristics of coal gangue with different grain sizes under sidelimit compression conditionsStudy on the macro–micro evolution of compaction Nature2024年3月27日 Underground backfilling stands out as a crucial technological strategy for the ecofriendly and effective management of solid waste in mining operations However, existing backfilling techniques have led to increased production processes at the working face, resulting in a reduction in coal extraction efficiency Addressing the temporal and spatial interference Gangue grouting filling in subsequent space of coal green mining 2019年12月31日 Iron ore tailings and coal gangue powder are the main sources of industrial solid wastes, the dispose of which has become severe and urgent with the increasing demand of environmental harmonyPreparation, characteristics and mechanisms of the composite

Define the following terms (i) Mineral (ii) Ore (iii) Gangue BYJU'S

All minerals are not ores, but all ores are minerals Examples: Bauxite (Al 2 O 32H 2 O) is the ore of Aluminium, and copper pyrite (CuFeS 2) is an ore of copper Gangue: Gangue is an unwanted substance or impurity that surrounds the mineral in an ore deposit, such as sand, rock, or 2022年9月30日 Coal gangue (CG) is a type of industrial solid waste produced by the process of coal excavation and separation 1,2,3Generally, one ton of CG is discarded for every 10 tons of produced coal 4,5 Preparation of coal gangue ceramsite highstrength concrete and 2022年11月25日 China’s total coal production in 2021 exceeded 413 billion tons, 52% of the world’s total Coal gangue, a solid waste of coal mining accounts for 15–20% of coal production, when directly discharged on the ground surface as waste heaps, it occupies large areas of land and cause environmental pollution This paper summarizes the existing gangue backfilling Underground Disposal of Coal Gangue Backfill in China MDPIThe coal gangue was obtained from a coal gangue power plant located in Shuozhou, Northern China (N 3951°, S 11229°) Plant ash was obtained from the leaves of polar plant (Populus L), which was burned completely in the air The mineral composition of the coal gangue and plant ash determined by XRF spectrometry (Simultix 12 XRF specA SiKBased Amendment Prepared by Coal Gangue and Plant

Properties and Hydration Mechanism of Autoclaved Aerated

A new type of autoclaved aerated concrete (ACC) was prepared using coal waste as the main raw materials The calcination temperatures of coal cangue (CG), effect of calcined coal gangue (CCG) content on properties of AAC, and the variation of hydration products and microstructure of ACC under curing conditions were analyzed using Xray diffraction (XRD), and scanning Download Citation On May 1, 2024, Mingyang Zhong and others published Preparation and alkali excitation mechanism of coal gangueiron ore tailings nonsintering ceramsite Find, read and cite Preparation and alkali excitation mechanism of coal gangueiron ore 2021年10月13日 Coal Gangue Pulverizer Raymond Mill Finished product fineness: 80325 mesh Production capacity: 15100t/h It is suitable for the processing of more than 300 kinds of highfine powder materials in nonflammable and explosive mineral, chemical, construction and other industries with Mohs hardness not greater than 7 and humidity below 6%How To Effectively Use Coal Gangue?21 Experimental materials The chemical composition of the coal gangue and iron ore tailings used in the test is shown in Table 1 The coal gangue was crushed to 2 mm and then ground by a ball mill, after that the fineness of the Effects of Heat Treatment System on Mechanical

Effects of heat treatment system on mechanical strength and

coal gangue and iron ore tailings 1400X muffle furnace (the calcination temperature was 800 The chemical composition of the coal gangue and iron ore tailings used in the test is shown in Table 1 The coal gangue was crushed to 2 mm and then ground by a ball mill, after that the fineness of the coal gangue was 008 mm, and the residue2019年12月1日 The accumulation of considerable coal gangue not only occupies a great deal of land resource, but also results in serious environmental problems, eg, soil pollution, air pollution, and geologic hazards (Stracher and Taylor, 2004)The heat continues to accumulate during the accumulation process, which leads to spontaneous combustion with the oxidization of coal Comprehensive utilization and environmental risks of coal gangue: A 2024年3月6日 The conical ball mill (XMQ–Ф240 × 90 A) was used, the filling medium was steel ball, was used to characterize major minerals and the distribution of REY in the coal gangue The microstructure of raw ore and roasting products was analyzed using a mercury intrusion porosimeter (MIP, Auto Pore V 9600 20300, America)Characterization and acid leaching of rare earth elements in coal 2013年9月1日 Request PDF Liberation characteristics of coal middlings comminuted by jaw crusher and ball mill The associated minerals make coal middlings possess a relatively high ash content Subsequent Liberation characteristics of coal middlings comminuted by

Mineral Processing and Ore Dressing 911Metallurgist

2016年6月2日 Before the event of ore dressing, crude ores were shipped directly to the smelters, or the refineries, with the shipper paying the freight and treatment 911 Metallurgist is a trusted resource for practical insights, solutions, and support in mineral processing engineering, helping industry professionals succeed with proven expertise Mineral Processing and Ore 2016年3月30日 In book: Encyclopedia of Iron, Steel, and Their Alloys (pppp 10821108) Chapter: i) Direct Reduced Iron: Production; Publisher: CRC Press, Taylor and Francis Group, New York(PDF) i) Direct Reduced Iron: Production ResearchGateHigh Performance Mtw178 Grinding Mill Coal Ore Granite Riverstone Gangue 4 Roller High Pressure Raymond Grinding Mill Prices US$2,600009,80000: 1 Set (MOQ) Product Details Customization: Available: Type: Raymond Mill: Motor Type: AC Motor: Start Order Request Contact Supplier Chat Shipping High Performance Mtw178 Grinding Mill Coal Ore Granite 2016年8月1日 Kaolinite as an aluminumrich clay mineral is widely distributed in kaolin, coal gangue and mill tailings, etc Herein, alumina extraction from the lowgrade kaolin was explored via multistage (PDF) Conversion of coal gangue into alumina ResearchGate