HOME→Grinding roller assembly installation Grinding roller assembly installation Grinding roller assembly installation

Grinding roller assembly installation Grinding roller assembly installation Grinding roller assembly installation

Raymond Roller Mill PartsUltimate Guide Fote Machinery

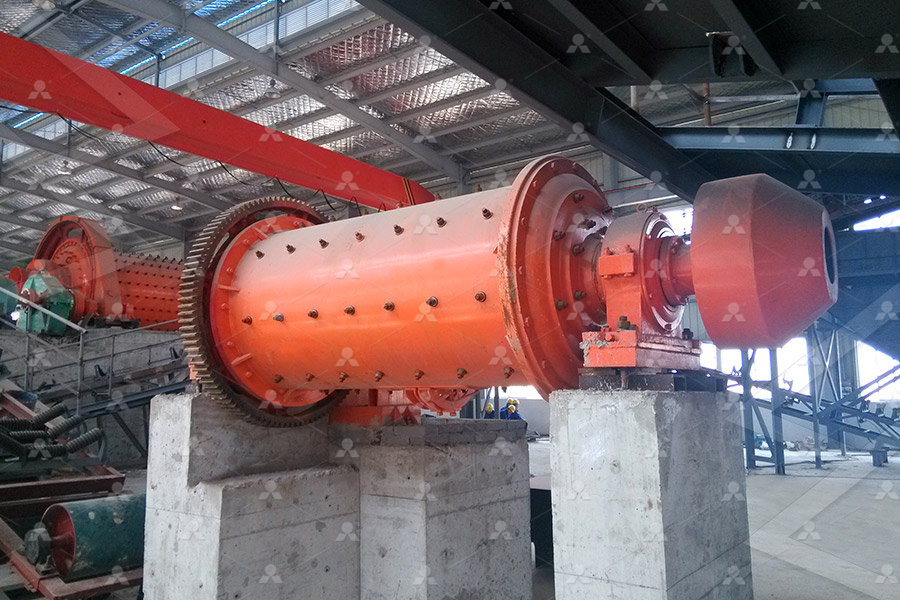

Main parts of Raymond mill include grinding roller, grinding ring, powder collector, classifier, air blower, reducer, base plate, shovel, 展开When the grinder mill is working, the plum blossom frame and the grinding roller assembly are rotating, and the materials are evenly fed into the grinding roller assembly by the feeder, while Grinder mill建冶重工机械官网Function: Convey the pressure and grinding materials Installation requirement: 1, Combined grinding roller assembly and the center yoke with bolts M80 The pressure of torque should be Grinding Roller Assembly Nanjing Perfect Machinery2024年3月25日 Prepare the grinding roller section assembly drawing Figure 2 Structural diagram of the grinding roller 3 ASSEMBLY OF THE SHAFT AND THE BEARING (PDF) Research on onsite installation process of grinding roller of

.jpg)

High Pressure Grinding Roller (HPGR) DirectIndustry

Features and main components Roller assemblies Roller Assemblies comprise the finished roller tire with studs, edge protection and shaft The roll shafts are fabricated from forged, heat treated alloy steel with integral journalsEnduron® high pressure grinding rollers (or rolls) are the primary grinding tools of the Enduron® HPGR Built to last, these grinding rolls contain a superior autogenous wear layer that Enduron® High Pressure Grinding Rolls (HPGR) Weir2018年12月21日 For decades, polycom® highpressure grinding rolls have been used successfully in the grinding of raw materials and binding agents polycom® HPGR grinding is Industrial Solutions polycom highpressure grinding rollroller mill designs for throughput rates of up to and exceeding 600 tph and drive powers of up to 6,000 kW, but also the optimisation of existing grinding plants and a broad range of customer Polysius Roller Mills For grinding

.jpg)

HPGR / HPGR Pro The next level in grinding FLSmidth

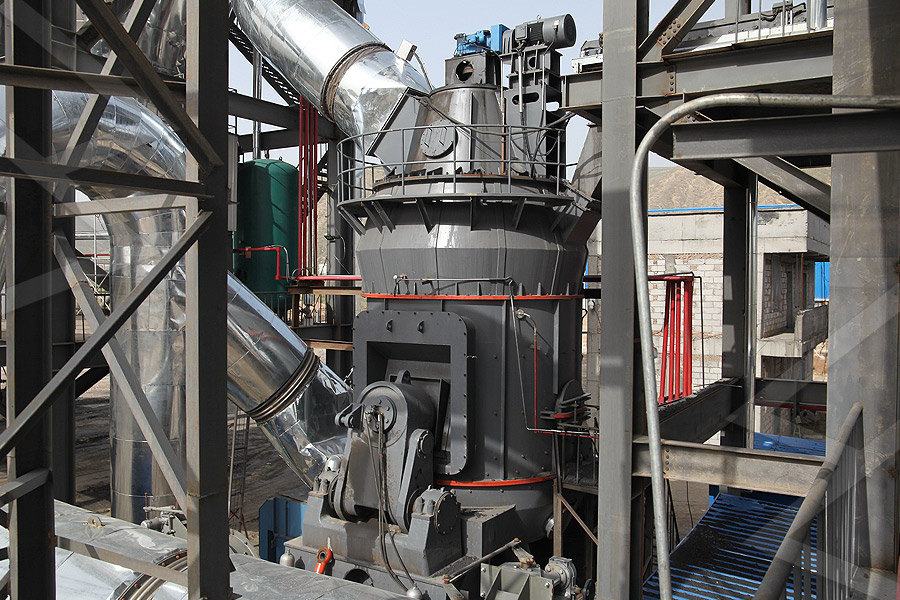

the HPGR Pro, our latest generation high pressure grinding roll HPGR Expertise 35+ years of experience supplying HPGR’s to mining customers More than 150 machines installed across Four traditional grinding roller lubrication systems in use also exist on the following cost and technical deficiency: (1) is when ambient temperature is low, start is front for the fluid in the heating fuel tank, system needs in addition configuration one station internal circulation pump, ON cycle pump in opening electric heater has increased the manufacture cost of equipment when Grinding roller lubricating system for fourroller vertical millsMombasa Cement Ltd ordered a QMK² 24/12 with three roller units for the 5,000 tons per day kiln line In addition, the raw material grinding process will be supported by a QMR² 48/24 For the 4,000 tons per day kiln line Shiva quadropol® thyssenkrupp Polysius Grinding The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for maintenance, a hydraulic system that controls grinding pressure, and a separator that Operation Manual: HRM1700M Vertical Roller Coal Mill

VRM – AMCL Machinery Limited

UBE Vertical Roller Mill performs drying, grinding, if roller size is same even for different table size, same roller assembly, same swing lever assembly and tension device are used By adopting this design method, parts standardization is achieved Raw Mill Cement Mill Test Mill Facility at AMCL AMCL will install test mill facilities at Grinding mills reduce the size of materials to a uniform particle size, enabling materials to progress for further processing Grinding mills use a grinding rather than crushing process to achieve the desired results Minerals processing generally uses wet grinding, where water is added to create a slurry that makes grinding more efficientFlexible, efficient grinding systems – FLSof a roller mill Stages in the assembly of a roller mill in Australia View into the interior of the mill during assembly Grinding table gear unit Coarse feed valve elevator to the grinding table or is conveyed to the highefficiency separator The discharge ring is of modular design and made of highly wearresistant elePolysius Roller Mills For grindingVertical mill Parts includes: roller core, grinding roller shaft, transparent cover, end cover, pressure ring, transmission arm, bearing bush, bearing seat, pin shaft, grinding roller assembly, grinding roller sleeve, grinding disc device, grinding disc lining plate, guide cone, grinding roller sheath, scraper frame, retaining ring, powder concentrator rotor assembly and wearresistant Vertical mill Grinding roller, Wear Parts, Vertical Roller Mill Parts

.jpg)

YGM High Pressure Grinding Mill

1 The grinding force is large The grinding roller assembly of the highpressure grinding mill adopts a highpressure spring device to increase the grinding force The grinding force of each grinding roller assembly can be increased by 500Kg on the original basis, which greatly improves the milling efficiency 2162 PostInstallation Running Test between which there are ball or roller rolling elements which support a rotating load by rolling forging, turning, heat treatment, grinding, and assembly The manufacturing process for deep groove ball bearings is shown belowROLLING BEARINGS HANDBOOK NTN AmericasEnduron® high pressure grinding rolls (HPGR) can handle a wide variety of ores and particle sizes from fine pellet feed all the way up to coarse grinding of 75mm magnetite iron ore When it comes to feed material characteristics, the specific ore type is not detected by an Enduron® HPGR, however ore hardness, size and bed compressibility are important considerationsOur Dynamic HPGR Technology for Mineral Grinding Weir2009年1月31日 Download Citation Grinding process within vertical roller mills: Experiment and simulation Based on screening analysis, laser size analysis, grindability and rigidity tests of samples Grinding process within vertical roller mills ResearchGate

use of lubricants grades in roller arm assembly for raymond mill

Posts Related to use of lubricants grades in roller arm assembly for raymond mill » raw mill rooler assembly » loesche mill or specialized needs, powder generation and processing for industrial process Now MTM series grinding mill has better performance than it Application Raymond mill or Raymond grinder is widely used to grind 2022年6月24日 CLUM vertical roller mill series mainly consists of grinding roller assembly, grinding disc assembly, hydraulic station, transmission arm assembly, powder separator, main reducer Vertical Roller Mill VS Ball Mill 1 How to choose between ball mill and vertical roller mill?When the grinder mill is working, the plum blossom frame and the grinding roller assembly are rotating, and the materials are evenly fed into the grinding roller assembly by the feeder, while the shovel knife fixed at the lower end of the assembly and kept at a certain angle will shovel up the fallen materials with the rotation of the assemblyGrinder mill建冶重工机械官网The normal operation of the grinding roller is the premise to ensure the operation of the vertical roller mill, and the grinding roller bearing is an important part of the grinding roller work 1 Roller bearing assembly clearance The assembly level of the roller bearing is one of the important factors affecting its service lifeAnalysis of installation and maintenance of vertical roller mill

Vertical Roller Mill Wear Mechanisms and Preventive Measures

2020年3月27日 Roller mill is the main equipment in the grinding process, and the roller is the roller wear 31 The roller assembly should be properly Make sure the quality of bearings before installation2024年6月7日 The ring roller mill has a unique design with a grinding ring and roller assembly The grinding ring is fixed on the inner wall of the mill while the roller assembly rotates around the ring As the roller assembly rotates, the material is fed into the mill and is ground between the grinding ring and rollers One of the advantages of the ring Roller Mill Calcium Carbonate Production Lineto install roller modules that had already been in operation in the fourroller arrangement This excluded the risks to the operational reliability of the grinding plant associated with the failure of newly developed sizes of grinding roller Similarly, the sixroller arrangement permits greater partial load operation of the mill, inRAW MATERIAL GRINDING ITadipatri’s big sixer Loescheof a roller mill Stages in the assembly of a roller mill in Australia View into the interior of the mill during assembly Grinding table gear unit Coarse feed valve elevator to the grinding table or is conveyed to the highefficiency separator The discharge ring is of modular design and made of highly wearresistant elePolysius Roller Mills For grinding

.jpg)

Installing roller bearing in the brake/clutch pedal

2021年6月30日 I removed and mailed my pedal assembly to them It came back to me very quickly, and looked brand new, including the installation of the roller bearing for the clutch, and welding on the quadrant to the clutch pedal for the cable (since I was doing this project as a part of a T5 conversion) Here's an afterinstall pic: The schematic of grinding mill along with the position of three rollers is given in Fig 1a An isolated assembly of a vertical roller has been also presented (Fig 1b) As depicted in Fig 1a, the central roller was failed during service The defective component was removed from the assembly for investigation The examination of the failedOperational Failure of Vertical Roller Attached to a Grinding Mill Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It OK™ Raw and Cement Mill2013年9月13日 The correct way to measure concentricity on a grinding machine is 180º from wheel (back side), if the roll is supported on grinding seats For example, if the grinding seat is out of round this form will be transferred to the roll shell by the grinding wheel Runout will not be seen on the wheel side but when aPractical Roll Techniques Grinding Balancing Valmet

Quick Fix Instructions– Spinning Reels Bail Assembly and Line Ro ller

Quick Fix Instructions– Spinning Reels Bail Assembly and Line Ro ller Bearing Replacement Shimano® spinning reels with broken bails or loud and grinding line roller bearings are easily repaired by consumers Models: Sustain®, Stradic®, Saros®, Symetre®, Sahara®, Sedona®, Sonora®, Sienna®, Slade®, Thunnus®, Baitrunner® B,Telephone: +8625ext304 Mailbox: Zongyan Guo@paifeite Mobile:+86 Address: 3401 East, Fuxin International Building, 359 Hongwu Road, Qinhuai District, Nanjing City, Jiangsu Province, ChinaRoller System Roller Assembly Nanjing Perfect MachineryYGM series Raymond roller mill is also called Raymond grinding mill,raymond pulverizer YGM series Raymond roller mill is the new type Raymond mill of our company, which is suitable for processing various nonflammable and nonexplosive mineral materials with Mohs hardness less than 93 and humidity less than 6% The main parts of Raymond roller mill is grinding roller, YGM Series Raymond Roller Mill Clirik2019年10月8日 Roll grinding To maintain rubber covered rolls in the best operating condition frequent grinding must be performed Grinding restores the original properties and qualities of the cover Oxidation and surface checks, cuts or cracks are removed by grinding Before grinding any roll, the following steps should be taken and recorded: Crown measurementRoll grinding procedures, wheels, belts, setup, end relief, tips

.jpg)

Research on onsite installation process of grinding roller of

6 ASSEMBLY GRINDING ROLLER LINING PLATE Cover the roller body part smoothly and firmly Clean the cast square socket of each grinding roller liner, check the size of the grinding roller liner, and the Angle of qualified installation Choose two grinding roller lining plates with large square nest size, assemble the symmetrical1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLSBearing Installation Process Bearing installation is just as critical as bearing design and cleanness Incorrect setup can destroy the bearing installation Throughout installation, never can any installation pressures be spread from an individual bearing ring through the Bearing Installation American Precision AssemblyFour traditional grinding roller lubrication systems in use also exist on the following cost and technical deficiency: (1) is when ambient temperature is low, start is front for the fluid in the heating fuel tank, system needs in addition configuration one station internal circulation pump, ON cycle pump in opening electric heater has increased the manufacture cost of equipment when Grinding roller lubricating system for fourroller vertical mills

.jpg)

quadropol® thyssenkrupp Polysius Grinding

Mombasa Cement Ltd ordered a QMK² 24/12 with three roller units for the 5,000 tons per day kiln line In addition, the raw material grinding process will be supported by a QMR² 48/24 For the 4,000 tons per day kiln line Shiva The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for maintenance, a hydraulic system that controls grinding pressure, and a separator that Operation Manual: HRM1700M Vertical Roller Coal MillUBE Vertical Roller Mill performs drying, grinding, if roller size is same even for different table size, same roller assembly, same swing lever assembly and tension device are used By adopting this design method, parts standardization is achieved Raw Mill Cement Mill Test Mill Facility at AMCL AMCL will install test mill facilities at VRM – AMCL Machinery LimitedGrinding mills reduce the size of materials to a uniform particle size, enabling materials to progress for further processing Grinding mills use a grinding rather than crushing process to achieve the desired results Minerals processing generally uses wet grinding, where water is added to create a slurry that makes grinding more efficientFlexible, efficient grinding systems – FLS

Polysius Roller Mills For grinding

of a roller mill Stages in the assembly of a roller mill in Australia View into the interior of the mill during assembly Grinding table gear unit Coarse feed valve elevator to the grinding table or is conveyed to the highefficiency separator The discharge ring is of modular design and made of highly wearresistant eleVertical mill Parts includes: roller core, grinding roller shaft, transparent cover, end cover, pressure ring, transmission arm, bearing bush, bearing seat, pin shaft, grinding roller assembly, grinding roller sleeve, grinding disc device, grinding disc lining plate, guide cone, grinding roller sheath, scraper frame, retaining ring, powder concentrator rotor assembly and wearresistant Vertical mill Grinding roller, Wear Parts, Vertical Roller Mill Parts1 The grinding force is large The grinding roller assembly of the highpressure grinding mill adopts a highpressure spring device to increase the grinding force The grinding force of each grinding roller assembly can be increased by 500Kg on the original basis, which greatly improves the milling efficiency 2YGM High Pressure Grinding Mill162 PostInstallation Running Test between which there are ball or roller rolling elements which support a rotating load by rolling forging, turning, heat treatment, grinding, and assembly The manufacturing process for deep groove ball bearings is shown belowROLLING BEARINGS HANDBOOK NTN Americas

Our Dynamic HPGR Technology for Mineral Grinding Weir

Enduron® high pressure grinding rolls (HPGR) can handle a wide variety of ores and particle sizes from fine pellet feed all the way up to coarse grinding of 75mm magnetite iron ore When it comes to feed material characteristics, the specific ore type is not detected by an Enduron® HPGR, however ore hardness, size and bed compressibility are important considerations