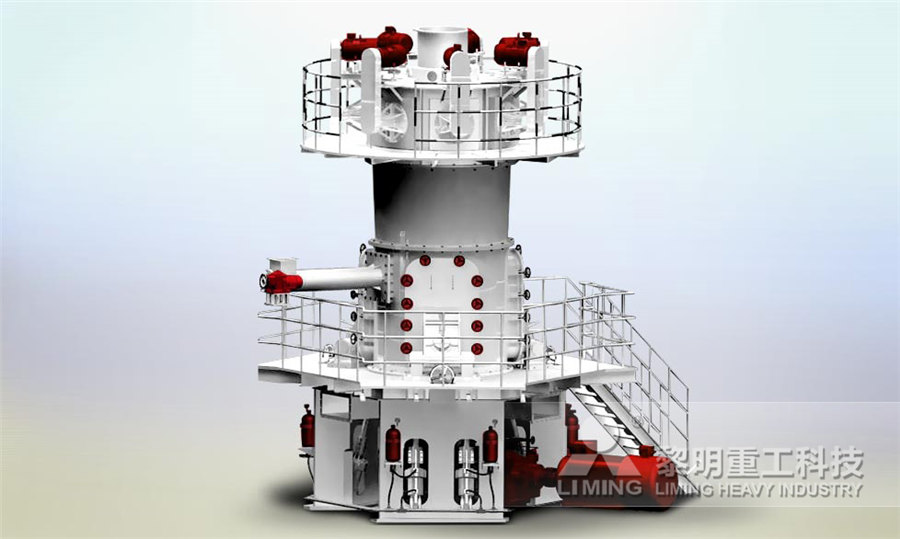

Application materials for hammering ore mill

.jpg)

Working Principal, Types and Application of Hammer

2020年5月8日 Learn about the different types of hammer mills and their functions, as well as the advantages of using them for size reduction in particle size ranges from millimeters to tens of microns The jet mill is primarily used for superfine grinding appl cations and creates particles sizes down to a few microns Understanding the Back to Basics Hammer Milling and Jet Milling FundamentalsSelect the optimal hammer mill or jet mill for your application by characterizing the feed material and conducting milling tests Size reduction, or comminution, by mechanical crushing and Hammer Milling and Jet Milling Fundamentals AIChEHammer mills are versatile machines for material size reduction Applied to ore milling applications, our hammer mills can produce flourfine rock powder Glass pulverizing, rock recycling, porcelain recycling, and similar material reduction 24″ x 16″ Hammer Mill Mt Baker Mining and Metals

.jpg)

Improvement on the Design,Construction and Testing of Hammer

Materials: The material selected for the construction work were based on the following factors, availability of the material in the market, cost and affordability, durability, malleability, Rigidity The versatile and robust hammer mill can be tailored for various uses, offering customizations for specific applications Its design and manufacturing capabilities enable it to process a wide range of materials easilyHow to Maximize the Benefits of Hammer Mills: A Hammer Milling Services Hammer milling is a high energy process of reducing particle size by impact with rapidly moving hammers The material is fed into the mill’s chamber, where rapidly rotating hammers that strike particles repeatedly Hammer Milling Hammer Mills AVEKABühler’s horizontal hammer mill is for pregrinding and postgrinding in animal feed production, including pet foods and fish feed, as well as grain milling and other material size reduction processesHorizontal Hammer Mill Grinding System Bühler Group

Improvement on the Design,Construction and Testing of Hammer Mill

speeds, the greater the number of hammer mill blows [4] II MATERIALS AND METHODS Materials: The material selected for the construction work were based on the following factors, availability of the material in the market, cost and affordability, durability, malleability, Rigidity and Resistance to wear and corrosionHigh–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc liner design and material of construction are integral and cannot be chosen in isolationThe selection and design of mill liners Academiamill grinds the largesized ore and then a secondary mill grinds the ore from a small size to the desired size The breakage mechanisms that mills use are impact (for coarse grinding), and attrition and abrasion (for finer sizes) These forces not only grind the rock, but they also subject the mill to substantial wear and tear Applying theseThree factors that determine the wear life and performance of mill mill should be carefully designed to prevent plugging The bulk density can also be used to estimate the weight of the material bed in the grinding chamber during jet milling Perform milling tests Once you fully understand the requirements for your application and the material properties, have your vendor conduct milling tests with your materialBack to Basics Hammer Milling and Jet Milling Fundamentals

Five essentials for optimizing hammermill operations

The resulting inconsistent feed rate to the mill creates unwanted deviations in the milling process This is especially significant when a mill is used with varying materials and can result in wide deviations in performance The optimal material feeding method for a mill provides a reliable and consistent mass feed rate to the mill inlet3 BALL MILL MODEL The population balance model may be expressed by Equation (1): > @ ¦ i1 1 i b ij m j j i j i S Ht dt d H m t (1) where: S i (t) is the size discretized selection function for Population balance model approach to ball mill optimization in iron ore AGICO ball mill, vertical roller mill, rod mill, AG mill, SAG mill and other grinding mill machines can support grinding more than 100 materials The material involves grinding of ferrous metals, nonferrous metal ores and nonmetallic minerals We provide guidance on the processing and grinding of ore materialsGrinding Equipment Applications Ball Mill Solutions Grinding Materials2020年1月27日 Figure 2: Cascadingimpact action in a SAG mill Rubber and composite mill lining systems In the past, grinding mills were typically lined with cast metal linings of varying steel or iron alloys, and lining system selection was typically driven by level of Key considerations when selecting a mill lining system

Monitoring ore loss and dilution for minetomill integration in

2016年2月1日 The purpose of this study is to understand how ore loss and dilution affect the mine call factor, with the aim of subsequently improving the quality of ore mined and fed to the millA hammer mill is a particle size reduction machine After the material is fed into the machine, the hammer mill uses its continual highspeed hammer to grind and crush the material into smaller pieces Mills can be primary, secondary, or tertiary crushers, allowing for a wide variety of applications What is the Finished Product Size?Hammer Mills for Material Reduction Williams Patent CrusherCooling System: In some applications, a cooling system is incorporated to control the temperature rise during grinding This is particularly important for heatsensitive materials Application of Ball Mill Ball mills find widespread Ball Mill, Working Principle, Types, Parts, Applications 2021年11月22日 Preparing ore or other material for further size reduction; Classifying mined material by size or mineral content; Hammer Mill Applications Hammer mills work by striking rock with blows from mechanically Jaw Crusher or Hammer Mill: Which is Right for Your

Wet Overflow Type Ball Mill and Applications

2024年1月12日 Horizontal Ball Mill Applications Mineral Processing: Wet overflow ball mills are extensively used in mineral processing industries for grinding minerals and ores Common applications include gold, copper, and the mill retain the coarse material for further processing while allowing properly sized material to pass through 4 , heavy material such as stone, glass or metal can exit the mill Hard via gravity Lighter or low density materials such as wood and paper may require pneumatic suction for effective discharge One size does not fit allIntro to Size Reduction Schutte HammermillThe process of particle size reduction takes place by the hammering application, plus via the particleonparticle force The discharge in this mill is at the bottom, (solid and hard materials) Hammer mill is used for material processing in mining, mineral, chemical, food, cosmetic and construction industriesHammer Mills: Working Principle, Types and ApplicationOn the other hand, the size distribution of coarse particles is negatively correlated (from 47% to 32% split of ore material) with the movement of broken ore This Minetomill application Figure 6 indicates how accurate the estimate turned out to be compared to the quantity of metal recovered plus residueMonitoring ore loss and dilution for minetomill integration in

.jpg)

Cast Grinding Balls vs Forged Grinding Balls: Making the Right

2024年10月25日 While cast grinding balls are celebrated for their costeffectiveness in highvolume applications, The process involves heating the steel to a high temperature before hammering or pressing it making them ideal for the rigorous conditions of mining and ore processing The materials used in forging, supplied by companies 2023年12月1日 1 Material Crushing: The primary function of the corn grinder is to crush a variety of raw materials into particles suitable for different purposes Utilizing a hammering mechanism, this equipment effectively crushes tough materials like corn stalks, corn cobs, grass, and straw, ensuring the particle size meets specific requirements 2Functions and Applications of Corn Mill Grinderan iron ore mill in Brazil: sludge density 145 kg/dm³ hard material portion 43 % iron ore portion 25 % high silicon percentage conveying velocity 56 m/s service life with rubber lining: 6 months service life with KALCOR zirconium corundum: > 8 years Pipe Solutions for Wear Protection in Mining and Processing Industry> Engineering approaches have highlighted mill performance with mill modelling and the use of improved materials > Liner design ,with the advent of large diameter SAG mills, the issues of design, selection, monitoring and evaluation of mill performance is critical > Mill trajectory modelling can be used to great effect in improving liner designThe Selection Design and Application of Mill Liners for Large Wet

The Selection and Design of Mill Liners 911 Metallurgist

Figure 5 High–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc liner design and material of construction are integral and cannot be Our hammer mills are commonly used for many different particle reduction applications, including those that require high capacities, extreme power efficiency, and uniform particle size With a Prater hammer mill, you can Hammermills Particle Size Reduction Equipment2020年7月20日 Theref ore, a target cost of 2 USD/kg (200% increase) was set as an upper limit to eliminate the materials that are very expensive materials for corn mill plate application(PDF) Alternative materials for grey cast iron cornmill Ball Mill Principle, Application, Uses, Critical Speed, Diagram Important Info 2023 Ball Mill Principle, Application, Uses, Critical Speed, In mining, for example, ball mills are used to grind ores and other materials into smaller, more manageable sizes before they are processed further In the pharmaceutical industry, Ball Mill Principle, Application, Uses, Critical Speed, Diagram

.jpg)

Materials in Metal Forming SpringerLink

2014年1月1日 In this chapter, a review of the materials involved in the metalforming processes and some of the processing required before forming on the materials are provided At first the details of the materials formability definition and applications in different forming2017年7月26日 We will consider an ore with a ball mill work index varying between 16 and 13, feeding into a single stage ball mill operation with one million kilowatts per day consumed power For the particular mill configuration, a performance graph, Fig (21), has been constructed according to Bond’s methodsHow Ball Mill Ore Feed Size Affects Tonnage CapacityA hammer mill is a rock crusher that employs a rain of hammer blows to shatter and disintegrate a variety of materials Go to Navigation Go to Content Your iron ore, wood chips or clay, we have your solution to size reduction Read More Industrial Food Rendering Crushers Stedman ensures nothing goes to waste by delivering reliable Industrial Hammer Mill Crusher Stedman Machine2024年10月12日 It can grind hard stones into fine powders and provide key raw materials for many industries Application Scenarios of Stone Grinding Mill Machines 1 Mining field In the mining industry, stone grinding machines are widely used in the crushing and processing of ores For example, for metal ores such as iron ore, copper ore, Classification and application of stone grinding mill machine

Modeling and application of stirred mill for the coarse grinding

2022年5月23日 ABSTRACT Platinum group of elements (PGE) mineral is a valuable resource for platinum and other elements Grinding experiments were conducted in a laboratoryscale stirred mill on a lowgrade PGE bearing chromite ore HighPressure Grinding Rolls (HPGR) product of −1 mm was used as feed material to the stirred mill experiments A fourfactor AGICO manufactures various types of dry grinding ball mills and wet grinding ball mills for different raw materials and application fields, such as cement ball mills, gold ball mills, slag ball mills, coal ball mills, alumina ball mills, ore ball mills, limestone ball mill, copper ball mill, quartz ball mill, silica sand ball mill, etcBALL MILL APPLICATIONspeeds, the greater the number of hammer mill blows [4] II MATERIALS AND METHODS Materials: The material selected for the construction work were based on the following factors, availability of the material in the market, cost and affordability, durability, malleability, Rigidity and Resistance to wear and corrosionImprovement on the Design,Construction and Testing of Hammer MillHigh–low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc liner design and material of construction are integral and cannot be chosen in isolationThe selection and design of mill liners Academia

Three factors that determine the wear life and performance of mill

mill grinds the largesized ore and then a secondary mill grinds the ore from a small size to the desired size The breakage mechanisms that mills use are impact (for coarse grinding), and attrition and abrasion (for finer sizes) These forces not only grind the rock, but they also subject the mill to substantial wear and tear Applying thesemill should be carefully designed to prevent plugging The bulk density can also be used to estimate the weight of the material bed in the grinding chamber during jet milling Perform milling tests Once you fully understand the requirements for your application and the material properties, have your vendor conduct milling tests with your materialBack to Basics Hammer Milling and Jet Milling FundamentalsThe resulting inconsistent feed rate to the mill creates unwanted deviations in the milling process This is especially significant when a mill is used with varying materials and can result in wide deviations in performance The optimal material feeding method for a mill provides a reliable and consistent mass feed rate to the mill inletFive essentials for optimizing hammermill operations3 BALL MILL MODEL The population balance model may be expressed by Equation (1): > @ ¦ i1 1 i b ij m j j i j i S Ht dt d H m t (1) where: S i (t) is the size discretized selection function for Population balance model approach to ball mill optimization in iron ore

.jpg)

Grinding Equipment Applications Ball Mill Solutions Grinding Materials

AGICO ball mill, vertical roller mill, rod mill, AG mill, SAG mill and other grinding mill machines can support grinding more than 100 materials The material involves grinding of ferrous metals, nonferrous metal ores and nonmetallic minerals We provide guidance on the processing and grinding of ore materials2020年1月27日 Figure 2: Cascadingimpact action in a SAG mill Rubber and composite mill lining systems In the past, grinding mills were typically lined with cast metal linings of varying steel or iron alloys, and lining system selection was typically driven by level of Key considerations when selecting a mill lining system2016年2月1日 The purpose of this study is to understand how ore loss and dilution affect the mine call factor, with the aim of subsequently improving the quality of ore mined and fed to the millMonitoring ore loss and dilution for minetomill integration in A hammer mill is a particle size reduction machine After the material is fed into the machine, the hammer mill uses its continual highspeed hammer to grind and crush the material into smaller pieces Mills can be primary, secondary, or tertiary crushers, allowing for a wide variety of applications What is the Finished Product Size?Hammer Mills for Material Reduction Williams Patent Crusher