Learning vertical mill operating lever

.jpg)

Vertical (Bridgeport) Milling Machine Head Every

Today we're starting a new series explaining Every Knob and Lever on a machine In this video, we're looking at a typical kneetype vertical milling machineThere are three basic types of work which can be performed with a vertical milling machine: milling, drilling and boring It would be extremely difficult to determine whether a vertical mill or a lathe would be the most valuable machine in a shop Theoretically, most vertical mills areVERTICAL MILLING MACHINE OPERATION VCSHobbies2020年7月31日 Like most people, I've been leveraging YouTube to learn machining I couldn't find a curated compilation of the best YouTube channels for learning machining or a list of the relevant videos on those channels so I will post some here[HowTo] How to learn machining via YouTube The Hobby This course introduces the student to the basic operations and functions of a vertical milling machine Additional, the course provides the steps required to mill various shapes on a work piece Rockwell Automation US

SERIES I MILLING MACHINES Massachusetts Institute of

HINEUTRALLO LEVER The HiNeutralLo Lever “O”, Figure 213, is used to put the attachment into either back gear or direct drive Rotate the spindle by hand to facilitate meshing of clutch or gears Neutral is provided to permit free spindle rotation for indicating and setup workThe Vertical Milling Machines training course identifies the basic control systems and machining methods used on the vertical milling machine It also explains the operations necessary to manufacture replacement or repair parts used in different equipment types80501 Vertical Milling Machine HSIIn vertical mills, milling cutters with solid shafts are usually used Milling cutters with keyed holes are predominantly for use in horizontal mills End mills are designed for cutting slots, keyways and pockets Two fluted end mills can be used to plunge into work like a drillIntroduction to the Mill MIT OpenCourseWareFIGURE 6347 Steps for using peripheral milling to machine a vertical surface A: Touching off using the Xaxis (table feed) B: The endmill is moved off the part using the Yaxis (saddle feed) and depth of cut is set using the Xaxis C: Conventional milling across the surface using the Yaxis D: Climb milling aSection 6 ─ Unit 3

.jpg)

Chapter 9 : Manual Vertical Milling Machines

Identify and address the safety concerns of operating a milling machine Identify milling machine components and define their function Identify and select tooling for milling Calculate speeds and feeds for milling operations Identify and select tool holding and work holding options Describe and perform proper setup solutions2018年5月2日 Coal mill malfunctions are some of the most common causes of failing to keep the power plant crucial operating parameters or even unplanned power plant shutdowns Therefore, an algorithm has been developed that Detection of Malfunctions and Abnormal Working vertical mill, raw meal, Adaptive Dynamic Programming (ADP), Extreme Learning Machine (ELM) Recommended Citation Lin Xiaofeng, Kong Weikai Adaptive Dynamic Programming in Raw Meal Fineness Control of Vertical Mill Grinding Process Based on Extreme Learning Machine[J] Journal of System Simulation, 2016, 28(11): 27642770Adaptive Dynamic Programming in Raw Meal Fineness Control of Vertical PDF On May 1, 2017, Caroline Woywadt published Grinding process optimization — Featuring case studies and operating results of the modular vertical roller mill Find, read and cite all the Grinding process optimization — Featuring case

Boring On a Mill Machine: A Complete Tutorial [2024] Lathe

2024年1月8日 2) Boring With a Vertical Boring Mill When working with vertical mill machinery, the workpiece rotates under the tool for cutting Generally, here’s how I suggest you go about it: Mount the workpiece onto the spindle Center the cutting edge over the hole to be bored Start the spindle and feed the cutter into the workpieceStirred media mills have been increasingly used in ultrafine grinding The VXPmill is a vertical high speed stirred media mill for grinding mineral ores with high efficiency Since it is a new technology in the industry, there is little understanding on the breakage kinetics ofDEM simulation and analysis of operating parameters on grinding 2016年9月1日 Diversified operating conditions, inputoutput constraints, and parametric variations in the Vertical Roller Mill (VRM) make it to have complicated dynamics and closedloop instabilityOperational parameters affecting the vertical roller mill Manual Mill Basics provides an introduction to the manual milling machine Manual mills are generally either vertical or horizontal, depending on their spindle orientation This class introduces the machine components, cutting tools and workholding devices commonly used on milling machines The class also provides an overview of the various controls on the mill that are Manual Mill Basics 201 Tooling USME

.jpg)

Vertical Milling Machine Operating Instructions studylib

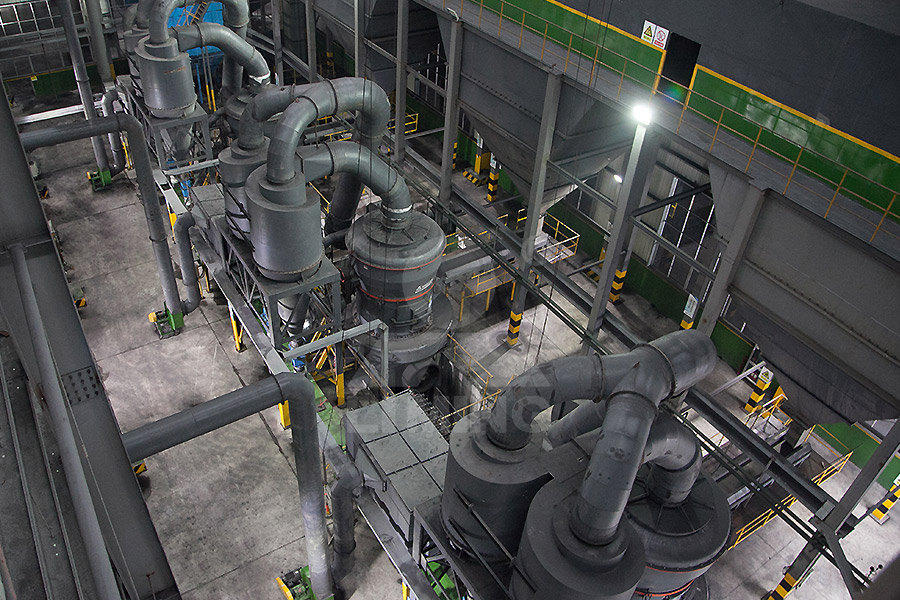

All machine slides Vertical Milling Machine Operating Instructions have an adjustable , however, to enable a good craftsman to get started Using a vertical mill correctly takes more skill and experience Cast 134 2800 2000 1300 Brass 400 2800 2800 2800 FIGURE 66—Mill column saddle lock MILL SADDLE LOCKING LEVER— TURN LEVER The mill consists of the lower casing, upper casing, table mounted on the vertical planetary gear reducer and grinding rollers supported by the swing levers The separator is installed at the upper parts of the mill The raw material fed through the air lock gate is ground between the rollers and table with the grinding force added byVERTICAL ROLLER MILLS AMCLInt J Miner Process 63 Ž2001 79–114 elsevierrlocaterijminpro Charge behaviour and power consumption in ball mills: sensitivity to mill operating conditions, liner geometry and charge composition Paul W Cleary ) CSIRO DiÕision of Mathematical and Information Sciences, PriÕate Bag 10, Clayton South MDC, Clayton, Victoria, 3169, Australia Received 21 January 2000; Charge behaviour and power consumption in ball mills: sensitivity Fig1 Flow of Conventional Vertical Mill Grinding System Mill Kiln IDF (Kiln gas exhaust fan) Fig2 Flow of direct dust collection system Results Power consumption of fan(s) reduces about 3 to4 kWh/t Cost estimation When a mill with a production Vertical roller mill for raw Application p rocess materials

The investigation of operating parameters in a vertical stirred mill

2014年1月1日 Request PDF The investigation of operating parameters in a vertical stirred mill Due to the depletion of easily treated coarser ores, more mineralogically complex ores with smaller valuable 2024年8月7日 Vijayabhaskar, B, Jayalalitha, S: Dual adaptive model predictive controller application to vertical roller mill process used in the cement industry IEEE Access 8, – (2020) Wenhuan, L, et al: Intelligent simulation computation and finite element intelligence analysis for key component of lowvibration vertical millMultiphysics Simulation of a Vertical Roller Mill in 2020年6月16日 Request PDF Machine Learning and Deep Learning Methods in Mining Operations: a DataDriven SAG Mill Energy Consumption Prediction Application Semiautogenous grinding mills play a critical Machine Learning and Deep Learning Methods in Mining2015年1月1日 In this paper, extreme learning machine learning methods establishment of a raw material vertical mill grinding index prediction model for online measurement quality parameter is used By using the data of online and offline variables from vertical mill grinding cement raw material production process, tests of records in a cement plant for the ELM model training and Modeling Based on the Extreme Learning Machine for Raw Cement Mill

.jpg)

An investigation of performance characteristics and energetic

2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose This is Mill Skills, a multipart series to help you learn basic machine shop work Exclusive videos, drawings, models plans available on Patreon!https://wVertical Mill Tutorial 4 : Basic Milling Operations YouTube2023年6月15日 In the cement manufacturing process, kiln process fans play a vital role This article presents an extensive investigation into the prediction of Raw Mill Fan vibrations using machine learning modelsPrediction of Raw Mill Fan Vibrations Based on Machine Learning 2015年3月15日 Vertical Agitated Media Mill modeling has become subject of a research project due to its potential application as a secondary grinding mill as well as regrind and pellet feed preparation projectsVertical Agitated Media Mill scaleup and simulation

.jpg)

Desktop Mill Training Mill Compact CNC Vertical Mills – Haas

Powered by a fullfunction Haas CNC control housed in our portable simulator enclosure, the Desktop Mill is perfect for teaching the basic principles of programming and operating a CNC mill Designed to cut plastics and machinable wax, it is also 5‐1 Operating levers instruction 21 5‐2 Spindle speed selecting 23 5‐3 Spindle down feed 25 5‐4 Swing milling head forward or backward 27 5‐5 Swing milling head right or left 27 CHAPTER 6 Maintenance 6‐1 Adjusting gibs 28 6‐2 Adjust lead screw back lash 29UNIVERSAL TURRET MILLING MACHINE OPERATING MANUAL2021年4月24日 The work uses the UFRJ mechanistic mill model and DEM to analyze the effect of several design and operating variables on the apparent breakage rates and breakage distribution function of a batch Predicting the effect of operating and design variables in grinding Operating experience with a vertical roller mill for grinding granulated blastfurnace slag and composite cements* ) Betriebserfahrungen mit einer VertikalRollenmühle bei der Mahlung von HüttensandOperating experience with a vertical roller mill for grinding

Efficient machine learning model to predict fineness, in a vertical

2023年3月1日 β [1 − α; p 2; n − p − 1 2] = (1–α) th quantile of β [p 2; n − p − 1 2] distribution For α = 005, the number of outliers is 44 among 280 data corresponding to an upper limit control U C L M a h a l a n o b i s = 455 as illustrated in Fig 3The results of these outliers have been carefully analyzed by a process expert from the cement plant Indeed, if an outlier carrying Describe the steps required to mount and align a vise on the mill table Describe the steps required to square a work piece clamped to the mill table Describe the steps required to square a work piece held in a vise on a vertical mill Describe the steps required to locate, drill, and ream holes using the coordinated method Rockwell Automation US2014年10月20日 Rio Paracatu regrind circuit Santos Júnior et al (2011) presented some data on the Paracatu Vertical Mill circuit process, as well as its comparison to the plant's conventional ball millRegrind of metallic ores with vertical mills: An overview of the 2019年4月16日 The vertical roller mill (VRM) is a comminution device in which crushing, grinding and classification processes are combine together into a single unit operation(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

Operating Instructions and Parts Manual Variable Speed Vertical Mill

Don’t use this mill in a dangerous environment, or damp or wet locations, or expose it to rain 13 Keep machine guards in place at all times when the machine is in use If removed for maintenance purposes, use extreme caution and replace the guards immediately upon completion of maintenance 14 Make sure the mill is firmly secured before The back gear lever is marked HiLo This will indicate the proper switch position They should be positioned alike Variable Speed Dial “B”, Figure 23, visibly indicates, in windows, the speed range that the machine is operating in, 60 to 500 low range, 500 to 4200 high range 22 M450 Figure 22 HighLow Range Switch A TP5286 SERIES I MILLING MACHINES Massachusetts Institute of 2022年5月1日 The vertical roller mill (VRM) is commonly used for secondary and tertiary crushing processes in numerous industries In this study, the discrete element method (DEM) was employed to explore the Analysis of vertical roller mill performance with changes in 2018年5月2日 Coal mill malfunctions are some of the most common causes of failing to keep the power plant crucial operating parameters or even unplanned power plant shutdowns Therefore, an algorithm has been developed that Detection of Malfunctions and Abnormal Working

Adaptive Dynamic Programming in Raw Meal Fineness Control of Vertical

vertical mill, raw meal, Adaptive Dynamic Programming (ADP), Extreme Learning Machine (ELM) Recommended Citation Lin Xiaofeng, Kong Weikai Adaptive Dynamic Programming in Raw Meal Fineness Control of Vertical Mill Grinding Process Based on Extreme Learning Machine[J] Journal of System Simulation, 2016, 28(11): 27642770PDF On May 1, 2017, Caroline Woywadt published Grinding process optimization — Featuring case studies and operating results of the modular vertical roller mill Find, read and cite all the Grinding process optimization — Featuring case 2024年1月8日 2) Boring With a Vertical Boring Mill When working with vertical mill machinery, the workpiece rotates under the tool for cutting Generally, here’s how I suggest you go about it: Mount the workpiece onto the spindle Center the cutting edge over the hole to be bored Start the spindle and feed the cutter into the workpieceBoring On a Mill Machine: A Complete Tutorial [2024] Lathe Stirred media mills have been increasingly used in ultrafine grinding The VXPmill is a vertical high speed stirred media mill for grinding mineral ores with high efficiency Since it is a new technology in the industry, there is little understanding on the breakage kinetics ofDEM simulation and analysis of operating parameters on grinding

Operational parameters affecting the vertical roller mill

2016年9月1日 Diversified operating conditions, inputoutput constraints, and parametric variations in the Vertical Roller Mill (VRM) make it to have complicated dynamics and closedloop instabilityManual Mill Basics provides an introduction to the manual milling machine Manual mills are generally either vertical or horizontal, depending on their spindle orientation This class introduces the machine components, cutting tools and workholding devices commonly used on milling machines The class also provides an overview of the various controls on the mill that are Manual Mill Basics 201 Tooling USMEAll machine slides Vertical Milling Machine Operating Instructions have an adjustable , however, to enable a good craftsman to get started Using a vertical mill correctly takes more skill and experience Cast 134 2800 2000 1300 Brass 400 2800 2800 2800 FIGURE 66—Mill column saddle lock MILL SADDLE LOCKING LEVER— TURN LEVER Vertical Milling Machine Operating Instructions studylibThe mill consists of the lower casing, upper casing, table mounted on the vertical planetary gear reducer and grinding rollers supported by the swing levers The separator is installed at the upper parts of the mill The raw material fed through the air lock gate is ground between the rollers and table with the grinding force added byVERTICAL ROLLER MILLS AMCL

.jpg)

Charge behaviour and power consumption in ball mills: sensitivity

Int J Miner Process 63 Ž2001 79–114 elsevierrlocaterijminpro Charge behaviour and power consumption in ball mills: sensitivity to mill operating conditions, liner geometry and charge composition Paul W Cleary ) CSIRO DiÕision of Mathematical and Information Sciences, PriÕate Bag 10, Clayton South MDC, Clayton, Victoria, 3169, Australia Received 21 January 2000;