Where to use grinding machine ore mill

.jpg)

Grinding Mill Types, Working Principle Applications

2017年10月3日 SemiAutogenous Mills/ SAG Mills (primary grinding mill) – these mills use grinding balls with forces of attrition, impact, and abrasion between grinding balls and ore particles that result in finer particles Feed size range is 400 mm / 16 in and product size of 75 microns2018年8月17日 Extreme temperatures, impact velocity, mill load, grinding media, ore types, and applications are some of the factors to be considered while installing new linersGrinding Mills — Types, Working Principle Applications2024年8月15日 Dry grinding reduces the material to a qualified fineness of ore powder, commonly used for hard stones like silica sand and quartz It is suitable for areas where moisture control is necessary or where water resources are Mineral Processing Plants: What You Need to KnowCustomized grinding mill parts including heads, shells, trunnions and liners, main bearings, gears and pinions, and more! Metallic, PolyMet™, Megaliner™, Rubber and Orebed™ mill liners for all mill types Whether old or new, we can Grinding mills for mining and minerals processing

.jpg)

Rod Mills: Efficient Grinding Solutions for Mining

2016年6月1日 The type of mill that is used for grinding ore in a modern concentrator is the wet tumbling mill These mills may be divided into three types ROD MILLS, BALL MILLS and AUTOGENOUS MILLS In the first type, the Customized grinding mill parts including heads, shells, trunnions and liners, main bearings, gears and pinions, and more! Metallic, PolyMet™, Megaliner™, Rubber and Orebed™ mill liners for Grinding MetsoBall mills are the most commonly used type of grinding mill They work by rotating a cylinder containing lead balls, called grinding media, at speeds of up to 700 revolutions per minute Understanding the operation of grinding mills in the mining and 2024年4月26日 Grinding Mills: Grinding mills, such as ball mills and rod mills, are commonly used for grinding iron ore These mills contain grinding media (steel balls or rods) that tumble and impact the ore, causing it to break into Iron Ore Processing: From Extraction to Manufacturing

.jpg)

Grinding Mill an overview ScienceDirect Topics

Grinding is typically performed with grinding machines, equipped with elastic grinding disks, which are either attached directly to the rotor engine axis or come as a flexible extension shaft Types of Grinding Machines These machines include the: Belt grinder, which is usually used as a machining method to process metals and other materials, with the aid of coated abrasivesAnalogous to a belt sander (which itself is often used for wood but sometimes metal)What Is Grinding Machine? Definition, and Types The The Autogenous Mill, also known as AG Mill, is a type of grinding mill used in the mining industry This machine uses ore and rock itself as grinding media to perform its job Unlike other types of mills that use steel balls or rods for Understanding the SAG Mill in Copper Ore Mining HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM SBM Ore Ultrafine Grinding Mill

Machining 101: What is Grinding? Modern Machine Shop

2021年7月3日 Grinding takes an abrasive and uses its many grains to cut a workpiece Variations on this process are useful for a wide variety of applications Chiron Group combines the best of both worlds at IMTS 2024, featuring live A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are many different types of mills and many types of materials processed in them Historically mills were powered by hand or by animals (eg, via a hand crank), Mill (grinding) Wikipedia2018年8月17日 Extreme temperatures, impact velocity, mill load, grinding media, ore types, and applications are some of the factors to be considered while installing new linersGrinding Mills — Types, Working Principle Applications2016年6月6日 Mill operating conditions including mill speed (for circuits with variablespeed drives), density, and total mill load; The effect of feed hardness is the most significant driver for AG/SAG performance: with variations in ore hardness come variations in circuit throughputSAG Mill Grinding Circuit Design 911Metallurgist

Different Types of Grinding Machines and How to Use a Grinder

2023年5月18日 What is Grinding Process How It Works – Different Types of Grinding Control Method Of Workpiece Thickness Of Grating Ruler And Tool Setter 7 Different Types Of CNC Machines – CNC Lathe, CNC Milling Machine More CNCLATHING Types Classification Of CNC Machine Tools Basics Of CNC Machining CNC Machining Center Vs CNC Mill – The best home grain milling machine for bread flour will have the following features: The milling/grinding process doesn’t raise the temperature of the flour by then a burr grinding mill is a good choice An impact mill, although will get you fine flour, won’t produce flour that is super fine For bread making, a finer texture is Best Grain Mill for Bread Flour: Full Buyers Guide2018年10月1日 Grinding Machine Definition A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the materialIt is a process of metal cutting by using a rotating abrasive wheel from the surface of the workpiece Generally, the grinding is a type of finishing operation to make sure that there is high surface quality, Grinding Machine: Types, Parts, Working Operations (With PDF)2017年6月2日 Pebble mills use rock pebbles as the grinding media to cause friction and attrition between the pebbles and ore material Pebble mills may be used when metal balls must be avoided Autogenous grinding (AG) and semi How it Works: Crushers, Grinding Mills and Pulverizers

Ball Mill Grinding Machines: Working Principle, Types,

Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments Ball mill grinding machines are widely used in various industries for the comminution of materials into fine A grinding machine is a machine tool equipped with an abrasive wheel used for producing fine finishes or making light cuts on metals and other materials There are various types of grinding machines Their wheels, which differ in size and Grinding machine New World Encyclopedia2021年11月8日 Illite ore industrial grinding mill machines include ultrafine grinding mills, vertical roller mills, highpressure mills, wet stirring mills, coarse mills, and so on It can be applied to different illite grinding operation requirements and meet Illite Ore Industrial Grinding Mill Machine SBM Ultrafine 2023年11月22日 Milling machines are among the most commonly used machine tools in modern manufacturing They’re found in assembly lines, small toolanddie shops, home workshops, and just about everywhere in between Almost every industry uses milling machines from small mills in highend scientific labs to machining centers in the automotive industryBeginner's Guide to Milling Machines: Types, Prices, Uses CNC

.jpg)

Amazonca: Grain Mills: Home Kitchen

Moongiantgo 150g Grain Grinder Mill Electric Spice Grinder 950W Stainless Steel HighSpeed Dried Cereal Grinding Machine 50300 Mesh 110V Pulverizer Dry Grinder US Plug 41 out of 5 stars 213 Quick look $68 Commercial Motor Grinding Stone Mill Grain, Vanilla Flour Machine Stainless Steel High Grain Grinder for Grinding Grains, Roots, Fl 2020年2月26日 There are several types of grinding wheels, some of which include grindstones, angle grinders, die grinders and specialized grinding machines Regardless of the grinding wheel, though, all grinding processes use abrasive particles to “grind” away material from a workpiece’s surface When a workpiece is exposed to a grinding wheel, some of Milling vs Grinding: What's the Difference? OneMonroeOur range of home flour mills grain mills are Australia‘s best stone grain mills for sale Not only are these grain mills all built to last, their gorgeous craftsmanship is an asset to any kitchen that needs a small flour mill for home useThe many benefits of being able to mill flour at home become apparent as soon as you taste it Our electric grain mills retain all of the nutritional Grain Mill Australia Living Whole2021年4月16日 Grinding hand tools A die grinder is a highspeed rotary tool that is typically powered by compressed air The tool has a smalldiameter abrasive bit that rotates to get the job done Check out Choosing the Right Air Die Grinder for more information and some recommended models Angle grinders are also abrasive hand tools Unlike die grinders, Intro to Grinding Methods, Machines and Tools

.jpg)

Ball Mill Rod Mill Design 911Metallurgist

2016年4月22日 In present day practice, ore is reduced to a size many times finer than can be obtained with crushers Over a period of many years various fine grinding machines have been developed and used, but the ball mill has become standard due to its simplicity and low operating cost GRINDING MILLS Ball mills efficiently perform a wide variety of services2019年8月14日 Ball mill is a common grinding equipment in concentrator Common Types of Ball mill back to top The common industrial ball mills mainly include cement ball mill, tubular ball mill, ultrafine laminating mill, cone ball mill, ceramic ball mill, intermittent ball mill, overflow ball mill, grid ball mill, wind discharge ball mill, double bin ball mill, energy saving ball millThe Ultimate Guide to Ball Mills MiningpediaThis machine can be can grind all kinds of ores and other materials, which Compare this product Remove from comparison tool ball grinding mill Ф2200×5500 horizontal for ore for cement ball grinding mill Ф2200×5500 Final grain size: 74 µm 400 µm Rotational speed: 21 rpm Output: 10 t/h 20 t/h Ball mill is common used grinding Ore mill, Ore grinding mill All industrial manufacturers2022年12月8日 A CNC grinding machine uses a rotating grinding wheel to remove small amounts of material from a workpiece They are, first and foremost, finishing machines In the case of round work, a machinist often removes CNC Grinding Machine Buyers Guide: Types, Price,

Grinding Mill an overview ScienceDirect Topics

Grinding Mills Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 71 Introduction Grinding is the last stage in the comminution process where particles are reduced in size by a combination of impact and abrasion, either dry, or more commonly, in suspension in waterRotating abrasive wheel on a bench grinder Pedalpowered grinding machine, Russia, 1902 A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grindingIt is a type of material removal using an abrasive wheel as the cutting tool [1] Each grain of abrasive on the wheel's surface cuts a small chip from the workpiece via shear Grinding machine Wikipedia2023年6月28日 Gristmills turned by water have been around for many centuries, some as early as 19 BC Although the terms “gristmill” or “corn mill” can refer to any mill that grinds grain, the terms were used historically for a local mill where farmers brought their own grain and received back ground meal or flour, minus a percentage called the “miller’s toll”Grist Milling 101 » Grant's Old Mill Museum2023年2月26日 By understanding these specialized uses, one can determine which type of machine to use for any machining project; now we will turn towards exploring those uses for each machinery type in the next section about "Uses of a Lathe and a Mill" Uses of a Lathe and a Mill A lathe and a mill are two machines that are widely used for various Lathe vs Mill: What’s the Difference and Which is Better?

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 It is used in jaw crushers, cone crushers, gyratory crushers, and roll crushers Impact crushing: This method uses highspeed moving parts to strike the material, breaking it under the force of impact This technique is employed in impact crushers, hammer crushers, sand making machines, fine crushers, and compound crushers2024年8月8日 In this process, a powder mixture is placed in a rotating drum, along with grinding media such as balls The kinetic energy imparted by the balls' motion breaks the powder into smaller pieces, making it a critical technique in various industries In mining, it's used for ore processing, enabling the extraction of valuable mineralsBall Mill Success: A StepbyStep Guide to Choosing the Right Grinding When iron ore is extracted from a mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushingThe six main steps of iron ore processing MultotecTypes of Grinding Machines These machines include the: Belt grinder, which is usually used as a machining method to process metals and other materials, with the aid of coated abrasivesAnalogous to a belt sander (which itself is often used for wood but sometimes metal)What Is Grinding Machine? Definition, and Types The

Understanding the SAG Mill in Copper Ore Mining

The Autogenous Mill, also known as AG Mill, is a type of grinding mill used in the mining industry This machine uses ore and rock itself as grinding media to perform its job Unlike other types of mills that use steel balls or rods for HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM SBM Ore Ultrafine Grinding Mill2021年7月3日 Grinding takes an abrasive and uses its many grains to cut a workpiece Variations on this process are useful for a wide variety of applications Chiron Group combines the best of both worlds at IMTS 2024, featuring live Machining 101: What is Grinding? Modern Machine ShopA mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are many different types of mills and many types of materials processed in them Historically mills were powered by hand or by animals (eg, via a hand crank), Mill (grinding) Wikipedia

.jpg)

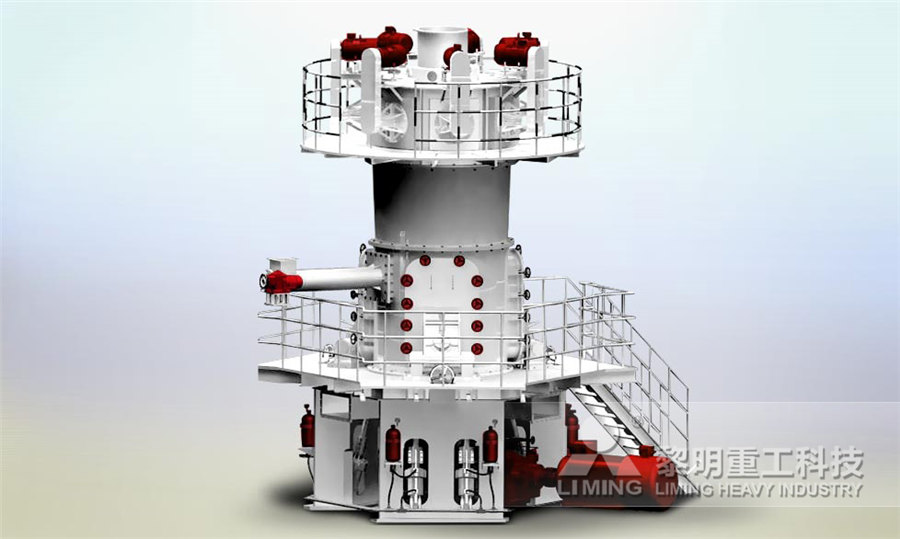

Grinding Mills — Types, Working Principle Applications

2018年8月17日 Extreme temperatures, impact velocity, mill load, grinding media, ore types, and applications are some of the factors to be considered while installing new liners2016年6月6日 Mill operating conditions including mill speed (for circuits with variablespeed drives), density, and total mill load; The effect of feed hardness is the most significant driver for AG/SAG performance: with variations in ore hardness come variations in circuit throughputSAG Mill Grinding Circuit Design 911Metallurgist2023年5月18日 What is Grinding Process How It Works – Different Types of Grinding Control Method Of Workpiece Thickness Of Grating Ruler And Tool Setter 7 Different Types Of CNC Machines – CNC Lathe, CNC Milling Machine More CNCLATHING Types Classification Of CNC Machine Tools Basics Of CNC Machining CNC Machining Center Vs CNC Mill – Different Types of Grinding Machines and How to Use a GrinderThe best home grain milling machine for bread flour will have the following features: The milling/grinding process doesn’t raise the temperature of the flour by then a burr grinding mill is a good choice An impact mill, although will get you fine flour, won’t produce flour that is super fine For bread making, a finer texture is Best Grain Mill for Bread Flour: Full Buyers Guide

Grinding Machine: Types, Parts, Working Operations (With PDF)

2018年10月1日 Grinding Machine Definition A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the materialIt is a process of metal cutting by using a rotating abrasive wheel from the surface of the workpiece Generally, the grinding is a type of finishing operation to make sure that there is high surface quality,