cement plant vertical mill wearresistant materials

Solutions for Wear Protection in the Cement Industry Kalenborn

ABRESIST is a basalt based wear protection for plant components in which the material to be conveyed predominantly causes friction induced abrasion in bunkers, troughs, chutes, chain conveyors, mixers, separators, pipes, pipe bends, cyclones, etc Installation: the shaped cast Xwin ® is the primary solution to improve wear performance of grinding elements in vertical mills compared to the standard high chromium or hardfacing solutions, while neoX ® will usually be used in high abrasive applications where the Improved performance with advanced wear materials 2021年1月1日 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials With the grinding capacity of a vertical roller mill and the Review on vertical roller mill in cement industry its performance Vertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller mill for raw Application p rocess materials

.jpg)

Operational parameters affecting the vertical roller mill

2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants Depending on the abrasiveness of the material to be ground and areas to be protected, different wear materials are used on our vertical roller mills Alloy cast iron as per DIN 1695, hardfaced Cement mills and raw mills for small to medium throughput ratesAdvanced cement additives, specifically designed for VRM, can be a helpful support for the cement industry to broaden the PSD and increase the productivity at the same time Cement SikaGrind® for vertical roller mills2014年4月1日 The newly developed modular roller mill for grinding cement raw material, cement clinker, and additives with an installed power of up to 12,000 kW was specifically designed to (PDF) The latest innovative technology for vertical roller mills

Performance Evaluation of Vertical Roller Mill in Cement Grinding:

Vertical roller mills are widely used for especially grinding of coal, cement raw materials, clinker and minerals like bauxite, phosphate, magnesite, etc2018年10月11日 wetend paper mills, food and beverage processing, and maritime applications, these bearings offer strong corrosion protection in cement plants where water poses special RESISTING WEAR AND CORROSION Timken CompanyThe vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement Vertical Roller Mill Operation in Cement PlantAbout Zhili New Materials Luoyang Zhili New Materials established in 1992, is one of the world's leading wearresistant materials processing center, providing high quality wearing parts service for mining, cement, power plant, steel, coal industries, etcZhili New Materials One of the leading suppliers of spare parts

Wear resistant products and materials for cement plants

Wear resistant solutions for Cement plant Extraction, milling, sizing, conveying, injection of primary or secondary fuels, cooling, dust removal, mechanical and pneumatic conveying of raw products, clinker or cement So many areas where your equipment is subjected to abrasion Produr and Welding Alloys specialists, with more than 40 years of experience in the cement Table 3 Power Consumption Of Roller Press Grinding System Overall, we can conclude the three tables: After the longterm operation, although unit raw material grinding power consumption of the cement roller press grinding system is still low, the indexes of the vertical roller mill grinding system are very close to it, among which the output power of the vertical mill and the roller Comparison Of Vertical Roller Mill And Roller Press MillManufacturer of spare and wear parts for cement plant, refractory installed in the tower be made of suitable steels Immersion tubes, flaps, valves, air cannons, in refractory steels resistant to high shafts, pinions, etc We can manufacture a wide range of elements involved in the transport of materials in the cement plant repuestos y Spare and wear parts for cement plants Aceros y Suministros SLHigh strength belt conveyor in cement plant supplied It can be used to transport various bulk materials and finished cement with a loose density of 5002500kg/m³ cement ball mill vertical roller mill roller press cement separator bucket elevator Cement Bag FilterCement Belt Conveyor Wear Resistant Longer Lifespan CNBM

制粉-10.25公众号.jpg)

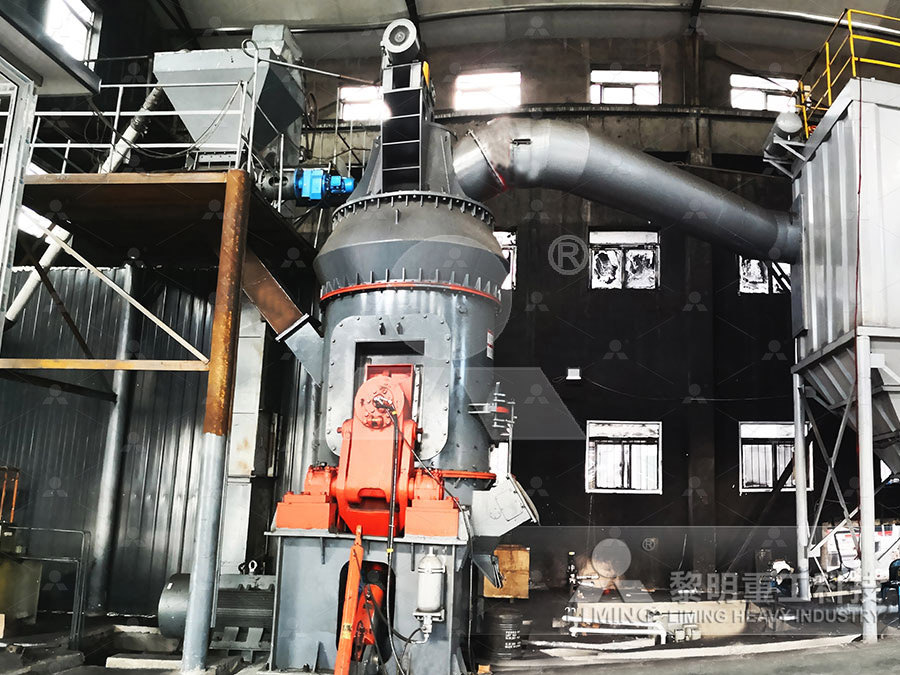

Vertical Roller Mill in Cement Manufacturing Plant

2023年7月4日 A cement vertical roller mill (VRM) is a type of grinding equipment commonly used in cement plants for raw material grinding and cement grinding It is an energyefficient alternative to traditional ball mills, as it utilizes rollers to grind and crush the materials between a rotating grinding table and a set of rollers mounted on a vertical axisMill Diaphragms; Mill liners plates; Vertical Roller Mill Rollers; Tables; Wear segments; Roller assembly; Clamps, Armour rings Accessories; Wear Plates for different applications in Cement plant Ecorporates provide wear resistant plates which show excellent features for AntiAbrasion, AntiCorrosion, AntiImpact and High ToughnessCastings Wear parts EcorporatesWe supply the complete range of wear resistant casting and grinding media balls We supply entire set of castings, diaphragm and balls for cement mill, raw mill and coal mill We also supply hammers, vertical mill rollers, kiln plate, and castings for mining and other applications Please write to us for more detailsConsumables for Cement Industry blackrockcementTextile Conveyor Belts with Slit Protection Belt conveyor works at mining site shall work in extreme conditions of abrasion After limestone is crushed, large and small blocks are conveyed to further crushing process – Milling, and this is where conveyor belt is usedBelt Conveyor Role and Design in Cement Plant

OK™ Raw and Cement Mill

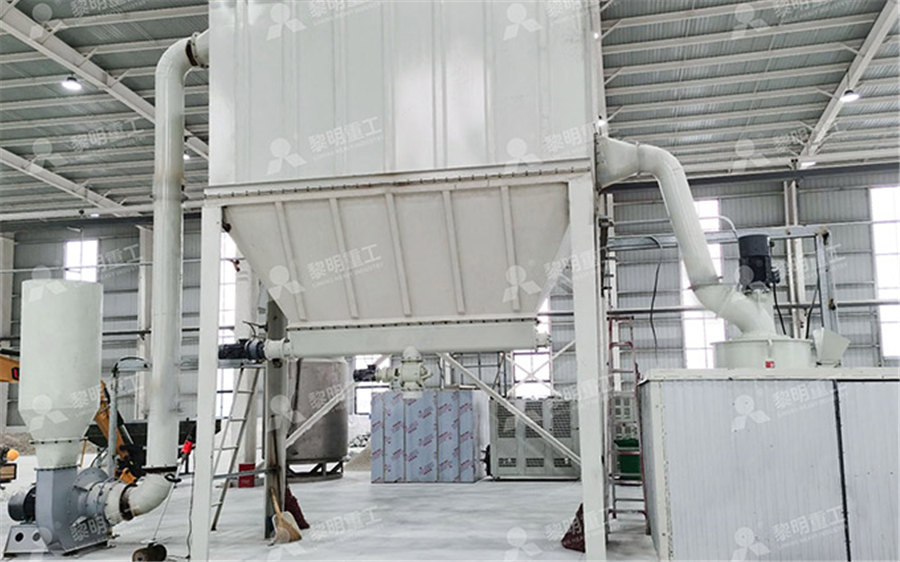

The OK™ Mill was originally designed for cement grinding In 2017 we released the OK™ vertical roller mill for raw materials grinding The OK™ Mill’s modular design comes with unique flexibility, showcasing parts commonality, where The vertical cement mill is largescale cement grinding machine With advantages of energyefficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic Vertical Cement MillAccording to the running characteristics of vertical coal mill, KINGCERA has designed different wearresistant lining plates for coal mill barrel and coal mill shell It can be widely used in the pulverization system of power, metallurgy, Mediumspeed coal mill wearresistant ceramic linerThe selection of industrial baghouse filter bags is of utmost importance An unsuitable filter bag not only affects the dust removal effect of the baghouse machine, but also reduces the service life of the dust collectorThe selection of dust filter bags should be comprehensively considered based on seven factors: the particle size of the filtered material, the filtration velocity, the How to Select Industrial Baghouse Filter Bags AGICO Cement Plant

.jpg)

vertical mill wearresistant, wearresistance division

Hong Cheng wearresistant engineering introduction and performance advantages: Roller press comprises two opposing synchronously rotating squeezing rollers (active roll, fixed roller), the roller press grinding system allows the grinding equipment production capacity into full play, can be used for pregrinding raw materials and mixing materials grindingapplications of cement screw conveyor Screw conveyor has been widely used in various sectors of the national economy, such as building materials, metallurgy, chemical industry, electricity, coal, machinery, light industry, food and food industries, suitable for conveying powdery, granular, small block materials, such as cement, pulverized coal, grain, fertilizer, ash, sand, coke and so Screw conveyor in cement plantAt Magotteaux, we are experts in vertical roller mill cement plant technology, something that allows us to innovate and keep one step ahead of what the market wantsThis is very much in evidence with our longlasting and extremely efficient vertical roller mill cement plant wear parts that allow companies that produce cement to gain a productivity as well as a commercial Vertical Roller Mill Cement Plant MagotteauxGenerally, the girth gear of the ball mill is lower in hardness than the pinion gear ZG45 is usually adopted for smallscale ball mills ZG310570 is preferred for ball mills with larger diameters such as 22m or wider It is more wearresistant than ZG45 and has good hardness and toughness Advantages of ball mill pinion gear by SINOMA ZiboBall Mill Pinion Gear cement grinding plant s

.jpg)

Ball Mill, Vertical Roller Mill Cement Plant

2020年11月5日 Which cement milling is proper for your cement manufacturing plant? We compare 3 cement milling and cement mill processes, including cement ball mill, vertical roller mill, and rod mill Find your answer here! Skip to It is not suitable for grinding hard and corrosive materials; Its’ wear parts is more expensive than that of Performance Evaluation of Vertical Roller Mill in Cement Grinding: Case Study ESCH Cement Plant D Altun, NA Aydogan, O Altun, AH BenzerPerformance Evaluation of Vertical Roller Mill in Cement Main easytowear parts and maintenance methods in cement and slag vertical mills 1 Determination of regular repair time After four steps of feeding, drying, grinding, and powder selection, the materials in the mill are driven by hot air to How to properly maintain cement and slag vertical vertical roller grinding mills for grinding: • Coal • Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

Cement Industry Loesche

The roller grinding mill technology, patented in 1928 and continuously developed since then, has become synonymous with Loesche‘s pioneering engineering knowhow CEMENT BLAST FURNACE SLAG CEMENT RAW MATERIALWe have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a Vertical roller mills FLSmidth CementAGICO Cement supplies various vertical roller mill components and Project Cases; Solutions Menu Toggle Factory Scales Menu Toggle Mini Cement Plant Hot Sale; Cement Plant 700 ~ 2000tpd; Cement Plant 2500~7000tpd; Cement Types Menu Toggle OPC the roll sleeve is generally made of integral wearresistant alloy casting (high chromium Vertical Roller Mill Parts AGICO Cement PlantVertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plantVertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one It can be widely used in cement, electric power, metallurgy, chemical industry, nonmetallic ore, and other industriesVertical raw mill Cement Plant

OK™ Pro+ ceramic wear segments for vertical roller mills

While we may be experts in vertical mill technology, we can’t stop wear in your OK™ mill What we can do is make sure that the interval between wear lining maintenance stops is as long as possible – up to three times longer than alternative wear solutions, in fact Guarantee mill performance with an expert OEMmade solution With our first Ecorporates GmbH is leading and experienced supplier of highquality wear resistant parts for Vertical Roller Mills in cement mining We supply Roller Tyres, Wear Segments and Tables for Vertical Grinding Mills in high Chromium we are able to send our engineers and sales staff to examine and draft your vertical mill wear parts at your plantVertical Roller Mill Parts EcorporatesFig 1 indicates a typical arrangement of a tube mill for cement grinding, consisting of two grinding compartments, WEAR PARTS AND WEAR RESISTANT MATERIALS IN MILLS 1 INTRODUCTION A cement plant handles large quantities of many different materials, which to a large extent, are MECHANICAL ELEMENTS INFINITY FOR CEMENT EQUIPMENTCement Plant: Capacity: 20720 t/h: Motor Power: 8002800 kW: Fineness: 80μmR 1215%: prevents vertical mill stops Segmented wear parts for table and rollers use the most wearresistant materials and hardfacing for long lifeVertical Raw Mill

Vertical Roller Mill Operation in Cement Plant

The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement About Zhili New Materials Luoyang Zhili New Materials established in 1992, is one of the world's leading wearresistant materials processing center, providing high quality wearing parts service for mining, cement, power plant, steel, coal industries, etcZhili New Materials One of the leading suppliers of spare parts Wear resistant solutions for Cement plant Extraction, milling, sizing, conveying, injection of primary or secondary fuels, cooling, dust removal, mechanical and pneumatic conveying of raw products, clinker or cement So many areas where your equipment is subjected to abrasion Produr and Welding Alloys specialists, with more than 40 years of experience in the cement Wear resistant products and materials for cement plantsTable 3 Power Consumption Of Roller Press Grinding System Overall, we can conclude the three tables: After the longterm operation, although unit raw material grinding power consumption of the cement roller press grinding system is still low, the indexes of the vertical roller mill grinding system are very close to it, among which the output power of the vertical mill and the roller Comparison Of Vertical Roller Mill And Roller Press Mill

Spare and wear parts for cement plants Aceros y Suministros SL

Manufacturer of spare and wear parts for cement plant, refractory installed in the tower be made of suitable steels Immersion tubes, flaps, valves, air cannons, in refractory steels resistant to high shafts, pinions, etc We can manufacture a wide range of elements involved in the transport of materials in the cement plant repuestos y High strength belt conveyor in cement plant supplied It can be used to transport various bulk materials and finished cement with a loose density of 5002500kg/m³ cement ball mill vertical roller mill roller press cement separator bucket elevator Cement Bag FilterCement Belt Conveyor Wear Resistant Longer Lifespan CNBM 2023年7月4日 A cement vertical roller mill (VRM) is a type of grinding equipment commonly used in cement plants for raw material grinding and cement grinding It is an energyefficient alternative to traditional ball mills, as it utilizes rollers to grind and crush the materials between a rotating grinding table and a set of rollers mounted on a vertical axisVertical Roller Mill in Cement Manufacturing PlantMill Diaphragms; Mill liners plates; Vertical Roller Mill Rollers; Tables; Wear segments; Roller assembly; Clamps, Armour rings Accessories; Wear Plates for different applications in Cement plant Ecorporates provide wear resistant plates which show excellent features for AntiAbrasion, AntiCorrosion, AntiImpact and High ToughnessCastings Wear parts Ecorporates

.jpg)

Consumables for Cement Industry blackrockcement

We supply the complete range of wear resistant casting and grinding media balls We supply entire set of castings, diaphragm and balls for cement mill, raw mill and coal mill We also supply hammers, vertical mill rollers, kiln plate, and castings for mining and other applications Please write to us for more detailsTextile Conveyor Belts with Slit Protection Belt conveyor works at mining site shall work in extreme conditions of abrasion After limestone is crushed, large and small blocks are conveyed to further crushing process – Milling, and this is where conveyor belt is usedBelt Conveyor Role and Design in Cement Plant