Boda angle coal mill

.jpg)

Performance optimisation of vertical spindle coal pulverisers

The effect of low calorific value coal was observed on mill’s response to match the boiler energy requirements Evaluation of the current operating pulveriser data enabled the determination of 2015年11月1日 Coal mills are bottleneck in coal–fired power generation process due to difficulty in developing efficient controls and faults occurring inside the mills In this paper, a dynamic A unified thermomechanical model for coal mill operation2022年12月1日 The effects of classifier blade length and opening angle on coal particle distribution in coal pulverize were numerically investigated Validation of simulation results with Computational Fluid Dynamics (CFD) investigation on associated The Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications (LM 122 D to LM 202 D), with table diameters from 1,200 to 2,000 LOESCHEMILLS

.jpg)

Coal mill pulverizer in thermal power plants PPT SlideShare

2012年11月17日 The document discusses coal mill/pulverizers used in thermal power plants It describes how pulverized coal is dried, ground, circulated, and classified within the mill to Coal Bowl Mill, for guaranteed performance at a 500 MW capacity NTPC thermal power plant The study was conducted to assess the effective performance of the pulverizers of this 500 A Study on 500 MW Coal Fired Boiler Unit’s Bowl Mill Performance A coal mill is an important component of a steam power plant which grinds precrushed raw coal particles of size 1020 mm to fine particles of size less than 150 µm using heated primary air Mathematical validation and comparison of ball tube and bowl 2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical An investigation of performance characteristics and energetic

Loesche Grinding Technology for the Power Industry

Loesche produces grinding mills and classifiers for all solid fuels, with throughputs ranging from 8 to 240 t/h (16,000 to 640,000 lb/h) With a long wear life and easy replacement of worn parts, 2014年1月15日 A particle mixing criterion for binary mixture angle of repose had been developed and applied to more binary mixed granular systems including biomass–coal blends Theoretical and experimental investigation on angle of repose of 2024年7月25日 La boda entre Christian Nodal y Ángela Aguilar fue un secreto muy bien guardado que contó con la complicidad de sus seres queridos En total se habrían reunido 45 personas, Las primeras fotos oficiales de la boda entre Ángela The ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 05% ~ Coal Mill in Cement Plant

.jpg)

Vertical Coal Mill Magotteaux

As a leading innovator with power station technologies – and other industries that need to process coal, Magotteaux is the ideal firm to turn to when seeking cuttingedge vertical coal mill technologyOur tires and tables mean that vertical coal mills can run more efficiently than ever beforeIn many cases, there is a compromise that needs to be made between the length of 2018年12月15日 Woody biomass cofiring with coal at existing pulverizedcoal boilers is known to be a green energy source and is a lowexpense alternative for pure coal combustionComilling woody biomass particles (15 wt%) with coal particles (85 wt%) before burning at a boiler is a complex problem because large woody biomass particles (>300 μm) exit the milling system Analysis of particle behavior inside the classifier of a Raymond 2014年1月15日 A particle mixing criterion for binary mixture angle of repose had been developed and applied to more binary mixed granular systems including biomass–coal blends The work would be helpful to the investigation of mixed particles system flow behavior and more directly useful to lay the root for the success of biomass–coal blends dense phase pneumatic Theoretical and experimental investigation on angle of repose of 2022年1月26日 The highest erosive wear occurred for the M3 mill dust ducts for the case coal 1 and amounted to 456 mm/5200 h On the other hand, the lowest erosive wear occurred for the M2 mill dust ducts Numerical Study of the Erosion Process and Transport of Pulverized Coal

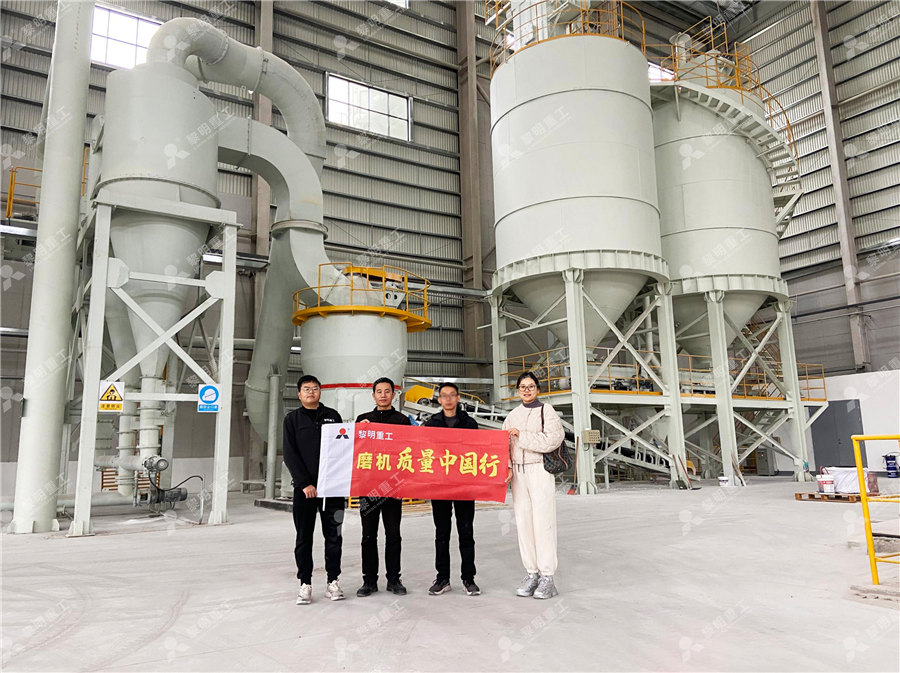

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

Rotary Vane Assembly Body Liners For XRP Type Coal Mill

6 The body liners in the rotary vane assembly are mainly to support and guide air pressure by inducing a PA fan effect inside the coal mill and produce perfect vortex 7 Due to the specified angle in the body liners, the air pressure is equally distributedA simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Coal Mill an overview ScienceDirect TopicsFinally, the temperature equation is based on heat balance equation of the coal millThe significant heat contribution comes from the primary air flow , moisture of the incoming coal particles, coal flow into the mill (1) and from grinding the moisture coal particles and temperature depends on the The mass of pulverised coal on the table grinding rate and the amount of coal (PDF) Modeling and Control of Coal Mill AcademiaThe raw material of coal powder is coal with various hardness, and it drying in the coal mill grinding process to obtain finished coal powder which can be efficiently burned Coal ball mills are widely used in the cement industry and thermal power generation industry, and are also suitable for metallurgical industry, chemical industry, sugar industry and other fieldsCoal Ball Mill Grinding for Different Kinds of Pulverized Coal

Modeling and Parameter Identification of Coal Mill

2009年9月20日 A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup 2021年11月4日 Test methods for grindability and abrasion testing: Full scale ring and ball mill, Hardgrove mill [30,31], BCURAroll mill, Rotating electrode ball wear tester [32], Dropweight test machine [28 Technique to Investigate Pulverizing and Abrasive Performance of Coals 2024年7月15日 ANANT AMBANI Y RADHIKA MERCHANT Así fue la boda más cara de la historia; costó 600 millones de dólares Trajes a la medida y joyas de incalculable valor son solo una probadita de la boda de lujo de una de las Así fue la boda más cara de la historia; costó 600 2014年3月1日 Request PDF Breakage and separation mechanism of ZGM coal mill based on parameters optimization model Sampling ports were firstly drilled on a ZGM95 coal mill in the power plant in China, and Breakage and separation mechanism of ZGM coal mill based

Sectional view of MBF coal mill Download Scientific Diagram

A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup 2023年6月1日 The effect of joint grinding of coal and biomass in a ball mill on the processes of ignition, combustion, From Figure 7, we can conclude that the flame opening angle for coal without the addition of wood waste with a particle size of less than 100 microns was 243°Influence of Grinding Methodology and Particle Size on Coal and 1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin 1953 500th coal mill plant sold worldwide 1961 Introduction of hydraulic spring assembly system 1965 Construction of first pressure mill (LM 122 D) 1980 Delivery of first modular coal mill (LM 263 D) 1985 Delivery of first selfinerting coal grinding plant (LM 212 D) for the steel industry (PCI LOESCHEMILLS2021年10月28日 CO2 emissions from coal power generation could be reduced by maximizing the amount of torrefied biomass that can be used in pulverizedcoalfired power plantsMilling Characteristics of Coal and Torrefied Biomass Blends in a

.jpg)

Combined operation mode of subcritical Wflame boiler and coal mill

For the [O] and [OH] groups, the partial equilibrium method is used Fuel type NO is mainly generated by the pyrolysis and oxidation reaction of nitrogen in fuel, which is the2015年11月1日 As presented by Andersen et al (2009) and Odgaard, Stoustrup, and Mataji (2007), coal moisture imposes limit on the maximum load at which a coal mill can be operated and the load gradient (how fast the mill may change its operating point), if it is desired that the pulverized coal entering the furnace has moisture content less than or equal to a certain value A unified thermomechanical model for coal mill operation2021年8月5日 In bowl mill pulveriser raw coal coming from feeder gets ground between the grinding rolls and bull ring segments installed on the revolving Bowl Bowl is made to rotate at medium speed for proper pulverization of coal Pulveriser in Thermal Power Plant Bowl Mill Ball Mill2024年10月17日 Ángel Cristo Jr y Ana Herminia han querido que celebrar su amor por todo lo alto con una boda con la que se sienten completamente identificados Por ello, el exconcursante de Supervivientes 2024 Los detalles del 'sí, quiero' de Ángel Cristo Jr y Ana

In discussion: Vincent Grosskopf, Coal Mill Safety

GC: What led you to establish Coal Mill Safety? VG: I established Coal Mill Safety (CMS) as a consultancy after I ‘retired’ in 2011 If a cement producer wants to install a new coal grinding system, they can commission CMS to look at the supplier’s design and probe it from a safety angle If it has an existingGrinding of coal, petcoke, clay, limestone, quicklime, gypsum, MPS 200 BK coal mill, Krimzement Bakhchisarayski, Ukraine MPS 3070 BK coal mill, Jaypee Cement Balaji, India MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, CroatiaCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills2020年3月1日 The classification performance of the air classifier in a vertical coal mill determines the size of pulverized coal particles Thus, the classification performance will influence the ignition, burning, and burnout of the coal particle, and NO x formation in the furnace as well [[1], [2], [3], [4]]The first generation of the coal mill classifier used static guide vanes to Classification performance of model coal mill classifiers with 2013年9月1日 Request PDF Liberation characteristics of coal middlings comminuted by jaw crusher and ball mill The associated minerals make coal middlings possess a relatively high ash content Subsequent Liberation characteristics of coal middlings comminuted by

.jpg)

R Todd Swinderman,PE, and Andy Marti, MartinEngineering, US,

This angle of repose for a given material may vary, depending on how the pile is created, as well as the density, particle shape, size consistency and moisture content of the material Surcharge angle The surcharge angle is the angle of the load cross section, measured by the inclination in degrees to the horizontal The surcharge angle isCan GE service my boiler mills? YES Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacitiesWe provide customized maintenance solutions, and offer a full spectrum of highquality solutions for each—in addition to our thousands of standard boiler mill parts and boiler service solutionsThis is the Power of YesBoiler Mill and Coal Pulverizer Performance GE Steam Power100000m2 de paraíso os esperan en el Cigarral del Ángel Esta finca, emplazada cerca de la gran capital, destaca principalmente por su encanto natural Centenares de flores, verdes jardines e imponentes arboledas son la carta de presentación delCigarral del Ángel Consulta disponibilidad y precios BodasDownload scientific diagram Angle of repose plotted against mean size from publication: Grain characteristics and engineering properties of coal ash Ash produced by the coal fired thermal Angle of repose plotted against mean size ResearchGate

.jpg)

Las primeras fotos oficiales de la boda entre Ángela

2024年7月25日 La boda entre Christian Nodal y Ángela Aguilar fue un secreto muy bien guardado que contó con la complicidad de sus seres queridos En total se habrían reunido 45 personas, The ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 05% ~ Coal Mill in Cement PlantAs a leading innovator with power station technologies – and other industries that need to process coal, Magotteaux is the ideal firm to turn to when seeking cuttingedge vertical coal mill technologyOur tires and tables mean that vertical coal mills can run more efficiently than ever beforeIn many cases, there is a compromise that needs to be made between the length of Vertical Coal Mill Magotteaux2018年12月15日 Woody biomass cofiring with coal at existing pulverizedcoal boilers is known to be a green energy source and is a lowexpense alternative for pure coal combustionComilling woody biomass particles (15 wt%) with coal particles (85 wt%) before burning at a boiler is a complex problem because large woody biomass particles (>300 μm) exit the milling system Analysis of particle behavior inside the classifier of a Raymond

Theoretical and experimental investigation on angle of repose of

2014年1月15日 A particle mixing criterion for binary mixture angle of repose had been developed and applied to more binary mixed granular systems including biomass–coal blends The work would be helpful to the investigation of mixed particles system flow behavior and more directly useful to lay the root for the success of biomass–coal blends dense phase pneumatic 2022年1月26日 The highest erosive wear occurred for the M3 mill dust ducts for the case coal 1 and amounted to 456 mm/5200 h On the other hand, the lowest erosive wear occurred for the M2 mill dust ducts Numerical Study of the Erosion Process and Transport of Pulverized Coal 6 The body liners in the rotary vane assembly are mainly to support and guide air pressure by inducing a PA fan effect inside the coal mill and produce perfect vortex 7 Due to the specified angle in the body liners, the air pressure is equally distributedRotary Vane Assembly Body Liners For XRP Type Coal MillA simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Coal Mill an overview ScienceDirect Topics

(PDF) Modeling and Control of Coal Mill Academia

Finally, the temperature equation is based on heat balance equation of the coal millThe significant heat contribution comes from the primary air flow , moisture of the incoming coal particles, coal flow into the mill (1) and from grinding the moisture coal particles and temperature depends on the The mass of pulverised coal on the table grinding rate and the amount of coal The raw material of coal powder is coal with various hardness, and it drying in the coal mill grinding process to obtain finished coal powder which can be efficiently burned Coal ball mills are widely used in the cement industry and thermal power generation industry, and are also suitable for metallurgical industry, chemical industry, sugar industry and other fieldsCoal Ball Mill Grinding for Different Kinds of Pulverized Coal