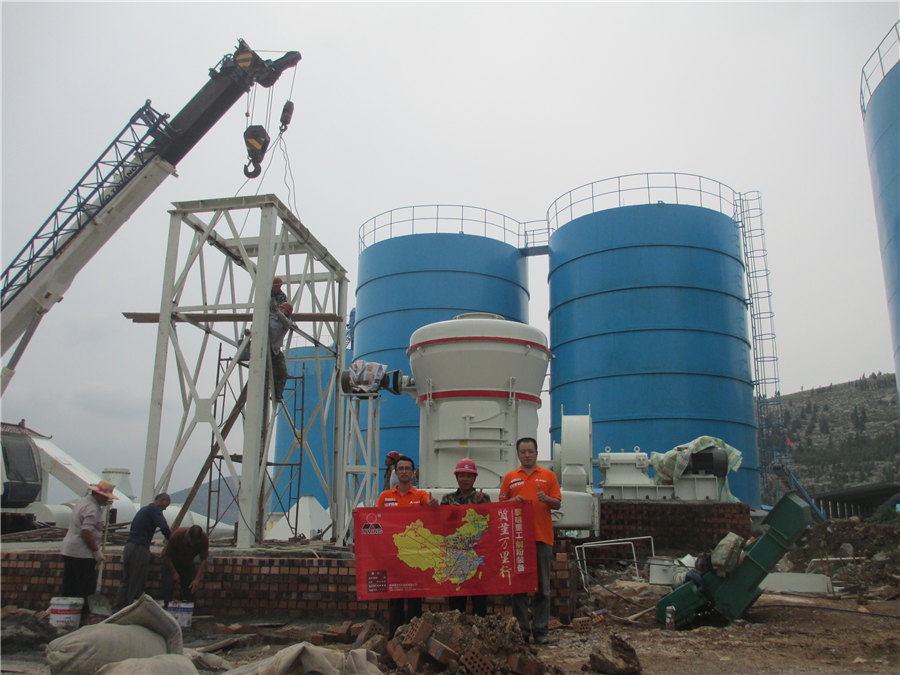

HOME→Models and specifications of calcite singlehead rock grinding mill commonly used on construction sites

Models and specifications of calcite singlehead rock grinding mill commonly used on construction sites

The effects on the grinding parameters of chemical, morphological

2022年1月1日 Recently, the kinetic model commonly uses the specific rate of breakage (Si) and the cumulative breakage distribution (Bi,j) functions to explain the grinding behavior of the material with respect to time in a laboratory batch mill Until now, important researches have been 2021年9月1日 Model quartz emitted the highest acoustic response, followed by iron ore and model calcite at the initial stages of grinding (5 min) The results further indicated that as the AG/SAG mill acoustic emissions characterisation under different 2022年1月1日 Recently, the kinetic model commonly uses the specific rate of breakage (Si) and the cumulative breakage distribution (Bi,j) functions to explain the grinding behavior of the The effects on the grinding parameters of chemical, morphological 2012年6月1日 Basic kinetic and energy models of the grinding process are described and the most commonly used control strategies are analyzed and discussed +1 Figures uploaded by Vladimir MonovGrinding in Ball Mills: Modeling and Process Control

SBM Ore Ultrafine Grinding Mill

PLC control system and multihead powder selection has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM ultrafine grinding mill, the finest can The The CLRM Enhanced Roller Mill adjusts for calcite powder from 80 to 500 mesh, ideal for materials under Mohs 6 It is energy efficient swing frequency and optimized cavity, offers efficiency and energy savings, making it an ideal upgrade from traditional models 3 Vertical Impact Crusher Type of Grinding Mill for Calcite 1Calcite Hardness Grinding Mill,Raymond Mill,Ball Mill,Ultrafine Mill2017年2月20日 Grinding Mill Specifications Data According to formula 423/√d, where d is equal to internal shell diameter within new liners In this case the thickness used was 60 mm for small mill sizes up to and including 2940 and 80 mm for larger millsGrinding Mill Design Ball Mill Manufacturer 911Metallurgist2022年5月5日 The YGM Raymond grinding mill can be used to produce calcium carbonate powder between 50500 mesh This equipment is an improvement on the traditional Raymond grinding mill, which is more efficient, more environmentally friendly, and has a low investment 1503000 mesh calcium carbonate powder can use SBM calcium carbonate ultrafine grinding Calcium Carbonate Grinding Mill Powder Modify SBM

.jpg)

(PDF) Comparison of Particle Shape, Surface Area, and

2023年1月8日 Since the particle size, shape, specific surface area, and purity of the ground calcium carbonate (GCC) decide its usability in the paper, paint, and plastic industries, the effect of grinding is 2021年6月17日 Due to its strong lifting capacity and excellent grinding performance, the trapezoidal liner is widely used in the SAG mill The structure of the trapezoidal liner is shown in Fig 1, the main dimensions are: dip angle \(\tau\), length of the top edge \(L\) and height \(h\)Dip angle \(\tau\) determines the trajectory of the mediums in the SAG mill, which directly affects PARAMETER OPTIMIZATION OF LARGE SAG MILL LINER BASED 2013年4月1日 However, a lot of academic applications have been developed using Matlab/Simulink R le Roux et al (2013) proposed and validated a novel and simple nonlinear model, Sbárbaro (2010), Liu and Analysis and validation of a runofmine ore grinding mill circuit 2016年6月1日 The Steel Head Rod Mill (sometimes call a bar mill) gives the ore dressing engineer a very wide choice in grinding designHe can easily secure a standard Steel Head Rod Mill suited to his particular problem The successful operation of any grinding unit is largely dependent on the method of removing the ground pulpRod Mills: Efficient Grinding Solutions for Mining

SAG Mill Grinding Circuit Design 911Metallurgist

2016年6月6日 AG mills (or SAG mills with low ball charges) are often used in singlestage grinding applications However the design stress levels at the trunnion/head transition in the case of the large mill are almost 250% of those 2020年10月9日 Simulation results under the ∅5250 × 500 mm mill model show that the mill operates with the optimal effect when the mill is under the condition of 80% critical speed and 15% fill level; the Operation Analysis of a SAG Mill under Different CLIRIK is China processional industrial grinding mill manufacturer, has established a whole production chain, the products cover micro powder grinding mill, high pressure grinding mill, vertical roller mill, Europe an version coarsegrinding mill, hammer crusher, jaw crusher, screw conveyor, bucket elevator and soonClirik calcite powder makingA rock powder grinding mill is a type of machine used to grind various types of rocks or minerals into powdered form It is commonly used in the mining and construction industries for grinding materials such as limestone, quartz, Model: HGM80, HGM90, HGM100, HGM125, HGM168L Capacity: 0545t/hRock Powder Grinding Mill

The Evolution of Grinding Mill Power Models Request PDF

2019年1月30日 Request PDF The Evolution of Grinding Mill Power Models Mill power models have been used in a variety of ways in industrial practice since power directly equates to throughput and fineness of 2015年4月9日 Very fine grinding mills The following are the mills used for very fine grinding Hammer mills Hammer mills are high speed mills operating at speeds of between 2000 rpm and 6000 rpm A set of ‘hammers’ rotate about a central axis in a vertical or horizontal plane The hammers are either be fixed or are swinging freelyGrinding Mills and Their Types IspatGuru2018年7月19日 The detailed design procedure for a hammer mill machine is presented The system designed is a modification to the conventional hammer mill with a circular bottom casing and a semicircular screen(PDF) Design, construction and performance evaluation of a DOVE Rod Mills are supplied in a wide range of capacities and specifications DOVE supplies 2 models of small Rod Mills designed for laboratories milling process, capacity range of (5000g/Hr – 20 Kg/Hr) For small to large scale grinding operations, DOVE Rod Mills are supplied in 15 models, capacity range of (15 TPH – 580 TPH)Rod Mills Grinding Mills DOVE

.jpg)

The Effect of Stirred Mill Orientation on Calcite Grinding

% 98824 0489 0388 0100 0065 0052 0022 0025 0020 0015 Grinding tests were carried out in a dry stirred ball mill both vertical and horizontal orientations with varyingPhase one: raw material crushing Calcite blocks will be crushed to 15mm50mm by crusher Phase two: grinding Crushed calcite material will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding Phase three: classifying Ground material will be classified, coarse powder will fall back to the main mill to be ground Calcite Grinding Mill Calcite Powder Processing Solutioncan be increased The major proportion of mill power is used to turn over the mill charge It follows that repeated ballrock shortrange lowenergy impacts within the tumbling charge are a significant proportion of the overall rockbreakage process throughout the life of the liner For fixedspeed mills, a common practice is to design shellSemiautogenous grinding (SAG) mill liner design and development2015年1月1日 Single superphosphate, a mixture of monocalcium monohydrate and gypsum formed by the reaction of sulfuric acid with phosphate rock, has been used as a fertilizer since the mid1800s Phosphoric acid, derived by the treatment of phosphate rock with sulfuric acid so as to produce gypsum in a separable form, was manufactured in many locations by batch and Phosphorus and Phosphates SpringerLink

The Effect of Stirred Mill Orientation on Calcite

PDF On Jan 1, 2017, Serkan Cayirli and others published The Effect of Stirred Mill Orientation on Calcite Grinding Find, read and cite all the research you need on ResearchGatePAES206RiceMill–Specifications Free download as PDF File (pdf), Text File (txt) or read online for free This document establishes specifications and requirements for rice mills in the Philippines It classifies rice mills based on their method of operation (singlepass or multipass) and type of huller (underrunner stone disc or rubber roll)PAES 206 Rice Mill Specifications PDF Rice Mill (Grinding)Metso Premier™ horizontal grinding mills are customized and optimized grinding solutions built on advanced simulation tools and unmatched expertise A Metso Premier™ horizontal grinding mill is able to meet any projects needs, even if it means creating something novel and unseen before Learn more about the Premier™ horizontal grinding Grinding mills for mining and minerals processing Metso2021年5月5日 There are four commonly used abrasive materials for the surface of the grinding wheels are Aluminum oxide, silicon carbide, cubic boron nitride (CBN), and diamond Crossfeed: Cross feed is also an important parts of this machine used for moving up and down or left and right of Wheel head and work table and so onGrinding Machine: Definition, Parts, Working Principle, Operation

Crystal structure of Calcite 3D model by Museum of

2021年7月29日 Carbonates class Mineral name: Calcite Formula: CaCO3 Classification: Carbonates Crystal system: Trigonal Crystal class (HermannMauguin): 3m Hexagonal Scalenohedral Space group: R3c Crystal data from Wyckoff (1931) Note: The color code used in these models is CPK2010年1月31日 In recent years, stirred ball mills have been increasingly used for grinding particles to microfine sizes due to their easier operation, simpler construction, higher grinding rate and lower Effect of grinding aids on the grinding energy consumed during grinding 2017年3月4日 Ball mills are used primary for single stage f ine grinding, regrinding, and as the second s tage in two stage grinding circuits According to the need of customers, ball mill can be either wet or drySIZE REDUCTION BY GRINDING METHODS ResearchGate2013年1月1日 Stirred mills are used in fine and ultrafine grinding where the liberation occurs at very fine sizes [11][12][13][14] [15] [16][17] The stirred media mills are introduced in different process Grinding of calcite suspensions in a stirred media mill: Effect of

Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 Basic kinetic and energy models of the grinding process are described and the most commonly used control strategies are analyzed and discussed +1 Figures uploaded by Vladimir MonovPLC control system and multihead powder selection has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM ultrafine grinding mill, the finest can The SBM Ore Ultrafine Grinding MillThe CLRM Enhanced Roller Mill adjusts for calcite powder from 80 to 500 mesh, ideal for materials under Mohs 6 It is energy efficient swing frequency and optimized cavity, offers efficiency and energy savings, making it an ideal upgrade from traditional models 3 Vertical Impact Crusher Type of Grinding Mill for Calcite 1Calcite Hardness Grinding Mill,Raymond Mill,Ball Mill,Ultrafine Mill2017年2月20日 Grinding Mill Specifications Data According to formula 423/√d, where d is equal to internal shell diameter within new liners In this case the thickness used was 60 mm for small mill sizes up to and including 2940 and 80 mm for larger millsGrinding Mill Design Ball Mill Manufacturer 911Metallurgist

Calcium Carbonate Grinding Mill Powder Modify SBM

2022年5月5日 The YGM Raymond grinding mill can be used to produce calcium carbonate powder between 50500 mesh This equipment is an improvement on the traditional Raymond grinding mill, which is more efficient, more environmentally friendly, and has a low investment 1503000 mesh calcium carbonate powder can use SBM calcium carbonate ultrafine grinding 2023年1月8日 Since the particle size, shape, specific surface area, and purity of the ground calcium carbonate (GCC) decide its usability in the paper, paint, and plastic industries, the effect of grinding is (PDF) Comparison of Particle Shape, Surface Area, and2021年6月17日 Due to its strong lifting capacity and excellent grinding performance, the trapezoidal liner is widely used in the SAG mill The structure of the trapezoidal liner is shown in Fig 1, the main dimensions are: dip angle \(\tau\), length of the top edge \(L\) and height \(h\)Dip angle \(\tau\) determines the trajectory of the mediums in the SAG mill, which directly affects PARAMETER OPTIMIZATION OF LARGE SAG MILL LINER BASED 2013年4月1日 However, a lot of academic applications have been developed using Matlab/Simulink R le Roux et al (2013) proposed and validated a novel and simple nonlinear model, Sbárbaro (2010), Liu and Analysis and validation of a runofmine ore grinding mill circuit

Rod Mills: Efficient Grinding Solutions for Mining

2016年6月1日 The Steel Head Rod Mill (sometimes call a bar mill) gives the ore dressing engineer a very wide choice in grinding designHe can easily secure a standard Steel Head Rod Mill suited to his particular problem The successful operation of any grinding unit is largely dependent on the method of removing the ground pulp