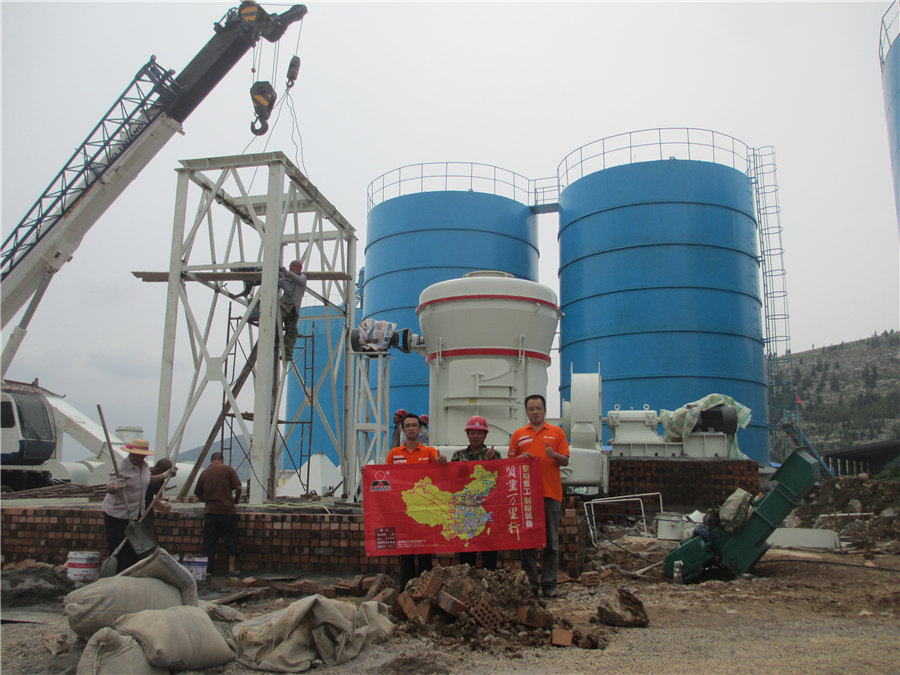

Power plant equipment coal grinder

Coal Crushers Coal Pulverizers Mills Williams Crusher

Coal is crushed to desired fineness between spheres or cylindrical rollers After that, air from the boiler is heated to around 330°C (650°F) The raw coal is then fed into the pulverizer where it is ground into fine coal particles 展开RingRoll (BowlMill) and BallRace Mills comprise most coal pulverizers currently in service at pulverized coal power plants The grinding rolls are stationary in this design, while a worm Coal Pulverizer – Power Plant Pall CorporationVertical Coal Mill is specially used for ultrafine grinding of raw coal and bituminous coal materials in cement, power plants, iron and steel plants and other fields The GRMC coal vertical mill coal grinding machine CHAENGReliable coal pulverizer performance is essential for sustained fullload operation of today's power plants An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large Reliable Coal Pulverizers and Mills » Babcock Wilcox

.jpg)

Pulveriser in Thermal Power Plant COAL HANDLING

The main Function of the Pulveriser in thermal power plant is to crush/grinding the raw coal coming from coal handling system through coal feeder into a predetermined size in order to increase the surface area of the coal If the coal is We are the standard of comparison for central stations, industrial power plants, and mine preparation plants around the world We make many types of coal crushing equipment, like Coal Crushers, Shredders, Mills for Mining Power IndustriesPulverizers (coal pulverizer) are used to pulverize pieces of coal into fine particles (100μm) before placing into a boiler, to ensure efficient combustion Pulverizers have three functions, Boilers machinery : Coal Pulverizer Mitsubishi Heavy Industries, Ltd2018年6月26日 The document summarizes ash handling systems used in thermal power plants It describes the two main types of ash bottom ash and fly ash Bottom ash is heavier and collected at the bottom of furnaces while fly ASH HANDLING PLANT PPT SlideShare

.jpg)

Ash Handling System In Thermal Power Plant

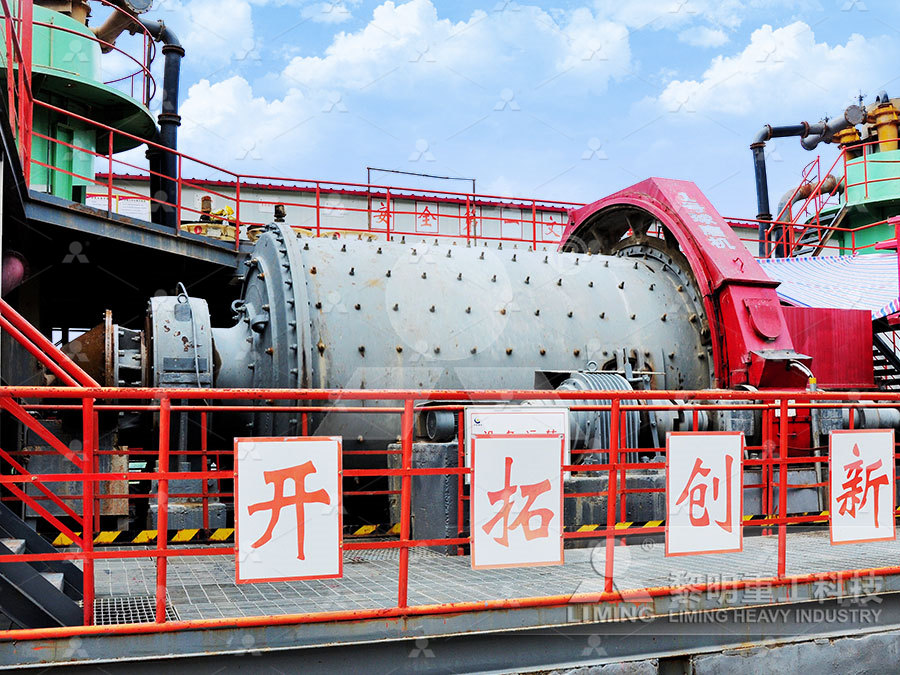

2018年9月30日 After burning of coal, 40 % of total coal consumption is converted into ash which need to be properly disposedoff from the thermal power plant Types of Ash Generated in Thermal Power Plant Bottom Ash – Ash This equipment is required to transport the coal stored onsite to the coal pulverizers Because this equipment is essential to the operation of the power plant, it is critical that this equipment must be free from contaminationrelated failure Case Study In March 2003, a major Canadian utility derated its Unit 4 due to a failure of the B millCoal Pulverizer – Power Plant Pall CorporationWe are the standard of comparison for central stations, industrial power plants, and mine preparation plants around the world We make many types of coal crushing equipment, like our ACC Series Rolling Ring Crusher with capacities ranging from 630–2,350 TPHCoal Crushers, Shredders, Mills for Mining Power IndustriesHP mediumspeed coal grinder which absorbs the structural characteristics of MPS and MBF coal grinders has the advantages of various grinders Heavy Industry Group produces a range of basic products, such as metallurgic and rolling mill machinery, grinding equipment for Vertical Coal Mill Power Generation Equipment Shanghai

.jpg)

Operation and Maintenance of Coal Handling System in Thermal Power Plant

At coal handling system in thermal power plant have interlock the equipment which can avoid equipment bad sequence startup interlock ,every equipment work according to sequence rule startup so1998年1月1日 The AR Heavy Duty Clinker Grinder is compatible with major OEM or equivalent wear parts and is a direct replacement for your existing equipment gas conversion for coalfired power plantsClinker Grinder Power Engineering2011年3月1日 As clean air requirements start to take a toll on coalfired plant operators, developers of crushing and grinding equipment are facing new challenges for adapting products to handle cleaner coal The Daily Grind Power EngineeringGeorgia Power’s problem exits at most coal plants – outdated sealing methods were causing water, fly ash, coal and other materials to leak out and contaminate clinker grinder bearingsBearing Isolator Eliminates Clinker Grinder Maintenance Power

6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

2023年10月8日 The selection of coal crushing equipment mainly depends on the input size of raw coal, the moisture of the coal, and the production scale (output) of the plant Of course, the output size and the final use of coal also need to be considered, such as 025 mm for gas furnaces, 825 mm for steam locomotives, 625 mm for industrial furnaces, and 025 mm for A coal based thermal power plant consists of large number of integrated plants/systems and equipment having mechanical, electrical, (BOP) system which includes all plants and equipment other than those included in main plant system The major components of BOP system include coal handling plant, ash handling plant, STANDARD DESIGN CRITERIA/ GUIDELINES FOR BALANCE OF PLANT 2018年11月2日 Coal from coal stock equipment is transferred to coal pulverizer (grinder) and then fed in the form of fluidized bed into a combustion chamber with the aid of hot air current At the power plants, large lumps of coal having a size range between 2 Atmospheric Emissions from Thermal (CoalFired) Power Plants Pulverizers (coal pulverizer) are used to pulverize pieces of coal into fine particles (100μm) before placing into a boiler, to ensure efficient combustion Pulverizers have three functions, pulverization, drying and classificationBoilers machinery : Coal Pulverizer Mitsubishi Heavy Industries, Ltd

Operation and Maintenance of Coal Handling System in Thermal Power Plant

At coal handling system in thermal power plant have interlock the equipment which can avoid equipment bad sequence startup interlock ,every equipment work according to sequence rule startup so 4 26 20 2032 2037Lihua ZHAO / Procedia Engineering 00 (2011) 000– 000 2035coal processing plant equipment alibaba Alibaba offers 951 coal processing plant equipment products About 1% of these are oil pressers, 1% are other farm machines, and 1% are feed processing machines A wide variety of coal processing plant equipment options are available to you, such as free samplescoal processing plants machinesThe airswept coal mill is also called a coal grinder It is the main equipment of the cement plant, used for drying and pulverizing coal powder It mainly consists of the feeding device, main bearing, Power(kW) Model: MFB2230: JR1368(380V) 180: ZD509I: 22: MFB2244: JR1368(380V) 240: ZD6011I:Air Swept Coal Mill Coal Mill In Cement Plant AGICO GROUPView the coal power plant equipment and services provided by Babcock Power The Babcock Power team provides industryleading power station solutions repair, alteration and maintenance of boilers and boilerrelated power plant equipment nationally Our services include: • Gas ConversionsCoal Power Plant Equipment Power Station Engineering

When a coalplant closes: Inside We Energies' Oak Creek Power

2023年12月28日 Here's what's involved in closing a 60yearold power plant Massive network of equipment from the 1960s shows its age Inside the power plant, there's a steady hum of coal grinders, 2011年8月1日 A typical MPS89 pulverizer found in many coalfired power plants Courtesy: Storm Technologies Inc 2 Typical expected performance for an MPS89 pulverizer is based on the coal HGI and finenessPulverizers 101: Part I POWER MagazineIt is an important auxiliary equipment for pulverized coal furnace, rotary kiln and other kilns which need pulverized coal as fuel As its output can reach 570h/t, vertical coal mill is more suitable for medium and large pulverized coal projects So we usually use coal mill in cement plant, coal mill in power plant, and coal mill in thermal Vertical Coal Mill for Coal Grinding in Cement Plant Power Plant2019年10月1日 New and pending federal regulations for coal combustion residuals (CCR) storage and handling are driving many coalfired power plants to convert to new technologies for bottom ash transportA New Technology for Bottom Ash Conversion

.jpg)

Inside We Energies’ move away from coal PressReader

2023年12月28日 Inside the power plant, there’s a steady hum of coal grinders, boilers, turbines and other massive equipment, all of which shows its age Other than a modern control room, the plant has a decidedly analog feel – it’s all A Coal Handling Plant Coal transported to the plant by the rail line and carrier trucks This coal is transfer from the underground bunker to crusher by series of conveyer belt In coal crusher coal size reduced up to ¾” after that coal transfer to the boiler’s coal bunker or coal yard In the case of emergency the coal is fetchHazards Identification and Risk Assessment in Thermal Power PlantVertical Coal Mill On the basis of retaining the advantages of RP grinders, the innovative HP mediumspeed coal grinder which absorbs the structural characteristics of MPS and MBF coal grinders has the advantages of various grinders Its grinding parts have a long service life and are easy to replace Ball Grinding Mill Dual inlet dual outlet steel ball mills have advantages of high Coal Mill Coal Fired Power Generation Shanghai ElectricFeatures of coal dust milling machine Shuliy Machinery is an excellent manufacturer of charcoal machines in China The charcoal powder mixing machine produced by our factory has the following characteristics: 1 Agitation and grinding are performed simultaneously So the mixing effect is good 2 Because the pulverized coal mixer has no Charcoal Powder Mixer Wheel Roller Mixing Machine Shuliy

2,200 TPD Coke and Coal Gasification Plant for Sale at Phoenix

The plant can process 2,200 TPD of coke Phoenix Equipment is a global buyer and seller of used refinery units, such as this world class Coke and Coal Gasification Plant for sale Call phoenix equipment today to receive a quote for this Coke and Coal Gasification Plant or any of our other used refinery unitsStock# 274Coalfired plants are the most widely used power plant today They involve the combustion of coal producing high pressure (typically 2400–3500 psig, ~165–240 bar) and high temperature (>500ºC) steam which is used to drive a turbine at synchronous speed (3000 rpm in countries such as the UK with a 50 Hz supply frequency, 3600 rpm in Instrumentation and control in coalfired power plant ICSC2024年6月7日 Shuliy charcoal grinder machine refers to a piece of equipment used to crush and grind charcoal into hookah charcoal production line charcoal briquette processing line bbq charcoal processing plant The Benefits of Shuliy Coal Grinder Machine Power(kw) Dust remover(pcs) Hammer(pcs) Fan(kw) Cyclone diameter(m) SLHM60: 0608 Charcoal Grinder Machine for Crushing Charcoal into PowderA pulverizer or grinder is a mechanical device for the grinding of many different types of materials For example, a pulverizer mill is used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power plants different equipment of coal processing Capabuild

.jpg)

How to Process Coal into Pulverized Coal in 5 Steps?

2024年1月11日 With a vertical roller mill (VRM) VRMs consist of a rotating table or bowl and rollers 1 To grind the coal, feed raw or initially crushed coal into the mill which is then ground between the rotating components; 2 Finally, hot air removes moisture, carries the pulverized coal out, and a classifier segregates the particles; Here is all you need to know about the VRM:2018年6月26日 The document summarizes ash handling systems used in thermal power plants It describes the two main types of ash bottom ash and fly ash Bottom ash is heavier and collected at the bottom of furnaces while fly ASH HANDLING PLANT PPT SlideShare2018年9月30日 After burning of coal, 40 % of total coal consumption is converted into ash which need to be properly disposedoff from the thermal power plant Types of Ash Generated in Thermal Power Plant Bottom Ash – Ash Ash Handling System In Thermal Power PlantThis equipment is required to transport the coal stored onsite to the coal pulverizers Because this equipment is essential to the operation of the power plant, it is critical that this equipment must be free from contaminationrelated failure Case Study In March 2003, a major Canadian utility derated its Unit 4 due to a failure of the B millCoal Pulverizer – Power Plant Pall Corporation

Coal Crushers, Shredders, Mills for Mining Power Industries

We are the standard of comparison for central stations, industrial power plants, and mine preparation plants around the world We make many types of coal crushing equipment, like our ACC Series Rolling Ring Crusher with capacities ranging from 630–2,350 TPHHP mediumspeed coal grinder which absorbs the structural characteristics of MPS and MBF coal grinders has the advantages of various grinders Heavy Industry Group produces a range of basic products, such as metallurgic and rolling mill machinery, grinding equipment for Vertical Coal Mill Power Generation Equipment Shanghai At coal handling system in thermal power plant have interlock the equipment which can avoid equipment bad sequence startup interlock ,every equipment work according to sequence rule startup soOperation and Maintenance of Coal Handling System in Thermal Power Plant1998年1月1日 The AR Heavy Duty Clinker Grinder is compatible with major OEM or equivalent wear parts and is a direct replacement for your existing equipment gas conversion for coalfired power plantsClinker Grinder Power Engineering

The Daily Grind Power Engineering

2011年3月1日 As clean air requirements start to take a toll on coalfired plant operators, developers of crushing and grinding equipment are facing new challenges for adapting products to handle cleaner coal Georgia Power’s problem exits at most coal plants – outdated sealing methods were causing water, fly ash, coal and other materials to leak out and contaminate clinker grinder bearingsBearing Isolator Eliminates Clinker Grinder Maintenance Power 2023年10月8日 The selection of coal crushing equipment mainly depends on the input size of raw coal, the moisture of the coal, and the production scale (output) of the plant Of course, the output size and the final use of coal also need to be considered, such as 025 mm for gas furnaces, 825 mm for steam locomotives, 625 mm for industrial furnaces, and 025 mm for 6 Types of Coal Crusher: Which Is Best for Crushing My Coal?