The process of making corundum powder with an output of 90 cubic meters per hour

Corundum powder preparation by SHSmethod Springer

2013年7月18日 Phase composition, crystal size development in powder, and microstructure are studied, and data are summarized for specific surface and particle size distribution of 2022年6月15日 Tabular corundum aggregate was prepared using four types of commercial alumina raw powder starting materials, with different characteristics, via the same process A Preparation of tabular corundum aggregate from different sources 2018年9月1日 Powders with a crystal size in the range 20–500 μm can be obtained directly from hydrargillite prepared in the course of the Bayer Process The size and habit of the crystals are (PDF) Preparation of FineGrained Corundum Powders with Given 2018年11月8日 The processes of obtaining finegrained corundum with a given crystal size and habit are considered It is shown that thermocouple treatment in aqueous supercritical fluid Preparation of FineGrained Corundum Powders with Given

Corundum powder preparation by SHSmethod ResearchGate

2013年5月1日 Phase composition, crystal size development in powder, and microstructure are studied, and data are summarized for specific surface and particle size distribution of 2022年1月12日 It is shown that in principle corundum ceramics with close to theoretical density and a defectfree polished surface with low roughness can be obtained by means of SPS On the Matter of Obtaining HighDensity Corundum Ceramics The influence of the transition phases of alumina raw powder on the sintering kinetics of tabular corundum is discussed, the sintering model of materials with pseudomorphic structure is Preparation of tabular corundum aggregate from different sources 1999年11月1日 The new synthesis of nanocorundum can be used to give pure corundum filtration membranes with average pore sizes that can be adjusted in the range between about Nanocorundum—advanced synthesis and processing ScienceDirect

Powder agglomeration processes of bulk materials – A state of the

2024年1月1日 Powder agglomeration is a simple process that reduces the particle size of powdery substances, making them more manageable and storing them less of a hassle 2019年10月25日 We report a simple synthesis of nanometersized αAl 2 O 3 (particle diameter ~13 nm, surface areas ~140 m 2 g −1) by the mechanochemical dehydration of boehmite (γ Highsurfacearea corundum by mechanochemically induced 2023年6月29日 At present, the powder materials used for metal printing have the problems of high cost, limited varieties, and low degree of industrialization Given the technical characteristics of the powder metallurgy process, a set of Powder‐Based Additive Manufacturing: A Critical 2018年1月26日 The absorption coefficient is, of course, dependent on the concentration of the chromophore If we want to compare two different chromophores but the samples have different chromophore concentrations, we can divide the absorption coefficient of each chromophore by its concentration in absorbers/cm 3 (note that 1 ppma in corundum is a concentration of 1178 × A Quantitative Description of the Causes of Color in Corundum

.jpg)

MANUFACTURING PROCESS OF AAC BLOCK ResearchGate

2017年9月17日 AAC blocks are light weight Aerated Autoclave Concrete Block It is manufactured through a reaction of aluminium powder and a proportionate blend of lime, cement, and fly ash or sand2014年1月1日 It is considered as one of the famous Precambrian metamorphic complexes in the Nubian Shield representing metamorphic, structural, and economic interests (Ahmed and Gharib, 2018;El Ramy et al, 1993)Evidence for the use of corundum abrasive in Egypt from the 2006年1月1日 Many different shape factors are being used in 2 Journal of Chemistry previous studies to describe the particles, such as Corey shape factor (cfs) [13], aspect ratio (AR) [9], circularity [9], new Particle shape characterization of brown corundum2016年7月11日 The following commercially available powders were used as the starting materials: copper powder (Fig 1a, by Sigma Aldrich, 999% purity) and two kinds of alumina powders: electrocorundum powder (ED Al 2 O 3) (Fig 1b, KOS, 99% purity) and αform of aluminum oxide powder (αAl 2 O 3) (Fig 1c, NewMet, 9999% purity) These two forms were The Influence of Al2O3 Powder Morphology on the Properties of

.jpg)

CORUNDUM AND CRYOLITE CRYSTALLISATION BY THE FLUX

The first descriptions of the flux growth technique were made by J J Ebelman in 1849 [1] He developed a method based on dissolving in different substances at high temperatures oxides and Corundum is a form of aluminum oxide (Al₂O₃) typically containing traces of iron, titanium, vanadium, and chromium Corundum powder is a granular, white, odorless powder that is chemically inert Corundum is a hard mineral with a high density and is the index mineral for a hardness of nine on the Mohs Hardness ScaleCorundum (Al₂O₃) Reade2022年1月15日 In the last paper, Novitskaya et al [24] studied HallPetch correlation between mechanical properties and microstructure for a single, binary (5050 vol%), and ternary (333333 vol%) phase composites of yttriastabilised zirconia (8Y–ZrO 2), spinel (MgAl 2 O 4), and alumina (Al 2 O 3) samples produced by spark plasma sinteringAmong all studied composites, a Study of the alumina sintering process with a low zirconia contentIn 1885, larger synthetic rubies made their appearance using a flame fusion process and alumina powder Later the seed is pulled from the melt at a rate of 00394394 in (1100 mm) per hour Crystals grown using this method can be How cubic zirconia is made material, making, used,

.jpg)

Extraction of Gallium from Brown Corundum Dust by

2023年7月1日 Brown corundum dust is a solid waste produced during the preparation of brown corundum with bauxite as the raw material The dust has a relatively high gallium content; therefore, it is of great 2022年10月10日 Hydrogenous environments put forward new requirements to refractories for the hydrogen metallurgy field The temperature and impurities in refractories played an important role in stability(PDF) Investigation on Application Prospect of 2018年7月13日 Students were carborundum powder beginners! Share: Previous Making plates from wetanddry carborundum paper Next Carborundum paint printing plates Related Posts Embossed Aluminium Printing Plates January 27, 2019 PVC foamboard printing plates July 24, 2020 Artists making carborundum printsMaking printing plates with carborundum powder2010年9月1日 The corundum structures of In2O3:Sn (ITO) nanoparticles were synthesized by hydrothermal processing of InCl3 and SnCl45H2O precursor at low temperature of 250 °C and 40bar pressure for 3 hSynthesis of corundum structure ITO nanocrystals by

.jpg)

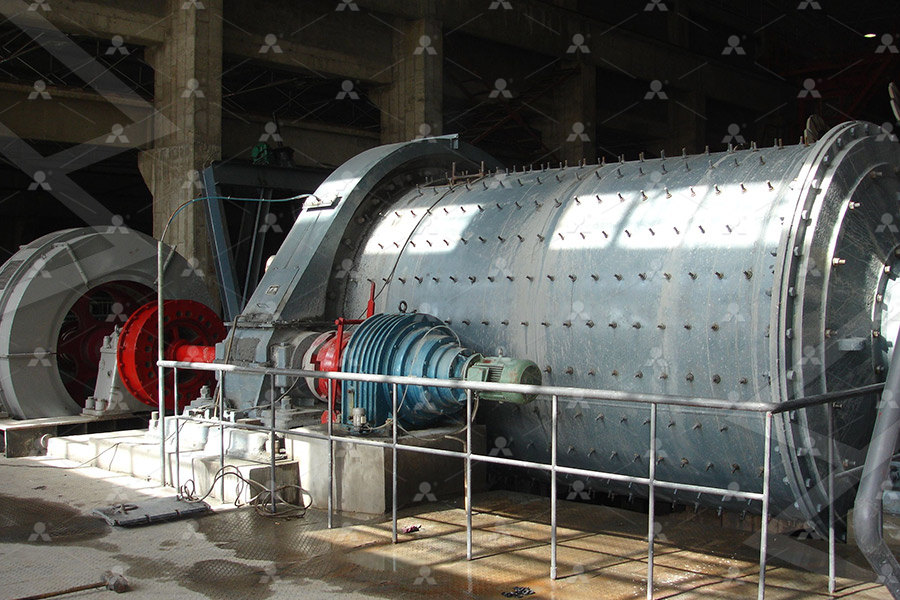

The evolution of microstructure and properties of CuCr alloys

2022年12月1日 In addition, the formation of homogeneous crystalline alloy structures during the MA process is expected to shorten the sintering process of CuCr alloys to be produced by powder metallurgy [25] MA, which is frequently used in the preparation of starting alloy powders for the manufacture of final products by powder metallurgy, is known as a very inexpensive The ball milling (BM) of blended Ni and Cr elemental powders was carried out in a Simoloyer performing on high energy scale mode at maximum production to obtain a nanostructured Ni 20Cr alloyXRD patterns of Al2O3 powder before and after milling for 20h2021年12月16日 For several decades, the metallurgical industry and the research community worldwide have been challenged to develop energyefficient and lowcost titanium production processes The expensive and energyconsuming Kroll process produces titanium metal commercially, which is highly matured and optimized Titanium’s strong affinity for oxygen Titanium: An Overview of Resources and Production Methods2021年10月15日 This project designed a plant that will process 250 tonnes of raw tomatoes per day The duration of this production was spread across 24 hours and operated for 300 days in a year, which gave a The Design of a Tomato Powder Processing Plant with a Capacity

Influence of nanoAl 2 O 3 Powder on the Properties of

2014年1月1日 With Al2O3 micropowder as main raw material, a kind of microporous corundum aggregate was prepared by adding nanoAl2O3 powder Effect of nanoAl2O3 powder on the properties of microporous corundum Influence of the abradant’s composition on the selected physical properties in the process of front grinding of surfaces with microcrystalline sintered corundum grinding wheels October 2013(PDF) Influence of the abradant’s composition on the selected After this process, alumina (aluminum oxide) emerges as a fine white powder It looks much like sugar used in baking, but is hard enough to scratch a pane of glass History of the Bayer process The Bayer process was invented in 1887 by Carl Josef BayerAlumina Refining 101 The Aluminum AssociationEffect of aluminum powder on the synthesis of corundummullite composites Ceramics – Silikáty 57 (2) 133137 (2013) 135 4 %, the bulk density of samples decreased and apparent porosity increased with increasing sintering temperature However when the content of EFFECT OF ALUMINUM POWDER ON THE SYNTHESIS OF CORUNDUM

.jpg)

Influence of nanoAl2O3 Powder on the Properties of Microporous Corundum

Abstract: With Al 2 O 3 micropowder as main raw material, a kind of microporous corundum aggregate was prepared by adding nanoAl 2 O 3 powder Effect of nanoAl 2 O 3 powder on the properties of microporous corundum aggregates and its sintering mechanism were studied The results show that, the closed porosity of sinter is too low when adding too less nanoAl 2 O 3 The honey process has its origins in a process known as pulped natural The pulped natural process originated in Brazil in the 1970s as a way to conserve water and speed up the drying process, increasing production and profits The honey process comes in five varieties, which are defined by colourCoffee Production 101: How Is Coffee Produced Processed?2022年11月23日 powder, mainly composed of corundum grains (RC), had on the mechanical, physical, and chemical properties of metakaolinbased geopolymers The waste was introduced into the geopolymer matrix(PDF) Chemical and Mechanical Properties of MetakaolinBased The flame fusion process of creating synthetic gemstones was perfected in 1902 by a Frenchman named Auguste Verneuil Also known as the Verneuil Process, this type of synthesis uses an aluminum oxide powder doped with trace elements to create synthetic corundum of various typesFlame Fusion Gemstone Synthesis from YourGemologist

.jpg)

A review of current techniques for the evaluation of powder

2018年7月1日 The scale of scrutiny according to the product specification is mainly used to determine the ideal size of samples The taken samples having the required size of scale of scrutiny must be analysed for the composition evaluation [12]Generally, sample size should be close to the size of the final product, eg tablet size in pharmaceutical industry2014年10月9日 Nonporous corundum powder, known as an abrasive material in the industry, was functionalized covalently with protein binders to isolate and enrich specific proteins from complex matricesState of the art in production, properties and applications of the From this curve, different powder rheology characteristics can be calculated The graph obtained, called wall yield locus is shown below (example not an actual powder) The following powder properties can be determined from the graph obtained (called "Yield Locus") Table 2 : Flow Properties of Powders : An overview (Powder Physical and 2023年6月29日 At present, the powder materials used for metal printing have the problems of high cost, limited varieties, and low degree of industrialization Given the technical characteristics of the powder metallurgy process, a set of Powder‐Based Additive Manufacturing: A Critical

A Quantitative Description of the Causes of Color in Corundum

2018年1月26日 The absorption coefficient is, of course, dependent on the concentration of the chromophore If we want to compare two different chromophores but the samples have different chromophore concentrations, we can divide the absorption coefficient of each chromophore by its concentration in absorbers/cm 3 (note that 1 ppma in corundum is a concentration of 1178 × 2017年9月17日 AAC blocks are light weight Aerated Autoclave Concrete Block It is manufactured through a reaction of aluminium powder and a proportionate blend of lime, cement, and fly ash or sandMANUFACTURING PROCESS OF AAC BLOCK ResearchGate2014年1月1日 It is considered as one of the famous Precambrian metamorphic complexes in the Nubian Shield representing metamorphic, structural, and economic interests (Ahmed and Gharib, 2018;El Ramy et al, 1993)Evidence for the use of corundum abrasive in Egypt from the 2006年1月1日 Many different shape factors are being used in 2 Journal of Chemistry previous studies to describe the particles, such as Corey shape factor (cfs) [13], aspect ratio (AR) [9], circularity [9], new Particle shape characterization of brown corundum

The Influence of Al2O3 Powder Morphology on the Properties of

2016年7月11日 The following commercially available powders were used as the starting materials: copper powder (Fig 1a, by Sigma Aldrich, 999% purity) and two kinds of alumina powders: electrocorundum powder (ED Al 2 O 3) (Fig 1b, KOS, 99% purity) and αform of aluminum oxide powder (αAl 2 O 3) (Fig 1c, NewMet, 9999% purity) These two forms were The first descriptions of the flux growth technique were made by J J Ebelman in 1849 [1] He developed a method based on dissolving in different substances at high temperatures oxides and CORUNDUM AND CRYOLITE CRYSTALLISATION BY THE FLUX Corundum is a form of aluminum oxide (Al₂O₃) typically containing traces of iron, titanium, vanadium, and chromium Corundum powder is a granular, white, odorless powder that is chemically inert Corundum is a hard mineral with a high density and is the index mineral for a hardness of nine on the Mohs Hardness ScaleCorundum (Al₂O₃) Reade2022年1月15日 In the last paper, Novitskaya et al [24] studied HallPetch correlation between mechanical properties and microstructure for a single, binary (5050 vol%), and ternary (333333 vol%) phase composites of yttriastabilised zirconia (8Y–ZrO 2), spinel (MgAl 2 O 4), and alumina (Al 2 O 3) samples produced by spark plasma sinteringAmong all studied composites, a Study of the alumina sintering process with a low zirconia content