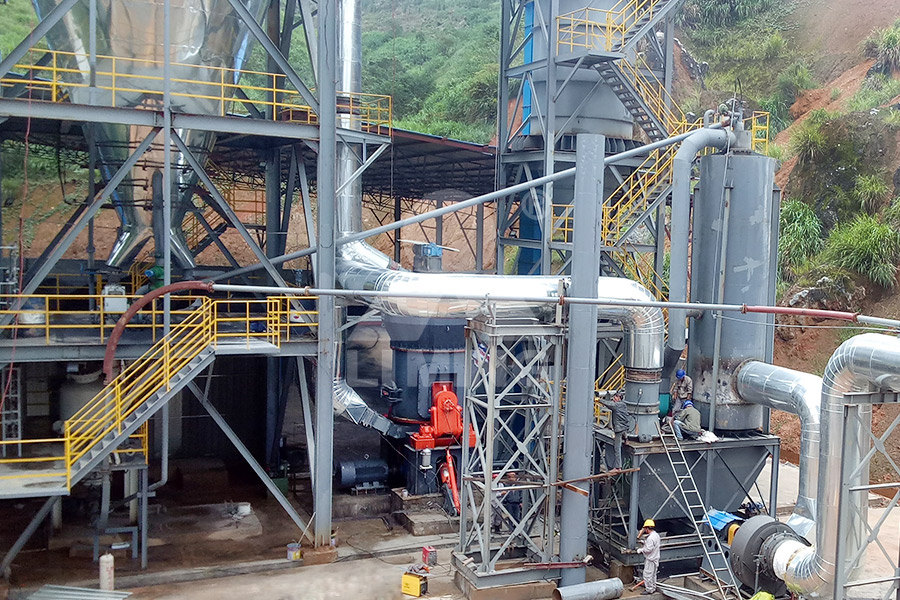

Slag micro powder vertical mill process diagram

Vertical roller mill for raw Application p rocess materials

Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table 2020年11月1日 Slag powder is produced in the closed vertical mill where complex physical and chemical change happens, leading to the difficulty of modeling by mechanism Generalized Analysis and multiobjective optimization of slag powder process2020年7月1日 Slag powder is a process with characters of multivariables, strongly coupling and nonlinearity The material layer thickness plays an important role in the process It can reflect Analysis and multiobjective optimization of slag powder processslag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, with a grinding track diameter of only 11 metres, was used as 2 µm 5 µm Loesche

The Vertical Mill Slag MicroPowders' Particle Size ResearchGate

In this paper, through the industry vertical mill grinding GGBS carried out a detailed analysis of particle size, on this basis, using the attached to the sample preparation method, obtainedThe core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and most efficient PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTSThis article compares and introduces the processing technology of several commonly used domestic slag powder Enterprises can choose the appropriate one according to the actual Comparison of Three Different Processes for Slag MicroIn this paper, through the industry vertical mill grinding GGBS carried out a detailed analysis of particle size, on this basis, using the attached to the sample preparation method, obtained the The Vertical Mill Slag MicroPowders' Particle Size Distribution and

VERTICAL ROLLER MILL TECHNICAL DETAILS Download Scientific

Diversified operating conditions, inputoutput constraints, and parametric variations in the Vertical Roller Mill (VRM) make it to have complicated dynamics and closedloop instabilitySlag powder is a process with characters of multivariables, strongly coupling and nonlinearity The material layer thickness plays an important role in the process It can reflect the dynamic Analysis and multiobjective optimization of slag powder processAccording to the display of slag powder production measured data, traditional ball mill needs power consumption 75~80kWh for per ton slag micro powder However, it needs power consumption 42~45 kWh for per ton slag micro powder if adopts advanced vertical roller mill technology, and it can be saving electricity 33~35kWh use of vertical roller mill production per GGBS Vertical Roller Mill Great Wall2023年11月28日 Steel slag grinding is an important link in the steel slag treatment and comprehensive utilization process It is generally believed that steel slag has a glass body structure, high iron content, and high product fineness requirements, making it difficult to grind using vertical mills However, ball mill grinding steel slag requires predrying and the process How does the vertical mill grind steel slag?

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

Analysis and multiobjective optimization of slag powder process

2020年11月1日 For slag powder process, operational stability of the vertical mill The vertical mill slag micropowders’ particle size distribution and microstructure analysis Applied Mechanics and Materials, Vol 487, Trans Tech Publ (2014), pp 308312 View in Scopus Google Scholar [6]Vertical mills are generally used for grinding slag powder A vertical cement mill is also called a vertical slag mill It has the advantages of high production capacity, low energy consumption, and environmental protection in the field of slag powder grinding The vertical cement mill of AGICO CEMENT is inseparable from the following points:Slag Grinding Plant GGBS Plant Slag Mill, Slag Grinding MillAs a new type of admixture for highperformance concrete, slag micro powder has the advantages of improving various properties such as compressive strength, tensile strength, LM130N Vertical Mill, Process slag, 325mesh, 6tph > 15 Microns 5TPH Talc Grinding Plant in Thailand > 10 Microns 4TPH Limestone Micro Powder Production Plant >The role and advantages of slag micro powder2024年4月2日 1 Feeding: Bauxite ore is fed into the HGM micro powder grinding mill through the feeding device, typically via a conveyor belt or a bucket elevatorThe material is evenly and continuously fed into the grinding chamber of the mill 2 Grinding: Inside the grinding chamber, the bauxite ore is subjected to a series of grinding processes The grinding rollers and rings in How does HGM micro powder grinding mill process bauxite?

vertical roller mill, vertical coal mill, vertical slag mill, superfine

Vertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, and ultrafine vertical millSlag is actually a term in a broad sense, which can generally refer to the waste slag discharged from all smelting furnaces or incinerators What is the purpose of slag grinding and what is the specific process flow of slag grinding? The following is a detailed explanation of the process flow of using the slag vertical roller mill to complete the slag grinding:Application Of Slag Grinding Mill Introduction To Treatment Process 2023年3月15日 SBM has launched the LM Vertical Grinding Mill which integrates five functions of crushing, grinding, Vertical Slag Mill Series Models and parameters: LM130N: LM150N: LM170N: LM190N: LM220N: LM280N: LM370N: Vertical Finepowder Mill Series Models and parameters: LM130XGX: LM150XGX: LM170XGX: LM190XGX:LM Vertical Grinding Mill SBM Mill CrusherThe document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag content Currently an MPS 5600 BC able to produce 120t/h of slag at 5000cm2/g fineness is being installed The MPS series uses a 3roller system and classifier to 2006 Slag Grinding With MPS Vertical Roller Mills PDF Mill

What Is The Market Prospect Of Steel Slag Vertical

Recently, the steel slag powder production line with the largest production capacity in China was completed and put into operation in Shagang Group The total investment of this project is about 170 million yuan, and it is estimated • Mill motor speed • Mill air flow/mill differential pressure • Temperature after the mill • Pressure before the mill • Grinding stock feed • Classifier speed • Mill fan speed • Water spraying • Hot gas • Fresh air Manipulated variables Disturbance variable Process measured value RelauchLMmaster 6 250814 11:47PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTSProcess Flow Diagram fo r Vertical Mill Application It can be used for processing of nonmetallic minerals ie calcium carbonate, calcite, clay, kaolin, dolomite, talc, barite, wollastonite, brucite, calcium oxide, gypsum, coke coal, Vertical Mill Manufacturer,Vertical Mill Price,Vertical The GRMSS steel slag vertical mill of CHAENG is a kind of special equipment for grinding industrial waste such as steel slag and water slag into powder Integrating crushing, transporting, grinding and drying, the steel slag vertical mill is a kind of ideal equipment for grinding steel slag The models of CHAENG’s GRMS steel slag vertical mill are complete, include GRMSS33 31 Steel Slag Vertical Mill

News Application prospect of ultrafine steel slag grinding

3 the preparation process and equipment of steel slag micropowder vertical grinding have been popularized and applied At present, the vertical grinding technology is used to grind steel slag micropowder and produce products that replace highenergy cement clinker, which belongs to the advanced production technology in the industryProcess Description The stacked slag is packed and feed by the forklift trucks, then transported by belt conveyor During transmission, the slag will pass through the iron separator and vibrating screen, then through the weighing equipment and elevator, and finally come into the vertical roller millslag will come through the powder selector and be dried with the hot air form air heating Slag Grinding Plant CHAENG2024年10月25日 Using the HGM series Micro Powder Grinding Mill to grind slag into ultrafine powder and mix it with silicate cement, a new type of slag silicate cement can be prepared This new type of cement can not only reasonably control the fineness of cement, but also achieve the optimal ratio of silicate cement and slag powder, thereby improving the performance of cementSlag Ultrafine Powder Processing TechnologyCaco3 Vertical Powder Grinding Mill and Modifying Machine production line in Malaysia Coarse Vertical Powder Mill Used in Dutch Agriculture Waste Tyre Pyrolysis Carbon Black Processing System Tyre Pyrolysis Carbon Black Processing Line in Brazil Dolomite vertical roller mill grinding in Uzbekistan Calcite dolomite vertical grinding vertical roller mill clirikultrafine vertical mill, Raymond vertical

Nickel Slag Vertical Mill CHAENG

The output of the GRMS nickel slag vertical mill produced by Great Wall Company can reach 160t/h, and the power consumption of the system is below 38kWh/t, which can meet the annual output of 200,000 to 15 million tons of nickel slag powder production line project2013年5月1日 The appearances and particle size distribution of slag micropowder produced by ball mill and vertical mill were researched with scanning electron microscope and laser particle size analyzerStudy on Particle Characteristics of Cement by Vertical Roller Mill Product advantage of talc powder ultrafine vertical roller mill 1 High quality powder size The fineness of the finished product is D97 545 microns Narrow particle size distribution, can produce 2 micron content of 20%70% products, Talc Powder Ultrafine Vertical Roller MillLM VERTICAL MI Raw materials: The product is also unique in the segmentation of the industry, building for the exclusive market It is dedicated to power plant, steel plant and coal injection boiler industry, exclusive in non metallic mineral powder grinding and the LM VERTICAL MIVipeak Heavy Industry Machinery Group

.jpg)

Introduction of GGBS vertical roller mill Great Wall

Introduction of GGBS vertical roller mill GGBS (Slag product applications) vertical roller mill is the equipment to grind Ground Granulated Blast furnace Slag (GGBFS) into small particlesGGBS (fineness:42004500cm2/g) produced by Slag grinder (also called slag micropowder mill and slag superfine mill) is a largescale grinding machine, which Vanguard absorbs advanced European technology and designs and improves It is highquality equipment for processing slag powderSlag mill, slag powder mill, slag uZhengzhou Vanguard 2011年3月17日 The invention relates to a production process of steel slag micropowder, which comprises the following steps: enabling wet steel slag powder with water content of 5% and particle size of 020mm generated after crushing and magnetic separation of steel slag to enter a mill for powder milling, conveying obtained fine powder into a vibration drying and powder Production process of steel slag micropowder Semantic ScholarSBM micro powder grinding mill is a highly efficient industrial grinding mill, Production Process of Micro Powder Grinding Mill The equipment includes two series of HGM ultra fine grinding mill and CLUM vertical roller mill, both of which can Micro Powder Grinding Mill

Slag Mill Vertical Slag Mill Provider SINOMALY

This vertical slag mill can be installed in a slag powder production line with an output range from 45t/h to 300t/h The separator completes the sorting process by a vortex plane, making the powder selection efficiency high The transmission adopts AC motor with variable frequency speed regulation, 2007年2月1日 First Polysius slag roller mill in China The first Polysius roller mill for slag grinding in China is in operation since 2002 in Anshan in the province of Liaoning The grinding plant of the Angang Group Slag Development Company is exactly the same size as the one which has been in operation since 1995 just a few hundred kilometres away in KoreaSlag grinding with the Polysius Roller Mill in China2013年5月15日 • 21 vertical roller mill vibration is too large: (1) Feed uneven, when the mixture into the vertical roller mill over the powder, the vertical roller mill's loading rate, leading to the vertical roller mill on the thin material, and even disc direct contact with the roller,resulting in mechanical milling; when into the vertical roller mill multimaterial mixture materials for the Vertical raw mill pradeep kumar PPT Free Download SlideShareThe GRMSS steel slag vertical mill of CHAENG is a kind of special equipment for grinding industrial waste such as steel slag and water slag into powder +79Steel Slag Vertical Mill CHAENG

.jpg)

GGBS Vertical Roller Mill Great Wall

According to the display of slag powder production measured data, traditional ball mill needs power consumption 75~80kWh for per ton slag micro powder However, it needs power consumption 42~45 kWh for per ton slag micro powder if adopts advanced vertical roller mill technology, and it can be saving electricity 33~35kWh use of vertical roller mill production per 2023年11月28日 Steel slag grinding is an important link in the steel slag treatment and comprehensive utilization process It is generally believed that steel slag has a glass body structure, high iron content, and high product fineness requirements, making it difficult to grind using vertical mills However, ball mill grinding steel slag requires predrying and the process How does the vertical mill grind steel slag?2020年11月1日 For slag powder process, operational stability of the vertical mill The vertical mill slag micropowders’ particle size distribution and microstructure analysis Applied Mechanics and Materials, Vol 487, Trans Tech Publ (2014), pp 308312 View in Scopus Google Scholar [6]Analysis and multiobjective optimization of slag powder processVertical mills are generally used for grinding slag powder A vertical cement mill is also called a vertical slag mill It has the advantages of high production capacity, low energy consumption, and environmental protection in the field of slag powder grinding The vertical cement mill of AGICO CEMENT is inseparable from the following points:Slag Grinding Plant GGBS Plant Slag Mill, Slag Grinding Mill

The role and advantages of slag micro powder

As a new type of admixture for highperformance concrete, slag micro powder has the advantages of improving various properties such as compressive strength, tensile strength, LM130N Vertical Mill, Process slag, 325mesh, 6tph > 15 Microns 5TPH Talc Grinding Plant in Thailand > 10 Microns 4TPH Limestone Micro Powder Production Plant >2024年4月2日 1 Feeding: Bauxite ore is fed into the HGM micro powder grinding mill through the feeding device, typically via a conveyor belt or a bucket elevatorThe material is evenly and continuously fed into the grinding chamber of the mill 2 Grinding: Inside the grinding chamber, the bauxite ore is subjected to a series of grinding processes The grinding rollers and rings in How does HGM micro powder grinding mill process bauxite?Vertical roller mills are mainly engaged in three major fields of slag, coal powder, and nonmetallic ore Divided into: vertical roller mill, vertical slag mill, vertical coal mill, and ultrafine vertical millvertical roller mill, vertical coal mill, vertical slag mill, superfine Slag is actually a term in a broad sense, which can generally refer to the waste slag discharged from all smelting furnaces or incinerators What is the purpose of slag grinding and what is the specific process flow of slag grinding? The following is a detailed explanation of the process flow of using the slag vertical roller mill to complete the slag grinding:Application Of Slag Grinding Mill Introduction To Treatment Process

LM Vertical Grinding Mill SBM Mill Crusher

2023年3月15日 SBM has launched the LM Vertical Grinding Mill which integrates five functions of crushing, grinding, Vertical Slag Mill Series Models and parameters: LM130N: LM150N: LM170N: LM190N: LM220N: LM280N: LM370N: Vertical Finepowder Mill Series Models and parameters: LM130XGX: LM150XGX: LM170XGX: LM190XGX:The document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag content Currently an MPS 5600 BC able to produce 120t/h of slag at 5000cm2/g fineness is being installed The MPS series uses a 3roller system and classifier to 2006 Slag Grinding With MPS Vertical Roller Mills PDF Mill