Vertical grinding ore grinding machine installation conditions

Latest Installations And Developments Of Loesche Vertical Roller

2012年9月1日 Mills (VRM) installations and summarises the main benefits of the dry compressive Loesche grinding technologies in Airflow and OverflowMode Some of these benefits are optimised energy efficiency of the grinding classifying circuits, increased Within the scope of the study, ore grinding performance of the VRM was investigated via a mobile grinding plant and relationships between operational parameters were identified In this (PDF) Operational parameters affecting the vertical roller mill The MinasRio regrinding circuit is currently the largest Vertimill installation in the world, consisting of sixteen VTM1500 Vertimills, in closed circuit with The Grinding Efficiency of the Currently Largest 2024年2月26日 Precision vertical grinding machines (PVGM) are widely used for grinding sleevetype parts and play a vital role in various precision machining fields such as aviation, aerospace, and vehicle engineering [1,2,3]Excellent profile accuracy is an essential guarantee to achieving their functions, which is a challenge for the current manufacturing industry []A study on machining error prediction model of precision vertical

ISO 1985:2015 Machine tools — Test conditions for

2015年3月3日 ISO 1985:2015 specifies, with reference to ISO 2301 and ISO 2307, both geometric and machining tests on general purpose, normal accuracy, manually, and numerically controlled (NC) surface grinding machines with 2021年11月8日 Illite ore industrial grinding mill machines include ultrafine grinding mills, vertical roller mills, highpressure mills, wet stirring mills, coarse mills, and so on It can be applied to different illite grinding operation Illite Ore Industrial Grinding Mill Machine SBM 2014年12月1日 A grinding dynamometer based on resistance strain gauge technology was developed for the special installation and work conditions of a glass edge grinding machine with a Vgrinding wheelGrinding Dynamometer for Vertical Glass Edge Grinding Machine UNITED GRINDING is your solutions partner, with products and services designed to assist you throughout the life cycle of your CNC grinding machine, including equipment sales, installation, training, applications support, preventive and predictive maintenance, parts and repair servicesBLOHM UNITED GRINDING North America

Grinding Machine: Definition, Parts, Working Principle, Operation

2021年5月5日 The grinding machine is widely used to finish the workpiece Do you know why? Because the work removal rate is low between 025 to 05 mm (This can be advantages or disadvantages also for various types of works) Grinding Machine Parts and Function: The Grinding Machine Consists of Following Main Parts: Base or Bed; Column; Headstock CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultrafine industrial ore grinding equipment that integrates grinding, grading, powder collection and conveying +17CLUM Ultrafine Vertical Grinding MillUNITED GRINDING is your solutions partner, with products and services designed to assist you throughout the life cycle of your CNC grinding machine, including equipment sales, installation, training, applications support, preventive and predictive maintenance, parts and repair servicesSpecial Grinding Machines2019年4月16日 Conference: Applying a Successful Technology from the Cement Industry: Advantages of Grinding Ore in a VerticalRollerMill; At: Antalya, Türkey(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM

Vertical disc grinding machine All industrial manufacturers

Find your vertical disc grinding machine easily amongst the 27 products from the leading brands (RECHERCHES REALISATIONS REMY, JUNKER, Gleason, ) on DirectIndustry, the industry specialist for your professional purchasespurpose and normal accuracy surface grinding machines with vertical grinding wheel spindle and reciprocating table The primary function of such machines is to provide flat surfaces on workpieces This International Standard specifies the tests to verify the geometric accuracy of the machine to achieve this primary functionMachine tools — Test conditions for surface grinding machines 2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot PlantRead this indepth blog to learn about the working principle of Vertical Grinding Mill, its application, and its advantages +91 226796 9655 11 Advantages Vertical Grinding Roller Mill Machine As a vertical installation, and Vertical Grinding Mill: How it Works, Application And

VG Vertical Grinding Machine

VGCNC vertical machine concept Features Only 1/3 space requirement compared to a horizontal grinding system; A Polymer concrete machine base absorbs vibration and, due to low heat conductivity, eliminates expansion while maximizing precision2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plant2021年7月3日 Creep feed grinding is a slow, onepass operation that makes a deep cut of up to one inch in steel materials at low table speeds between 05 and 1 ipm It is not suitable for conventional grinding machines, but for those which are compatible with it, it offers high productivity and cost effectivenessMachining 101: What is Grinding? Modern Machine ShopRequest PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermill

.jpg)

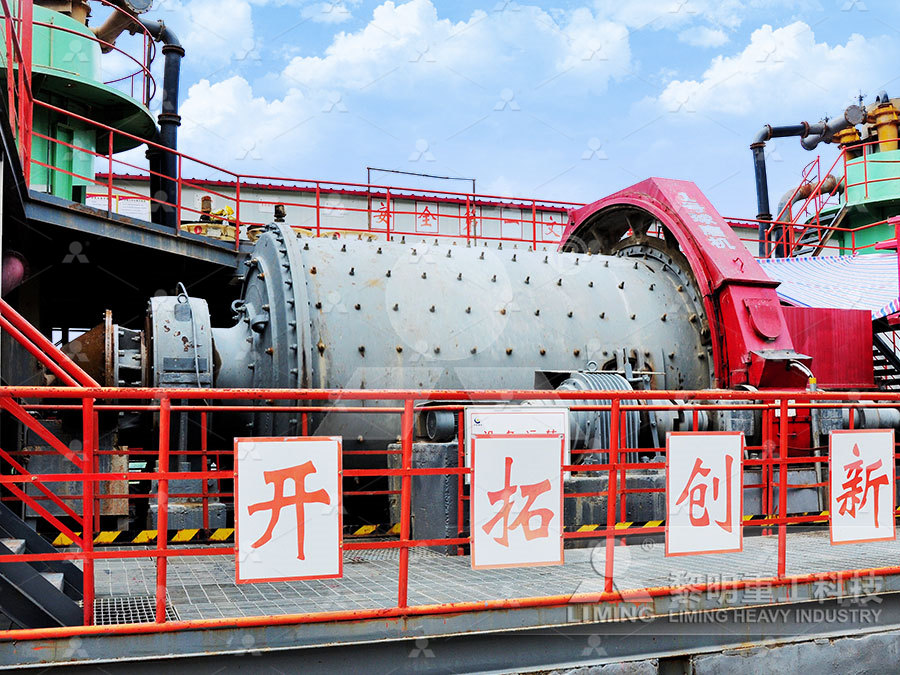

Industry Grinder for Mineral Processing JXSC Machine

A ball mill, also known as a ball grinding machine, is a wellknown ore grinding machine widely used in mining, construction, and aggregate applicationsJXSC started the ball mill business in 1985, supplying global services including design, manufacturing, installation, and 2015年3月10日 Vertical roller mills (VRM) have been used extensively for comminuting both cement raw materials and minerals like limestone, clinker, phosphate, manganese, magnesite, feldspar and titanium These mills combine crushing, grinding, classification and drying operations in one unit and have advantages over conventional machines and literature reports that 15% Copper ore grinding in a mobile vertical roller mill pilot plantNVGH series is the highest spec model among Taiyo Koki’s vertical grinding machines adopting highrigidity structure for the main parts such as bed, table, grinding spindle and work spindle It fulfills a wide range of customer needs by customization and automation, and contributes to various industries with its highaccuracy grinding performanceNVGH Series Vertical grinding from DMG MORI DMG MORI 2015年3月15日 The total energy consumption for ore comminution will further increase within the next decades One contribution to minimise the increase is to use more efficient comminution equipment Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principleResearch of iron ore grinding in a verticalrollermill

.jpg)

Campbell Grinder Creep Feed Grinders, Vertical

Campbell Grinder Company solves manufacturers’ most challenging grinding problems by designing and manufacturing the best vertical, creep feed, and 5axis grinding machines available This allows our OEM and Tier 1 customers 2024年1月27日 Machine Inspection: Before use, inspect the grinding machine for any damage or wear, particularly the grinding wheel Ensure all guards and safety shields are in place and in good condition Proper Training: Only What is a Grinding Machine: Definition, Types, ISO 1985:2015 specifies, with reference to ISO 2301 and ISO 2307, both geometric and machining tests on general purpose, normal accuracy, manually, and numerically controlled (NC) surface grinding machines with reciprocating table and vertical grinding wheel spindleISO 1985:2015 Machine tools — Test conditions for surface grinding 2014年2月1日 According to characteristics of vertical glass edge grinding machine, such as narrow installation space and foul working conditions, based on homemade strain type grinding dynamometer and Orthogonal test research on grinding force of vertical glass edge

IGV3NT Vertical grinding from DMG MORI DMG MORI USA

Both internal and external grinding spindles equipped as standard, which enables grinding of ID, OD and face in onetime chucking Internal grinding spindle : selectable from 30,000min1, 45,000min1 or 75,000min1 External grinding spindle : 3,700min1 High productivity in a compact installation spaceThe installation of refractory in a vertical grinding mill is essential to line the internal components that are exposed to high temperatures and abrasive materials Refractory materials are chosen for their high thermal resistance and ability to withstand the harsh conditions within the millInstalling refractory in a vertical grinding mill2021年1月1日 for controlled vertical spindle surface grinding multiaxis Comput er Numerical Control (CNC) machine are provided and addressed in depth in this stud y During the grinding pr ocess, a method in CONTROL OF VERTICAL SPINDLE SURFACE GRINDING FROM A 2020年10月9日 We also provide electrospindles with 8000 RPM for those features/materials that require higher grinding speeds The electrospindles are liquid cooled Additionally, we offer solutions for high horsepower grinding For two axis machines, the grinding spindle is 30 HP (continuous) with 3000 RPM as standardPrecision Grinding Head for Vertical Turning Centers

]@S0{UDKK%G24F3JGHC.jpg)

THE GRINDING EFFICIENCY OF THE CURRENTLY LARGEST VERTIMILL INSTALLATION

2015年9月1日 The grinding efficiency of this plant was recently verified through a sampling campaign and the results showed that the measured specific energy consumption was similar to the predicted specific 2024年2月26日 Precision vertical grinding machines (PVGM) are widely used for grinding sleevetype parts and play a vital role in various precision machining fields such as aviation, aerospace, and vehicle engineering [1,2,3]Excellent profile accuracy is an essential guarantee to achieving their functions, which is a challenge for the current manufacturing industry []A study on machining error prediction model of precision vertical 2015年3月3日 ISO 1985:2015 specifies, with reference to ISO 2301 and ISO 2307, both geometric and machining tests on general purpose, normal accuracy, manually, and numerically controlled (NC) surface grinding machines with ISO 1985:2015 Machine tools — Test conditions for 2021年11月8日 Illite ore industrial grinding mill machines include ultrafine grinding mills, vertical roller mills, highpressure mills, wet stirring mills, coarse mills, and so on It can be applied to different illite grinding operation Illite Ore Industrial Grinding Mill Machine SBM

Grinding Dynamometer for Vertical Glass Edge Grinding Machine

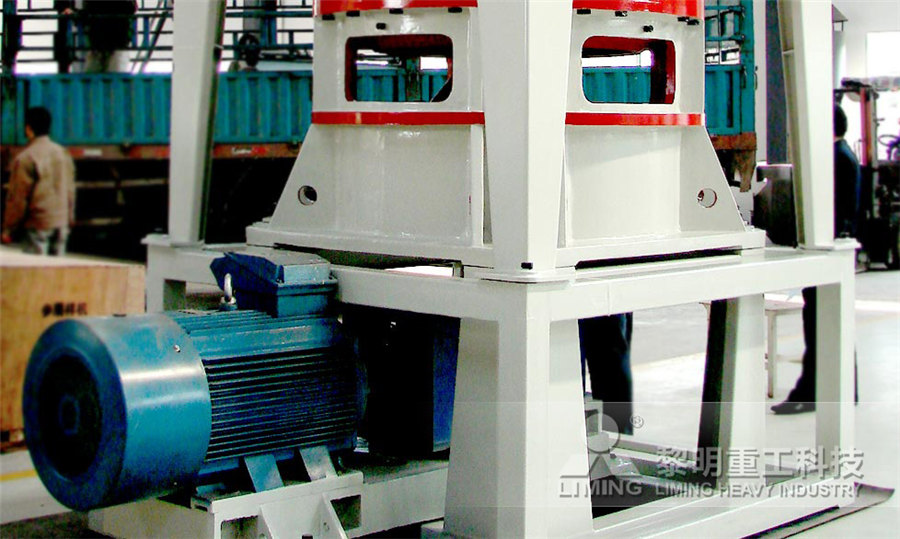

2014年12月1日 A grinding dynamometer based on resistance strain gauge technology was developed for the special installation and work conditions of a glass edge grinding machine with a Vgrinding wheelUNITED GRINDING is your solutions partner, with products and services designed to assist you throughout the life cycle of your CNC grinding machine, including equipment sales, installation, training, applications support, preventive and predictive maintenance, parts and repair servicesBLOHM UNITED GRINDING North America2021年5月5日 The grinding machine is widely used to finish the workpiece Do you know why? Because the work removal rate is low between 025 to 05 mm (This can be advantages or disadvantages also for various types of works) Grinding Machine Parts and Function: The Grinding Machine Consists of Following Main Parts: Base or Bed; Column; Headstock Grinding Machine: Definition, Parts, Working Principle, Operation CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultrafine industrial ore grinding equipment that integrates grinding, grading, powder collection and conveying +17CLUM Ultrafine Vertical Grinding Mill

.jpg)

Special Grinding Machines

UNITED GRINDING is your solutions partner, with products and services designed to assist you throughout the life cycle of your CNC grinding machine, including equipment sales, installation, training, applications support, preventive and predictive maintenance, parts and repair services2019年4月16日 Conference: Applying a Successful Technology from the Cement Industry: Advantages of Grinding Ore in a VerticalRollerMill; At: Antalya, Türkey(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRMFind your vertical disc grinding machine easily amongst the 27 products from the leading brands (RECHERCHES REALISATIONS REMY, JUNKER, Gleason, ) on DirectIndustry, the industry specialist for your professional purchasesVertical disc grinding machine All industrial manufacturers