How much is a rare earth grinding equipment

Unlocking Potential: Rare Earth Elements Processing

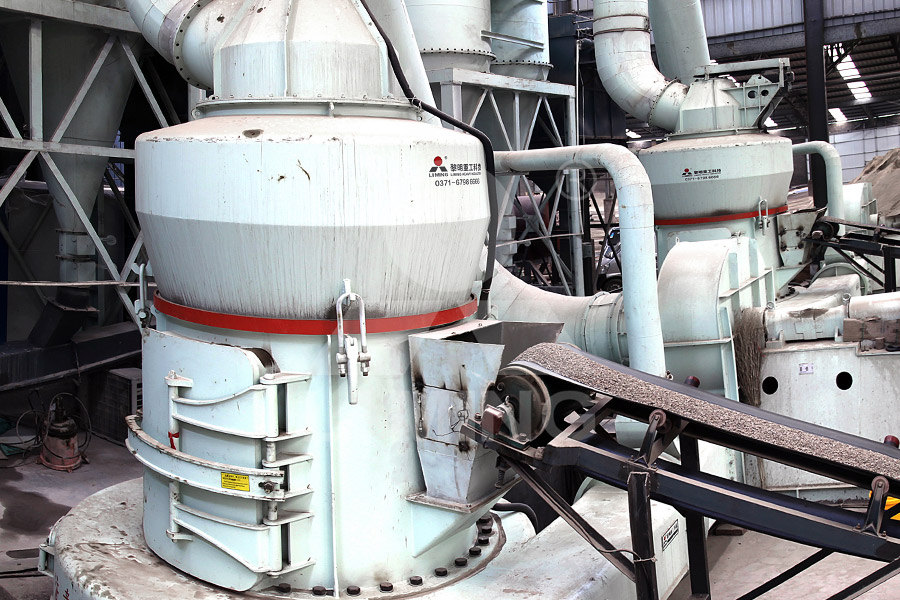

2023年11月9日 The screened rare earth ore enters a ball mill for dry grinding, improving mineral powder fineness and uniformity Overgrinding can waste resources and reduce recovery of brittle minerals FTM Machinery offers ball Processing equipment and references in the rare earths classifying Learn more about the Niagara vibrating screens and processing plantsRare Earths Elements Processing Equipment Haver2013年6月24日 A recently announced rare earth separation plant in the UK with a capacity of 125 kt/year is projected to cost USD 190 million (Mineralprices, 2021) CRITICAL MATERIALS FOR THE ENERGY (PDF) Rare earth mine costs ResearchGateRare earth ore gravity separation process is based on the difference in density between rare earth minerals and gangue minerals It is mainly aimed at the separation of rare earth minerals and gangue minerals such as quartz and Rare Earths Processing Equipment, Process Flow,

Rare Earths Mining Processing Equipment Flow Chart

Rare Earths mining process, how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design read more2013年8月21日 Fine grinding is the most energyintensive process and requires from 011 GJ to 028 GJ/tonne of ore depending on the hardness of the rock14 The energy required to grind Material and Energy Requirement for Rare Earth Production JOM2022年3月21日 Rareearth elements (REEs) are required for use in modern hightech applications and demand has increased significantly over the last decade 1 However, Processing the ores of rareearth elements MRS Bulletin2020年3月26日 The production of rare earth oxides from beach sand involves several steps such as mining, preconcentration of the heavy minerals, separation of monazite, and finally, Mineral Processing of Rare Earth Ores SpringerLink

.jpg)

Fine Grinding and Classifying of Rare Earth Alloys

Residuefree grinding and minimal buildup of material inside the machine make the mJet the ideal mill for highquality products Each batch is ∙ completely ground under equal conditions 2019年5月31日 From crushing and grinding equipment to blasting tools and excavators, PLATINUM GROUP METALS POTASH PHOSPHATES PROJECT MANAGEMENT RAREEARTH MINERALS SILVER A Guide on Mining Equipment Used in the Mining 2013年8月21日 In the past few years, rare earth metals (REMs) have received special attention because they are considered critical In general, a resource is critical when it is scarce, is subject to potential supply constraints, costly, and is needed for a particular function where substitutes are inferior1–5 Although REMs are relatively abundant in the Earth’s crust, discovered minable Material and Energy Requirement for Rare Earth Production2024年3月15日 Canada has some of the largest known reserves and resources (measured and indicated) of rare earths in the world, estimated at over 152 million tonnes of rare earth oxide in 2023 Manufacturing permanent magnets Rare earth elements facts Canada

.jpg)

A review on complex utilization of mine tailings: Recovery of rare

2024年6月1日 Among rare earths, dysprosium faces particularly high supply risks relative to its steep demand trajectory and low geological availability [203] It is essential to acknowledge that metals markets are highly complex and volatile, with neodymium oxide prices ranging from $70–130/kg over the past five years, making conservative price assumptions advisable [204] 2024年1月5日 Finding critical minerals All but one of the 17 rare earth elements appear on a 2022 list of 50 designated “critical minerals”—meaning they are economically important yet vulnerable to The race to produce rare earth materials MIT Technology Review2023年6月21日 With China currently dominating the world’s rare earth magnet supply chain, the competition for raw materials is playing out on the international stage But so too is the development of more efficient processing, grinding, and Grinding rare earth magnets into shape Cutting Tool EngineeringERES2014: 1st European Rare Earth Resources ConferenceMilos04‐07/09/2014 PAGE 26 CHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATION TECHNIQUES Ling ZHI LI1, Xiaosheng YANG2 1China Western Mining Co, Ltd, Xining, Qinghai, PRChina : lzli8288@sinaCHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATION

Grinding and classifying of rare earth powders and their use in

Furthermore, due to the differences in design, the product content during the grinding phase of an MJet is 20 to 25 times lower than that of a fluidized bed jet mill with the same amount of grinding gas At the same time, this results in an extremely low product loss during product change due to the smaller volume of the grinding chamber2019年10月3日 What makes a rare earth element 'rare'? The term 'rare' is really a bit of a misnomer because REEs actually exist in abundance Even the rarest of REEs (thulium) is still 125 times more prevalent in the earth's crust than gold and the most prolific REE (cerium) is 15,000 times more abundantWhy are rare earth elements so crucial for electronics ESCATEC2023年4月6日 Grinding Rare Earth Magnets into Shape April 6, 2023 Guest Blog Materials/Manufacturing Comments Off on Grinding Rare Earth Magnets into Shape Amid global rivalries and increasing demand for rare earth magnets, more precise, efficient grinding technology offers proactive manufacturers a competitive advantageGrinding Rare Earth Magnets into Shape Magnetics Magazine2014年10月29日 Rare earths are used in the renewable energy technologies such as wind turbines, batteries, catalysts and electric cars Current mining, processing and sustainability aspects have been described in this paper Rare Rare Earth Elements: Overview of Mining, Mineralogy,

.jpg)

(PDF) Rare Earths’ Recovery from Phosphogypsum: An

2021年9月28日 Rare Earths’ Recovery from Phosphogypsum: An Overview on Direct and Indirect Leaching Techniques2012年1月1日 More specifically, in this chapter we will describe and discuss the principles, processing and applications of rareearth magnets based on the compounds: SmCo 5, Sm 2 (Co,Fe,Cu,Zr) 17 and Nd 2 Fe 14 B Rareearth magnets have developed over the past 45 years to become critical components in engineering systems, providing the excitation flux for many Rareearth magnets: properties, processing and applications2023年12月29日 One of the most important and wide range of applications for rare earth (REs) containing materials is the production of permanent magnets Since the 1960s, this class of magnets has given designers and engineers the ability to increase performance, reduce the size of devices and even create applications that would not be possible with other magnet materialsRare Earth Magnets: Manufacturing and Applications2024年4月1日 Rare earth elements (REEs) are irreplaceable materials supporting lowcarbon technology and equipment, and their commercial demand and strategic positJournal of Rare Earths ScienceDirect

EV Motors Without Rare Earth Permanent Magnets IEEE Spectrum

2024年7月2日 Researchers at Oak Ridge National Laboratory analyze leading projects to produce electricvehicle motors without rare earth permanent magnets, which currently make the most powerful EV motors One The demand for rare earth elements (REEs) has significantly increased due to their indispensable uses in integrated circuits of modern technology However, due to the extensive use of hightech applications in our daily life and the depletion of their primary ores, REE’s recovery from secondary sources is today needed REEs have now attracted attention to policymakers and Emerging technologies for the recovery of rare earth elements 2017年9月10日 All content in this area was uploaded by Wan Hanisah B W Ibrahim on Oct 16, 2017(PDF) A Review of Rare Earth Mineral Processing Technology2020年5月17日 Many studies have been published in recent years focusing on the recovery of rare earth elements (REEs) from coalrelated materials, including coal, coal refuse, coal mine drainage, and coal combustion byproducts particularly fly ash The scientific basis and technology development have been supported by coal geologists and extractive metallurgists, and A Comprehensive Review of Rare Earth Elements Recovery from

The recovery of rare earth elements from waste electrical and

2023年10月1日 Demand for REE grows as the consumption of new electronic equipment increases (Brewer et al, 2019)Estimates suggest that the REE market grows at an annual rate of 37 to 86% (Tan and Li, 2019), contributing to the criticality of these raw materialsDespite their relative abundance on the Earth's crust, REE are considered critical metals due to their poor 2023年10月16日 They typically contain around 31 wt% of rare earth elements (REEs), principally, Nd and Pr, which makes crushing and grinding the ingot into a powder much more difficult and deteriorates the magnetic performance Sourcing, Refining and Recycling of RareEarth RESEARCH ON AUTOMATIC GRINDING PLATFORM FOR RARE EARTH INGOT CASTING Received – Primljeno: Accepted – Prihvaćeno: search on grinding robots and related equipment for rare earth metal ingots [5] Therefore, for a rare earth production line, an automatic grinding system for rare earth metal ingots hasRESEARCH ON AUTOMATIC GRINDING PLATFORM FOR RARE EARTH 2018年6月26日 Production and use The United States Geological Survey produces annual statistics on various aspects of rare earths in its Minerals Yearbook16 The yearbook is the source of information in this section, unless otherwise stated The global production of rare earths have increased dramatically since the 1950s (Fig 1 17)The United States was the primary Rare earths: A review of the landscape MRS Energy Sustainability

)D`ERF`389RMI4.jpg)

Rare earths in the crosshairs of new hightech arms race

2018年10月29日 Bloomberg covered the story and published it on Wednesday The article says that for the second half of 2018, China’s quota for rare earths separation and smelting has been cut by 36%, quoting Rare earth metallurgy, including separation, metal making, casting and magnet making, are technologically challenging This poses limits to the entry of new suppliers DERISKING THE SUPPLY CHAIN The majority of REE mining (58% in 2020) and purification (90%), as well as most permanent magnetCritical materials for the energy transition: Rare earth elements2022年2月2日 History of Permanent Magnet Development Several comprehensive reviews exist which extensively cover the development of rare earth (RE) magnets and the factors determining their coercivity 3,4,5,6,7,8,9 Figure 3 shows the historical development and commercialization of permanent magnets based on their (BH) max 10 It is noteworthy that the main discoveries of Manufacturing Processes for Permanent Magnets: Part The expected growth of the global economy and the projected rise in world population call for a greatly increased supply of materials critical for implementing clean technologies, such as rare earth elements (REEs) and other rare metals Because the demand for critical metals is increasing and landbased mineral deposits are being depleted, seafloor resources are seen Seabed mining and blue growth: exploring the potential of marine

A Guide on Mining Equipment Used in the Mining

2019年5月31日 From crushing and grinding equipment to blasting tools and excavators, PLATINUM GROUP METALS POTASH PHOSPHATES PROJECT MANAGEMENT RAREEARTH MINERALS SILVER 2013年8月21日 In the past few years, rare earth metals (REMs) have received special attention because they are considered critical In general, a resource is critical when it is scarce, is subject to potential supply constraints, costly, and is needed for a particular function where substitutes are inferior1–5 Although REMs are relatively abundant in the Earth’s crust, discovered minable Material and Energy Requirement for Rare Earth Production2024年3月15日 Canada has some of the largest known reserves and resources (measured and indicated) of rare earths in the world, estimated at over 152 million tonnes of rare earth oxide in 2023 Manufacturing permanent magnets Rare earth elements facts Canada2024年6月1日 Among rare earths, dysprosium faces particularly high supply risks relative to its steep demand trajectory and low geological availability [203] It is essential to acknowledge that metals markets are highly complex and volatile, with neodymium oxide prices ranging from $70–130/kg over the past five years, making conservative price assumptions advisable [204] A review on complex utilization of mine tailings: Recovery of rare

.jpg)

The race to produce rare earth materials MIT Technology Review

2024年1月5日 Finding critical minerals All but one of the 17 rare earth elements appear on a 2022 list of 50 designated “critical minerals”—meaning they are economically important yet vulnerable to 2023年6月21日 With China currently dominating the world’s rare earth magnet supply chain, the competition for raw materials is playing out on the international stage But so too is the development of more efficient processing, grinding, and Grinding rare earth magnets into shape Cutting Tool EngineeringERES2014: 1st European Rare Earth Resources ConferenceMilos04‐07/09/2014 PAGE 26 CHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATION TECHNIQUES Ling ZHI LI1, Xiaosheng YANG2 1China Western Mining Co, Ltd, Xining, Qinghai, PRChina : lzli8288@sinaCHINA’S RARE EARTH ORE DEPOSITS AND BENEFICIATIONFurthermore, due to the differences in design, the product content during the grinding phase of an MJet is 20 to 25 times lower than that of a fluidized bed jet mill with the same amount of grinding gas At the same time, this results in an extremely low product loss during product change due to the smaller volume of the grinding chamberGrinding and classifying of rare earth powders and their use in

.jpg)

Why are rare earth elements so crucial for electronics ESCATEC

2019年10月3日 What makes a rare earth element 'rare'? The term 'rare' is really a bit of a misnomer because REEs actually exist in abundance Even the rarest of REEs (thulium) is still 125 times more prevalent in the earth's crust than gold and the most prolific REE (cerium) is 15,000 times more abundant2023年4月6日 Grinding Rare Earth Magnets into Shape April 6, 2023 Guest Blog Materials/Manufacturing Comments Off on Grinding Rare Earth Magnets into Shape Amid global rivalries and increasing demand for rare earth magnets, more precise, efficient grinding technology offers proactive manufacturers a competitive advantageGrinding Rare Earth Magnets into Shape Magnetics Magazine